Nail cap support device

A technology of nail caps and cap holders, which is applied in the direction of hats, cap products, applications, etc., can solve the problems of being unable to meet large-scale large-scale production, time-consuming, laborious, and poor quality, and achieve consistent nail formation, accurate positioning, and easy operation. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

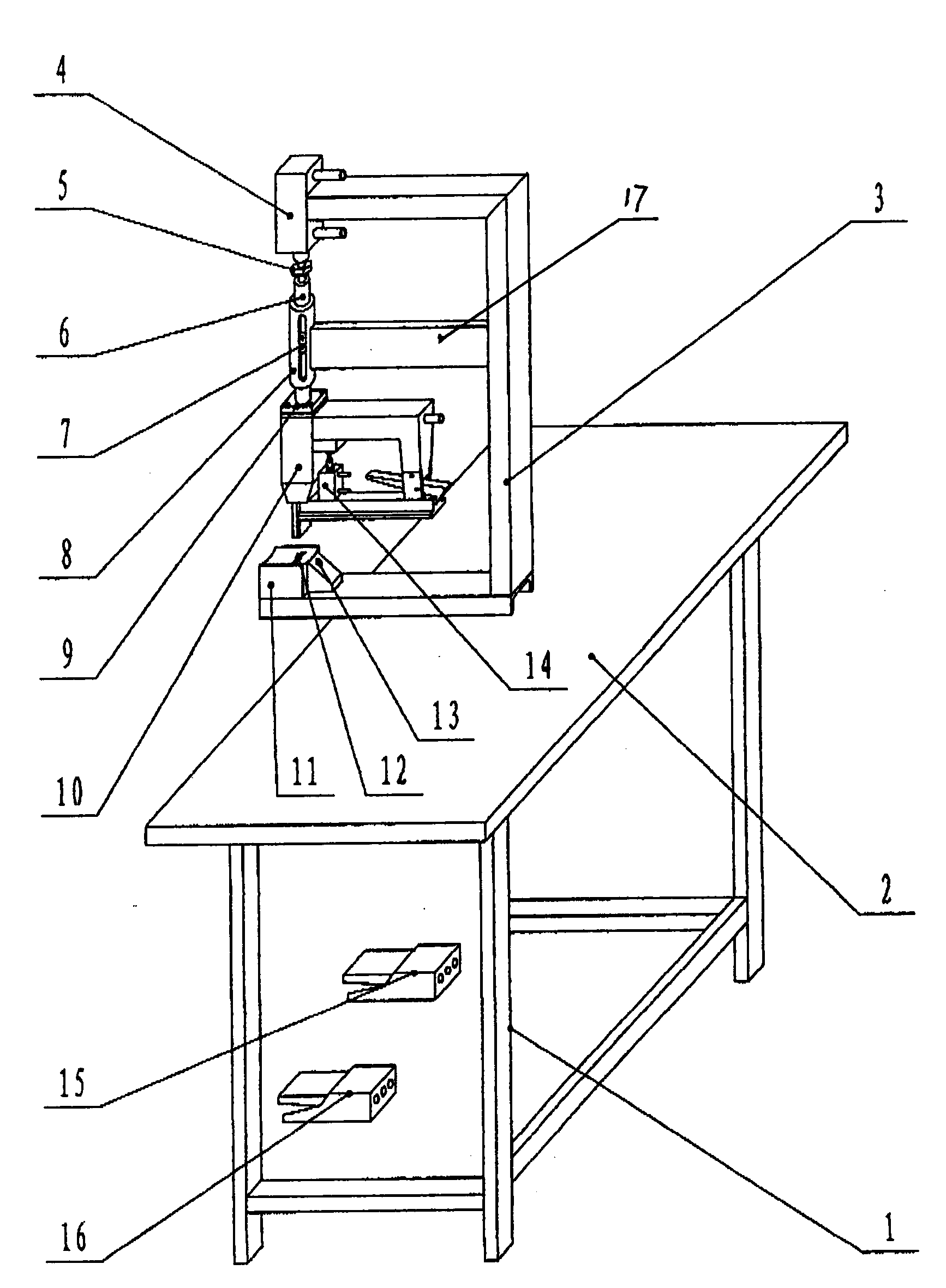

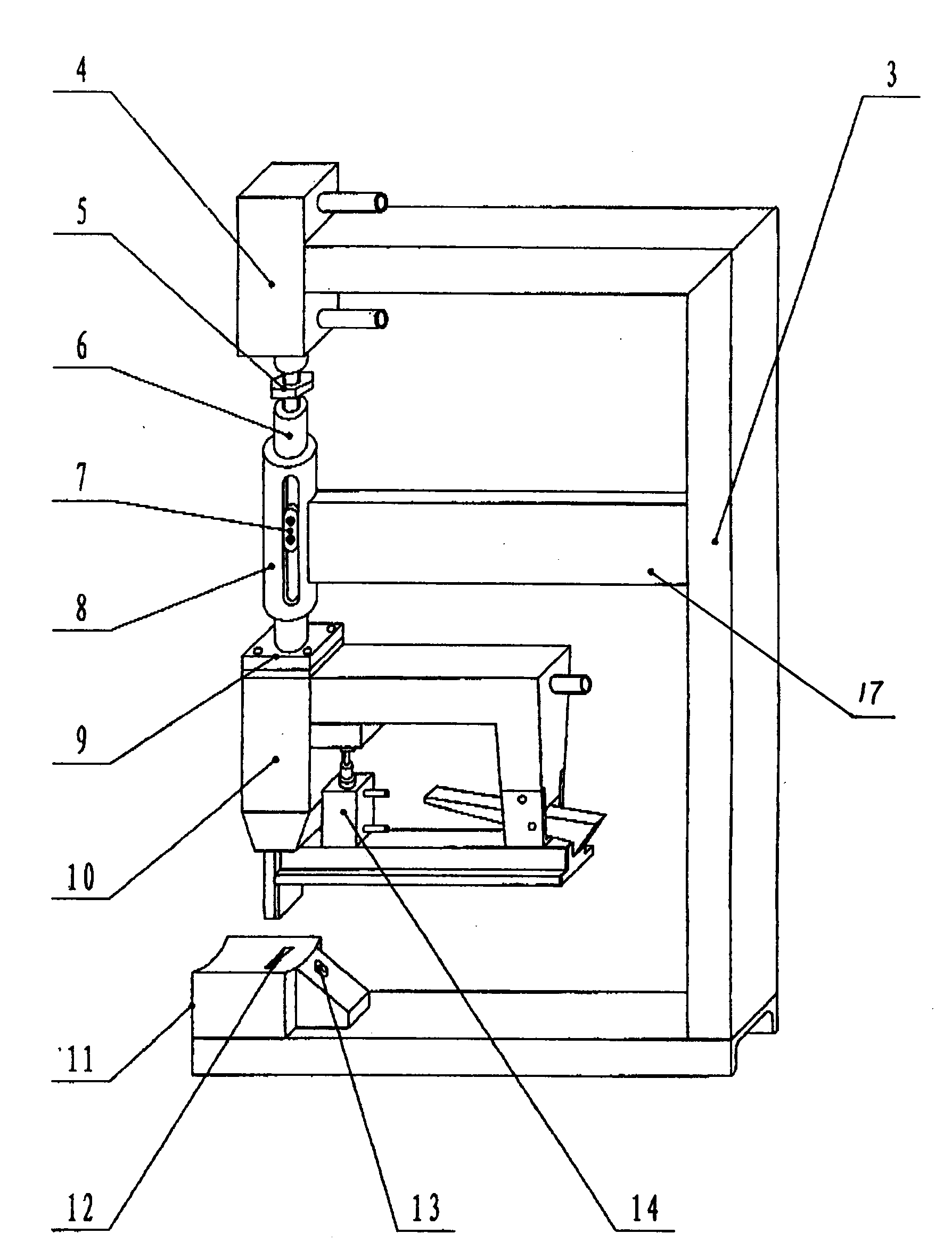

[0008] Such as figure 1 with figure 2 Shown, the nail nut support device among the present embodiment comprises frame 1, platen 2, left foot valve 15 and right foot valve 16, platen 2 is arranged on the upper end of frame 1, left foot valve 15 And right pedal valve 16 is located at the bottom of frame 1 front, wherein: it also includes by main frame 3, pressure gun cylinder 4, lock nut 5, main shaft 6, slide block 7, main shaft sleeve 8, connecting plate 9, pneumatic Code nail gun 10, cap holder seat 11, hat holder positioning block 13 and trigger cylinder 14 constitute the main body; pressure gun cylinder 4 is located on the top of main frame 3 and is connected with main frame 3 with bolts, and the piston rod of pressure gun cylinder 4 Connect with the main shaft 6 through a threaded buckle and fix it with the lock nut 5. The main shaft sleeve 8 is set outside the main shaft 6. The outer wall of the main shaft sleeve 8 is fixedly connected with the main frame 3 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com