Packaging method for packaging device of rubbish packaging machine

A packaging method and technology for garbage bags, applied in packaging and other directions, can solve problems such as not being able to achieve an ideal state, and achieve the effects of fast packaging, complete packaging, and reduced harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

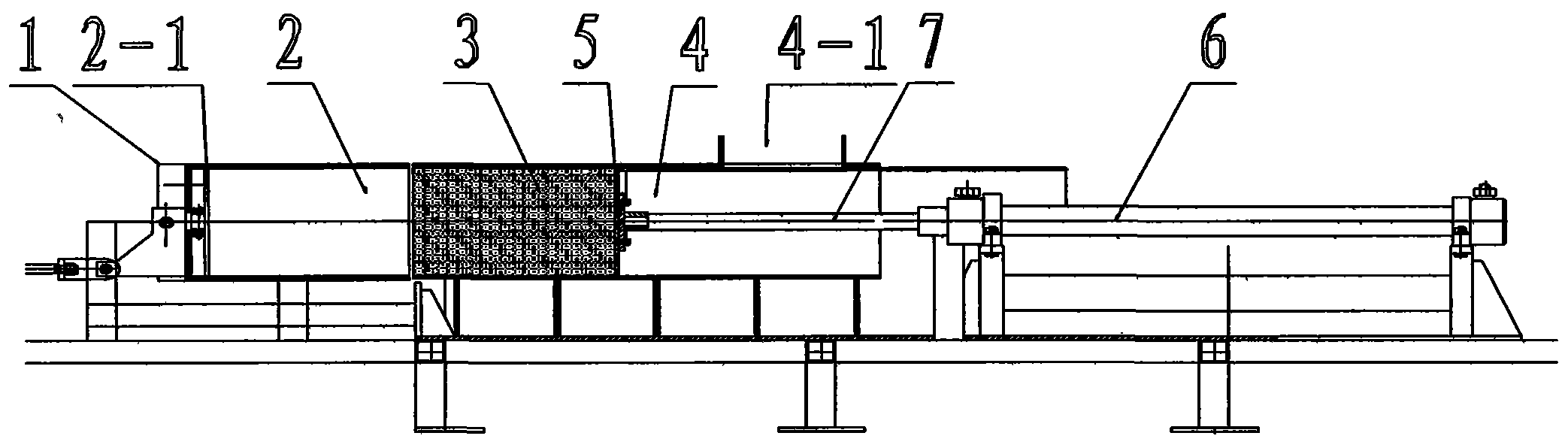

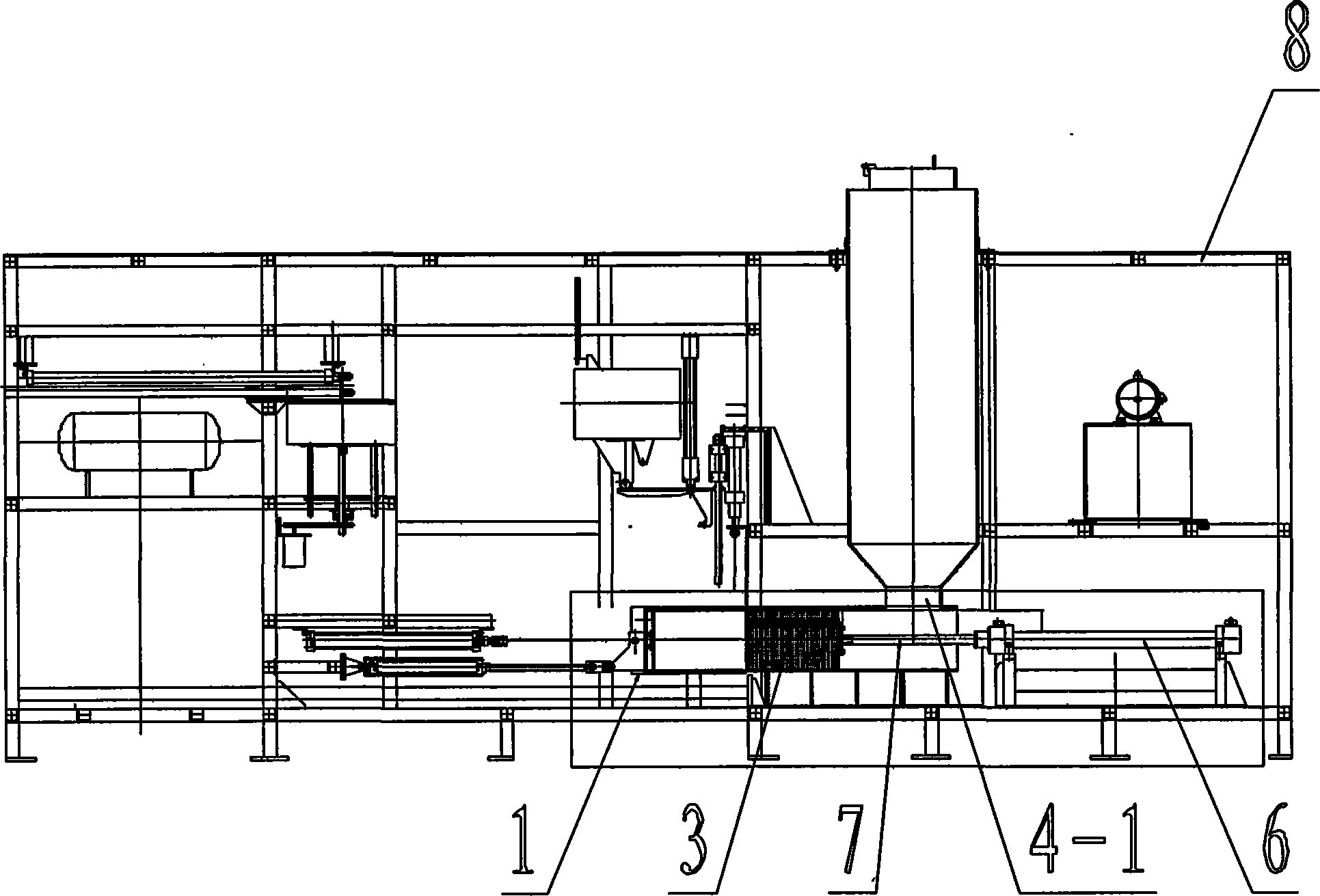

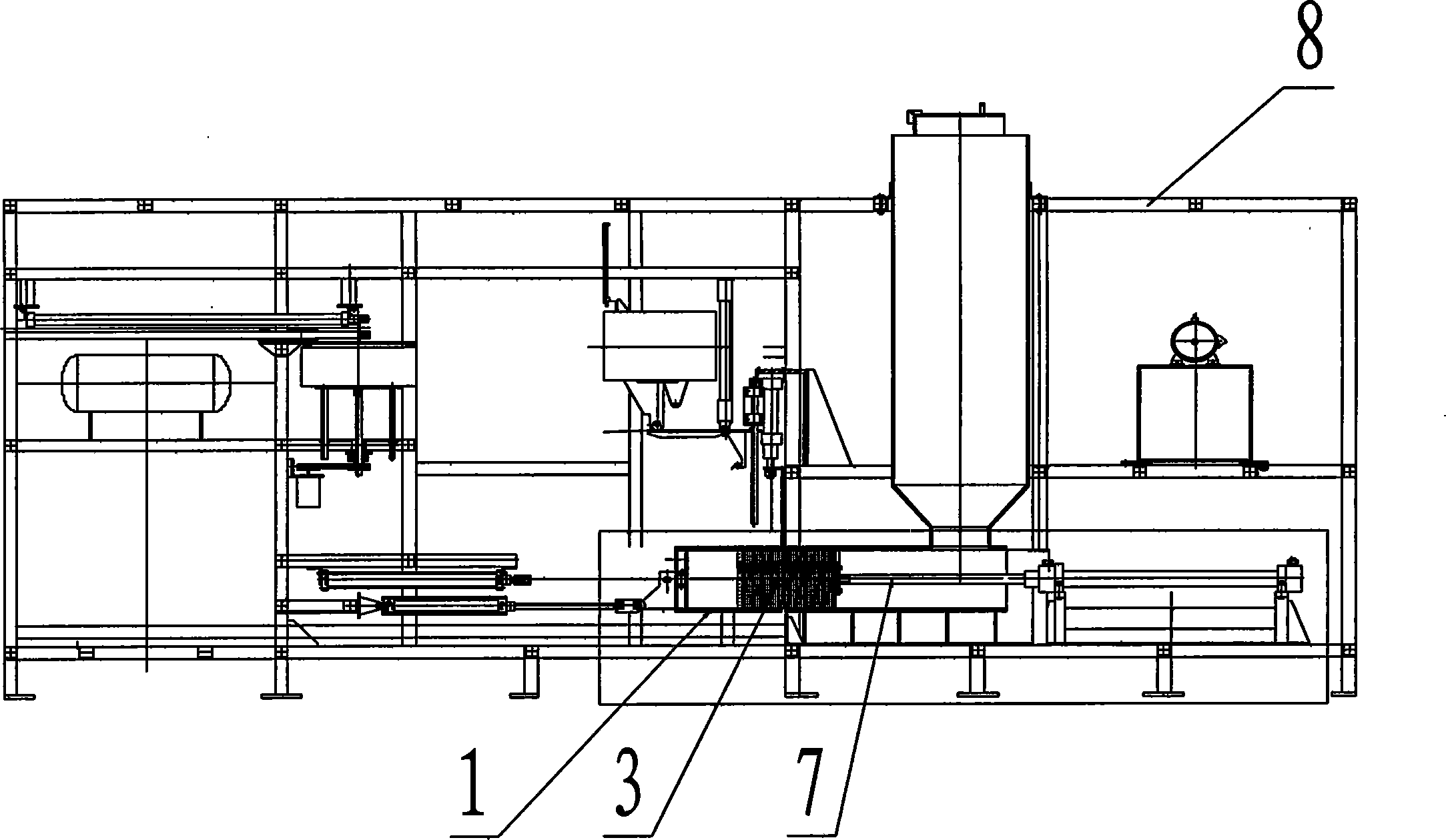

[0018] As shown in the figure; a compression box 4 is arranged above the support in the middle part of the garbage automatic packaging machine 8, and a packing box 2 is arranged at one end of the compression box 4, and a push plate 2-1 is arranged in the packing box 2, and a garbage bag 1 is placed outside the packing box 2, and a garbage bag The bottom of 1 corresponds to the port 2 of the packaging box; the other end of the compression box 4 is provided with a compression cylinder 6, and the garbage bin 4-1 is provided above the compression box 4; An oil cylinder push rod 7 is set between the push head 5 and the compression cylinder 6, and the block-shaped garbage 3 is compressed between the push head 5 and the bottom of the compression box 4; the packing box 2 is coaxial with the compression box 4 and the compression cylinder 6 set up.

Embodiment 2

[0020] The rubbish 3 of compression box 4 has been compressed into block before garbage bagging, and the baffle plate of compression box 4 bottoms is extracted, and the bottom is opened;

Embodiment 3

[0022] The compression oil cylinder 6 is pressurized, and the oil cylinder push rod 7 pushes the blocking material compression push head 5 to push the lumpy garbage 3 into the packing box 2. At the same time, the garbage 3 pushes the bottom of the garbage bag 1 into the packing box 2; the outside of the packing box 2 The garbage bag 1 is pushed by the garbage 3 and slides into the mouth of the packaging box 2, and enters the packaging box 2 along with the operation of the garbage 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com