Termite-proof low-temprature-resisting and flame-retarding PC/PE (Polycarbonate/Polyethylene) alloy material and preparation method thereof

An alloy material and termite prevention technology, applied in the field of alloy materials, can solve the problems of poor fluidity and low temperature resistance of PC resin, and achieve the effects of reducing volatilization loss, simple operation and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

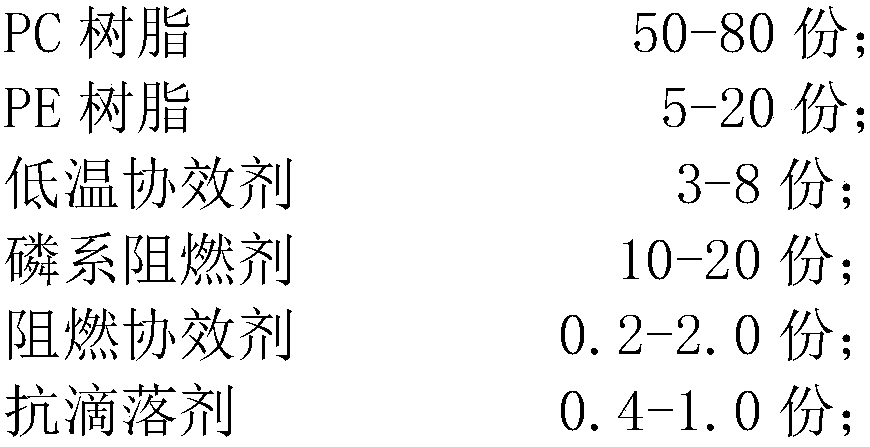

Method used

Image

Examples

Embodiment 1

[0039] The preparation of anti-termite masterbatch specifically comprises the following steps:

[0040] First, add 0.2 parts of initiator DCP, 2 parts of maleic anhydride, 5 parts of bifenthrin and 10 parts of methyl carbamate in a closed stirring pot for pre-mixing at a low speed for 1 minute, then add 82.4 parts of high-density polyethylene HDPE, Stir and mix at high speed for 2 minutes, then add to a twin-screw screw extruder for melting and reaction granulation. The temperature of each section of the twin-screw extruder is 160°C, 180°C, 200°C, 220°C, 220°C, 200°C, 200°C, 180°C, 180°C, the die head temperature is 160°C, and the screw speed is 50r / min . The prepared anti-termite masterbatch is packaged in an aluminum foil packaging bag and vacuum-sealed in time for future use.

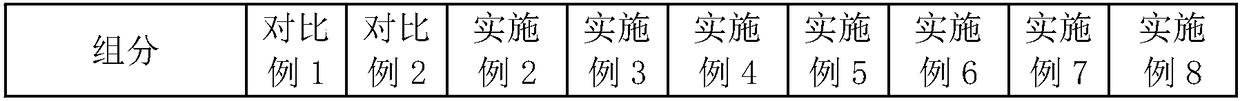

Embodiment 2-8

[0042] Weigh a certain amount of PC resin, high-density polyethylene HDPE, low-temperature synergist, phosphorus flame retardant, flame retardant synergist, anti-dripping agent, anti-termite masterbatch, antioxidant and add it to the high-speed mixer In the middle, the mixed material after stirring for 3 minutes is added from the main feeding port of the twin-screw extruder; the anti-termite masterbatch is added from the ninth zone by using a weight loss scale, and melted and granulated by the twin-screw extruder. In the twin-screw extruder, the temperature of each section from the feed section to the machine head is 200°C, 220°C, 230°C, 230°C, 245°C, 245°C, 235°C, 235°C, 230°C, 230°C, 230°C °C, 230 °C, the die temperature is 230 °C. The prepared anti-termite, low-temperature and flame-retardant PC / PE alloy pellets were placed in a vacuum oven at 80°C for 3 hours, and then the test specimens were prepared by injection molding machine.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com