Method for preparing dual-scale iron-based composite gradient coating based on high-speed laser cladding method

A technology of laser cladding and gradient coating, applied in coating, metal material coating process, etc., can solve the problem of low bonding force of dual-scale gradient coating, and achieve good structural stability, high overall hardness and high hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the material of the base material is 27SiMn steel, which is mostly used in hydraulic supports for coal mining, and is prone to wear and failure during service. The traditional treatment method is to use electroplating Cr for surface protection, but the bonding between the coating and the base is poor. , At the same time, the electroplating technology pollutes the environment a lot.

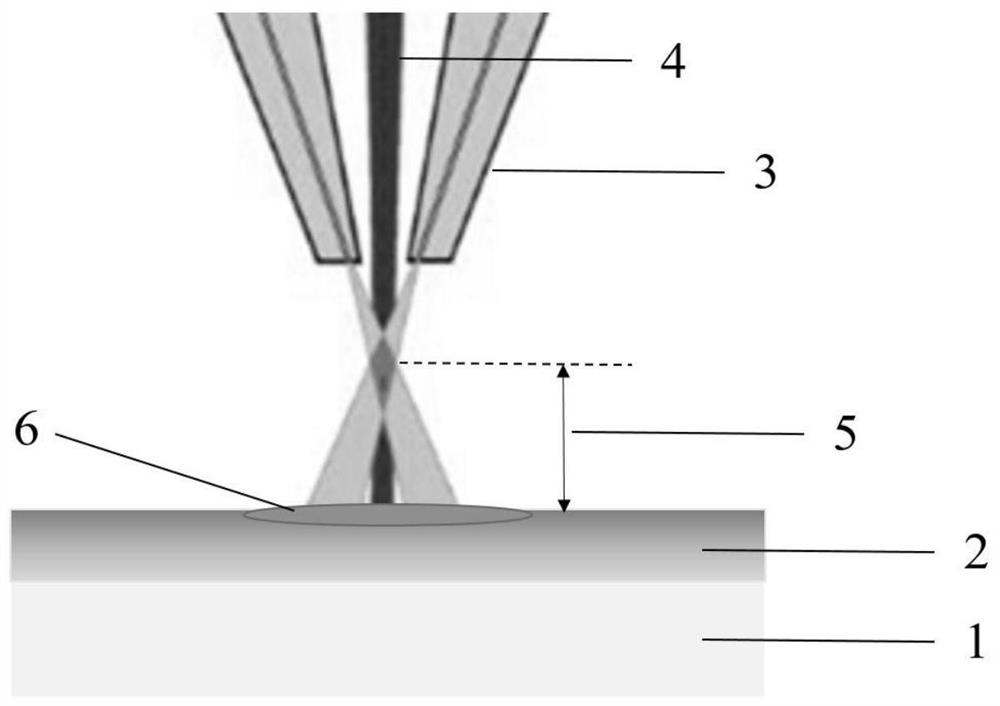

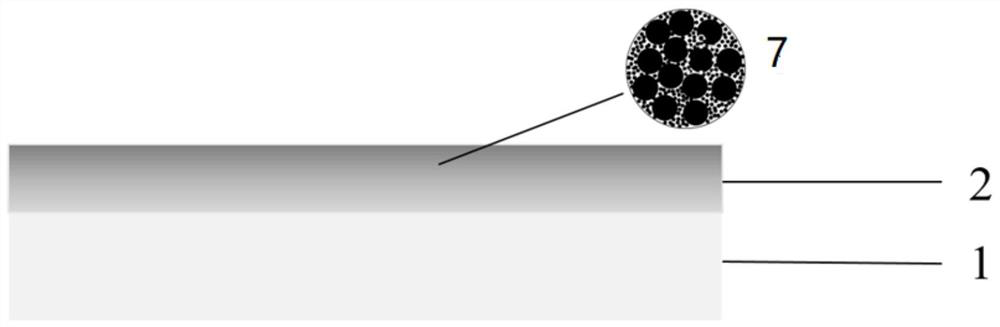

[0046] In this embodiment, by performing high-speed laser cladding surface strengthening on 27SiMn steel, a high wear-resistant composite gradient coating can be formed to improve the performance of 27SiMn steel and prolong the service life, including the following steps:

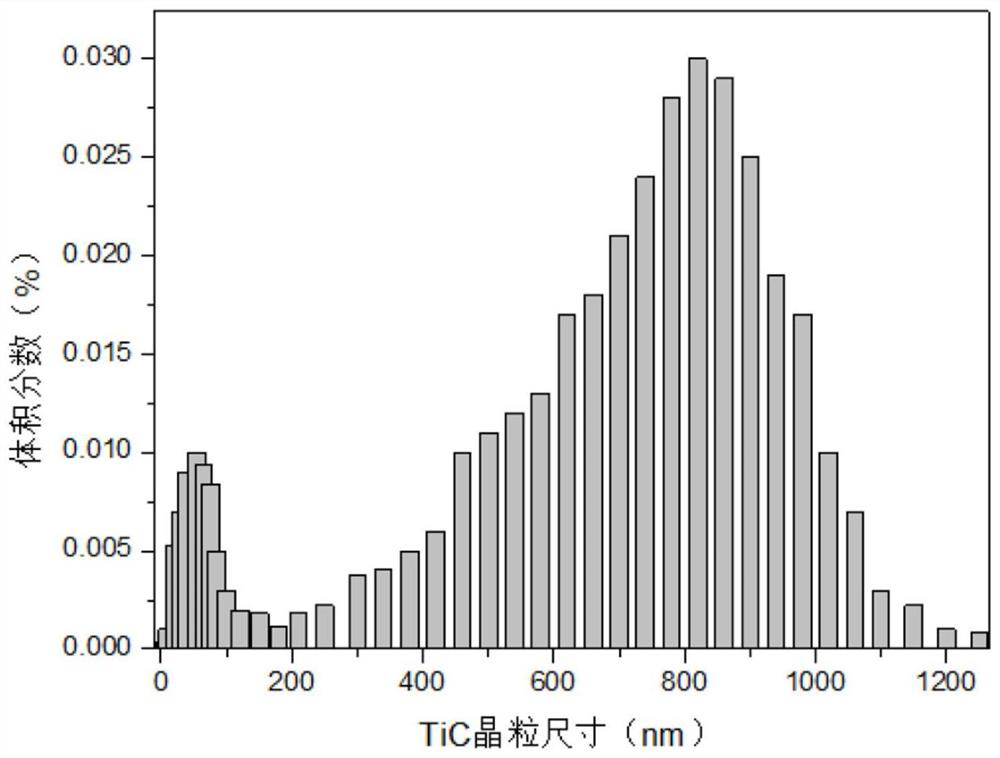

[0047] (1) Fe-based powder, TiC powder, Ti powder and C powder are selected for doping in different proportions. The parts by weight of each component in the mixed powder are as follows: 90 parts of Fe-based powder (17.0% Cr, 0.03% C, 0.8% Si , 0.3% Mn, 1.3% B, 80.57% Fe), 5 parts of TiC powder, 4 par...

Embodiment 2

[0059] In this embodiment, the base material is H13 die steel, which is used to manufacture forging dies, hot extrusion dies, precision forging dies with large impact loads; die-casting dies of aluminum, copper and their alloys. During use, it needs to withstand high wear-resistant conditions, and it is often local wear. The replacement of the whole mold due to partial damage caused a lot of waste, and at the same time, the shutdown of production greatly reduced the production efficiency of the enterprise.

[0060] In this embodiment, high-speed laser cladding surface strengthening is performed on H13 die steel to form a highly wear-resistant composite gradient coating to improve the performance of H13 die steel and prolong the service life, including the following steps:

[0061] (1) Fe-based powder, TiC powder, Ti powder and C powder are selected for doping in different proportions. The parts by weight of each component in the mixed powder are as follows: 80 parts of Fe-base...

Embodiment 3

[0072] In this embodiment, the material of the base body is GCr15 high-carbon chromium bearing steel, and the GCr15 high-carbon chromium bearing is used for rolling strip steel. The online service period is very short, and the failure of the roll causes a lot of waste. Greatly reduced the production efficiency of the enterprise.

[0073] In this embodiment, high-speed laser cladding surface strengthening is performed on the GCr15 cold roll to form a high wear-resistant composite gradient coating to improve the performance of the GCr15 cold roll and extend the service life, including the following steps:

[0074] (1) Fe-based powder, TiC powder, Ti powder and C powder are selected for doping in different proportions. The parts by weight of each component in the mixed powder are as follows: 70 parts of Fe-based powder (16.5% Cr, 0.12% C, 0.8% Si , 0.9% B, 81.68% Fe), 15 parts of TiC powder, 12 parts of Ti powder and 3 parts of C powder;

[0075] In the above mixed powder, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com