Multifunctional automatic capping machine

A capping machine and multi-functional technology, which is applied to flange-type bottle caps, conveyor objects, bottle/container caps, etc. Guaranteed accuracy and flatness, reasonable structural design, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

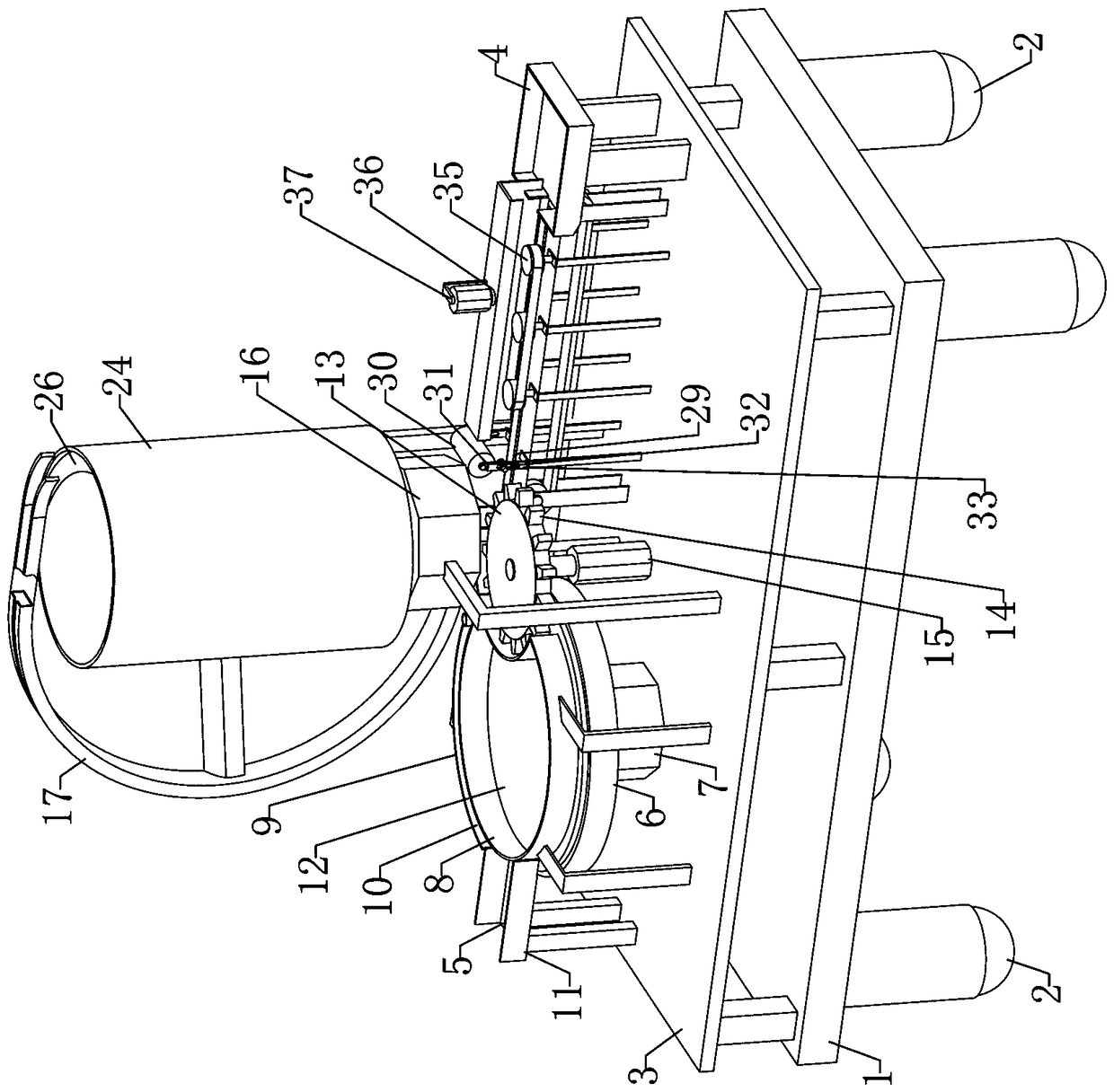

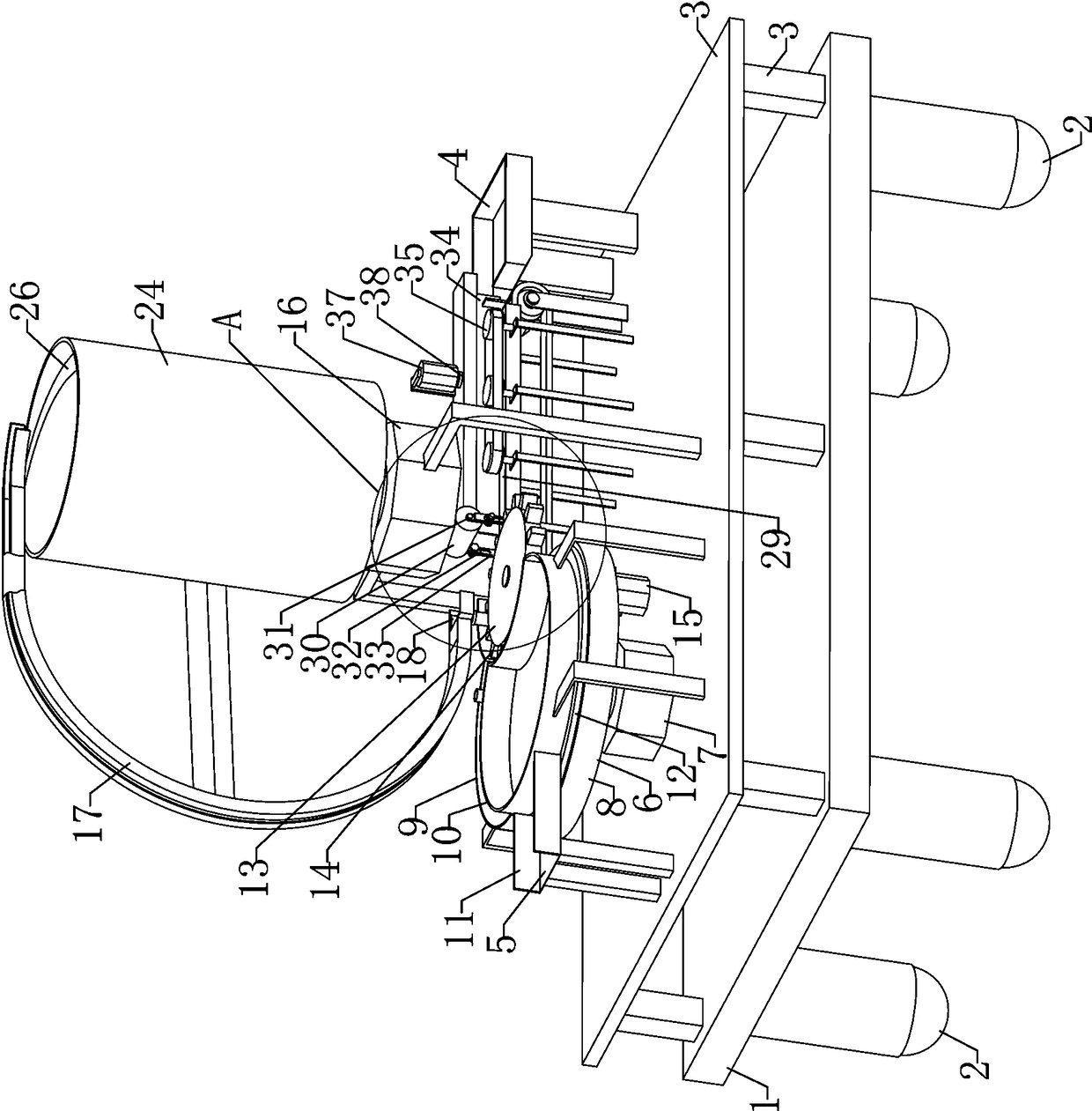

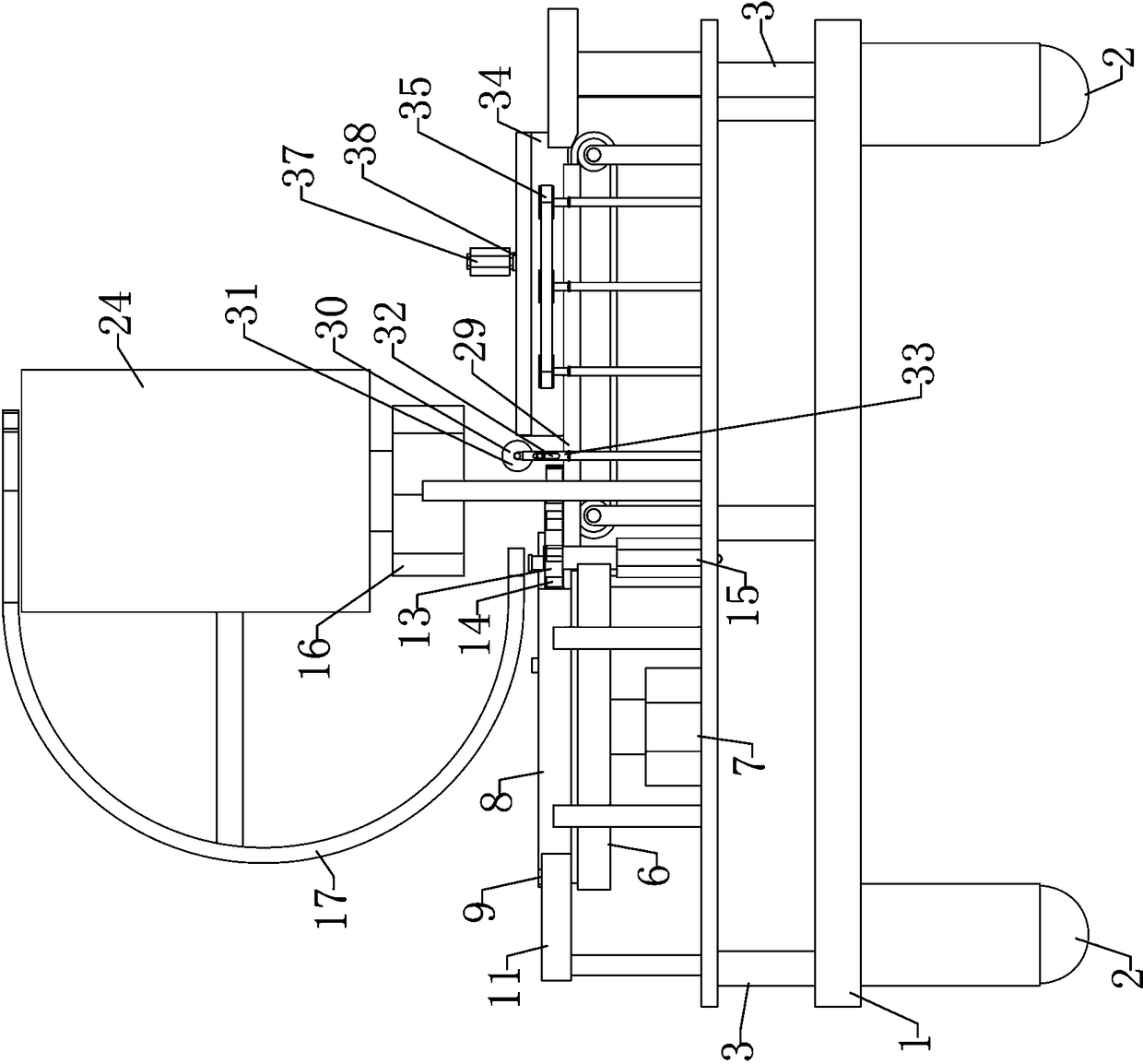

[0031] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0032] Such as Figure 1-9 As shown in the figure, the multi-functional automatic capping machine includes a base 1, and a wheel 2 with self-locking function is provided at the bottom of the base 1, which can easily shift the entire device and adapt to work in different positions. A frame body 3 is arranged on the seat 1, a bottle body conveying device is provided on the top platform of the frame body 3, a capping device is arranged at the end of the bottle body conveying device, and a bottle body conveying device on the side close to the capping device A bottle cap conveying device is provided above the capping device, and a medicine bottle exporting collection platform 4 is provided on the rear side of the capping device; through the bottle body conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com