Patents

Literature

32results about How to "Satisfy mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dress ornament non-ironing drying shaper

InactiveCN101205684AEasy to operateIncrease productivityTextiles and paperLaundry driersEngineeringEnergy consumption

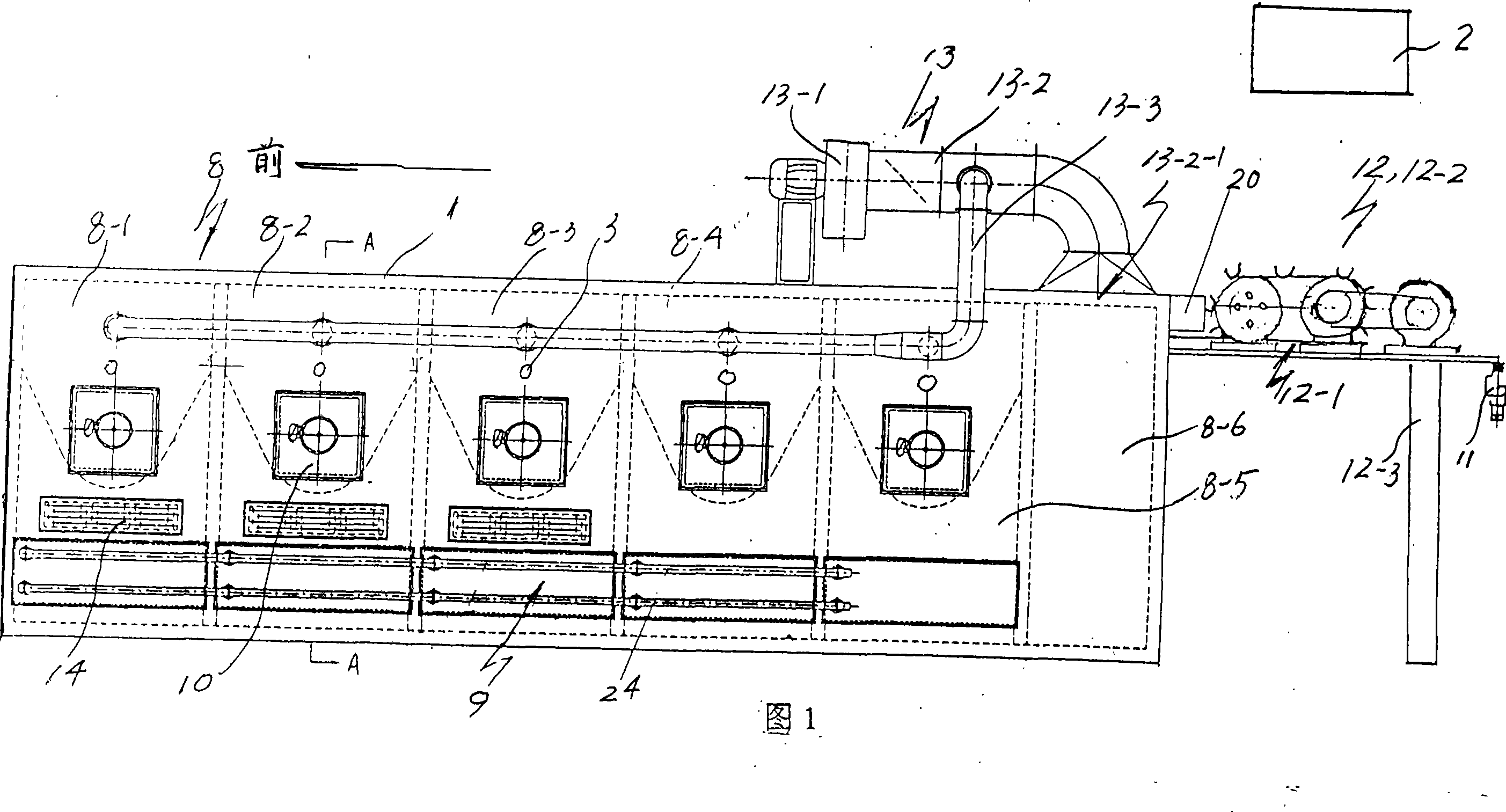

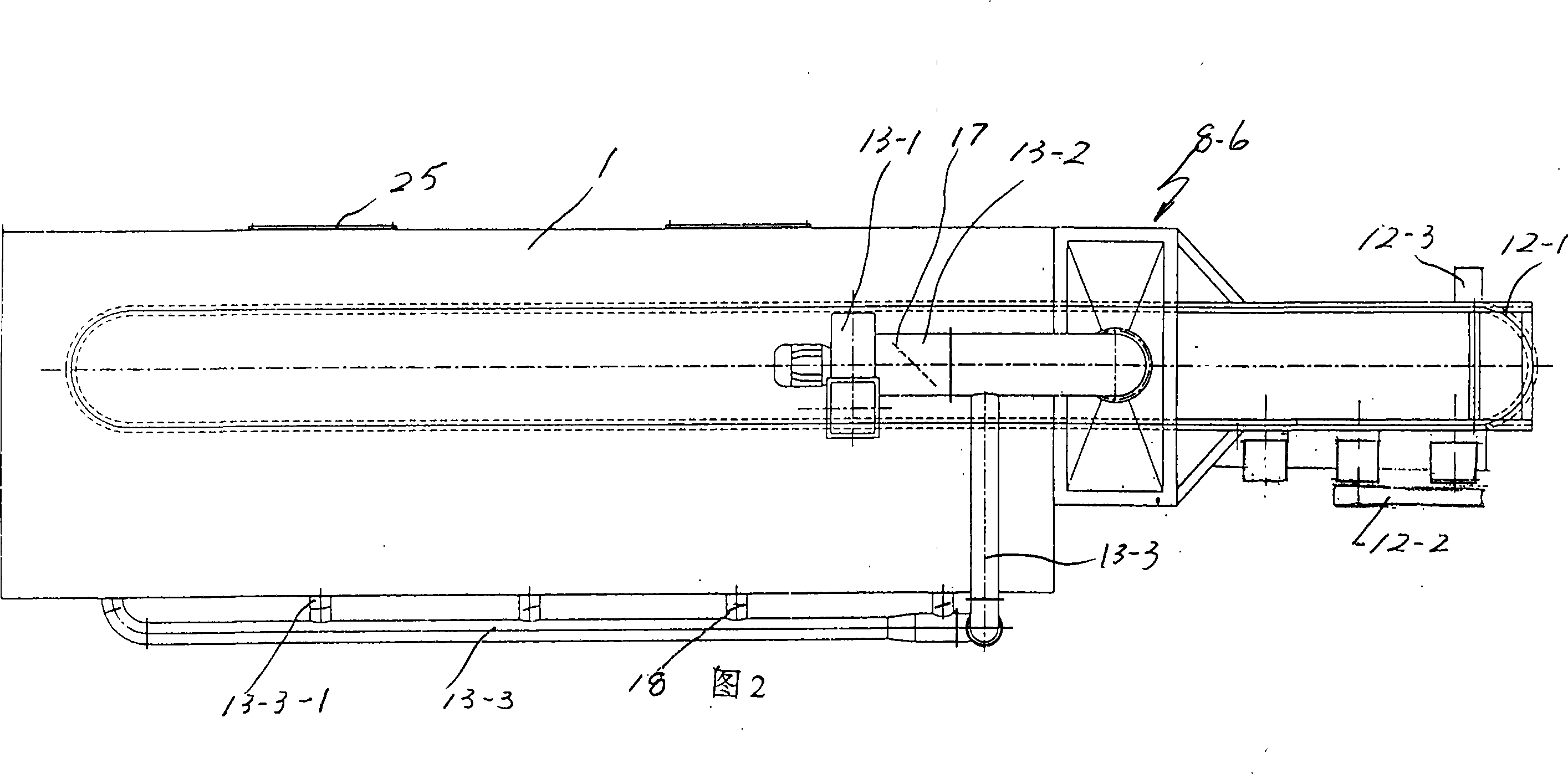

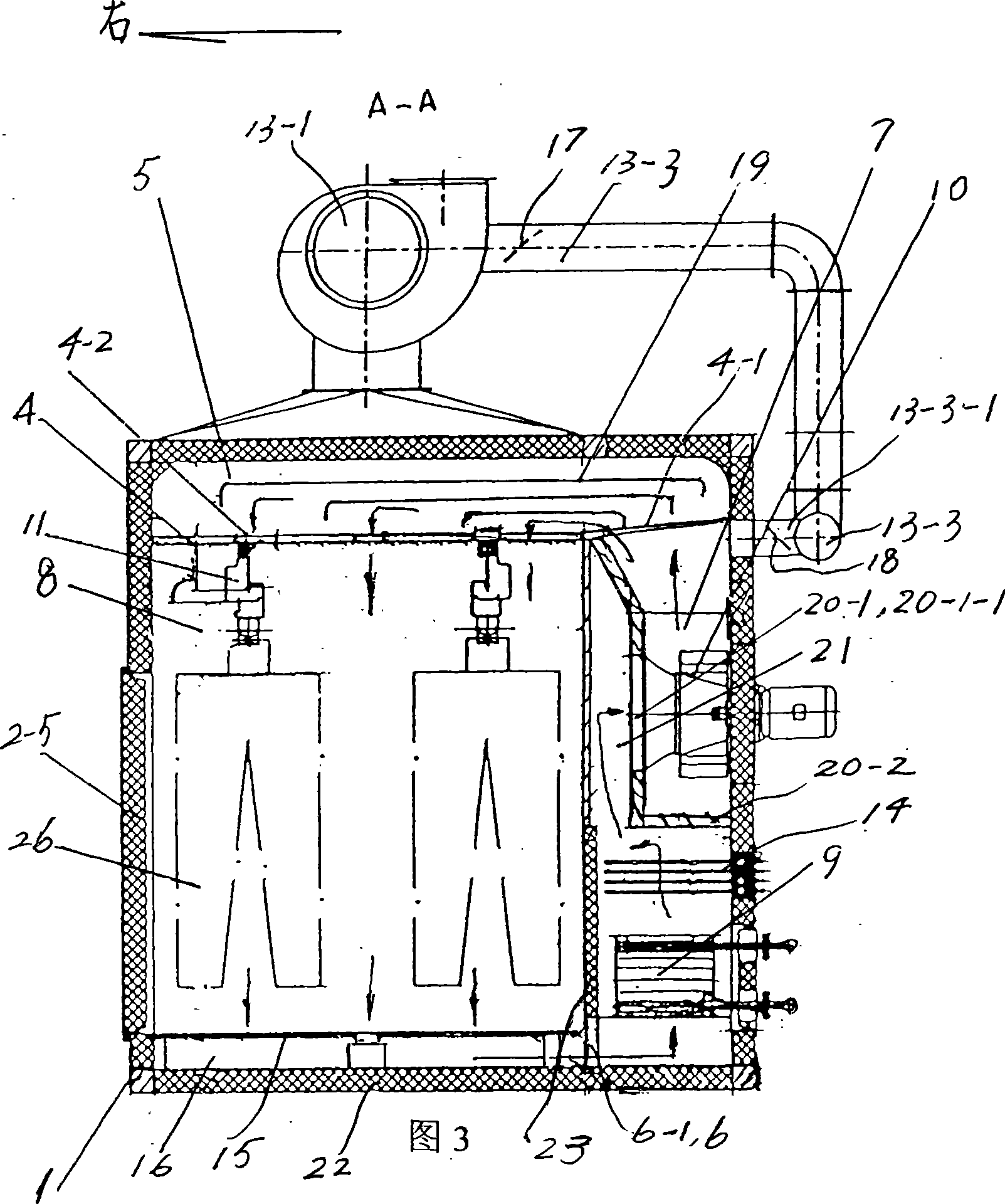

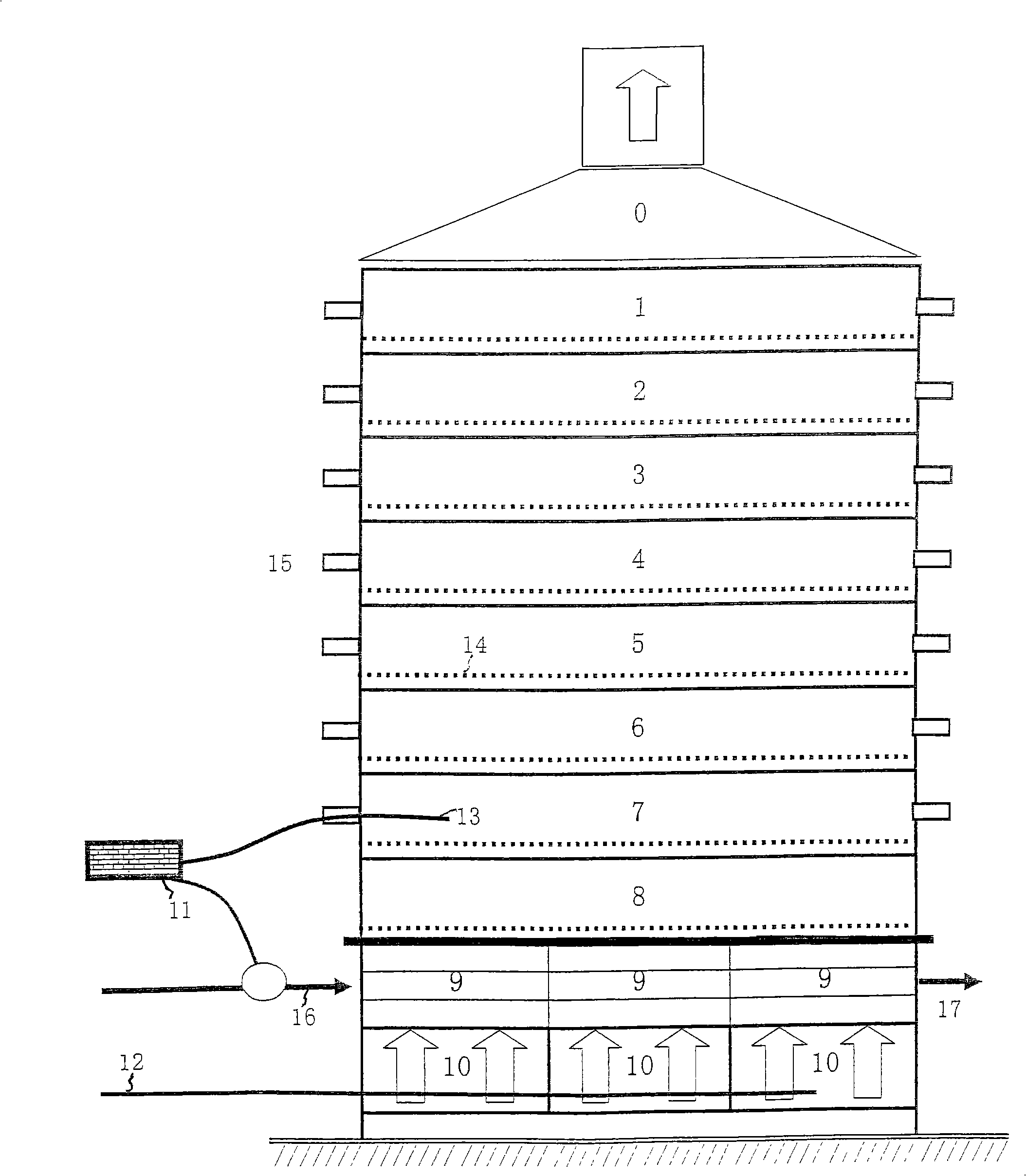

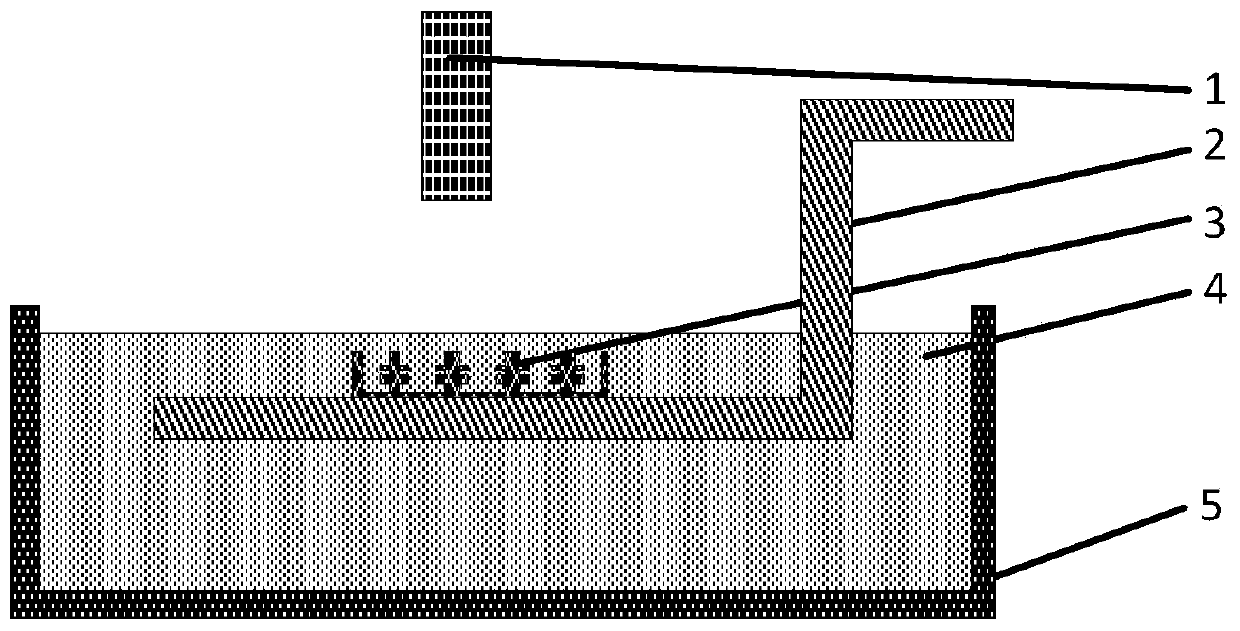

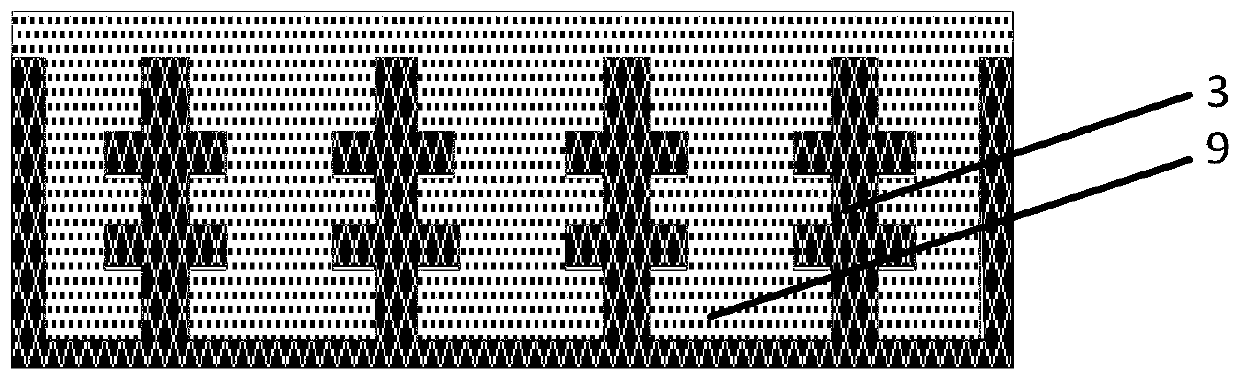

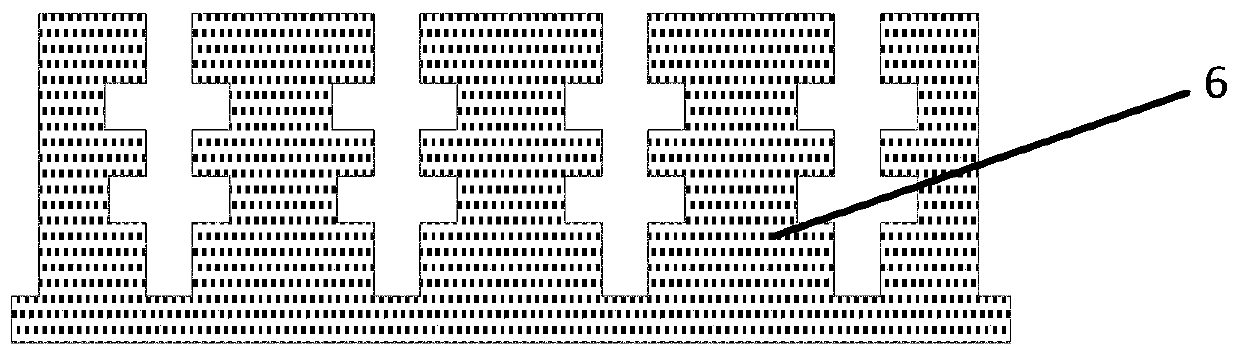

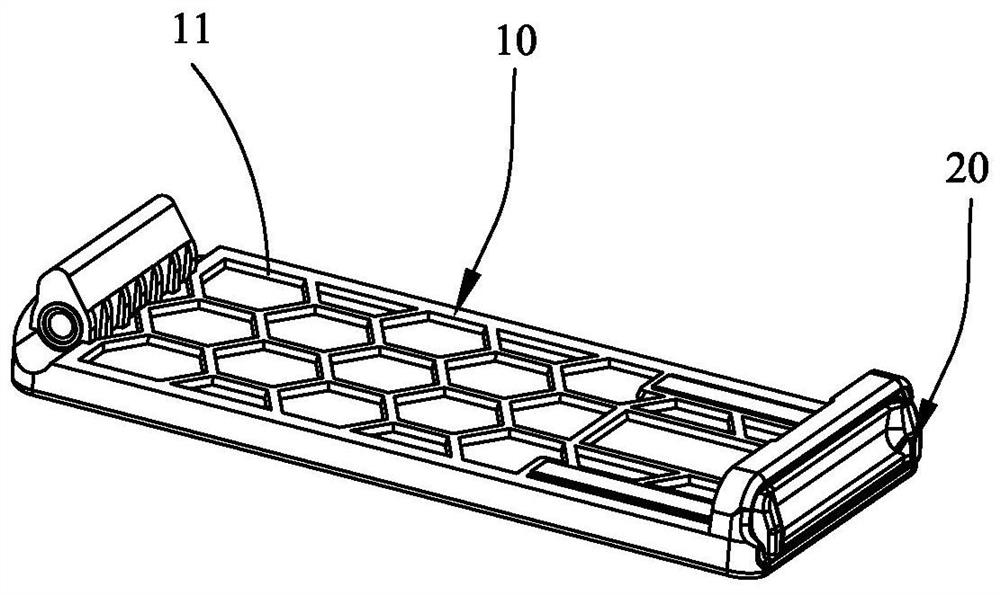

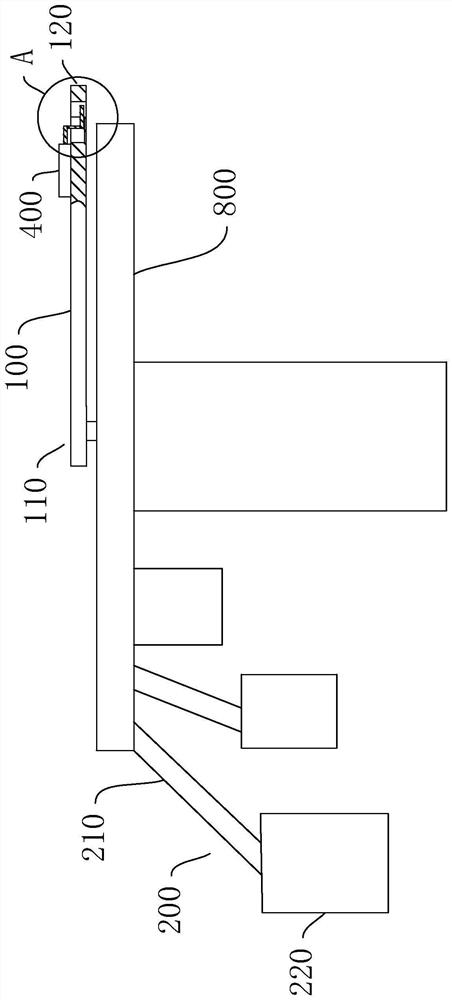

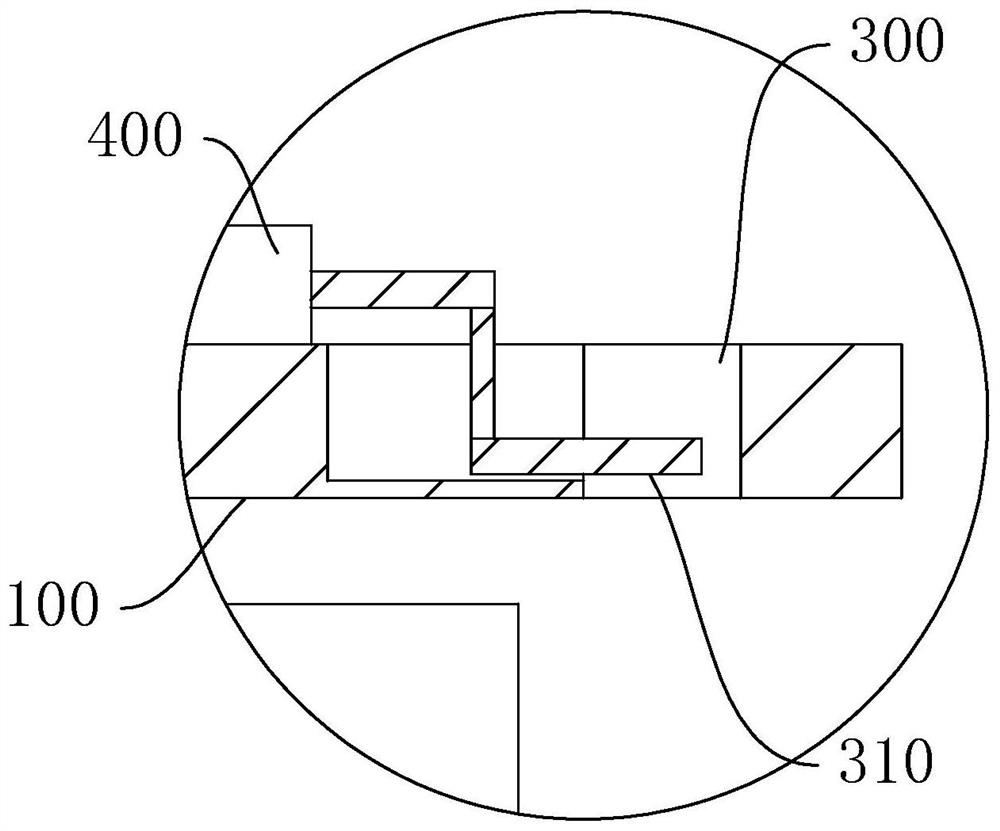

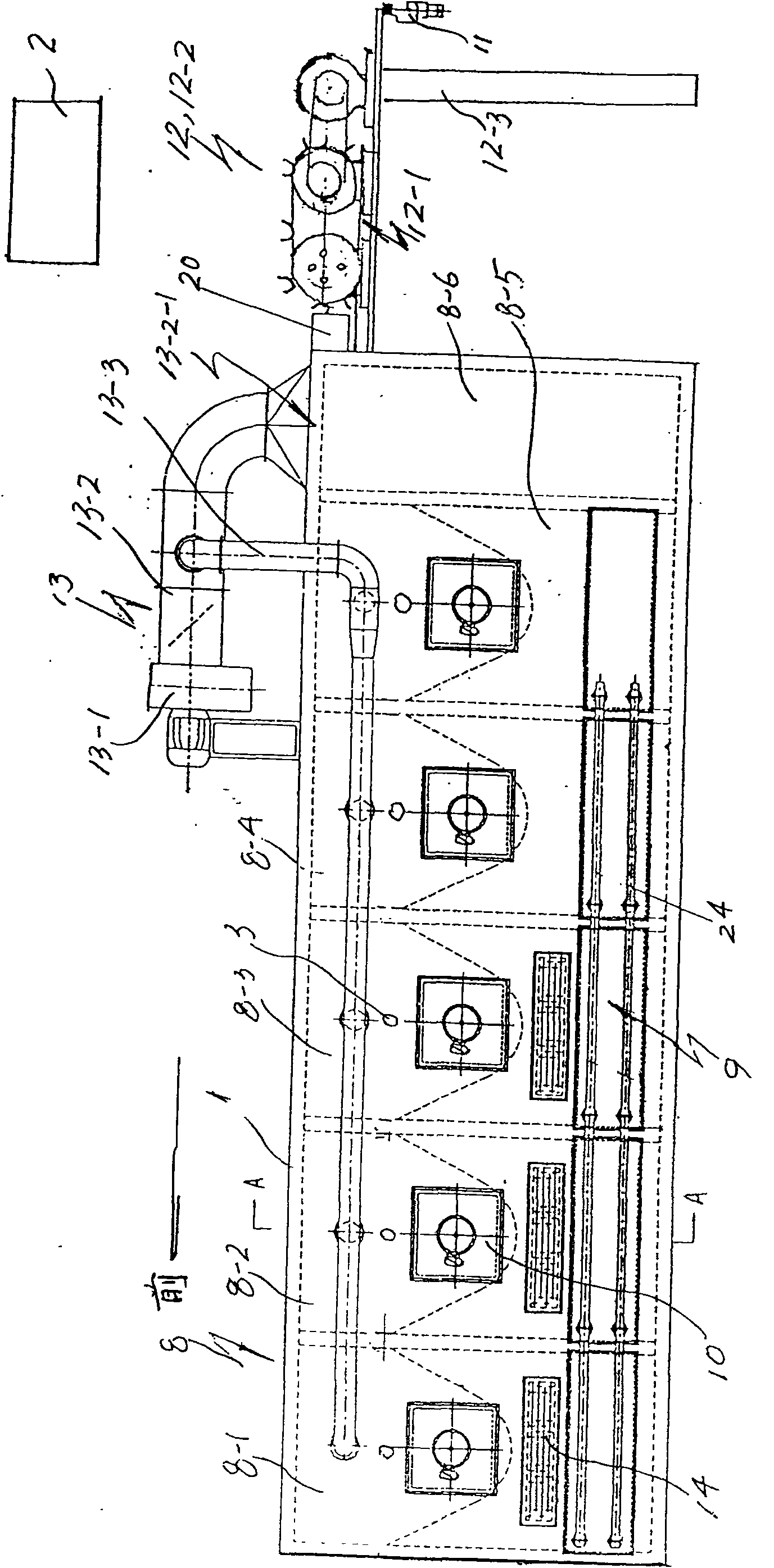

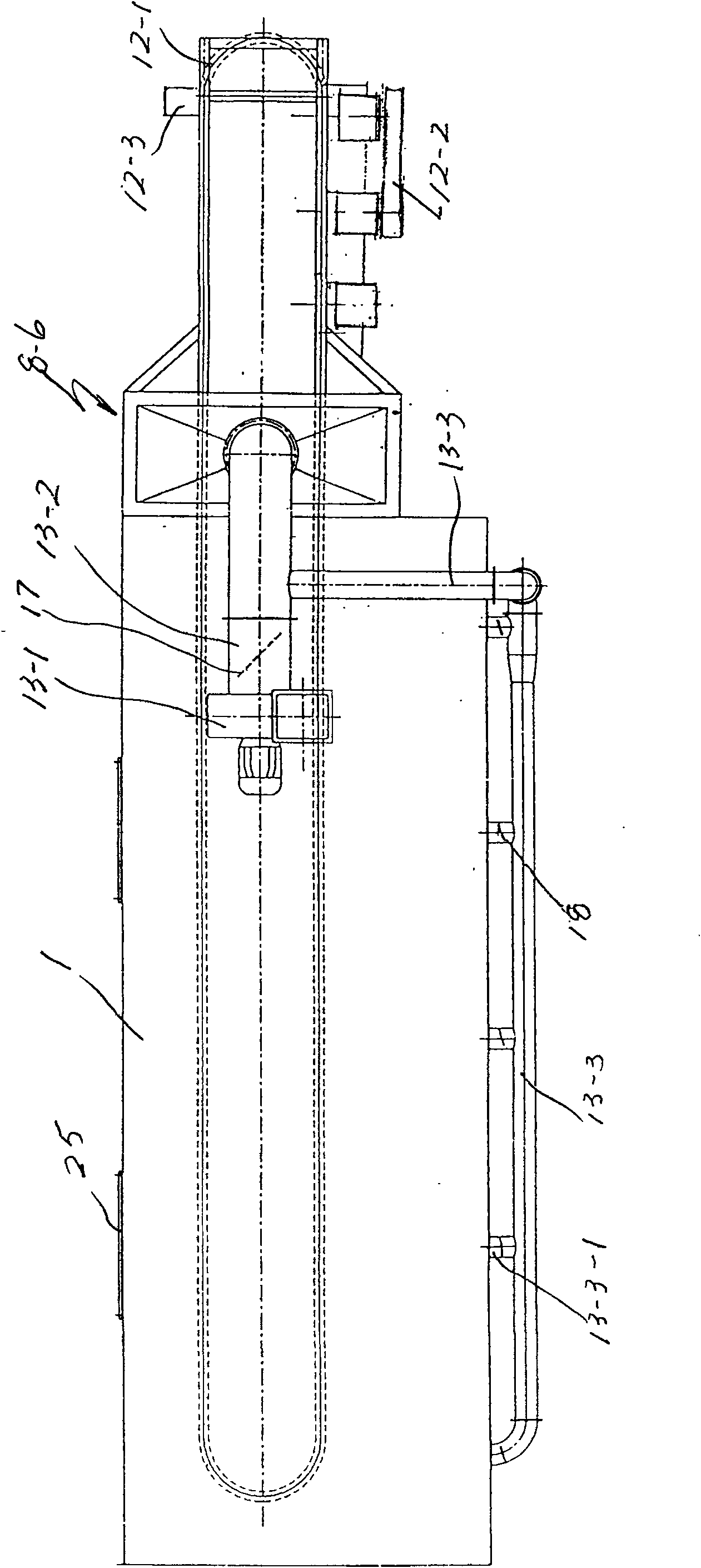

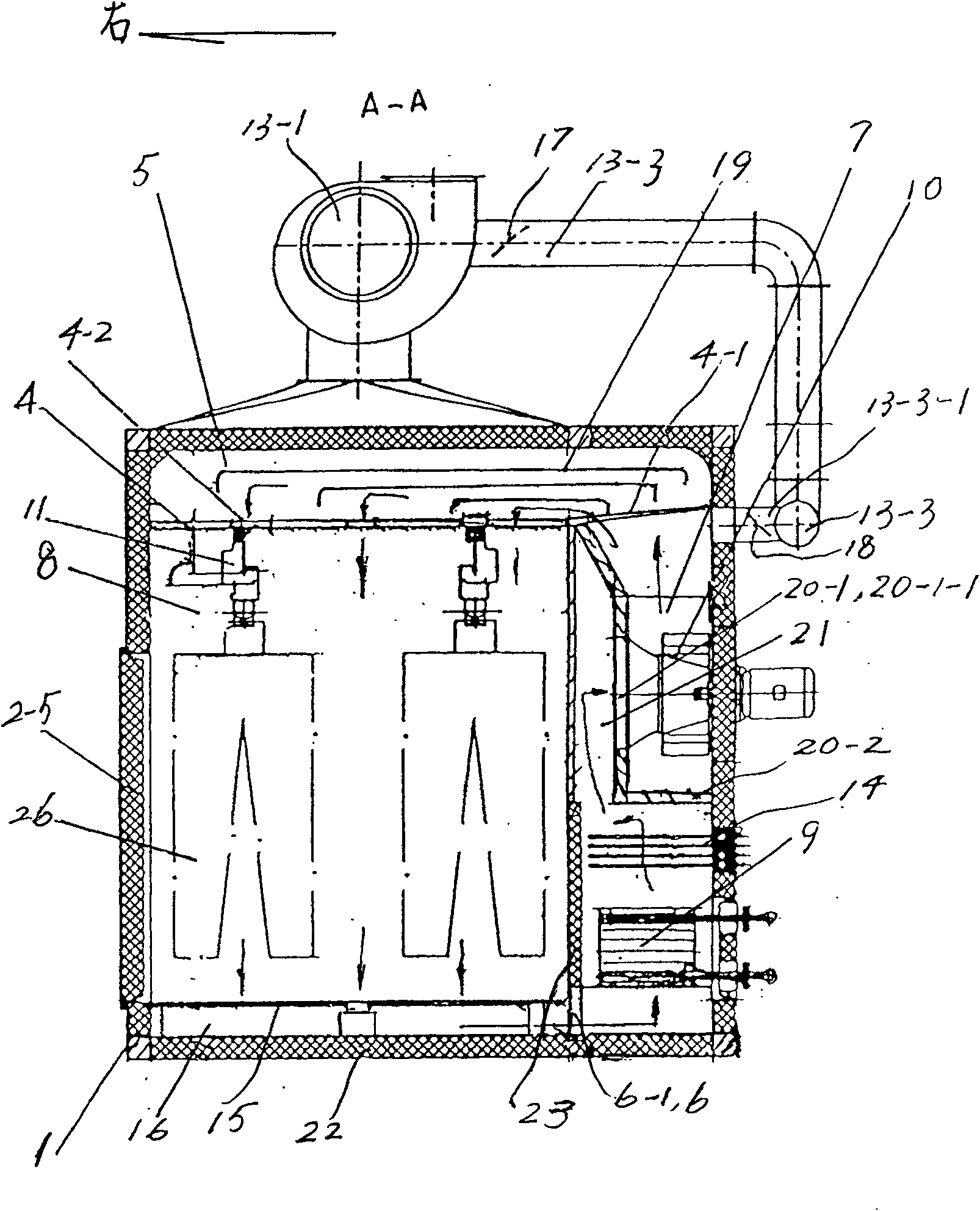

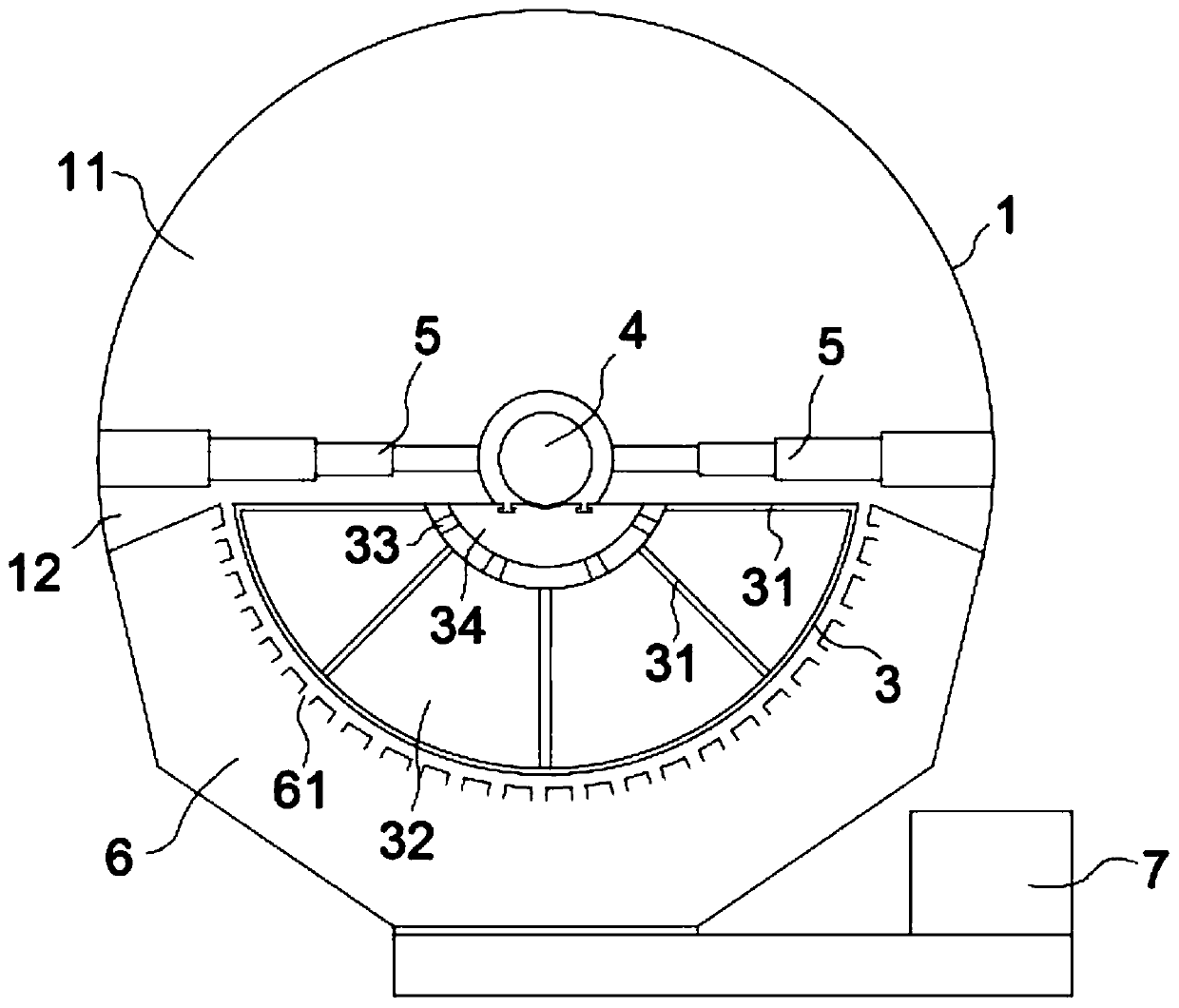

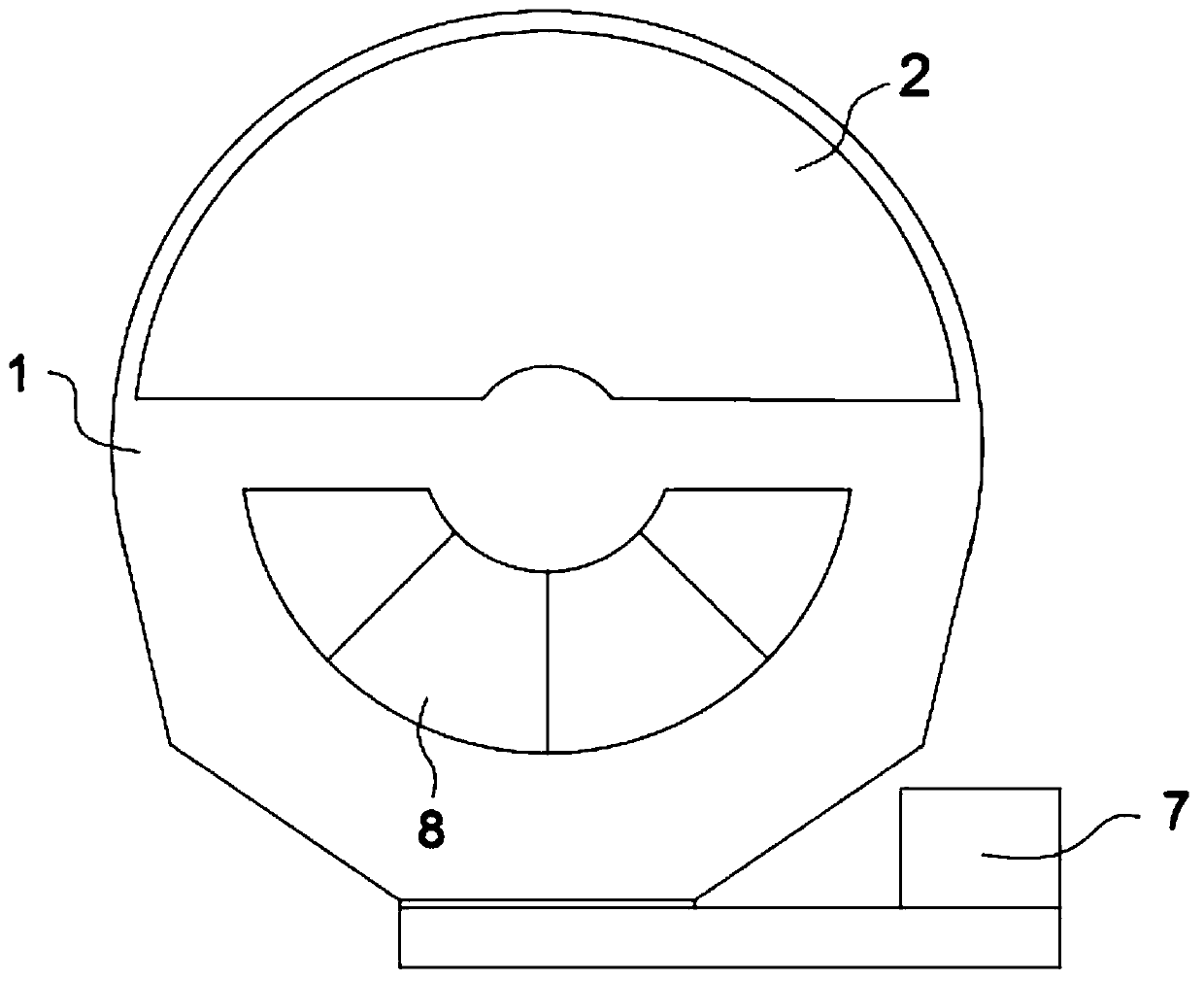

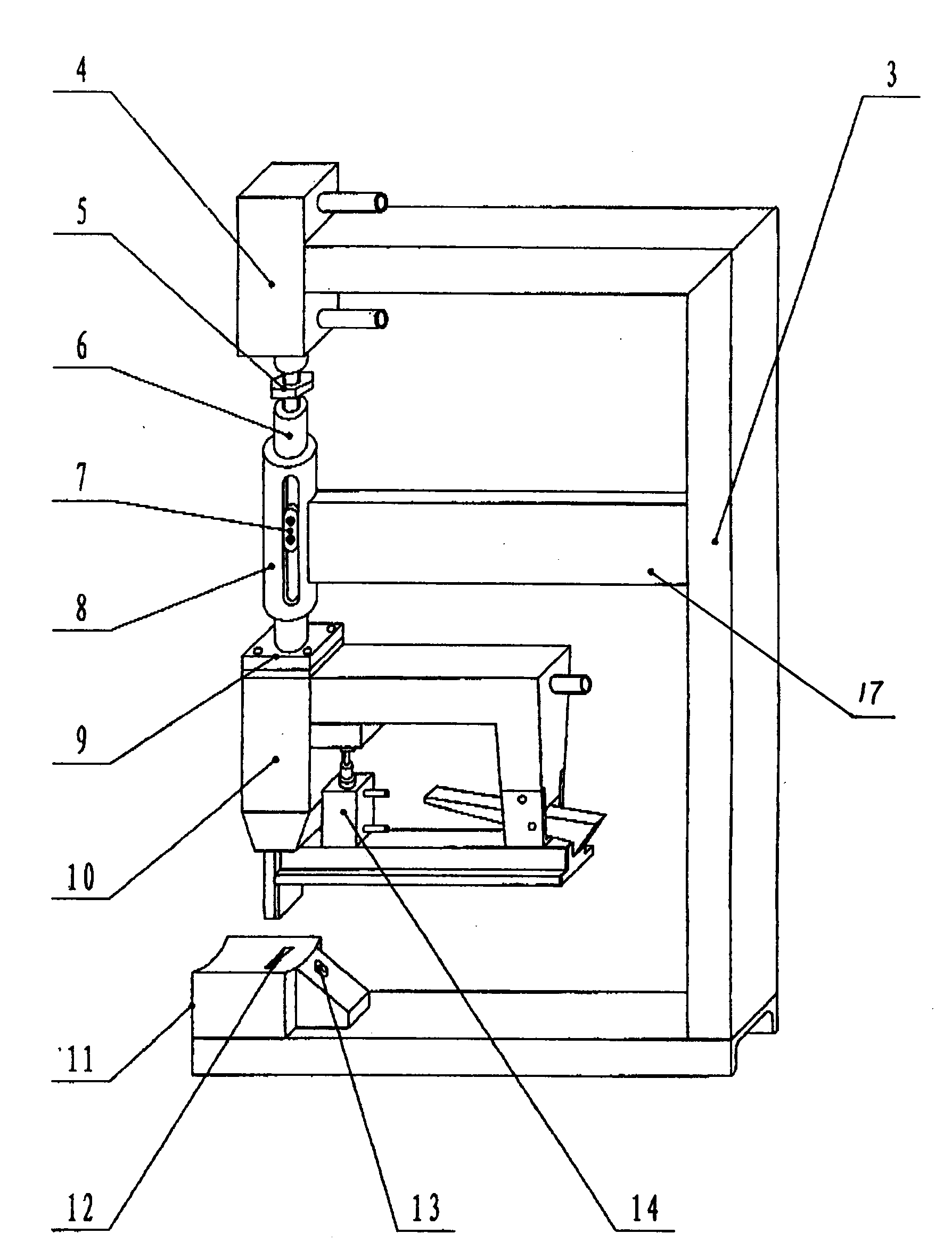

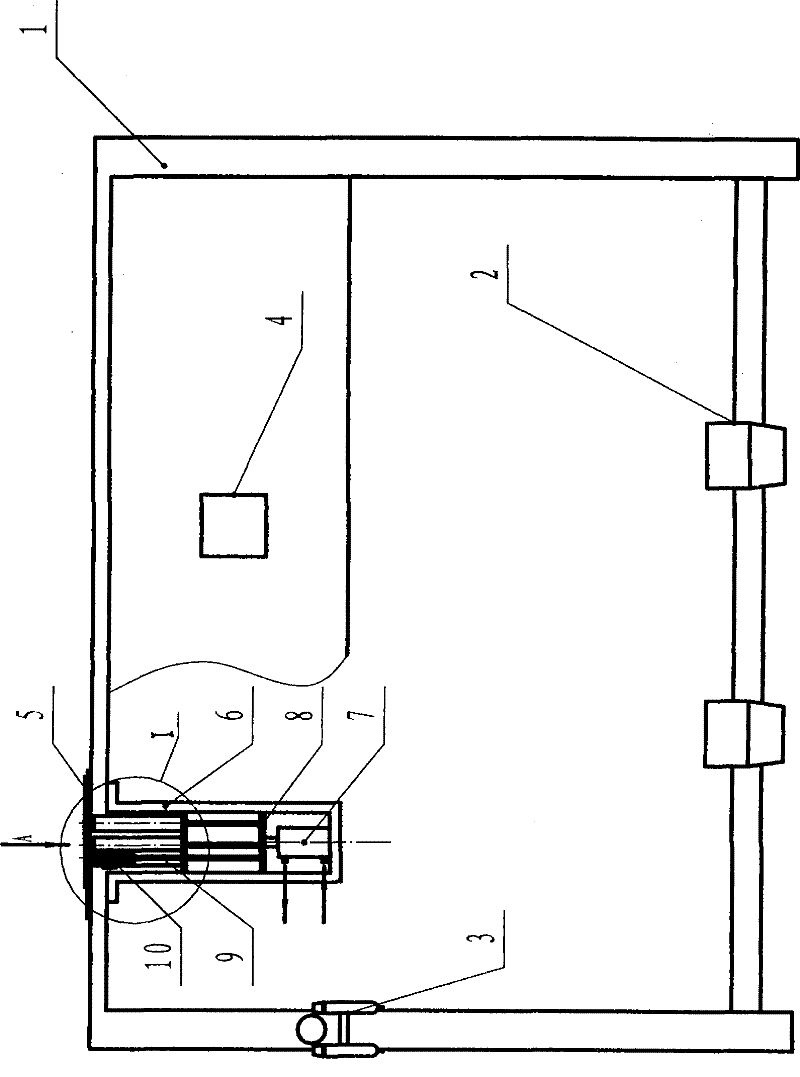

The invention discloses a clothes non-iron drying and forming machine which comprises a box body (1) an electric control device (2) and has the main characteristics of comprising a steam heater component (9), a blower component (10), a clothes hanging circulation conveying device (12) and a negative-pressure wind-suction and wet-exhaust device (13); the invention is characterized by having advanced structure, high production efficiency and low energy consumption ratio and satisfying large-batch and large-sized production. The invention can be suitable for drying, forming and processing of non-iron clothes, solid fringe clothes, bags, caps and other articles.

