High-modulus rubber compound and high-load synchronous belt

A rubber composition, high modulus technology, used in the field of belt transmission equipment, can solve the problem of poor adhesion performance, fatigue performance, compression permanent deformation and elasticity of the tensile body cord and tooth cloth, neoprene rubber Problems such as deterioration of material process performance, inability to perform normal processing, etc., to achieve the effects of not being prone to local stress accumulation, improving hardness, and being easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

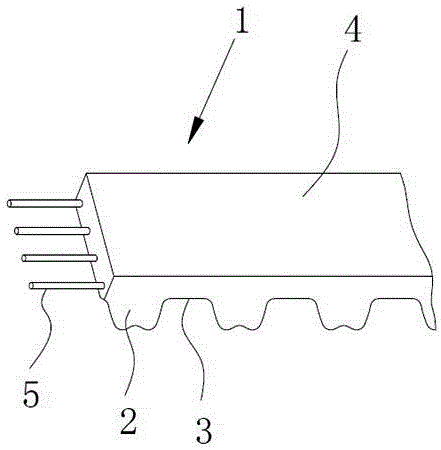

[0053] A high-load timing belt 1, wherein the rubber composition of the teeth 2 and the belt back 4 are both:

[0054] Neoprene CR121 100 parts;

[0055] 4 parts of magnesium oxide;

[0056] 0.5 parts of stearic acid;

[0057] Anti-aging agent ODA 2 parts;

[0058] Carbon black N550 35 parts;

[0059] 5 parts aromatic oil;

[0060] 30 parts of SL-2101 phenolic reinforcing resin;

[0061] 3 parts of cross-linking agent HMT;

[0062] 2 parts of N,N'-m-phenylene bismaleimide (PDM);

[0064] Accelerator TMTD 2

Embodiment 2

[0066] A high-load timing belt 1, wherein the rubber composition of the teeth 2 and the belt back 4 are both:

[0067] Neoprene CR121 100 parts;

[0068] 4 parts of magnesium oxide;

[0069] 0.5 parts of stearic acid;

[0070] Anti-aging agent ODA 2 parts;

[0071] Carbon black N550 35 parts;

[0072] 5 parts aromatic oil;

[0073] 20 parts of SL-2101 phenolic reinforcing resin;

[0074] 2 parts of cross-linking agent HMT;

[0075] 4 parts of N,N'-m-phenylene bismaleimide (PDM);

[0076] Zinc oxide 5

[0077] Accelerator TMTD 2

Embodiment 3

[0079] A high-load timing belt 1, wherein the rubber composition of the teeth 2 and the belt back 4 are both:

[0080] Neoprene CR121 100 parts;

[0081] 4 parts of magnesium oxide;

[0082] 0.5 parts of stearic acid;

[0083] Anti-aging agent ODA 2 parts;

[0084] Carbon black N550 35 parts;

[0085] 5 parts aromatic oil;

[0086] 15 parts of SL-2101 phenolic reinforcing resin;

[0087] 1.5 parts of cross-linking agent HMT;

[0088] 7 parts of N,N'-m-phenylene bismaleimide (PDM);

[0089] Zinc oxide 5

[0090] Accelerator TMTD 2

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com