Inner support positioning spot welding device

A positioning point and support type technology, applied in the field of internal support type positioning point solid welding device, can solve the problems of unavoidable human error and cannot meet the batch and large-scale production and processing, so as to reduce human error and meet large-scale Batch production, the effect of reducing the difficulty of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

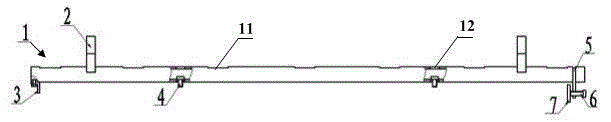

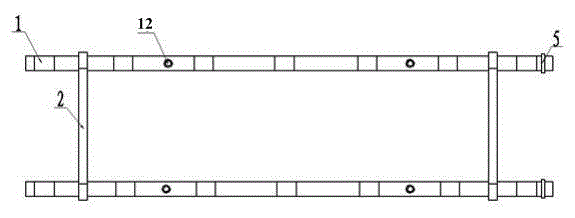

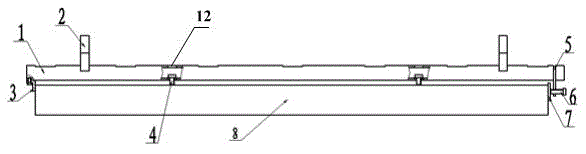

[0026] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

[0027] Such as Figure 1~6 As shown, an internally supported positioning point solid welding device includes two longitudinal beams 1 placed in parallel at a certain distance, and two beams 2 are respectively arranged at the two ends of the two longitudinal beams 1, and the longitudinal beams 1 are horizontal beams. The section is a hollow square steel, and the shape of the beam 2 is an inverted "]" shape.

[0028] A plurality of evenly distributed grooves 11 (fourteen in total in the present invention) are formed on the upper end surfaces of the two longitudinal beams 1, and a plurality of through holes 12 are formed between the two grooves 11 on the upper end surfaces of the two longitudinal beams 1 (four in total in the present invention), form the threaded hole screwed into the set bolt 4 at the lower end faces of the two longitudinal beams 1 and the through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com