Owner:常州艾贝服饰有限公司

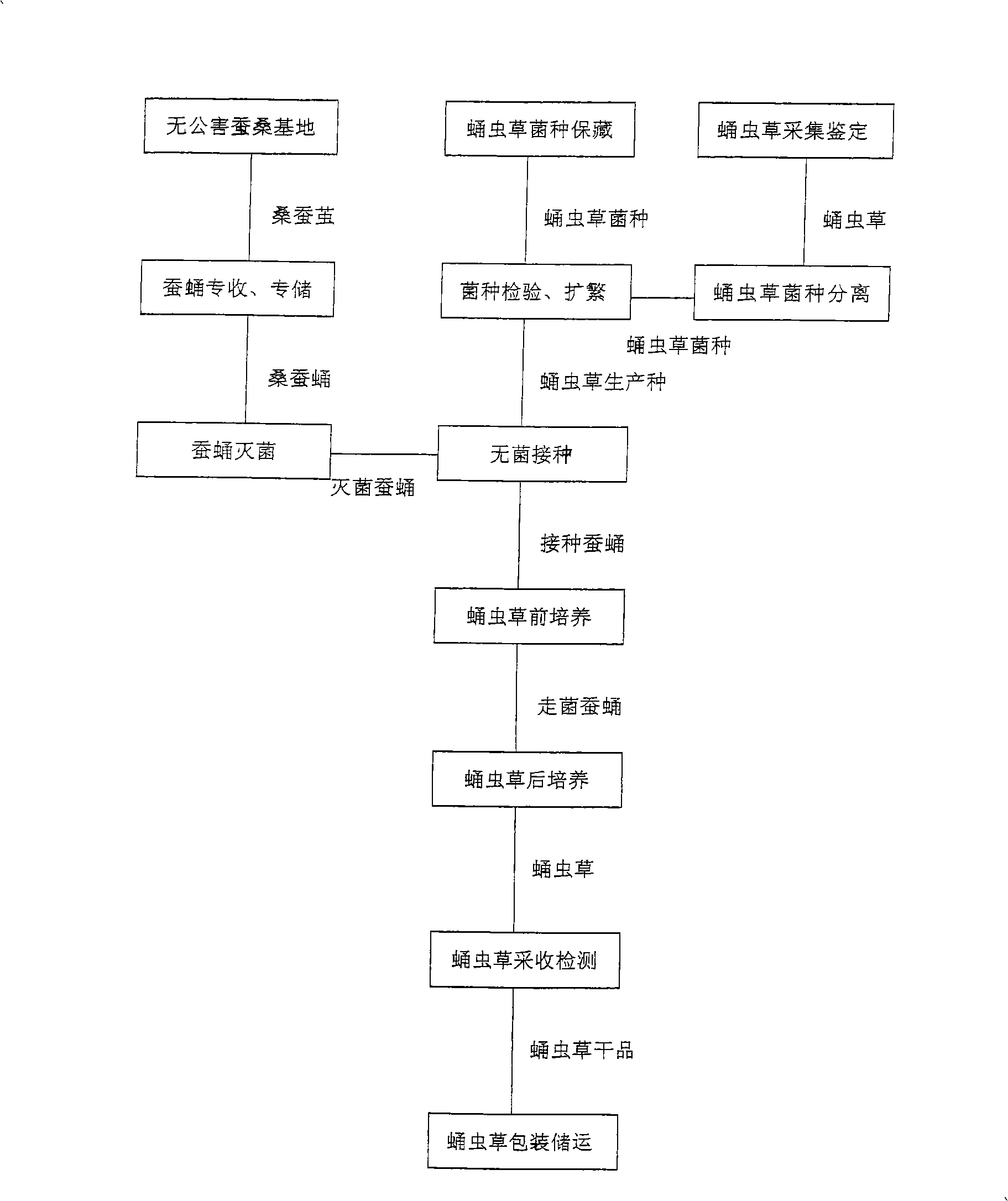

Standard operation method for producing Cordycepsmilitaris of Chinese medicine

InactiveCN101338278APromote the development of finished medicineReduce manufacturing costFungiMicroorganism based processesBiotechnologyMedicinal herbs

The invention discloses a method for culturing Chinese caterpillar fungus which is taken as Chinese medicinal plant in standardized scale culturing, comprising the using of the organic silkworm chrysalis. The silk cocoon is picked form the organic silkworm base. The silkworm chrysalis is obtained form the special silkworm harvest, storage and process sites, and is taken as the culture medium of Chinese medicinal plant Chinese caterpillar fungus. The strains should be adopted after being processed seed selection, freeze drying, preserving, activating and checking. The standardized culturing method should be adopted. The method comprises the pre culturing method and post culturing method. The standardized post treatment method is used, which comprises picking and drying method, packaging, storing and transporting methods. The Chinese medicinal plant Chinese caterpillar fungus quality guarantee method should be used, which comprises the Chinese medicinal plant Chinese caterpillar fungus quality standard and Chinese medicinal plant Chinese caterpillar fungus quality inspecting method, namely the Q / 320691DJK01-2007 standard should be established. The method can produce the Chinese caterpillar fungus which is taken as Chinese medicinal plant in standardized way.

