Special-shaped sliding block

A slider and special-shaped technology, which is applied in the field of special-shaped sliders, can solve the problems of lower yield rate, product scrapping, and product damage, etc., and achieve the effect of improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

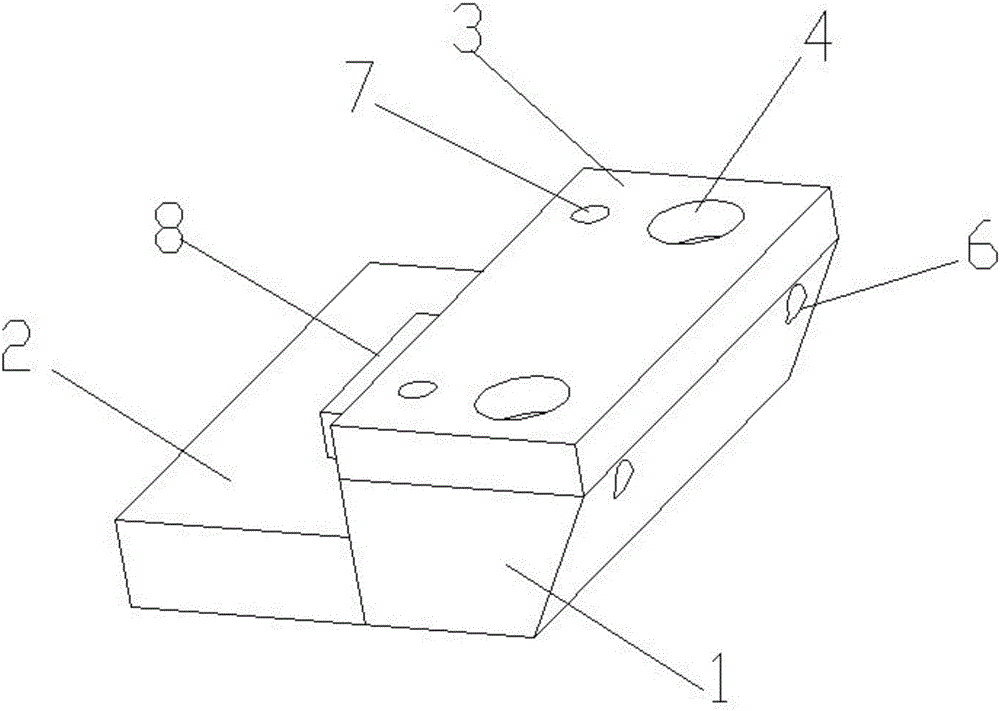

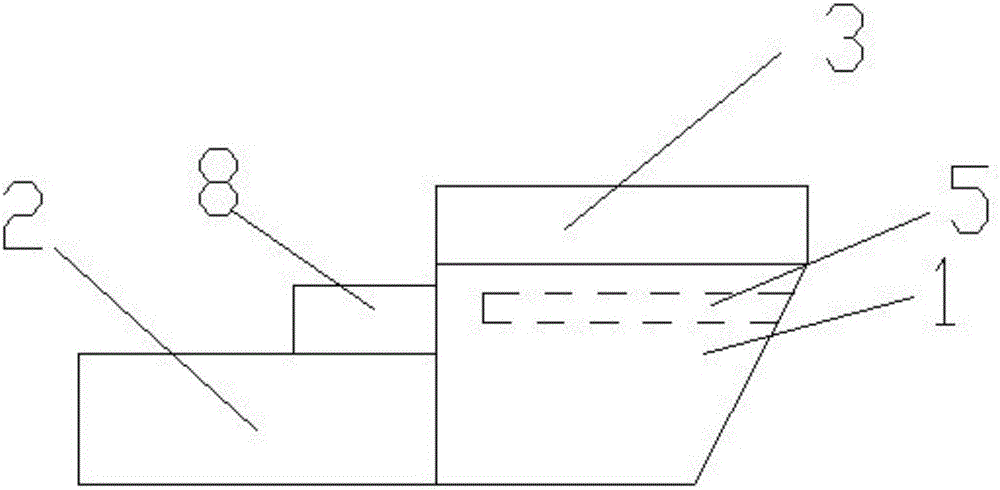

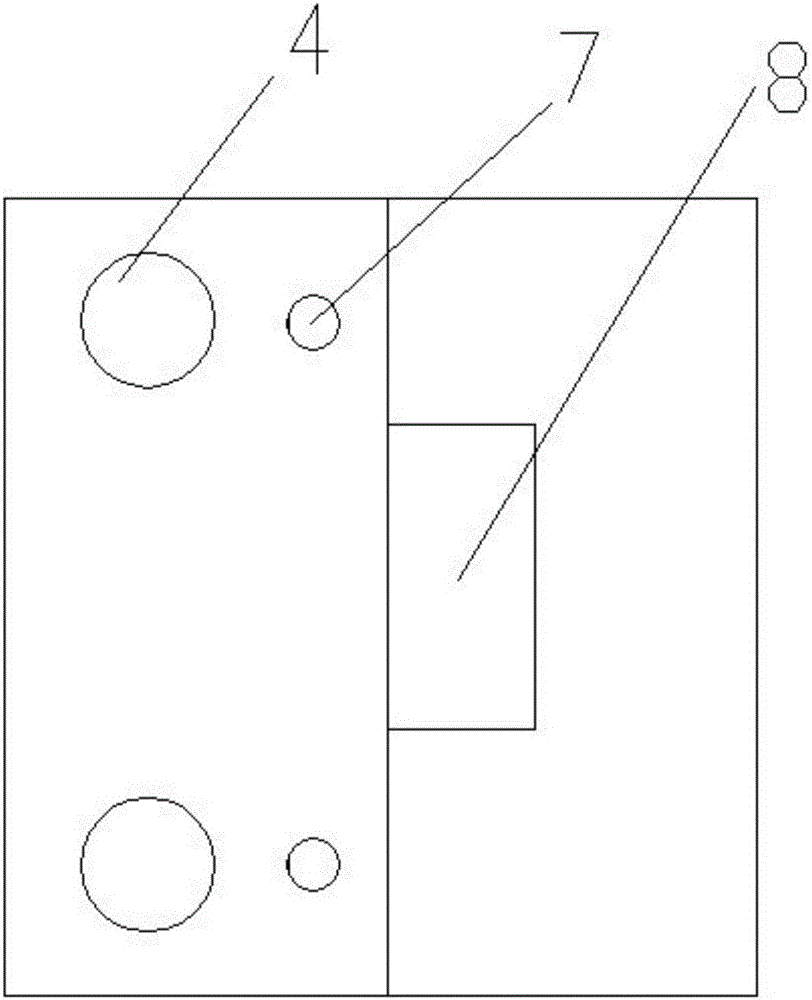

[0018] Embodiment: a special-shaped slider, including an inverted right-angled trapezoidal slider body 1, a cuboid support block 2 and a cuboid positioning block 3, the support block is fixed on one side of the right-angled surface of the slider body, the The positioning block is fixed on the top surface of the slider body, and the positioning block is provided with two mutually symmetrical positioning holes 4, and the inside of the slider body is provided with a number of exhaust passages 5, and the slider body A number of exhaust holes 6 are provided on the inclined surface of the positioning block, and a number of through holes 7 are provided on the positioning block, and the through holes communicate with the exhaust passage. The cuboid support block and the cuboid positioning block are mutually fixed on the main body of the inverted trapezoidal slider to form a special-shaped slider. Through this special-shaped slider, some structures that are difficult to form can be form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com