Owner:王立臣 +1

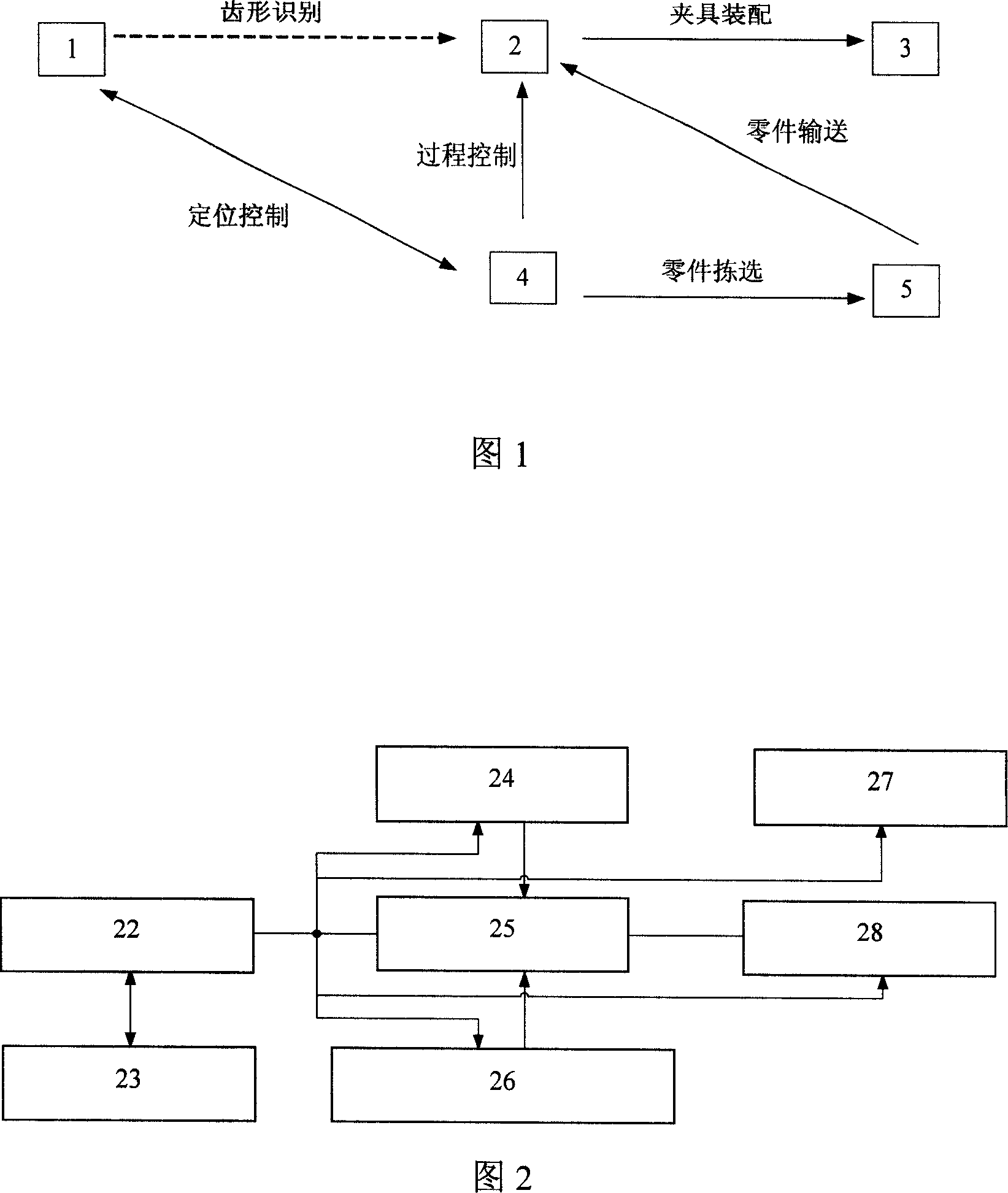

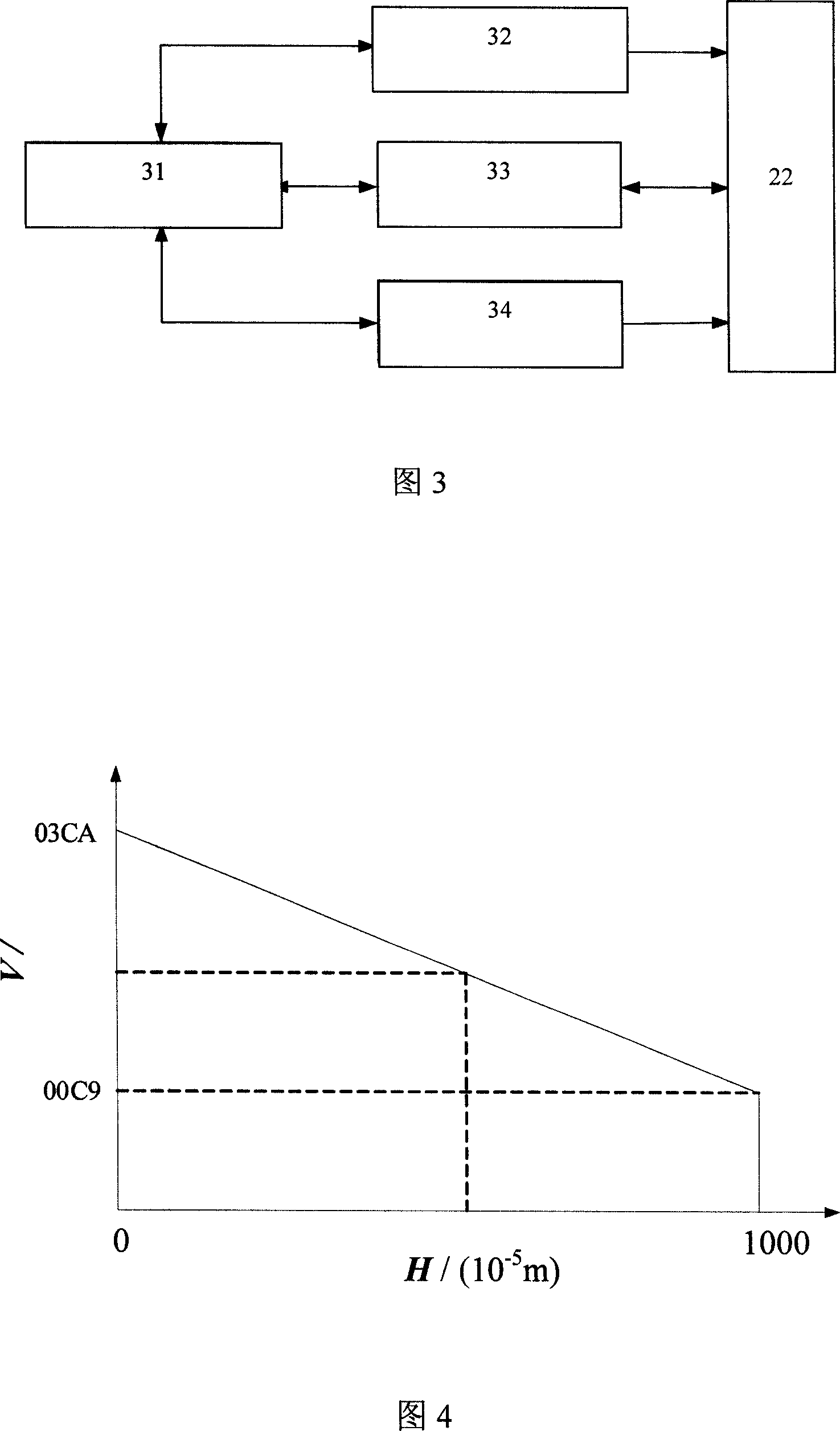

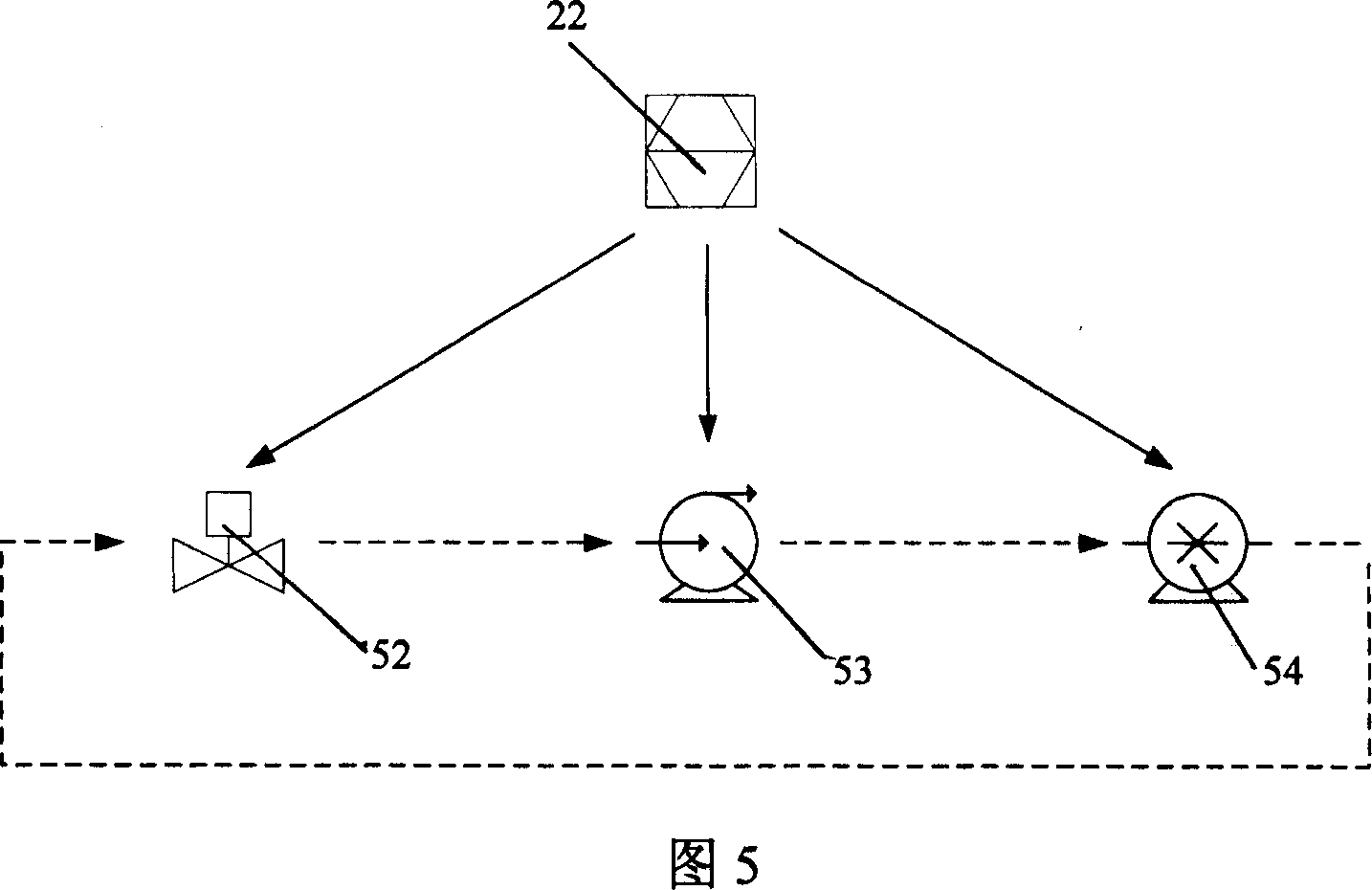

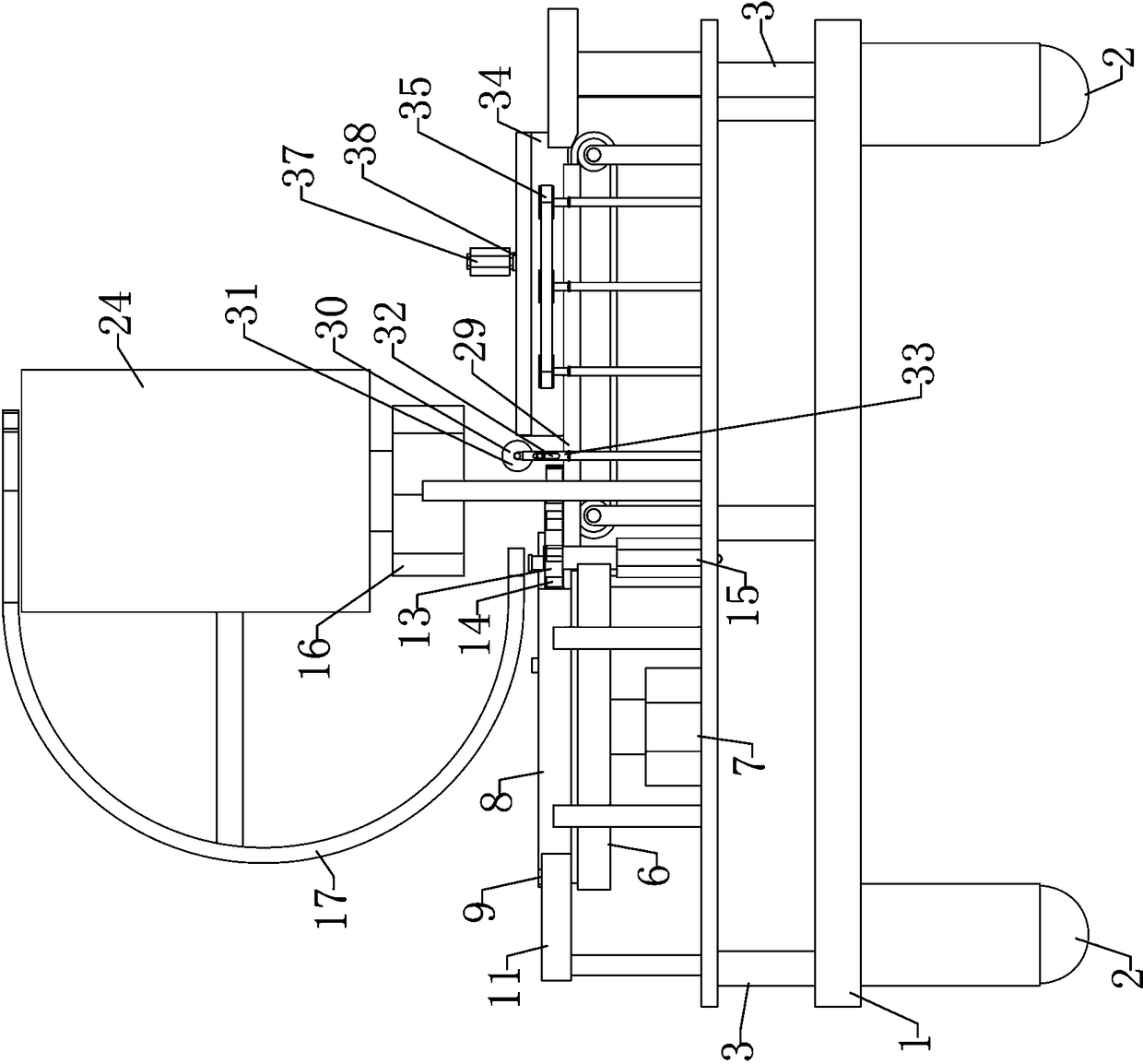

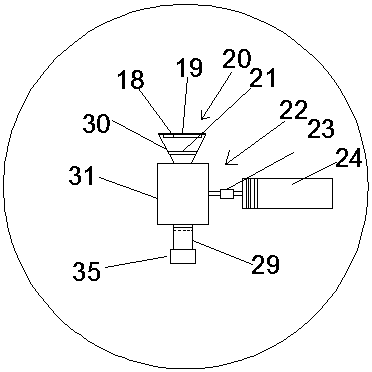

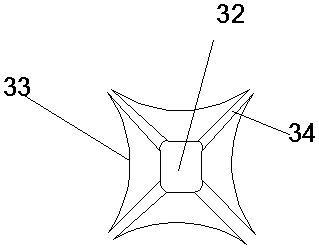

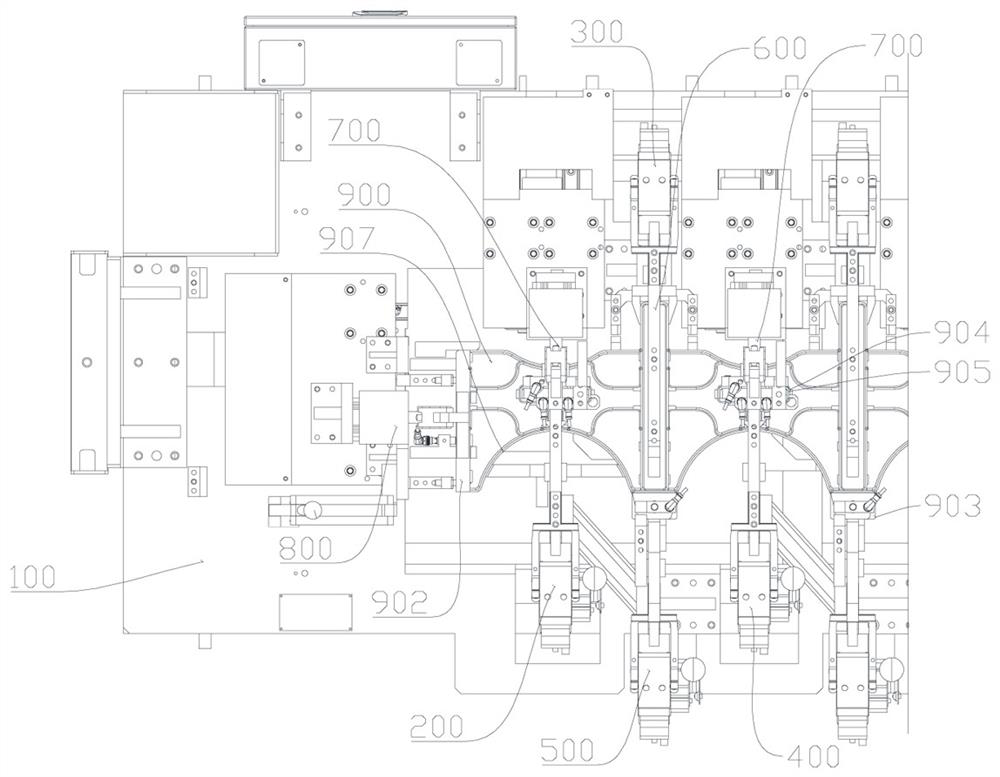

Automatic assembly apparatus system and method for automobile door lock

InactiveCN101011788AImprove detachabilityImprove maintainabilityComputer controlAssembly machinesComputer control systemProduction rate

The invention relates to the mechanical assembly of the door lock of vehicles, which comprises locking plate snap clip, key teeth identification device, locking plate automatic choosing device, automatic spring discharging and delivery device, locking plate snap clip moving device and its thrusting device, lock core jig and location exchange device, and embedded computer control system, with the method composed of key automatic location and identification, snap clip feeding and assembly, lock plate feeding and assembly, to finish the assembly of vehicle doors with accurate matching. Through lock core jig and location exchange device with the repetition of above procedures, it can get to the operation of next lock core. It is accurate, highly efficient, easy for operation, convenient for maintenance.

Owner:ZHEJIANG UNIV

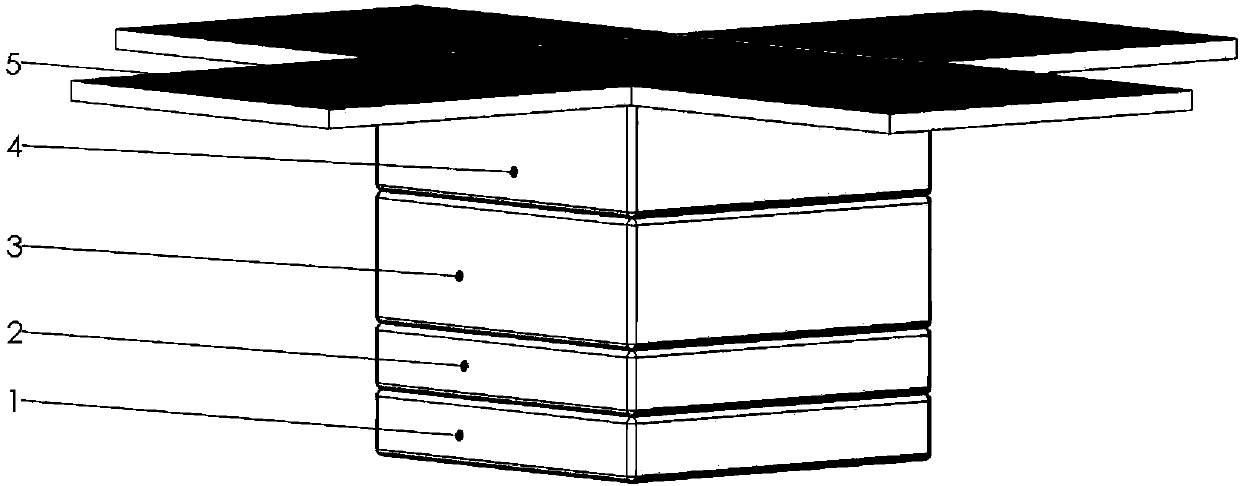

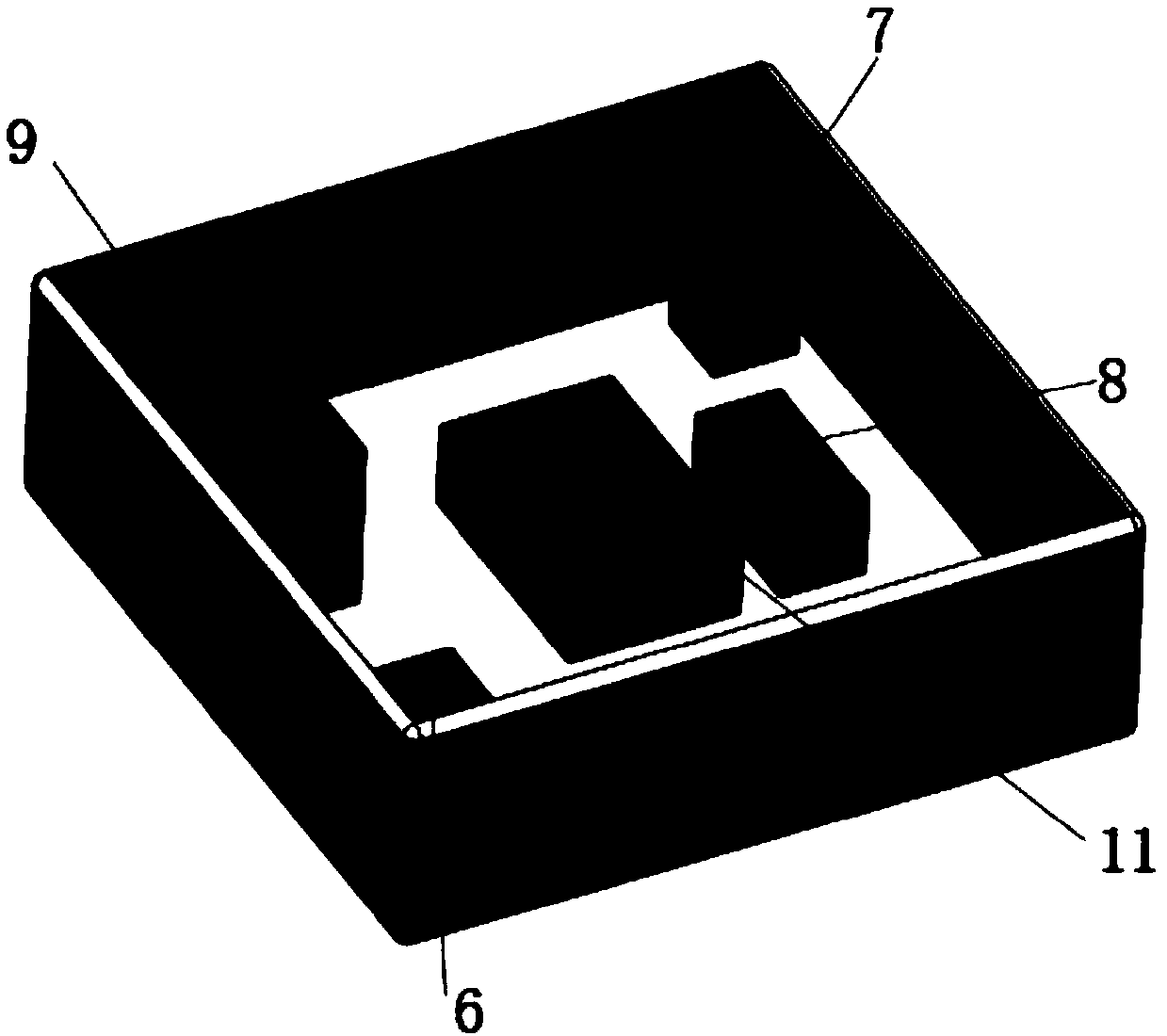

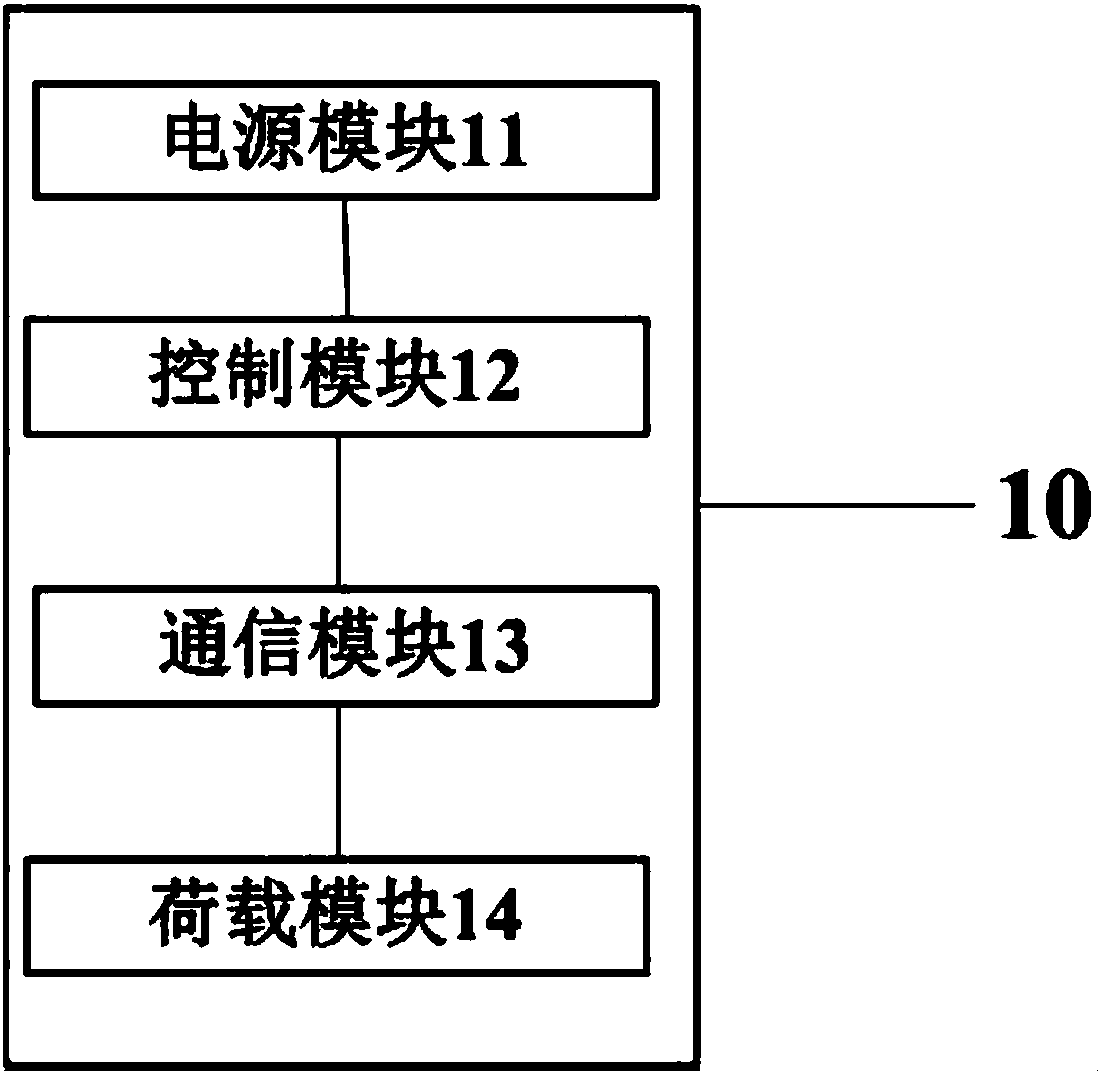

Modular satellite architecture

PendingCN108052030AShorten the timeLow costProgramme control in sequence/logic controllersModularityEmbedded system

The present invention provides a modular satellite architecture that includes a plurality of functional modules. The size and parameters of each functional module in the multiple functional modules are adjustable, and the plurality of functional modules can be freely combined. The combination can be arbitrarily according to the needs of the task, the debugging time is reduced, the mass productionand rapid launch can be fully met, and at the same time the time and cost of the satellite mass production can be greatly reduced; and the main structure of the modular satellite architecture is the various functional modules, each functional module is composed of component modules, and the component modules included in each functional module also have their own modular western standards. Therefore, the architecture has dual modularity features.

Owner:黄一君

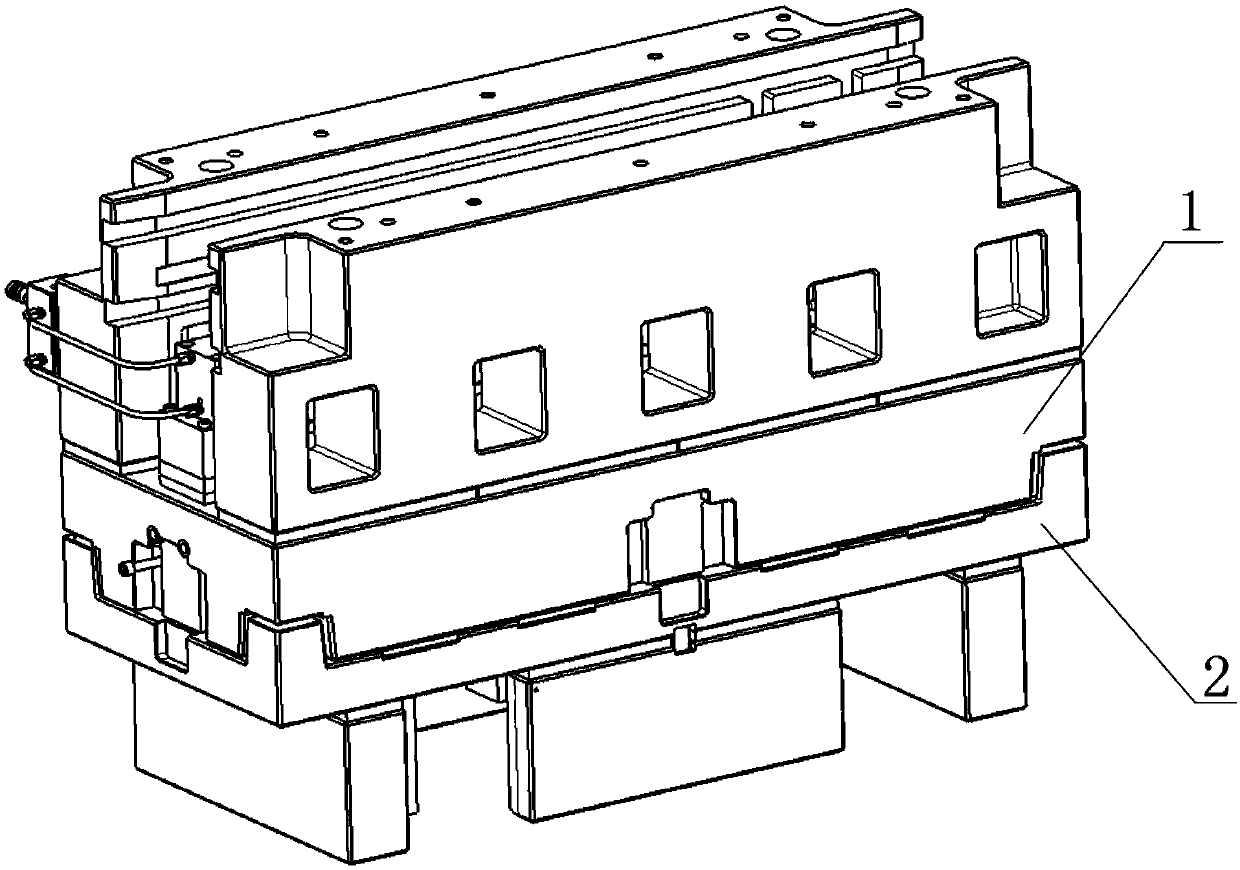

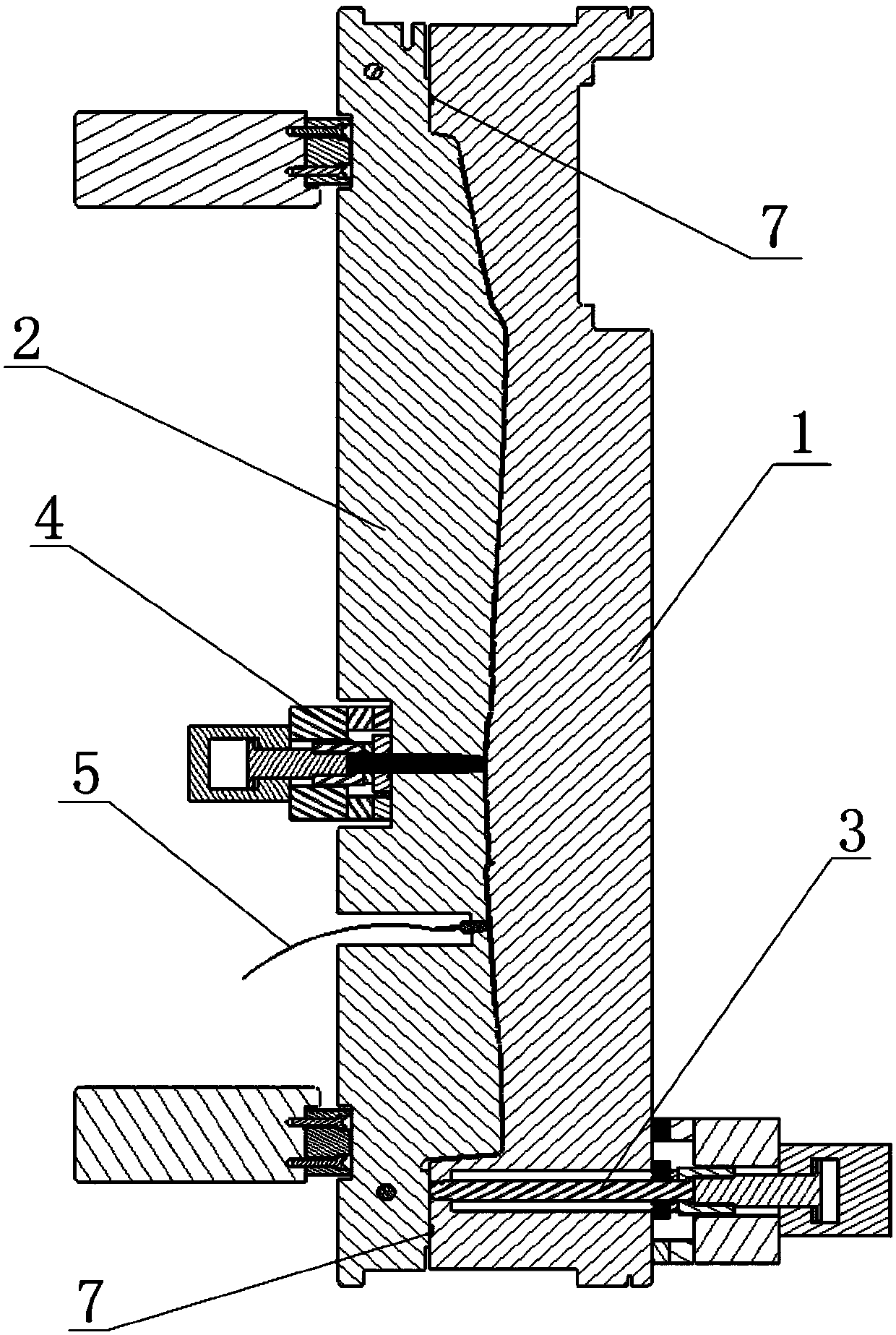

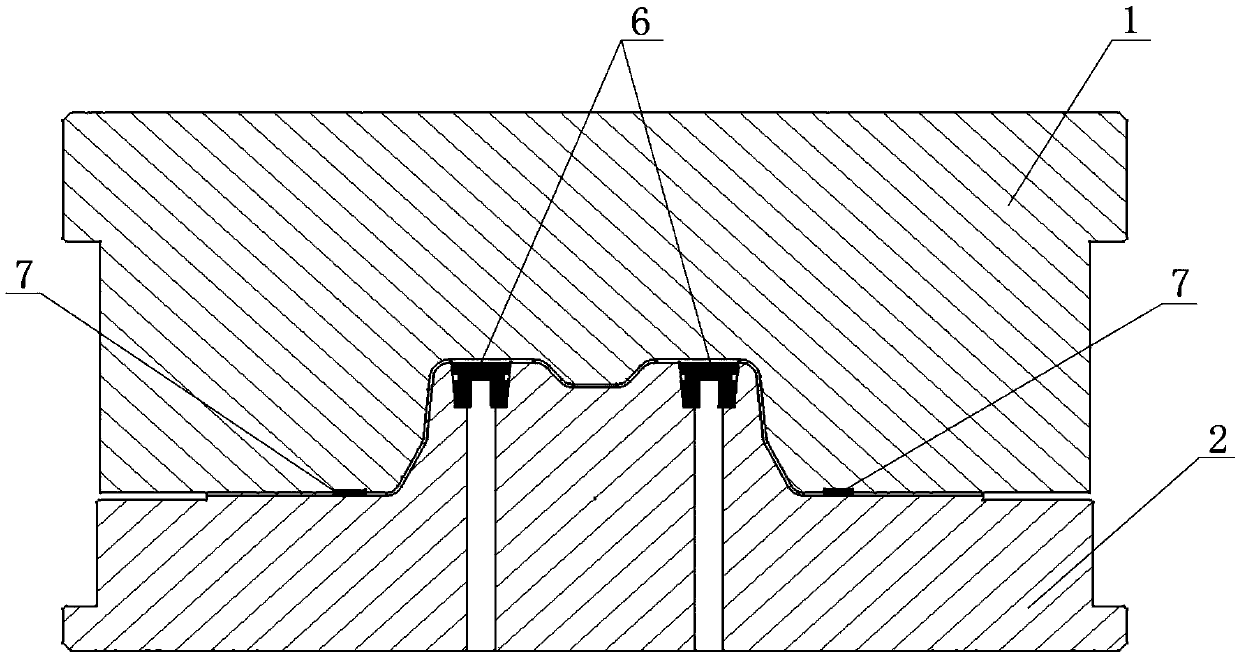

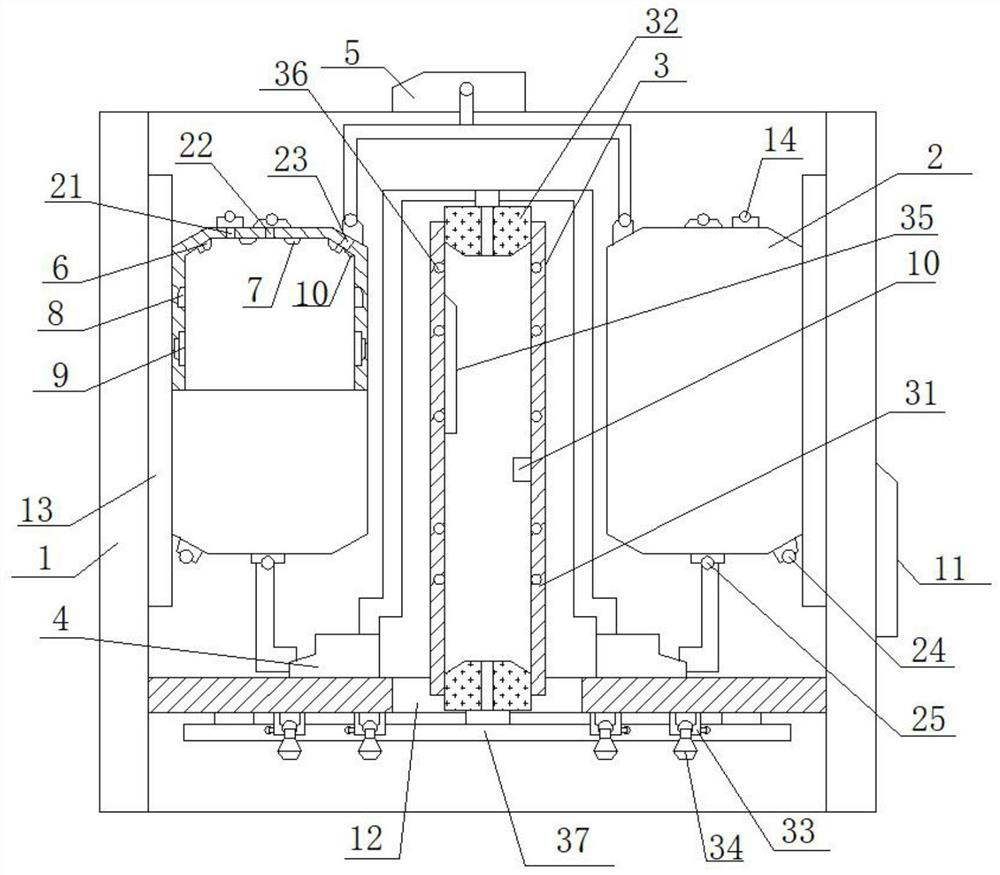

Vehicle composite material wet molding die

The invention discloses a vehicle composite material wet molding die. The vehicle composite material wet molding die matches with a press to solidify a fiber layer coated with liquid resin outside. The die comprises an upper die body, a lower die body, a vacuum pumping mechanism, a pressure sensor, a temperature sensor and multiple ejection sealing mechanisms. The upper die body is fixed on the upper table of the press; the lower die body is fixed on the lower table of the press; when the press drives the upper die body to move downward to be combined with the lower die body, a die cavity is formed between the upper die body and the lower die body; the fiber layer coated with liquid resin is arranged in the die cavity; the vacuum pumping mechanism is arranged on the upper die body; the vacuum pumping mechanism is used for vacuum pumping operation of the die cavity; and the pressure sensor is arranged on the surface of the lower die body and is used to monitor the pressure change in thedie cavity in real time. Thus, the vehicle composite material wet molding die has a simple and reasonable structure, and can meet the large-scale, batch and low-cost production demand of the automobile industry.

Owner:康得复合材料有限责任公司

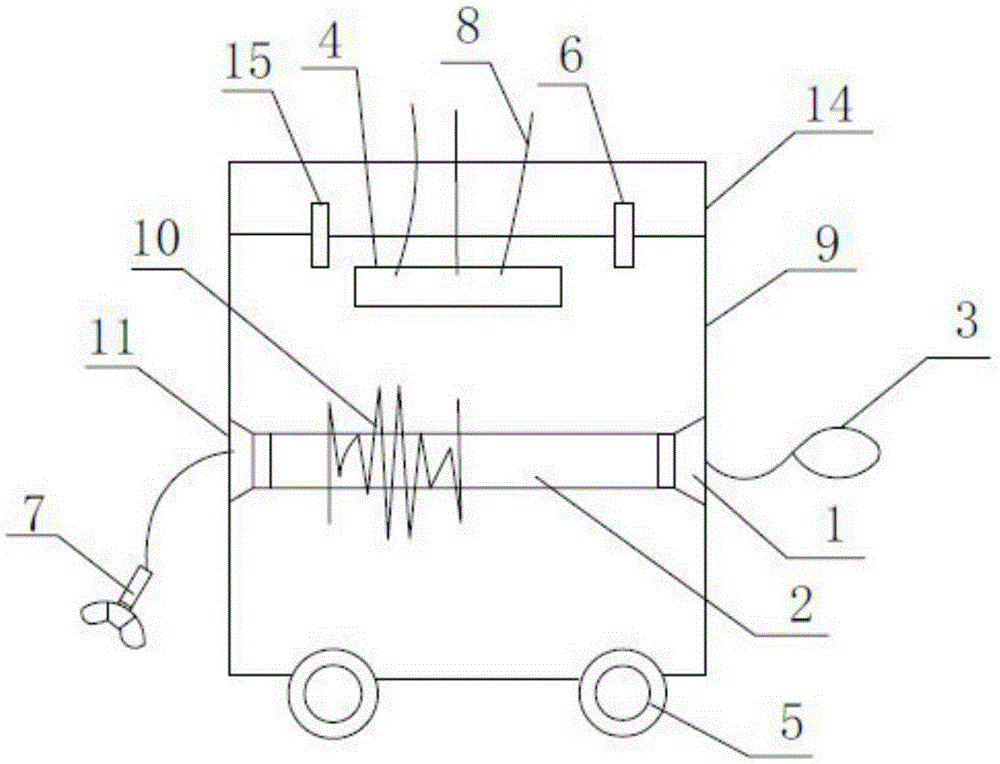

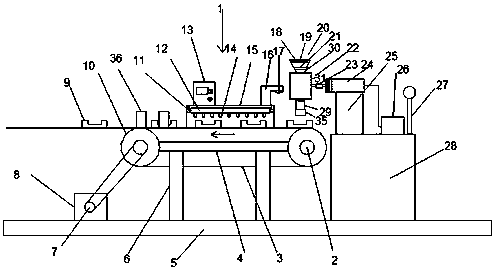

Multifunctional automatic capping machine

PendingCN108529528AReasonable structural designImprove operational efficiencyCapsFlanged caps applicationWorking environmentSelf locking

The invention relates to the field of drug subpackage capping equipment, in particular to a multifunctional automatic capping machine. The multifunctional automatic capping machine comprises a base. Wheels with a self-locking function are arranged at the bottom of the base, and a frame body is arranged on the base. A bottle conveying device is arranged on a top platform of the frame body, and a capping device is arranged at the tail end of bottle conveying device. A bottle cap conveying device is arranged on the position, close to one side of the capping device, of the upper portion of the bottle conveying device, and a drug bottle leading-out collection table is arranged on the rear side of the capping device. The multifunctional automatic capping machine is reasonable in structural design, the steps such as full-automatic conveying of bottles and bottle caps, sleeving connection of the bottles and the bottle caps and capping can be achieved, the operation efficiency and accurate rateare high, accordingly, the multifunctional automatic capping machine can adapt to the working environment with the large yield, and the requirements for mass production and automatic capping can be effectively met.

Owner:山东天振药业有限公司

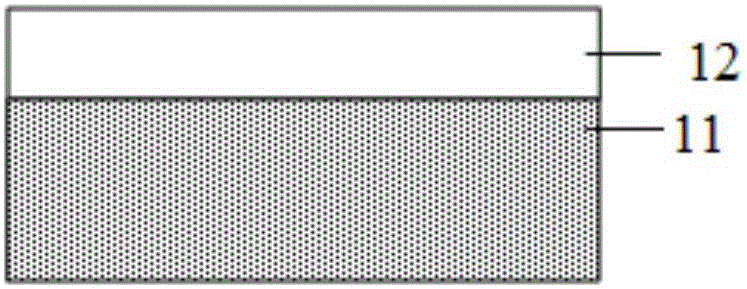

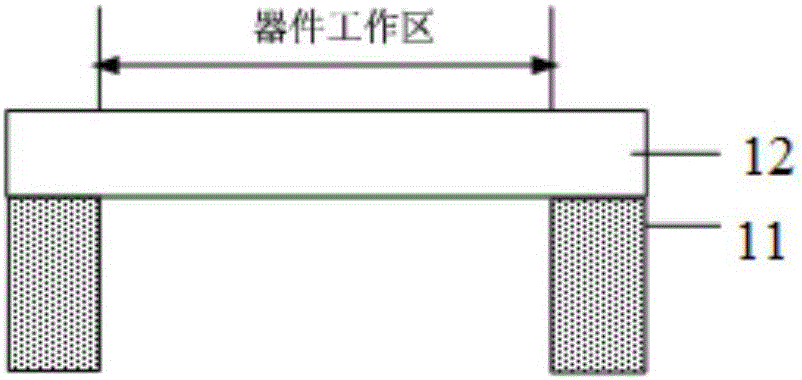

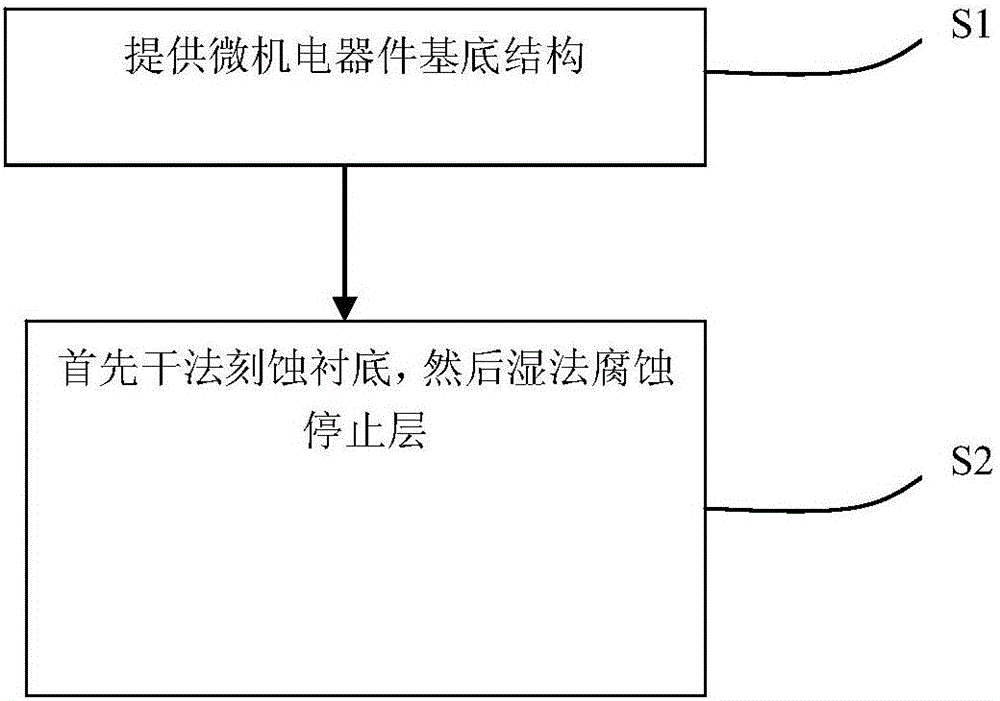

Manufacturing method of micro-electromechanical device, micro-electromechanical device and micro-electromechanical device base structure

InactiveCN106379858ASatisfy mass productionEasy to mass produceTelevision system detailsImpedence networksEngineeringUltimate tensile strength

The invention relates to a manufacturing method of a micro-electromechanical device, a micro-electromechanical device and a micro-electromechanical device base structure. The manufacturing method of the micro-electromechanical device comprises the following steps: S1: providing a micro-electromechanical device base structure, wherein the micro-electromechanical device base structure comprises a substrate provided with an upper surface and a lower surface, at least one stop layer arranged on the upper surface of the substrate, and a device layer arranged on the topmost stop layer, wherein the substrate and the stop layer most adjacent to the substrate are made from different materials; and S2: etching the substrate by a dry process, and etching the stop layer(s) by a wet process. In the dry-process substrate etching according to the manufacturing method, the etching firstly stops at the stop layer, and the stop layer is etched by the wet-process etching technique; and thus, in the dry-process etching, the stop layer is utilized to enhance the strength of the device layer so as to avoid the damage of the device layer, thereby enhancing the yield and satisfying the manufacturing of minisize devices.

Owner:苏州工业园区纳米产业技术研究院有限公司

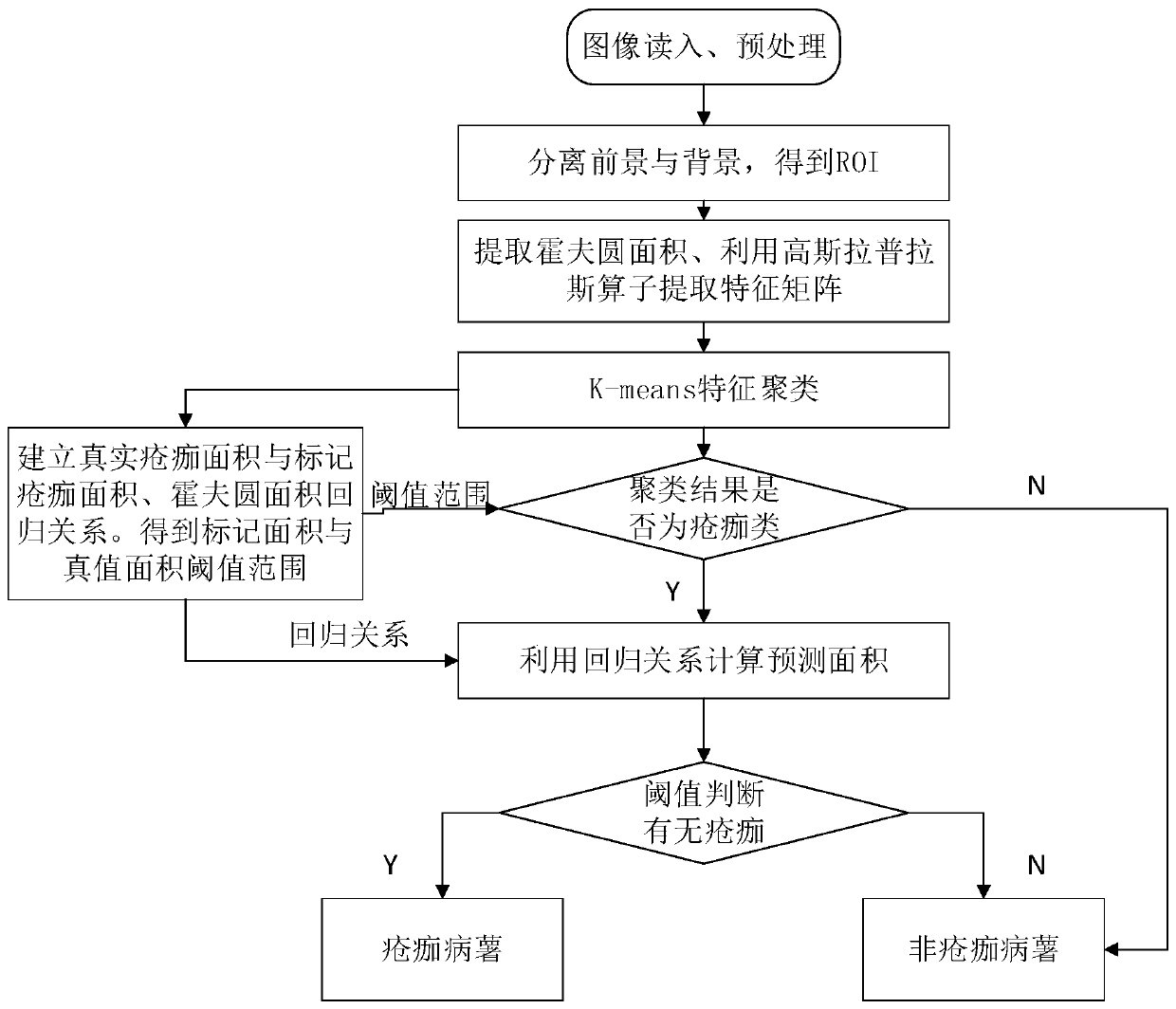

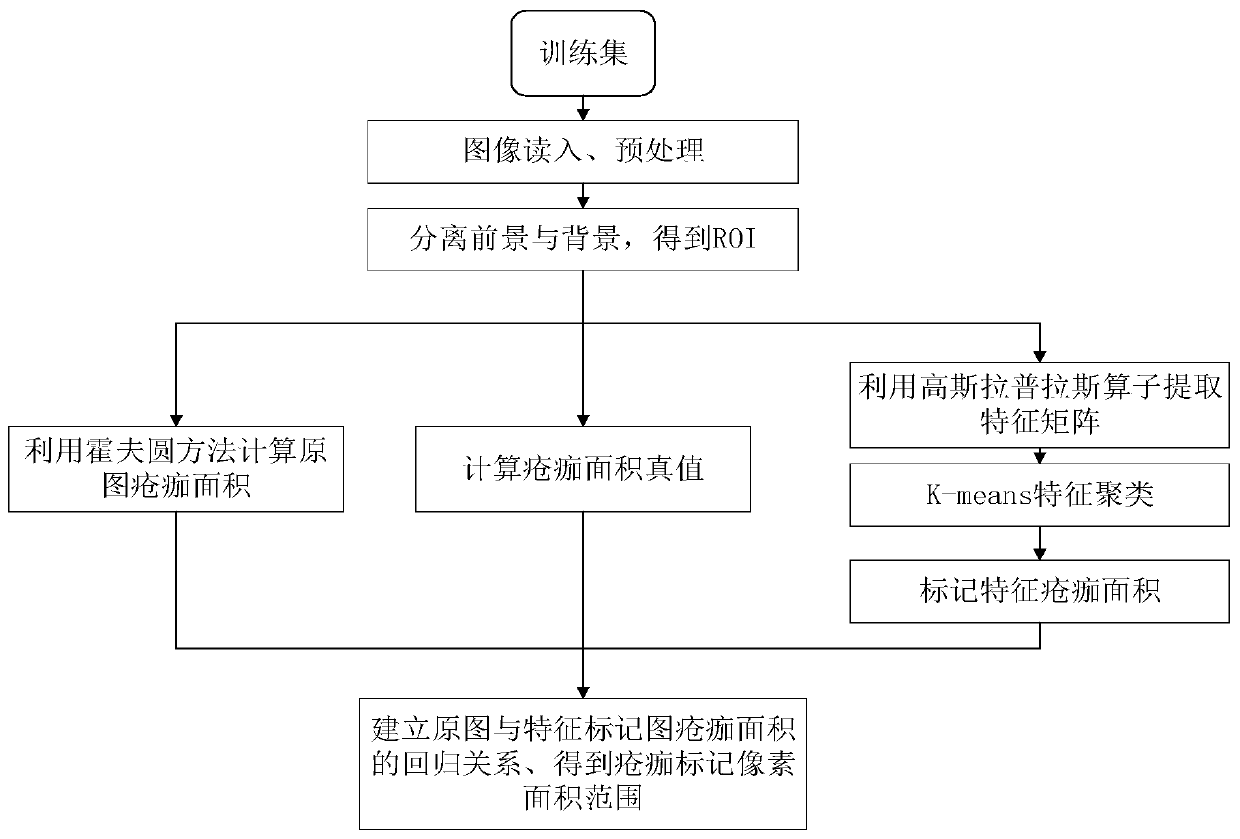

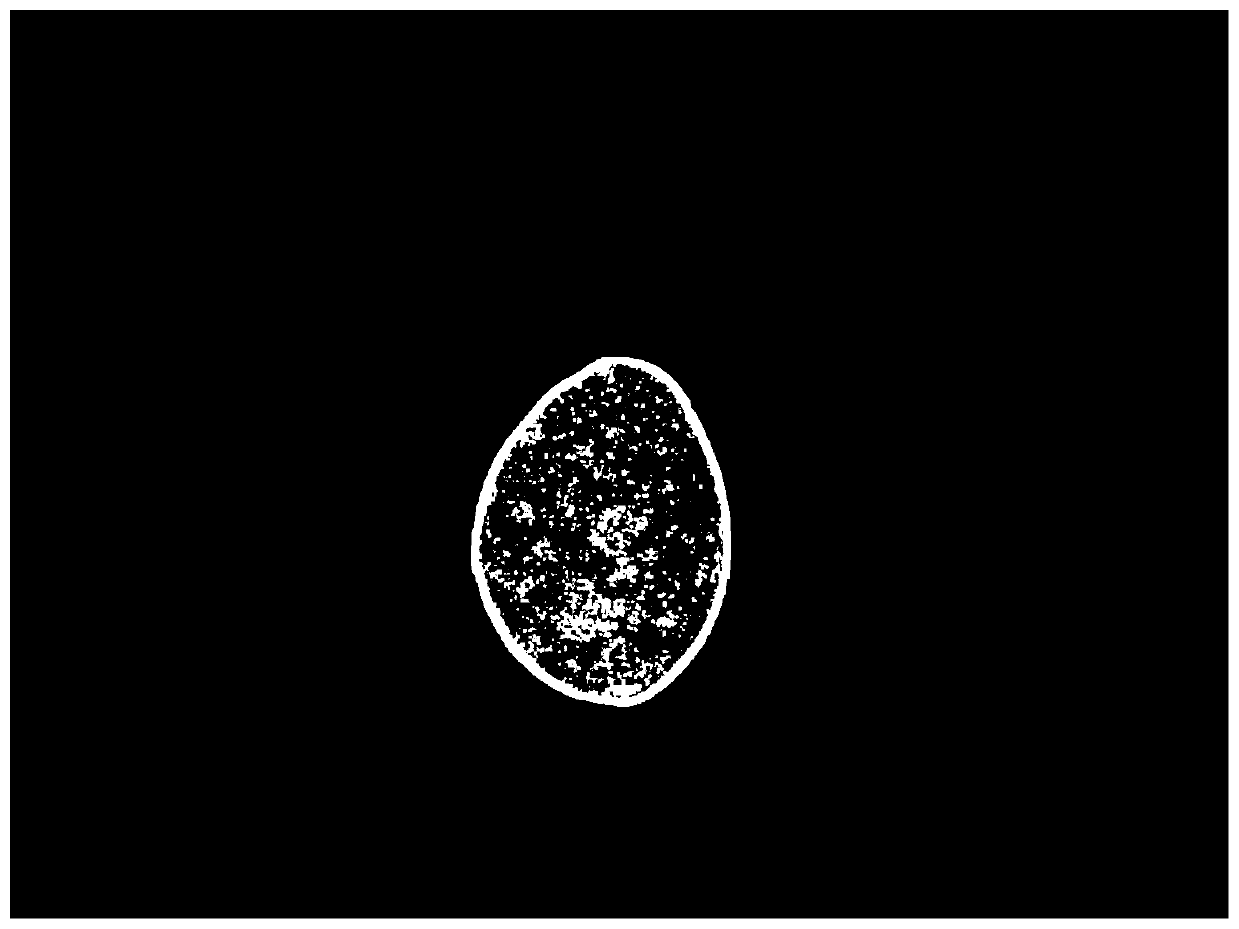

Potato scab detection method

ActiveCN110047064ASatisfy mass productionMeet needsImage enhancementImage analysisPattern recognitionRelational model

A potato scab detection method comprises the following steps: establishing a regression relation model of the Hough circle area of potato scab, the marked scab area and the real scab area by utilizinga training data set, and obtaining a screening threshold value for marking the scab area and the real scab area; acquiring and reading a to-be-detected potato image, and obtaining a region of interest by utilizing boundary extraction, boundary communication and mask segmentation; extracting a Hough circle of the region of interest, solving the area of the Hough circle, and extracting a feature matrix of the region of interest by utilizing a Gaussian Laplace operator; carrying out K-means clustering on the feature matrix to extract the features of the feature matrix, and obtaining the markedscab area of the to-be-detected potato; and judging whether the marked scab area of the to-be-detected potato is a scab type or not according to the regression relation model, calculating a regressionreference area of the to-be-detected potato, comparing the regression reference area with the screening threshold value, and judging whether the to-be-detected potato is a scab potato or not.

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

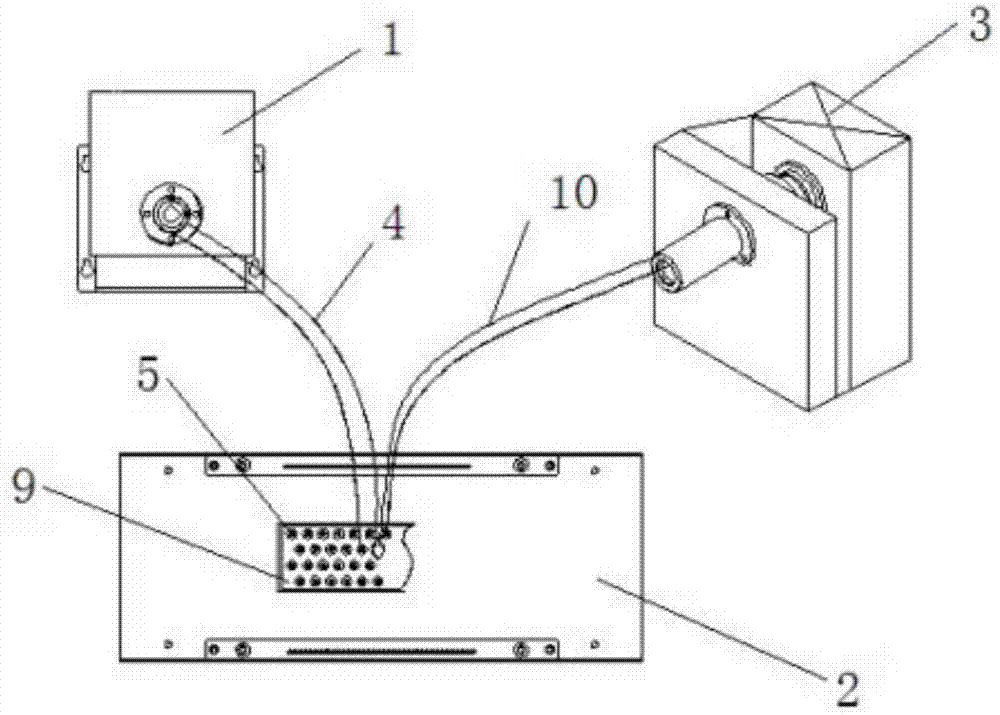

Fluorescence detection device

PendingCN107367496ASave the problem of weak signalFreely adjust the optical pathFluorescence/phosphorescenceMicrocontrollerFluorescence

The invention discloses a fluorescence detection device, which comprises a laser light source device, a radiator device and an incident fluorescence detection device. The laser light source device communicates with the bottom of the sample tube on the upper surface of the radiator device through an exciting optical fiber, and the receiving optical fibers converge into a bundle. It is connected with the incident fluorescence detection device, and the incident fluorescence detection device is connected with a single-chip microcomputer to read and process the signal. The technical solution of the present invention is not only simple and practical, but also convenient for subsequent engineering, batch production, and clear process introduction; two optical fibers reach the bottom of the sample, The signal is strong, which saves the problem of weak optical signal in other solutions; and the optical path between the optical fiber and the sample can be adjusted freely to achieve free adjustment of light intensity, which solves the problem of light inhomogeneity in traditional solutions.

Owner:苏州合惠生物科技有限公司

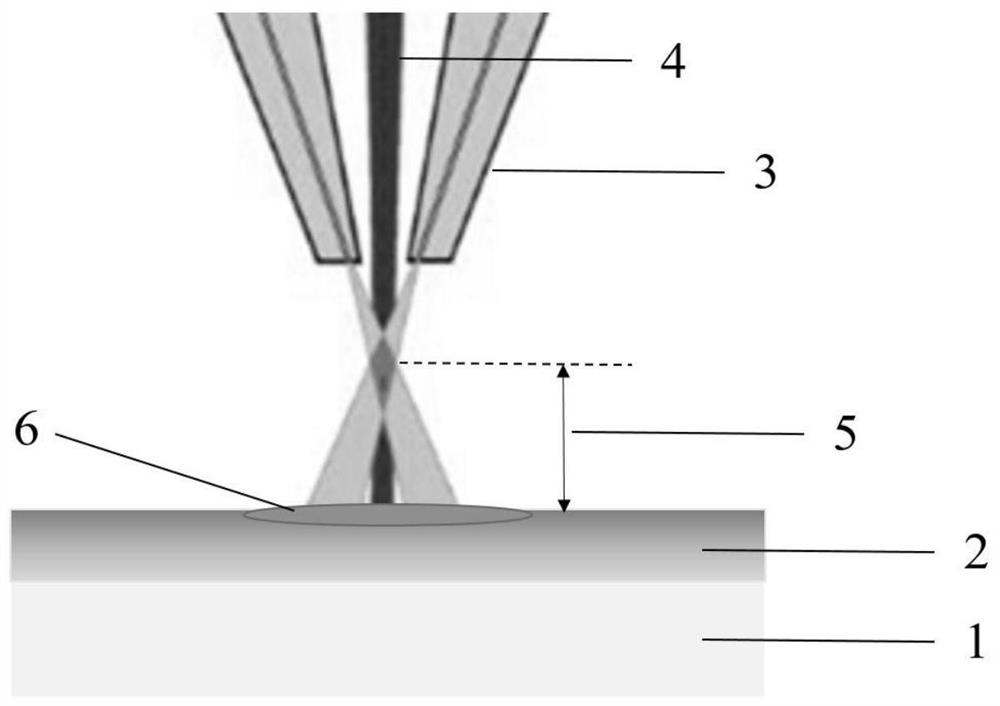

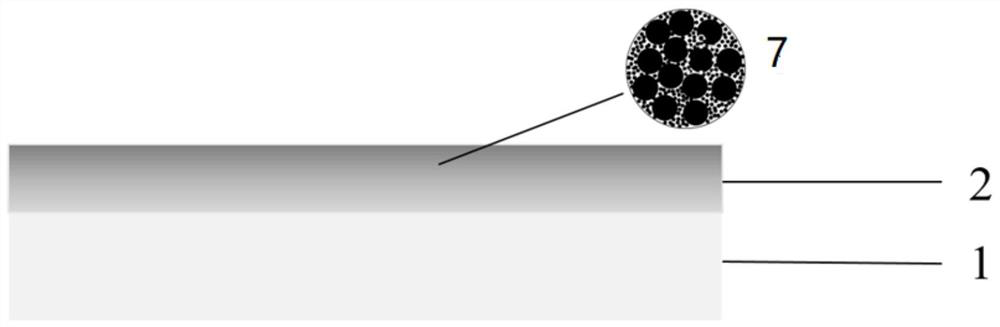

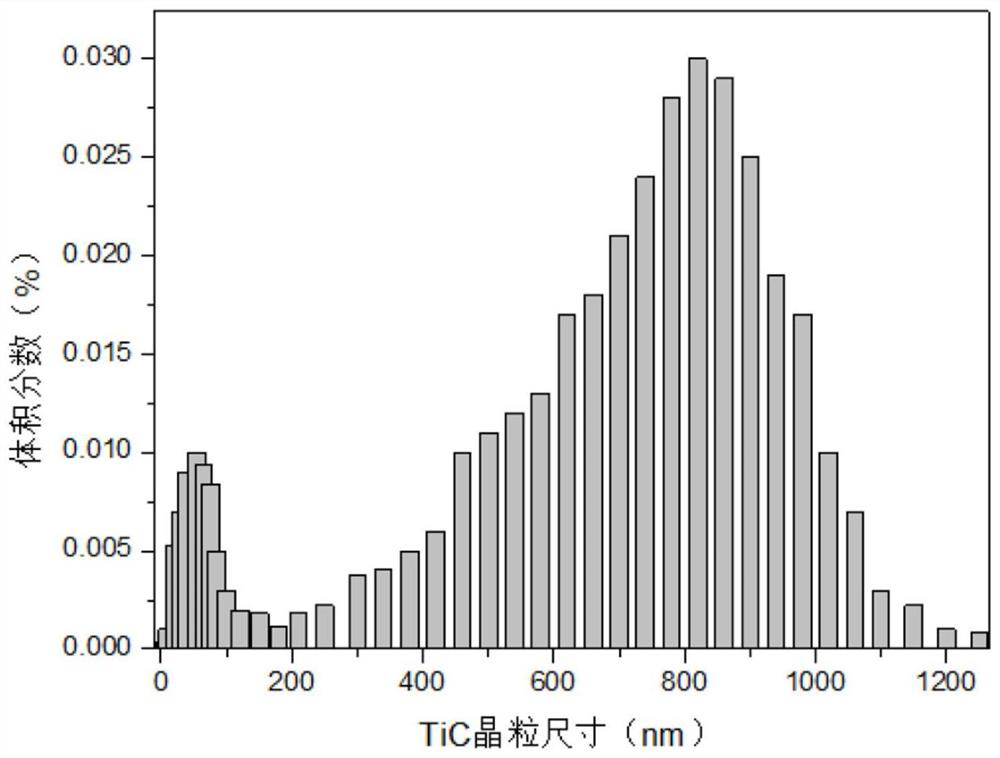

Method for preparing dual-scale iron-based composite gradient coating based on high-speed laser cladding method

PendingCN113337815AHigh hardnessImprove surface wear resistanceMetallic material coating processesCoated surfaceMicron scale

The invention belongs to the technical field of coating processing, and particularly relates to a method for preparing a dual-scale iron-based composite gradient coating based on a high-speed laser cladding method. According to the method for preparing the dual-scale iron-based composite gradient coating based on the high-speed laser cladding method, the synergistic effect of two thermal fields of powder transportation and deposition in the high-speed laser cladding process is fully utilized, the microstructure of the TiC / Fe-based gradient composite coating can be accurately regulated and controlled, TiC ceramic particle density gradient distribution in the growth direction of the coating can be achieved, the TiC grain size in the surface direction of the coating is a micron-nanoscale coexisting dual-scale composite gradient coating, and the whole coating is high in hardness and excellent in wear resistance.

Owner:XIAN UNVERSITY OF ARTS & SCI +1

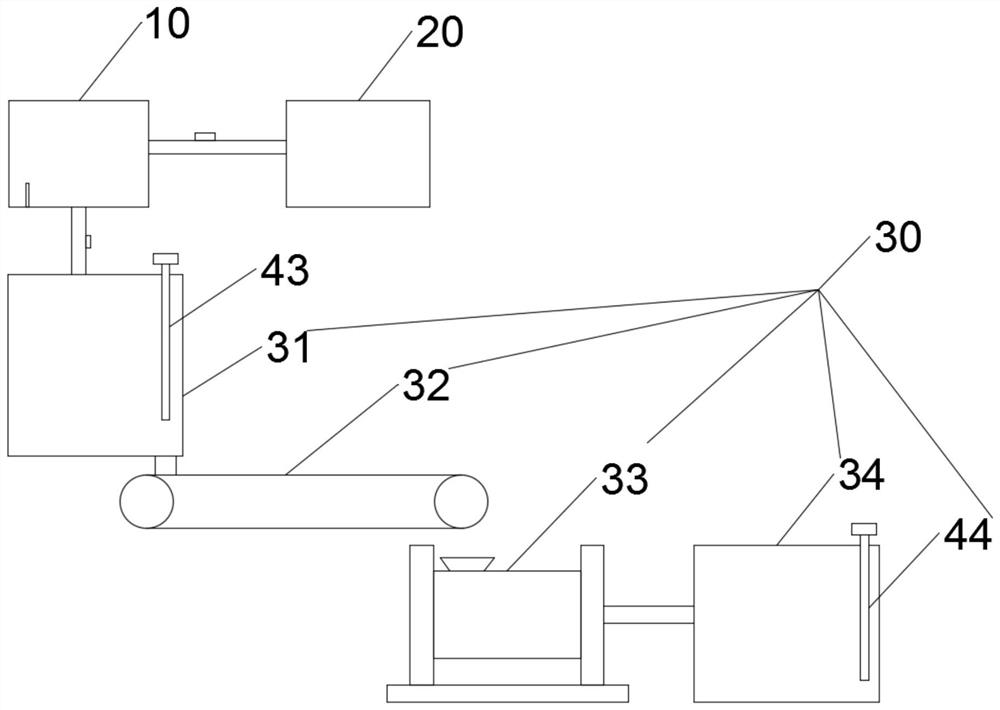

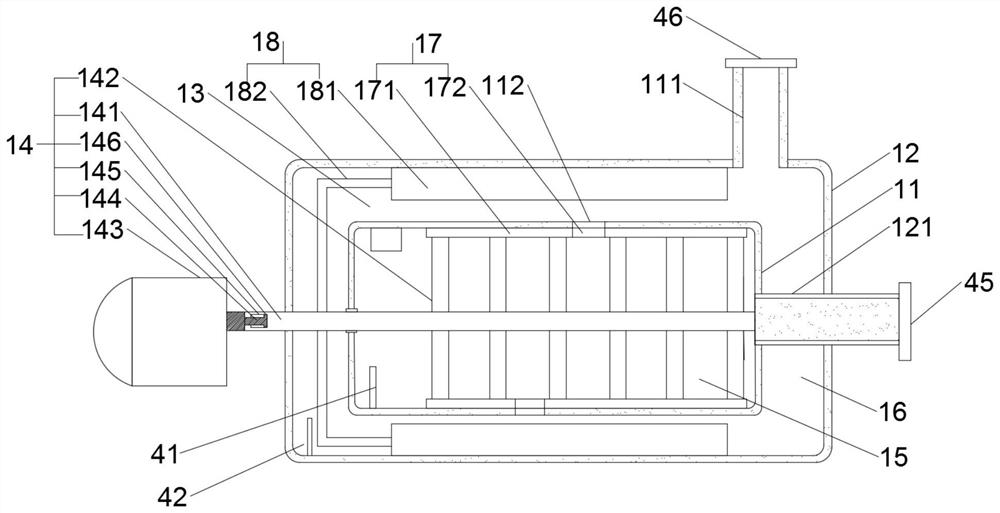

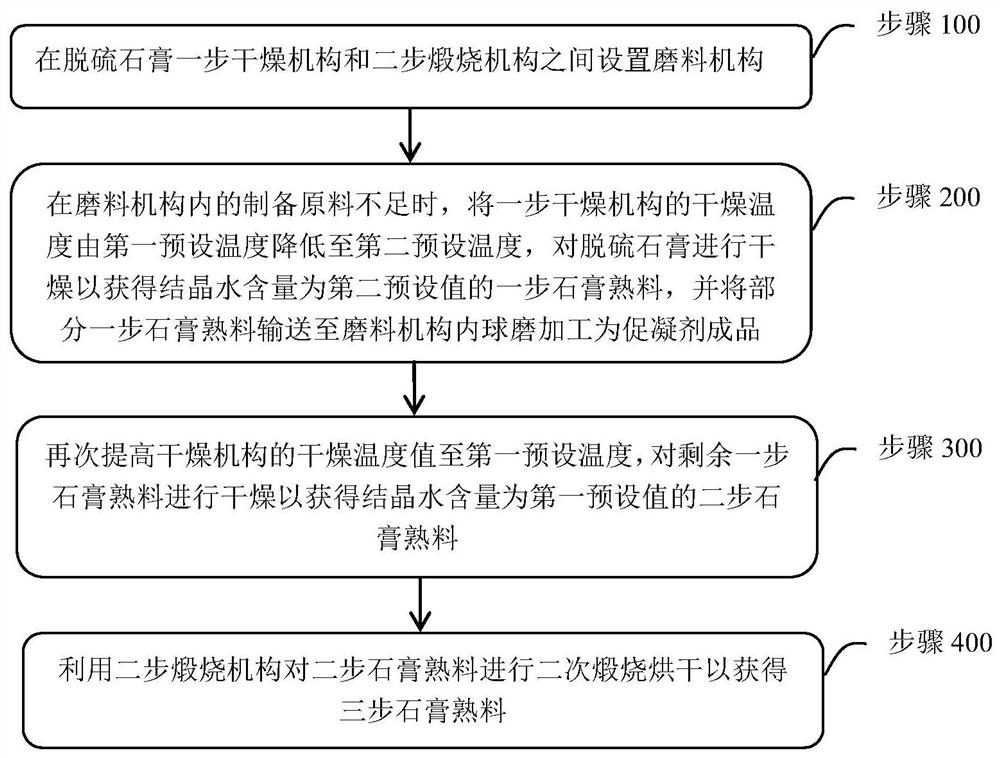

Preparation method and system of efficient coagulant

The invention discloses a preparation method and system of an efficient coagulant. The system comprises a drying mechanism which is provided with a first discharge hole and a second discharge hole; a calcining mechanism which is connected with the first discharge hole; and a grinding mechanism which is connected with the second discharge hole of the drying mechanism, and is used for grinding the dried desulfurized gypsum to obtain a coagulant finished product. The drying mechanism is internally provided with a first cavity and a second cavity, the first cavity and the second cavity are used for forming different drying temperature areas, the first cavity and the second cavity are controlled to be communicated or not communicated through an intercommunication piece, the first discharge hole is connected with the first cavity, and the second discharge hole is connected with the second cavity. The method and system can be directly applied to a two-step calcined gypsum board production factory, the raw material for preparing the coagulant of the grinding mechanism directly uses the desulfurized gypsum one-step clinker, there are no impurities such as waste paper pieces, and the purity of the raw material is high.

Owner:北新建材(苏州)有限公司

Ground wire accommodation box

InactiveCN105207016AEasy to useEasy to recycleFlexible lead accommodationEngineeringMechanical engineering

The invention belongs to the technical field of tools for transmission line maintenance work, particularly relates to a ground wire accommodation box, and mainly solves the problem that ground wires are time-consuming and labor-consuming and low in efficiency to wind up at present. The ground wire accommodation box provided by the invention includes a box body, wherein a hole is formed in the center of each of the two corresponding side walls; a bearing is arranged in each hole; a hollow rotating shaft horizontally supports the part between the two bearings; one end of the hollow rotating shaft is connected with a hand-rocking handle positioned on the outer side of the box body; an opening is formed in the other end of the hollow rotating shaft; a side port communicated with the inner cavity is formed in the position, near to one end of the opening, on the surface of the hollow rotating shaft; a wire outlet is formed in the position, higher than the bearing, in the side wall of the box body without the bearing; universal wheels are arranged at the bottom of the box body. The ground wire accommodation box has the advantages of being simple and convenient in operation and high in efficiency.

Owner:LINFEN POWER SUPPLY COMPANY OF STATE GRID SHANXI ELECTRIC POWER +1

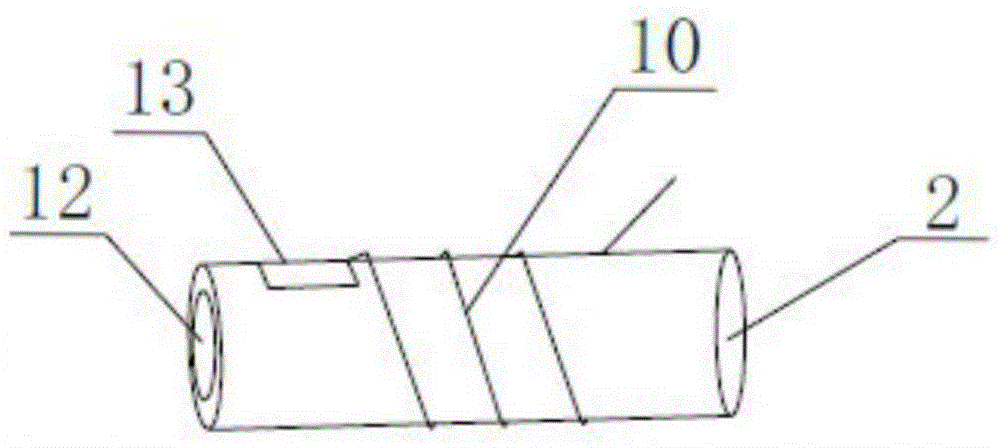

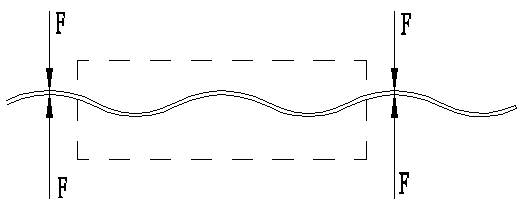

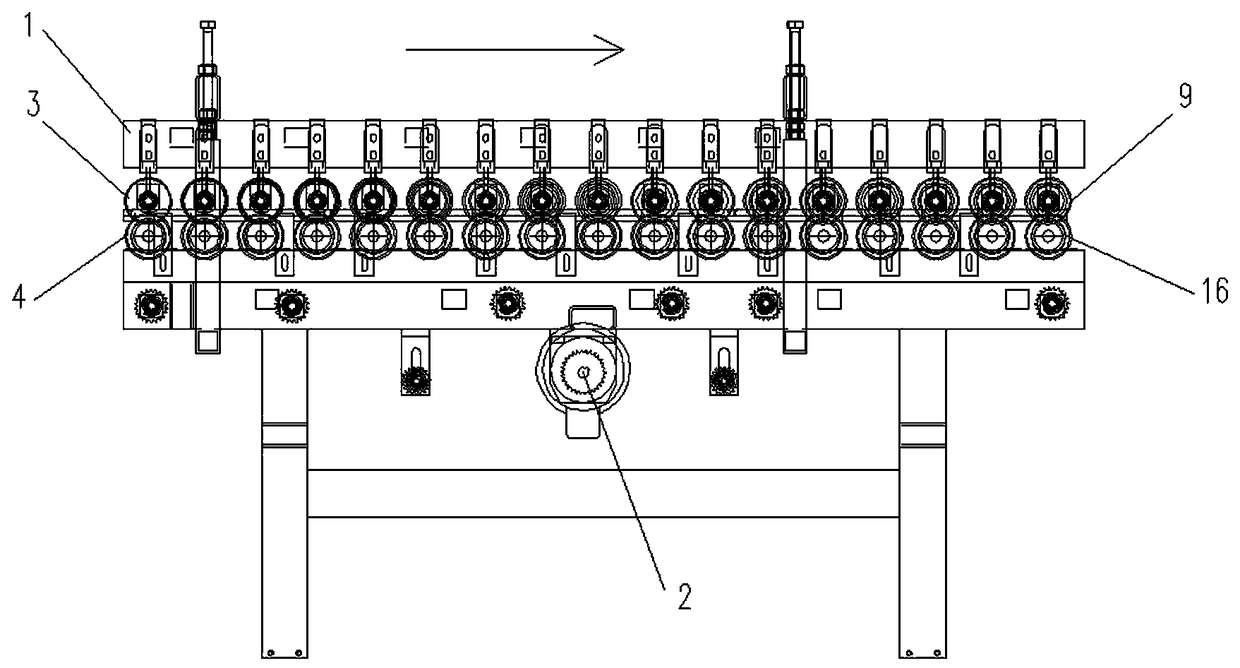

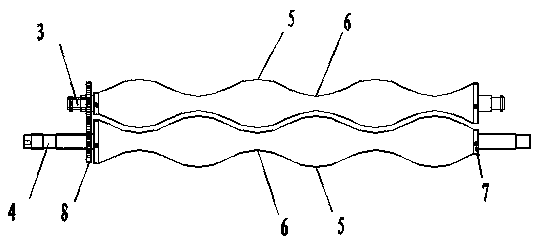

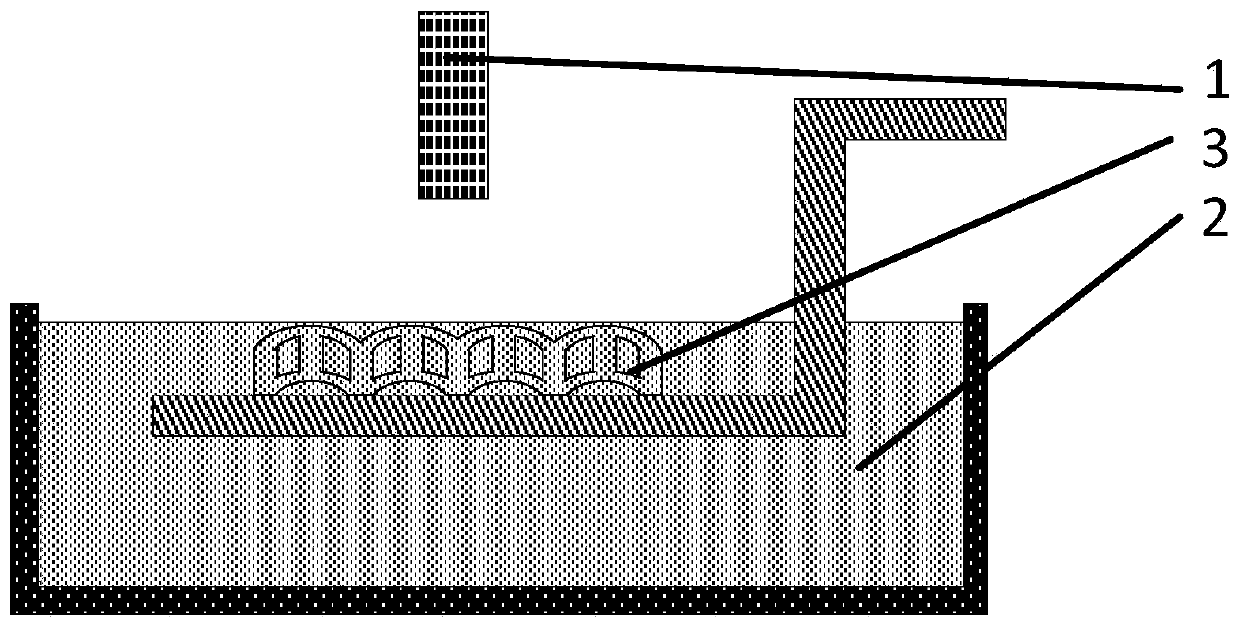

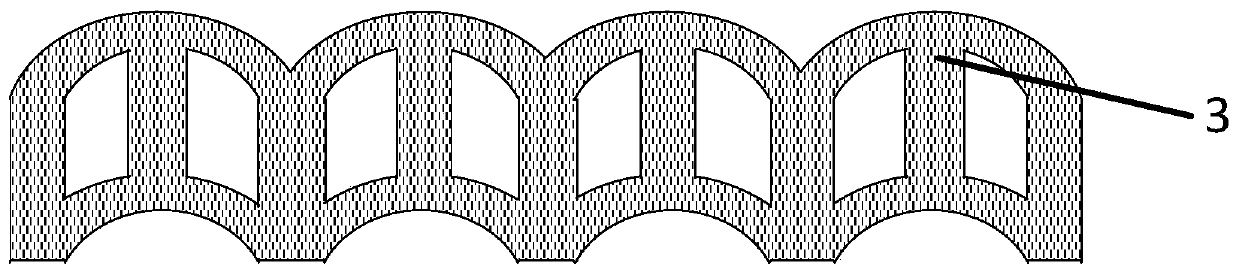

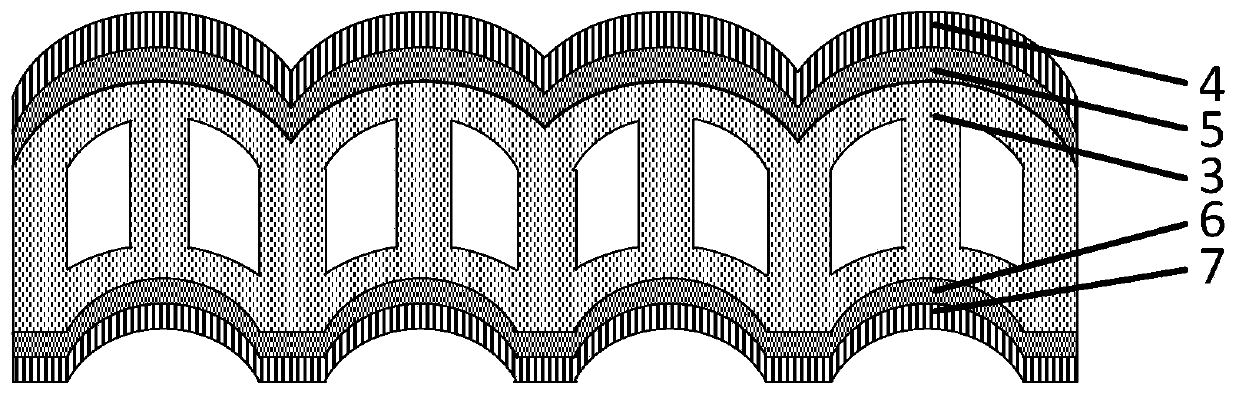

Grouped continuous gradient forming method and forming equipment for corrugated glass

PendingCN109133590AAvoid problems such as deformation difficultiesSatisfy mass productionGlass reforming apparatusEngineeringGlass sheet

The invention relates to a grouped continuous gradient forming method for corrugated glass, a forming section alternately gradually form different to-be-formed areas on a glass plate; forming equipment comprises a rack and a plurality of upper roller ways and lower roller ways, the upper roller ways and the lower roller ways are arranged along the moving direction of the glass plate; the upper roller ways and the lower roller ways correspond up and down to form a forming roller way group, then the forming section is formed, the forming section is divided into more than two forming units arranged along the conveying direction, each forming unit is divided into a forming part and a supporting part along the direction vertical to the moving direction of the glass plate, the forming part and the supporting part both comprise turning surfaces of the upper roller way and the lower roller way, the corresponding generatrix of the turning surface is a wavy curve extending along the central axisof the roller way, and the peak height and the trough depth of the wavy curve gradually increase from an inlet end to an outlet end of the forming section in the forming parts formed in the same areaof the glass plate. The forming accuracy is high, the production requirement on batch and continuous production of the corrugated glass is met, and the forming equipment has the advantages of simplestructure and easiness in operation.

Owner:LUOYANG LANDGLASS TECH CO LTD

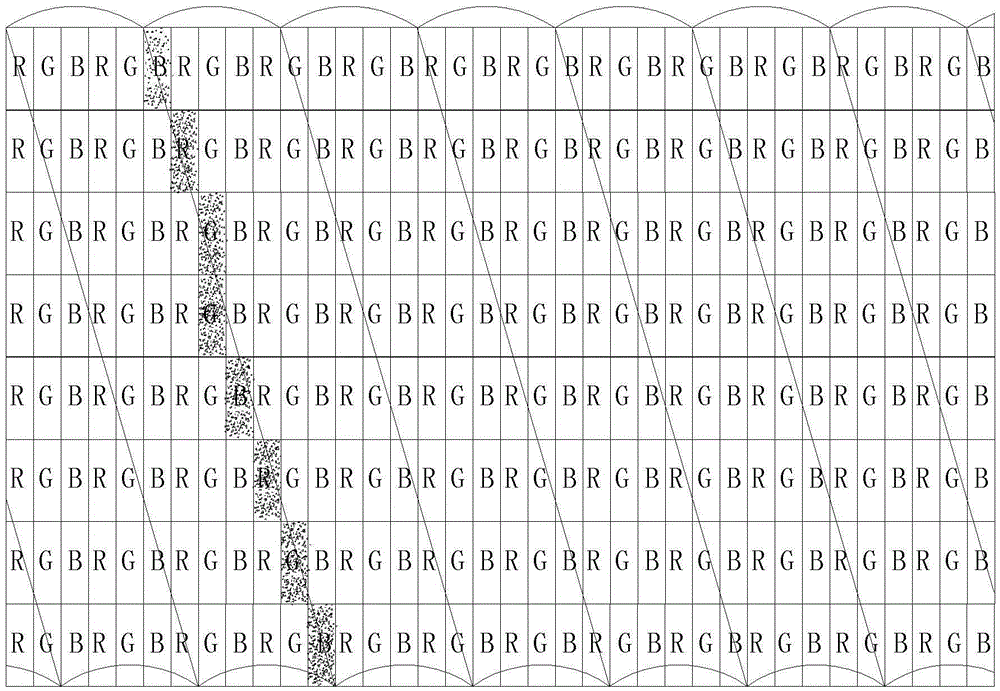

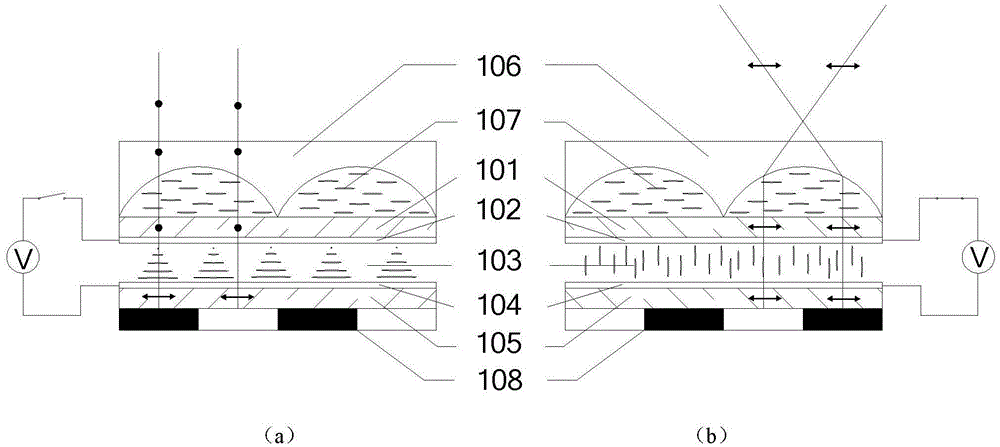

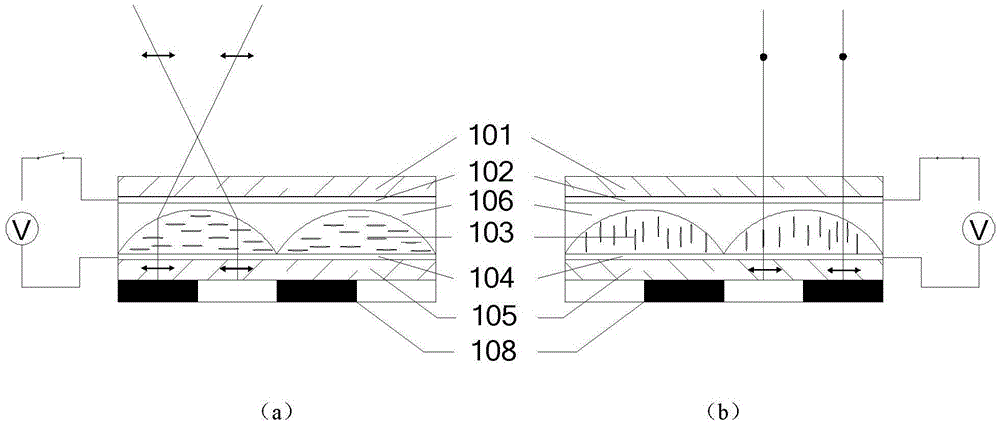

Low-crosstalk liquid crystal lens 2D-3D switching device

InactiveCN105652456AMeet the production line requirementsReduce crosstalkNon-linear opticsOptical elementsElectric fieldCrosstalk

The invention provides a low-crosstalk liquid crystal lens 2D-3D switching device, belongs to the technical field of optical 3D display, and aims at solving the problems that an existing 2D-3D switching technique is obvious in 3D crosstalk and low in comfort degree. According to the low-crosstalk liquid crystal lens 2D-3D switching device, the inner surface of an upper glass substrate and the inner surface of a lower glass substrate are provided with an upper ITO electrode and a lower ITO electrode respectively, and a liquid crystal layer is filled between the two electrodes; the liquid crystal layer is in a parallel distribution mode when the device is powered off; a whole-plate electrode is adopted as the upper ITO electrode; a segmented electrode is adopted as the lower ITO electrode, and the lower ITO electrode is uniformly etched into n conductive electrodes in an equivalent period, wherein n is an odd number; voltages loaded on the n conductive electrodes are in a mirror symmetry mode and are asymptotically increased from the centers to the two ends; the on-load voltage of the conductive electrode located in the center is 0, the on-load voltages of the conductive electrodes located at the left end and the right end are + / -m V, and the on-load voltages of the conductive electrodes located at any other positions are + / -m(1-y / h). A gradual electric field is applied, and a liquid crystal layer equivalent lens is formed.

Owner:NINGBO VISION DISPLAY TECH

Food online detection device

InactiveCN107831553ADetection speedSatisfy mass productionFood preservationOptical detectionDesiccantConstant speed

The invention discloses an online detection device for food, which comprises a detection device body. A fixed base is provided at the bottom of the detection device body. Two symmetrically arranged pillars are arranged on the upper surface of the fixed base. There is a horizontally placed support, and the two ends of the support are provided with symmetrically arranged rotating shafts. Beneficial effects of the present invention: by installing the on-line detection device body, it is possible to detect whether there are impurities in the food, ensuring that all foods can be detected; at the same time, using infrared thermal image detection, all foods containing impurities can be detected , the detection speed is fast; through the set feeding system and tank machine system, the desiccant can be delivered quantitatively at a certain speed, which further ensures the drying of the food inside and improves the safety of the food. At the same time, it replaces the existing manual operation. It is suitable for productive production, reduces the working intensity, has simple structure and strong usability.

Owner:WUXI X RES PROD DESIGN & RES

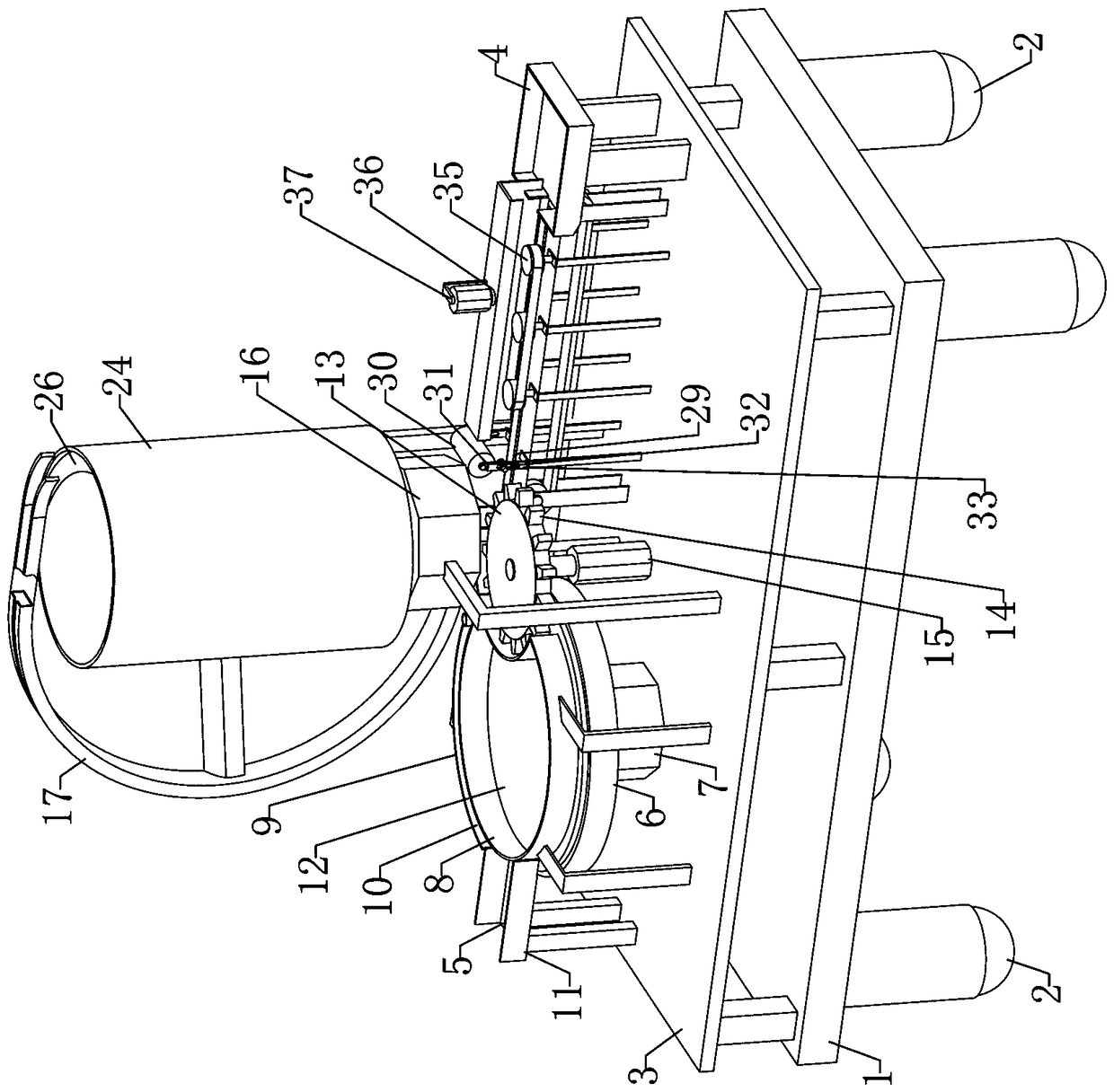

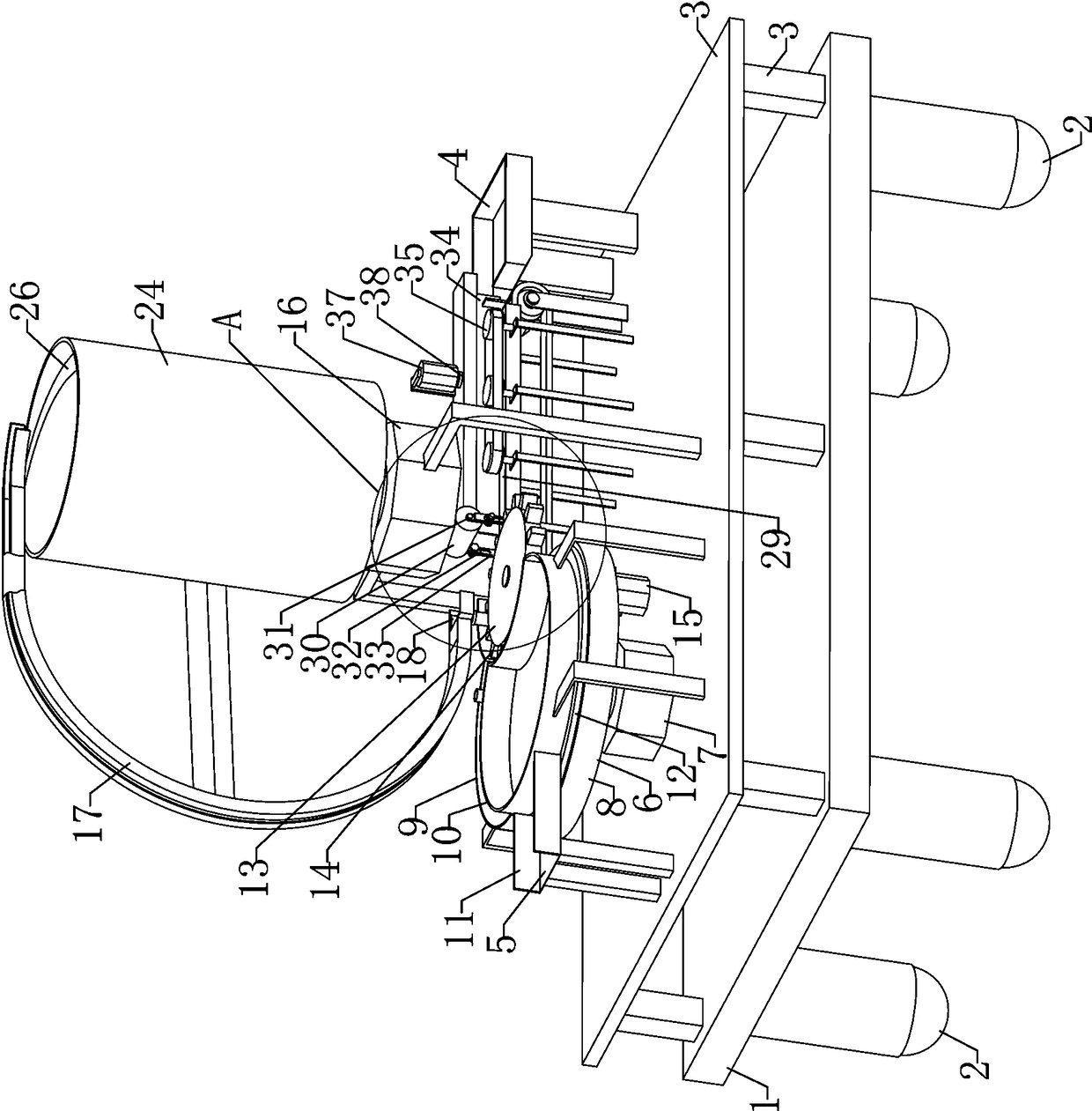

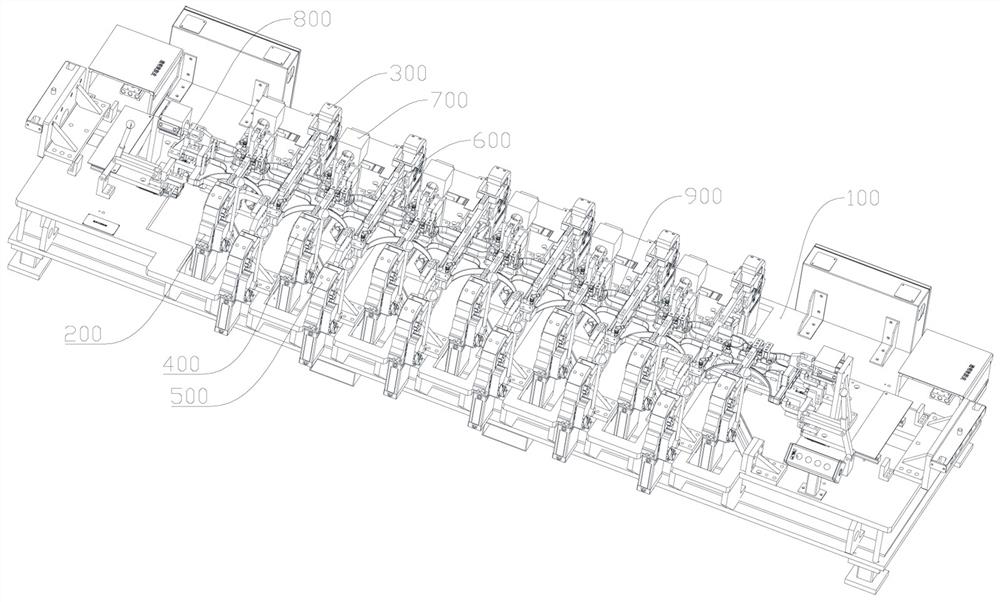

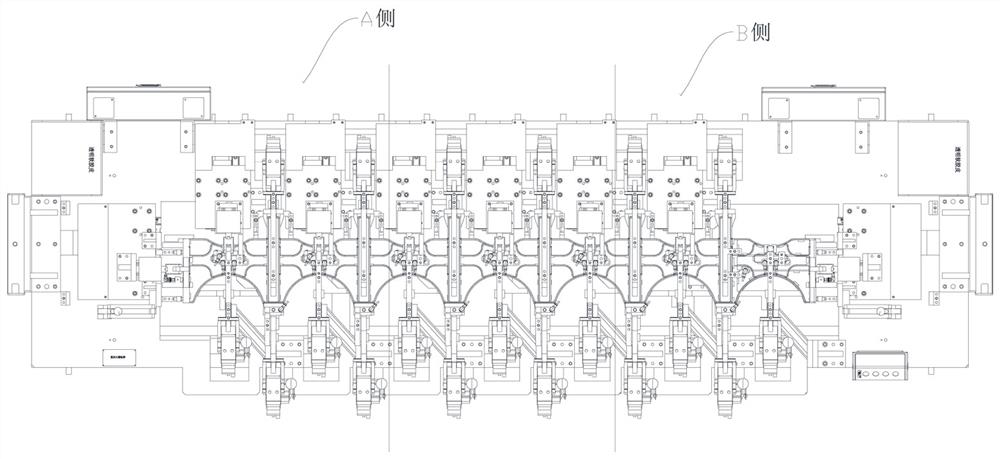

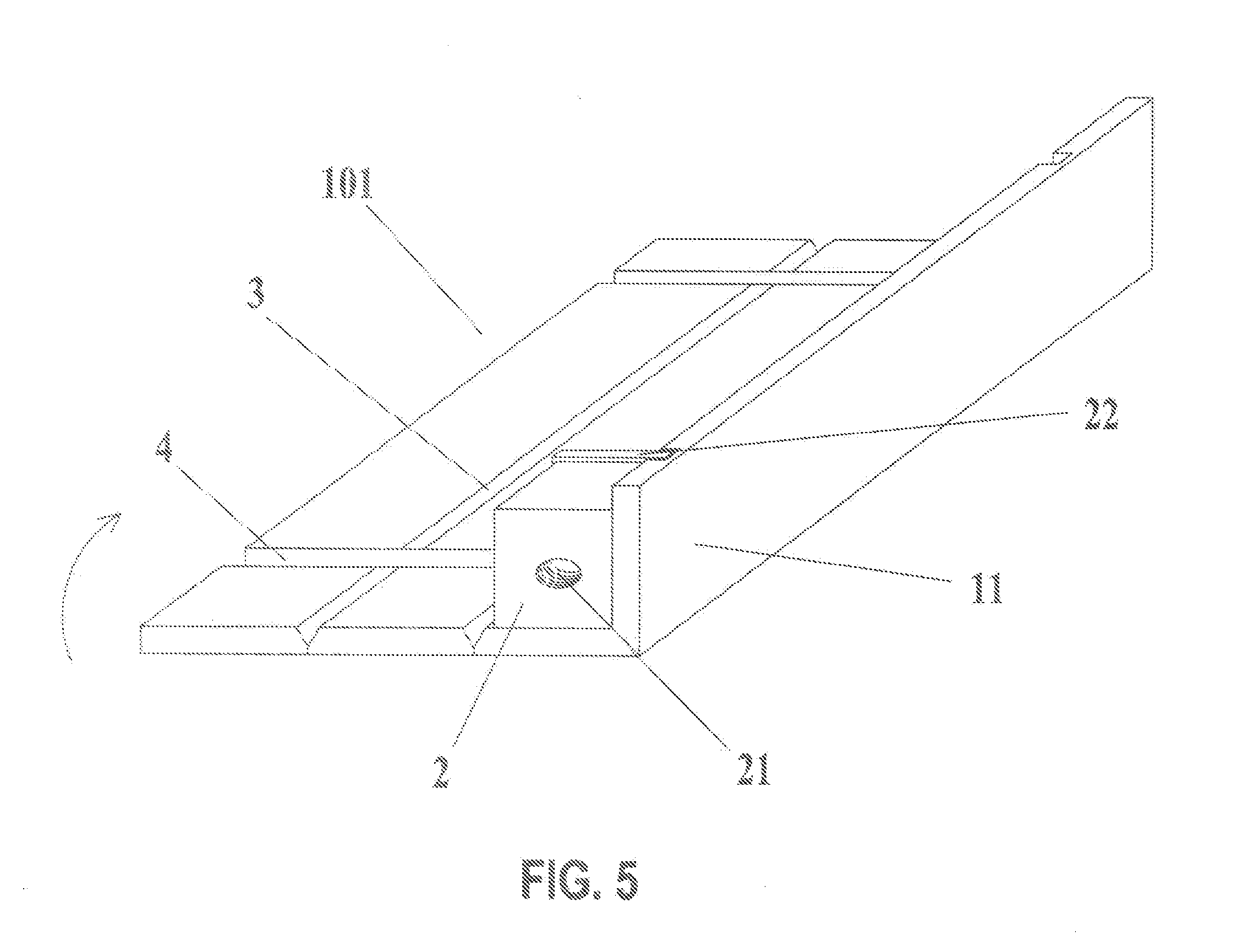

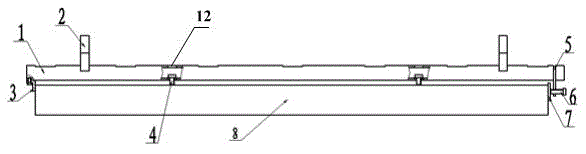

Automatic welding platform and welding positioning method for clamping plate assembly

ActiveCN114535917AGuarantee welding qualityRealize automatic welding operationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to the technical field of automatic welding, and discloses a clamping plate assembly automatic welding platform and a welding positioning method.The clamping plate assembly automatic welding platform is used for positioning and clamping a clamping plate assembly and comprises a mounting table; the first positioning and clamping mechanisms are arranged on one side of the mounting table, and each first positioning and clamping mechanism comprises a first positioning assembly and a first supporting assembly; the one or more second positioning and clamping mechanisms are arranged on the other side of the mounting table, and each second positioning and clamping mechanism comprises a second positioning assembly; and the structural part positioning mechanism is arranged on the mounting table and used for clamping and positioning the to-be-welded structural part at the corresponding position of the clamping plate. According to the structural characteristics of the clamping plate assembly, all the positioning mechanisms are arranged on the welding platform, the structures of all the positioning mechanisms are designed, accurate positioning and fixed clamping of the clamping plate and structural parts on the clamping plate can be achieved, automatic welding operation of the clamping plate assembly can be achieved, and the requirement for batch and efficient production of the clamping plate assembly is met.

Owner:AEROSPACE WANXIN SCI & TECH CHENGDU

A method for fabricating flexible friction-piezoelectric hybrid energy harvesters by micro-stereolithography

ActiveCN110365246BIncrease potential differenceSatisfy mass productionPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesPhoto irradiationEnergy harvester

A method for preparing flexible tribo-piezoelectric composite energy harvesters by micro-stereolithography, the dispersion of advanced piezoelectric materials, and then the preparation of piezoelectric photosensitive resins, and then the preparation of microstructured wave-shaped piezoelectric energy harvesters , the piezoelectric photosensitive resin is irradiated with ultraviolet light, and the microstructure wavy piezoelectric film is prepared by using the micro three-dimensional curing process. The substrate, the upper and lower metal electrodes are connected to the power supply, and thermally polarized in an oven. After the oven is cooled to room temperature, the voltage is removed to obtain a microstructure wave-shaped piezoelectric energy harvester; finally, a flexible friction-piezoelectric composite energy harvester is performed. The preparation of the microstructure wave-shaped piezoelectric energy harvester is placed on the conductive substrate with friction material to form a flexible friction-piezoelectric composite energy harvester; the invention has simple process, low cost, and greatly improves the output of the energy harvester performance.

Owner:XI AN JIAOTONG UNIV

A Method for Fabricating Microstructured Piezoelectric Energy Harvesters Based on Dissolvable Molds

ActiveCN110138263BSatisfy mass productionIncrease stressPiezoelectric/electrostriction/magnetostriction machinesEnergy harvesterThin membrane

The invention provides a method for preparing a microstructured piezoelectric energy harvester based on a soluble mold. The method comprises the steps of preparing a soluble resin mold, preparing a composite piezoelectric material, then pouring the composite piezoelectric material into the soluble resin mold, dissolving the soluble resin mold after solidification to obtain a microstructured composite piezoelectric film, symmetrically adhering electrodes formed by flexible substrate / metal / composite piezoelectric materials on upper and lower sides of the microstructured composite piezoelectric film, heating and curing to form a piezoelectric energy harvester, placing the piezoelectric energy harvester into an oven, applying direct current power supply, raising the temperature of the oven tothermally polarize the piezoelectric film, maintaining application voltage such that internal molecules are oriented in the direction of an electric field, and cooling the oven to the room temperatureand then removing voltage under the condition of maintaining the voltage to obtain the microstructured piezoelectric energy harvester. The method has the advantages of simple process, low cost and high efficiency, and the output performance of the piezoelectric energy harvester is greatly improved.

Owner:XI AN JIAOTONG UNIV

Ejection mold for front mold sticking of double-color inverted mold product

The invention discloses an ejection mold for front mold sticking of a double-color inverted mold product. The ejection mold comprises a first injection mold and a second injection mold. The first injection mold is provided with a first cavity formed by a first front mold core, a rear mold core, a first sliding block and multiple first oblique tops. The first cavity is used for manufacturing a one-color product. The second injection mold is provided with a second cavity formed by the one-color product, a second front mold core, a rear mold core, a second sliding block and a second oblique top. The second cavity is used for manufacturing a double-color product. The one-color product is provided with an auxiliary prosthesis and / or a groove. Each first oblique top comprises an oblique rod, a first clamping portion and a second clamping portion, wherein the first clamping portion and the second clamping portion are arranged at the two ends of the oblique rod correspondingly. The first clamping portions are used for being clamped with the auxiliary prosthesis or the groove in a matched manner. The second clamping portions are used for being connected with ejector pins. According to the ejection mold, by additionally arranging the first oblique tops, the product can be ejected smoothly in the mold stripping process, thus the problem of front mold sticking in the mold stripping process of the product is solved, the mold stripping effect is good, and productivity and stability of the product are met.

Owner:SHENZHEN FENDA TECH CO LTD

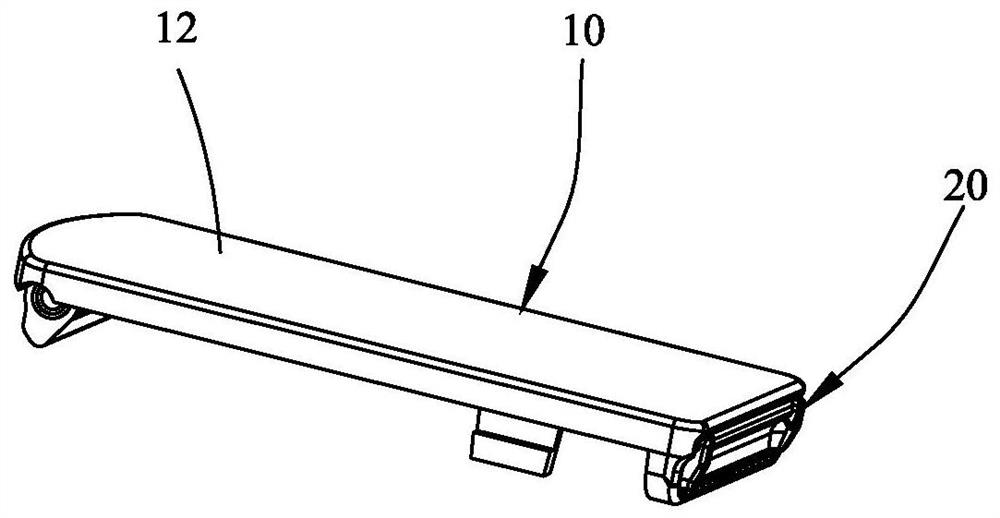

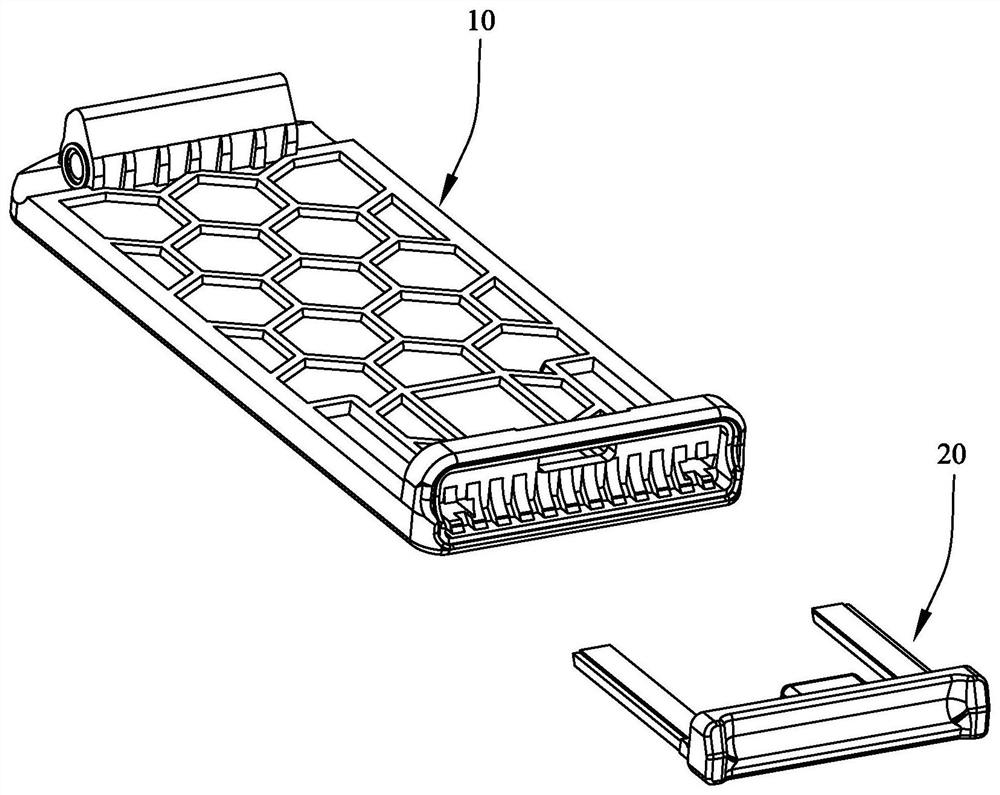

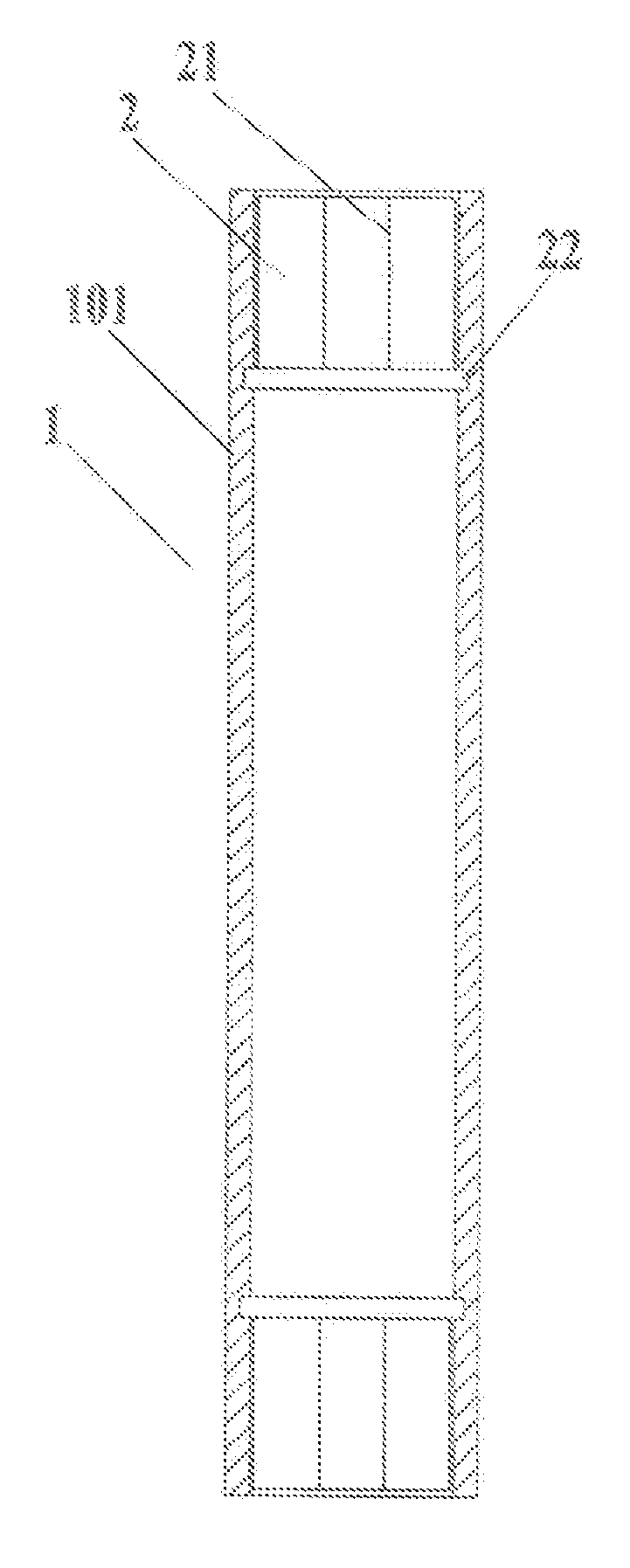

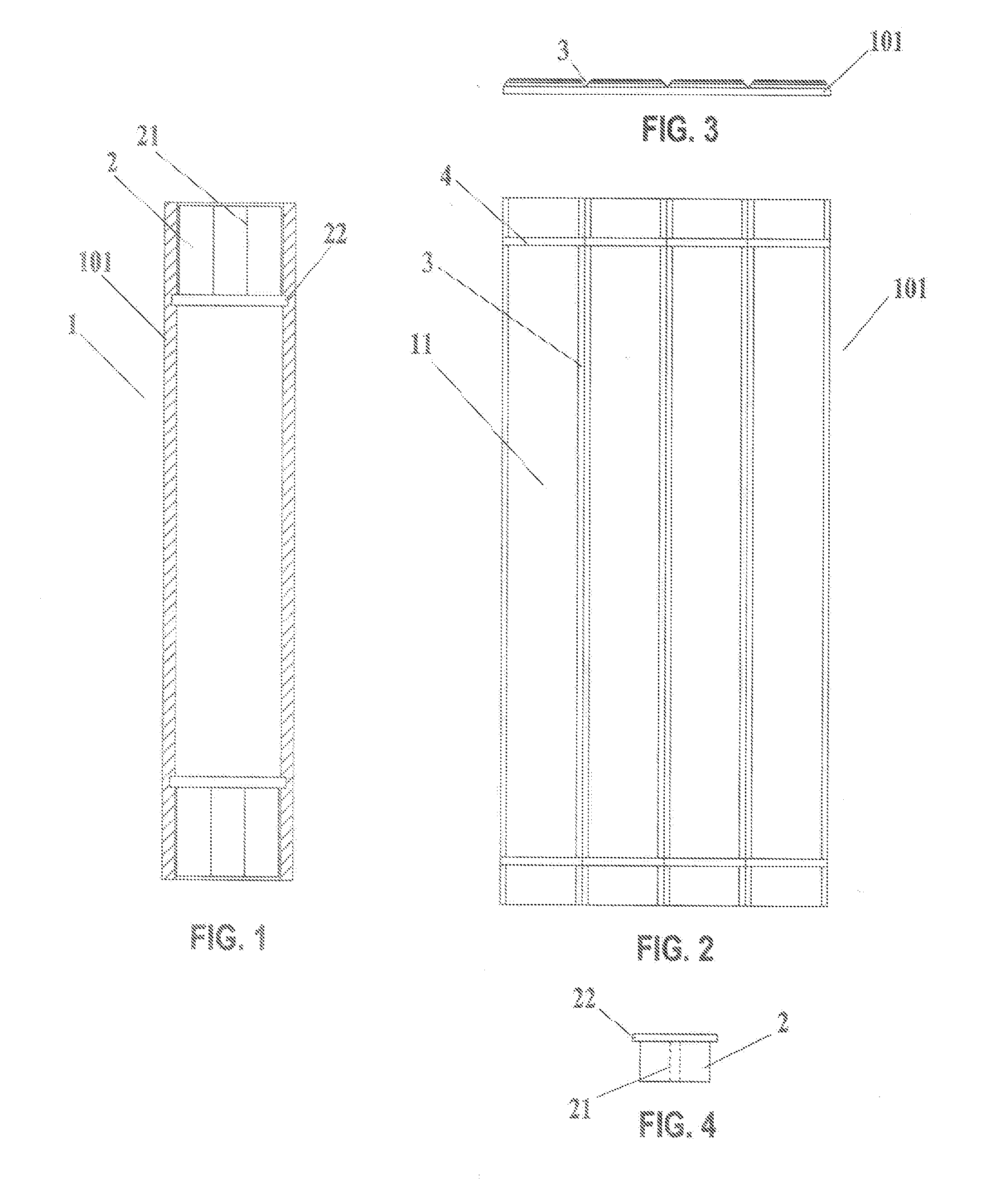

Post for a Combined Light Fitting

ActiveUS20120163006A1Low costSatisfy mass productionNon-electric lightingLighting support devicesFiberEngineering

A post for a combined light fitting includes a hollow post body composed of at least two post walls, a connector is installed in at least one end of the post body, the connector is provided with a screw connecting hole for connection with outside. All the post walls constituting the post are made of one piece of fiber plate, and on the surface of the fiber plate, at least one V-shaped groove extending along the direction of its height is formed, the V-shaped groove divides the fiber plate into several post walls, and the respective post wall is turned over inward along the V-shaped groove to form the hollow post. In addition, on the upper side and lower side of the fiber plate, positioning grooves are set along the direction of its width, the positioning grooves are perpendicular to the V-shaped groove, a connector is embedded in each of the two ends of the hollow post composed of various post walls after tuned over, and the base of the connector is embedded in the positioning groove for defining the position of the connector.

Owner:CHEN CHING HUI

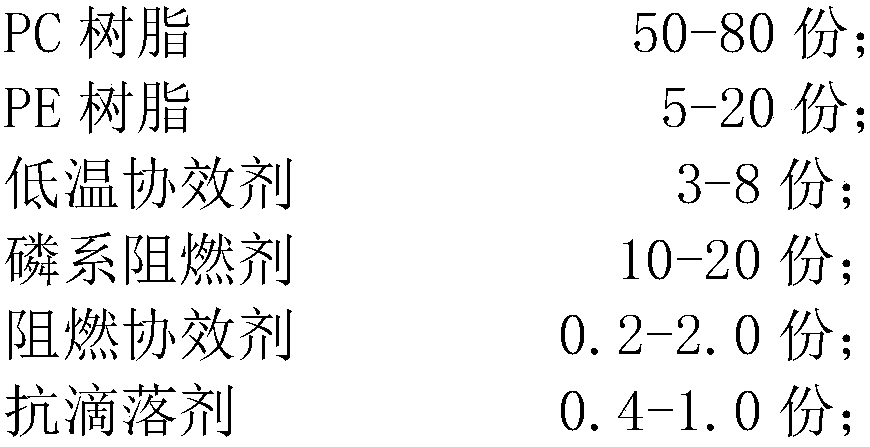

Termite-proof low-temprature-resisting and flame-retarding PC/PE (Polycarbonate/Polyethylene) alloy material and preparation method thereof

The invention discloses a termite-proof low-temprature-resisting and flame-retarding PC / PE (Polycarbonate / Polyethylene) alloy material and a preparation method thereof. The termite-proof low-temprature-resisting and flame-retarding PC / PE alloy material is prepared from the following components in parts by weight: 50 to 80 parts of PC resin, 5 to 20 parts of PE resin, 3 to 8 parts of a low-temperature synergist, 10 to 20 parts of a phosphorus-based flame retardant, 0.2 to 2.0 parts of a flame-retarding synergist, 0.4 to 1.0 part of an anti-dropping agent, 1 to 10 parts of termite-proof master batch and 0.4 to 1.0 part of an antioxidant. In a PC / PE alloy system, the PE resin is distributed in the PC resin in a dispersed phase manner; active groups of the PE resin and the PC resin are subjected to grafting reaction in a melting and blending process of the low-temperature synergist, so that a two-phase interface of PC and PE is improved, and the low-temperature toughening effect of the PEresin is sufficiently expressed; the phosphorus-based flame retardant is cooperatively matched with the flame-retarding synergist, so that flame-retarding requirements of large-size thin-wall parts are met. According to the termite-proof low-temprature-resisting and flame-retarding PC / PE alloy material, the termite-proof master batch is prepared firstly and then is used for synthesizing the PC / PEalloy material, so that the obtained termite-proof low-temprature-resisting and flame-retarding PC / PE alloy material keeps relatively good low-temperature-resisting and flame-retarding properties; meanwhile, the termite-proof low-temprature-resisting and flame-retarding PC / PE alloy material also has a long-effect termite-proof effect and is applicable to optical fibers and cable wiring boxes.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

Vacuumizing technology for vacuum low-temperature thermal insulation pipeline

InactiveCN102797943BReduce contentReduce cold lossThermal insulationPipe protection by thermal insulationThermal insulationNitrogen gas

Owner:SUZHOU TOWAY ENG & EQUIP

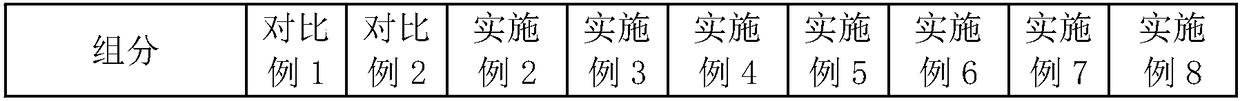

Chip frequency screening and subpackaging device

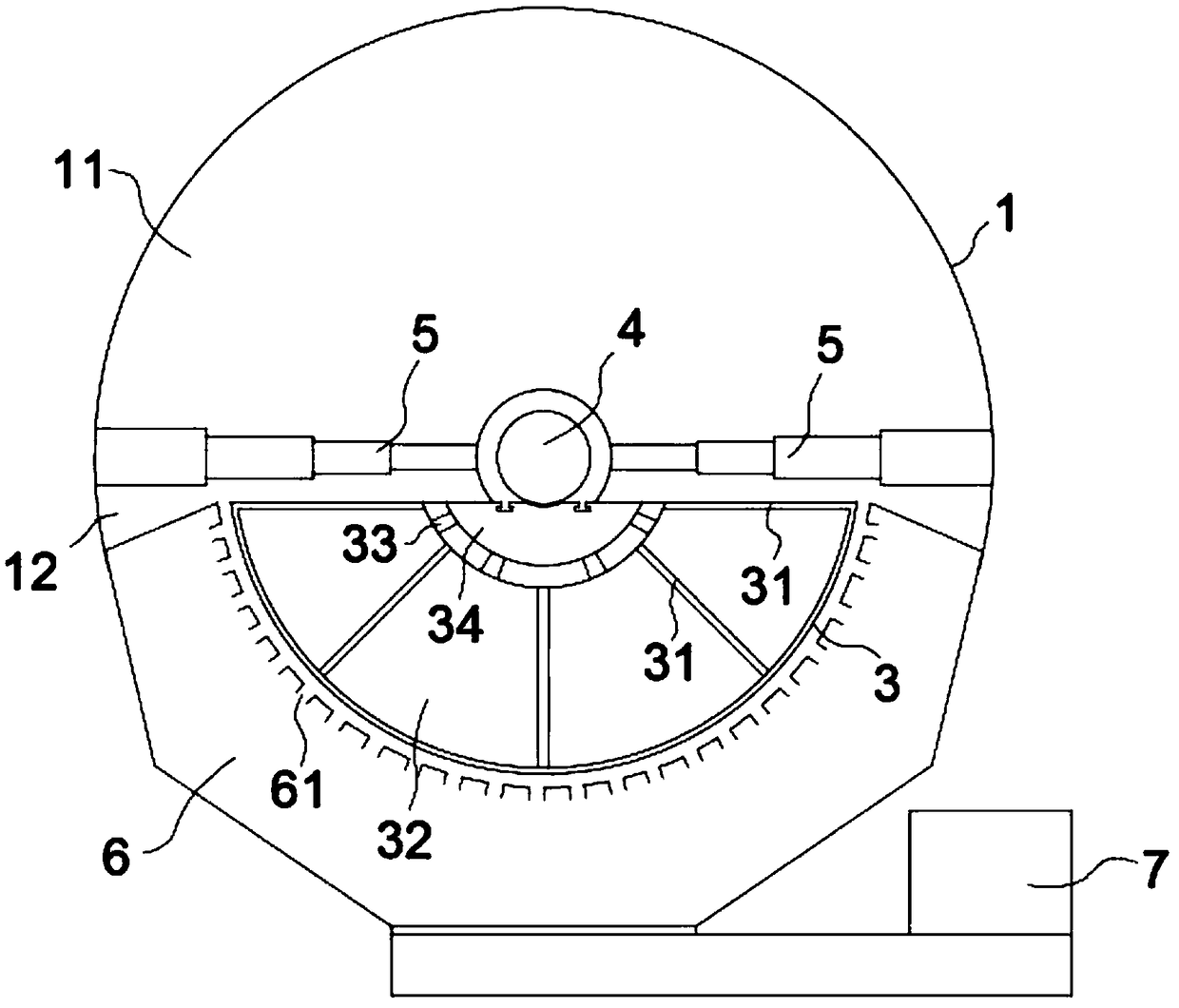

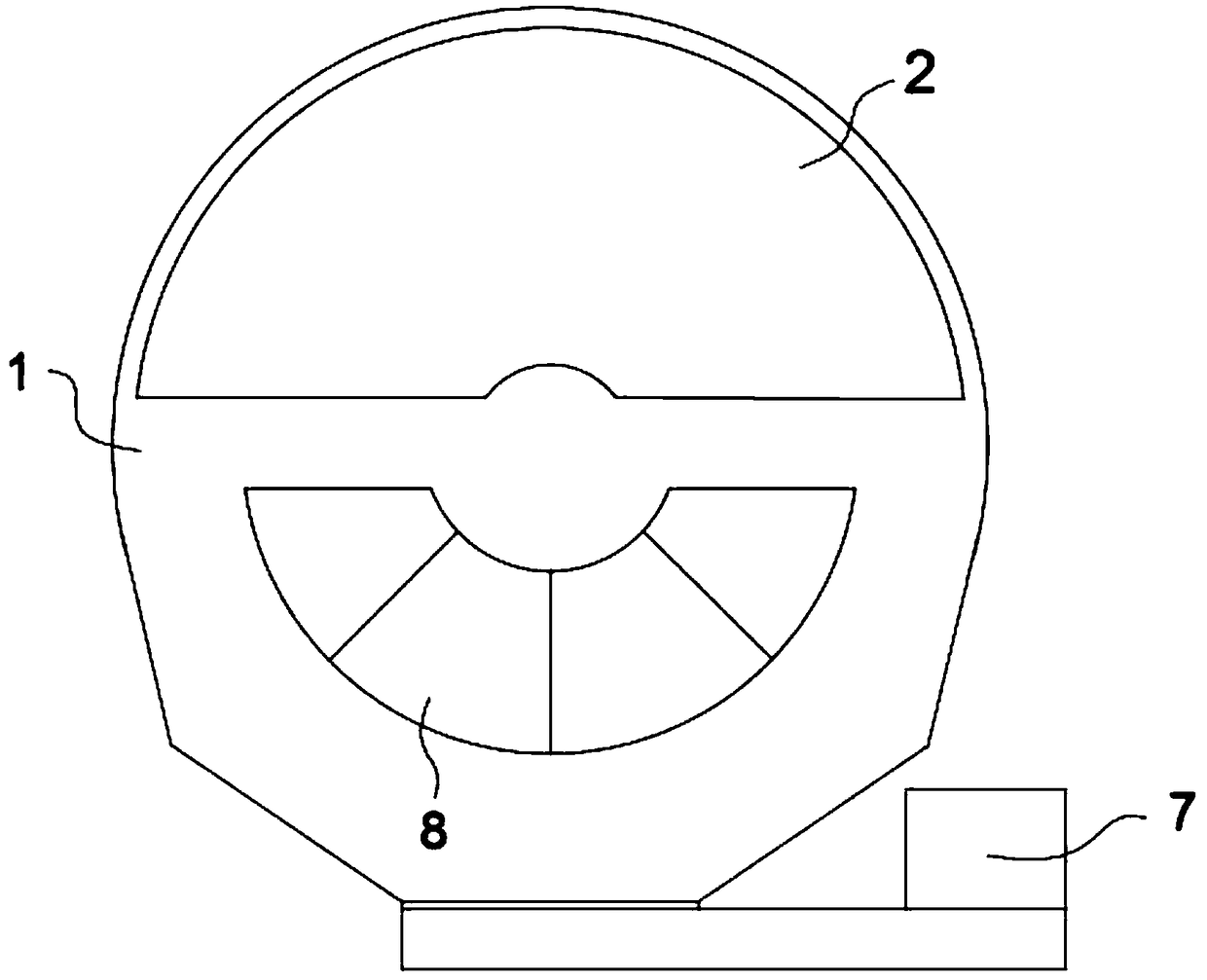

PendingCN114345760ASatisfy mass productionIncrease productivitySortingBatch productionRotational axis

The invention discloses a chip frequency screening and sub-packaging device which comprises a sub-packaging rotating mechanism and a plurality of sub-packaging material receiving mechanisms, the sub-packaging rotating mechanism comprises a rotating frame and a rotating driving assembly, and a clamping structure used for clamping and releasing chips is arranged at the free end of the rotating frame; the rotating driving assembly is used for driving the rotating frame to rotate around a vertical rotating axis, and a feeding station, a detecting station and a plurality of split charging and receiving stations are arranged on a rotating path of the clamping structure; the split charging feeding ends of the split charging and receiving mechanisms correspond to the split charging and receiving stations in a one-to-one mode. An external chip feeding device conveys a chip to a clamping structure, the clamping structure clamps the chip, the clamping structure rotates to a detection station and detects the chip, according to a detection result, the clamping structure rotates to a corresponding split charging and receiving station, then the clamping structure releases the chip, the chip is recycled to a split charging and receiving mechanism from a split charging feeding end, and the split charging and receiving mechanism is started. The chips are automatically conveyed and classified, and large-batch production is met.

Owner:佛山市南海区鑫来智能电子有限公司

Dress ornament non-ironing drying shaper

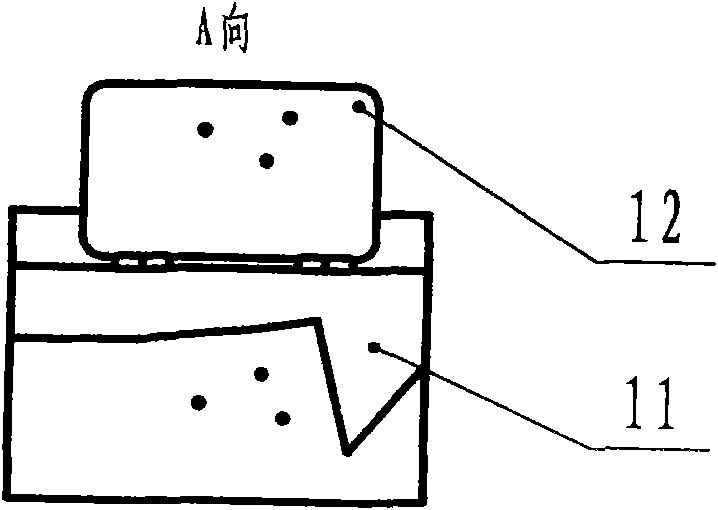

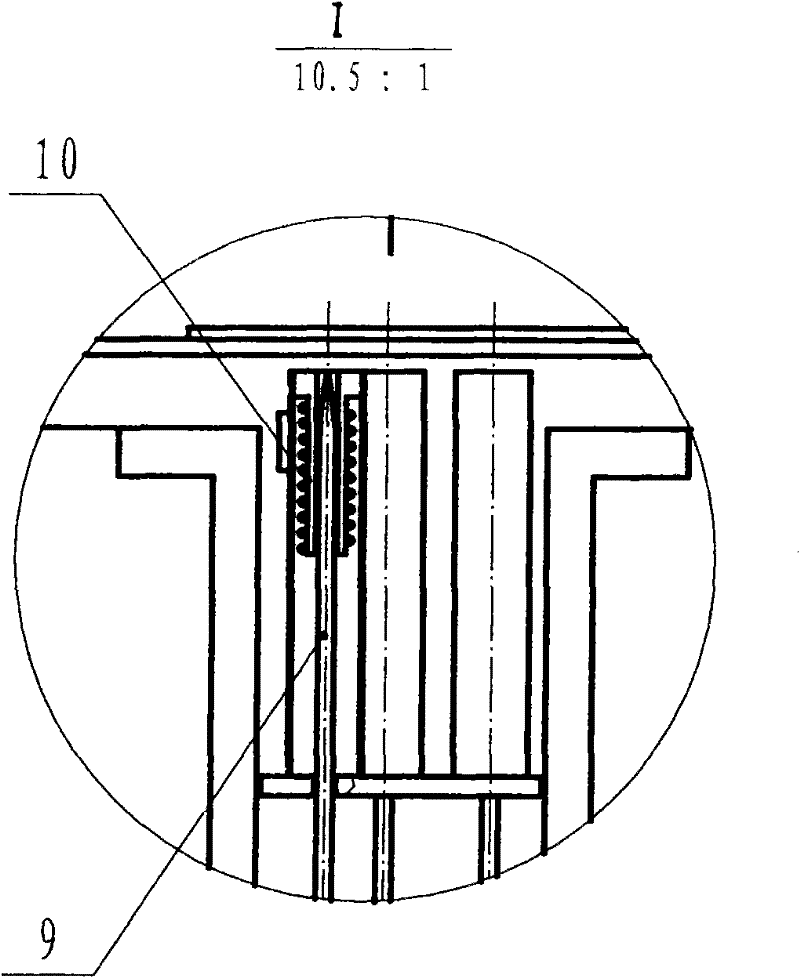

InactiveCN100564656CGuaranteed drying and setting effectEasy to operateTextiles and paperLaundry driersEngineeringElectric control

The invention discloses a clothes non-iron drying and forming machine which comprises a box body (1) an electric control device (2) and has the main characteristics of comprising a steam heater component (9), a blower component (10), a clothes hanging circulation conveying device (12) and a negative-pressure wind-suction and wet-exhaust device (13); the invention is characterized by having advanced structure, high production efficiency and low energy consumption ratio and satisfying large-batch and large-sized production. The invention can be suitable for drying, forming and processing of non-iron clothes, solid fringe clothes, bags, caps and other articles.

Owner:常州艾贝服饰有限公司

A method for preparing two-dimensional nanomaterials in a physical vacuum

ActiveCN109019674BImprove mechanical propertiesImprove bending abilityMaterial nanotechnologyTitanium dioxideFreeze-dryingBis(trimethylsilyl)amine

The invention discloses a physical vacuum method of preparing a two-dimensional nano-material, which includes: S1) according to the types of metals, preparing buffer solutions in corresponding pH values; S2) adding graphene oxide, metal salt, N-vinyl pyrrolidone and hexamethyl disilazane to the solution in S1) to form a mixed solution; S3) heating the mixed solution and performing continuous centrifugal washing to obtain a precipitate; S4) moving the precipitate to a vacuum-freeze-drying device to prepare to-be-processed powder; S5) calcining the to-be-processed powder in a calcinator, and performing temperature controlled cooling, magnetic stirring and ball milling to obtain the two-dimensional nano-material. In conclusion, the method is simple, employs accessible raw materials, can satisfy large-scale production, is green and environment-friendly, and effectively improves the bending strength of the nano-material.

Owner:广东致密纳米技术有限公司

Nail cap support device

The invention relates to a nail cap support device, and belongs to equipment for producing nail cap supports for big rimmed caps. The nail cap support device mainly solves the technical problems of time and labor waste, low efficiency and poor quality in the conventional manual rivet cap supports. According to the technical scheme, the nail cap support device comprises a frame, a bedplate, a left foot valve, a right foot valve and a main machine body, wherein the main machine body consists of a main frame, a pressure gun cylinder, a lock nut, a main shaft, a sliding block, a main shaft sleeve, a connecting plate, a pneumatic code nail gun, a cap support seat, a cap support positioning block and a trigger cylinder; the pressure gun cylinder is arranged on the upper part of the main frame, a piston rod of the pressure gun cylinder is connected with the main shaft through a screw buckle, the main shaft sleeve is arranged outside the main shaft, and the sliding block is arranged on the middle part of the main shaft and positioned in a slipway of the main shaft sleeve; the lower end of the main shaft is provided with the connecting plate which is connected with the top of the pneumatic code nail gun, and the cap support seat is arranged on a bracket on the lower part of the main frame; and the cap support positioning block is arranged on the inclined plane of the rear part of the cap support seat.

Owner:JIHUA 3534 CLOTHING

Device for ironing collar badge hole

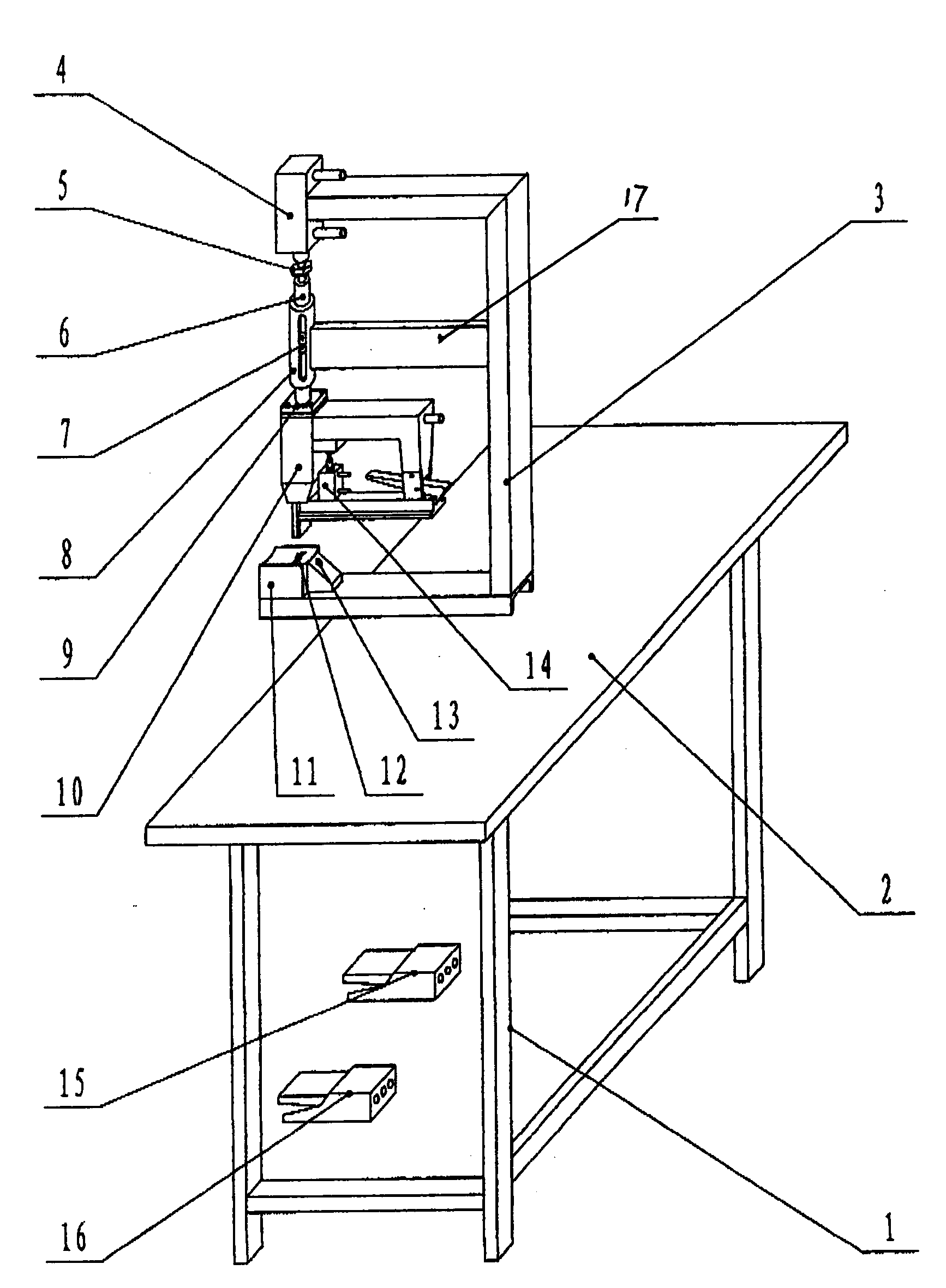

InactiveCN101748593BSatisfy mass productionMeet the needs of mass productionSevering textilesEngineeringPiston rod

The invention relates to a device for ironing a collar badge hole, which belongs to equipment for producing clothes. The invention mainly solves technical difficult points that the traditional manual operation has low efficiency, time and labor saving, unstable product quality and incapability of meeting the requirement of large-batch scale production. The technical scheme of the invention is that the device for ironing the collar badge hole comprises a stand, a pedal switch, a pressure-reducing valve, a temperature controller and an ironing needle body consisting of an air cylinder, an air cylinder bracket, a positioning plate, an ironing needle, an ironing needle supporting plate and an outer heating tube, wherein the air cylinder is arranged at the lower part of the air cylinder bracket; the bottom surface of the ironing needle supporting plate and the end part of a piston rod of the air cylinder are connected together through bolts; the bottom of the ironing needle is arranged on the top surface of the ironing needle supporting plate according to the position of the collar badge hole; the outer heating tube is sleeved at the upper part of the ironing needle and arranged at theupper part of the air cylinder bracket; the upper end of the air cylinder bracket is arranged on the bottom surface of the tabletop of the stand and positioned below the ironing needle hole; and the positioning plate is arranged on the top surface of the tabletop of the stand and positioned above the ironing needle hole.

Owner:JIHUA 3534 CLOTHING

Physical vacuum method of preparing two-dimensional nano-material

ActiveCN109019674AImprove mechanical propertiesImprove bending abilityMaterial nanotechnologyTitanium dioxideTemperature controlFreeze-drying

The invention discloses a physical vacuum method of preparing a two-dimensional nano-material, which includes: S1) according to the types of metals, preparing buffer solutions in corresponding pH values; S2) adding graphene oxide, metal salt, N-vinyl pyrrolidone and hexamethyl disilazane to the solution in S1) to form a mixed solution; S3) heating the mixed solution and performing continuous centrifugal washing to obtain a precipitate; S4) moving the precipitate to a vacuum-freeze-drying device to prepare to-be-processed powder; S5) calcining the to-be-processed powder in a calcinator, and performing temperature controlled cooling, magnetic stirring and ball milling to obtain the two-dimensional nano-material. In conclusion, the method is simple, employs accessible raw materials, can satisfy large-scale production, is green and environment-friendly, and effectively improves the bending strength of the nano-material.

Owner:广东致密纳米技术有限公司

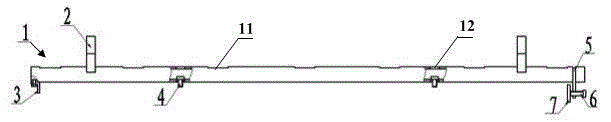

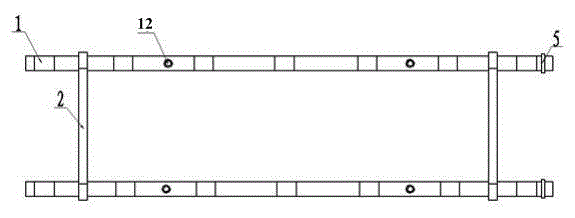

Inner support positioning spot welding device

ActiveCN104014972BHigh positioning accuracyReduce the difficulty of positioningWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingStructural engineering

The invention discloses an interior bracing type locating point solid welding device. The interior bracing type locating point solid welding device comprises two longitudinal beams arranged at a certain distance and in parallel, two cross beams are arranged at two ends of the two longitudinal beams respectively, the longitudinal beam is square steel with hollow cross section, a plurality of grooves distributed uniformly are formed in the upper end surface of each longitudinal beam, a plurality of through holes are formed between two grooves in the upper end surface of each longitudinal beam, a threaded hole in which a positioning bolt is screwed is formed in the lower end surface of each longitudinal beam, corresponding to the through hole, an inverted L-shaped locating plate is arranged at the lower part of the left end of each longitudinal beam, an end plate is arranged at the right ends of two longitudinal beams, an adjusting bolt is fixed with a base plate by a screw hole of the end plate, a locating plate directly faces the base plate, and a square pipe fitting is arranged at the lower parts of the two longitudinal beams and between the locating plate and the base plate. The interior bracing type locating point solid welding device can reduce the locating difficulty of operators, improve the workpiece position precision, reduce the personal error and meet the large-scale batch production.

Owner:CHINA NUCLEAR TIANJIN TECH DEV

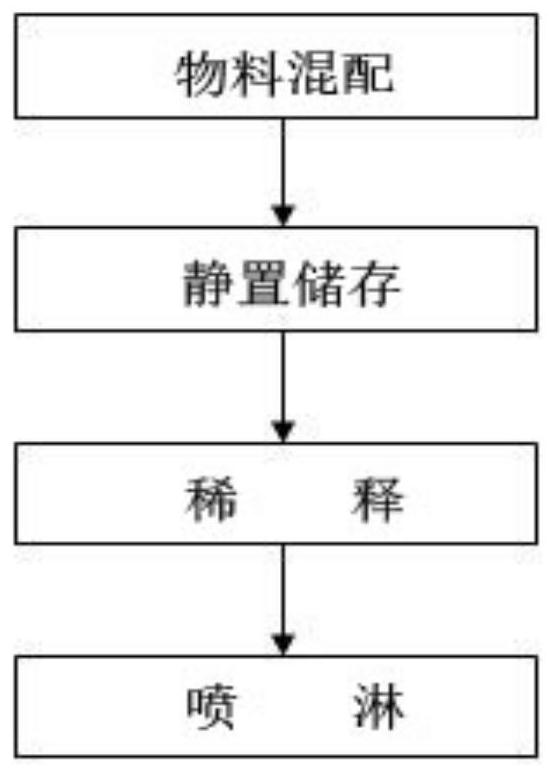

Product capable of improving disease resistance of plants and optimizing growth of plants and preparation method of product

PendingCN113661994AImprove disease resistanceQuality improvementPlant growth regulatorsBiocideBiotechnologyBrassica

The invention relates to a product capable of improving the disease resistance of plants and optimizing the growth of the plants and a preparation method of the product. The product is composed of the following components in parts by weight: 8%-15.3% of a brassinolide aqueous solution, 10%-30.1% of an ascorbic acid aqueous solution and the balance being deionized water. The preparation method comprises the four steps: mixing the preparation materials, standing and storing, spraying a diluent and the like. The production process is simple, the production efficiency is high, the production process flow is short, and the production raw material cost is low, so that the production cost and the production difficulty of the product are effectively reduced, and the requirements of batch and large-scale production can be effectively met; and in the growth and development period of crops, the use requirements of an initial flowering period, a full-bloom period, a fruiting period and a fruit expanding period can be effectively met, and the disease resistance and development quality of the plants are effectively improved.

Owner:MULTI-FARMER MULTI-HARVEST TECH RES (JIANGSU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com