Chip frequency screening and subpackaging device

A sub-packaging and chip technology, applied in sorting and other directions, to meet the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

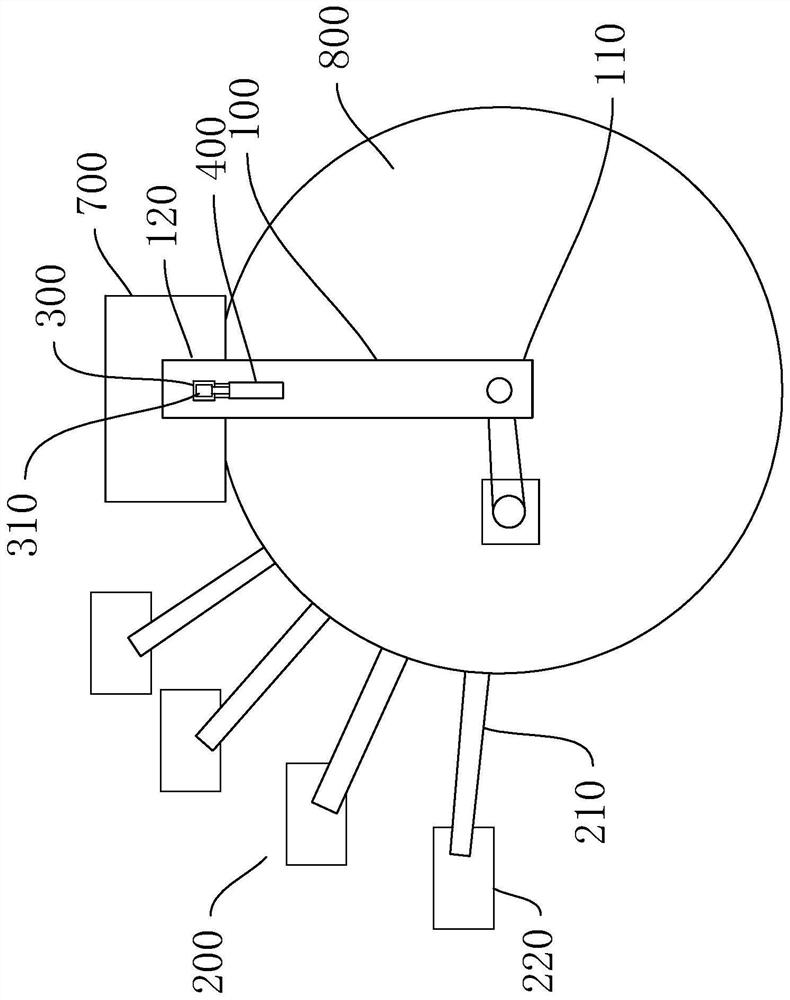

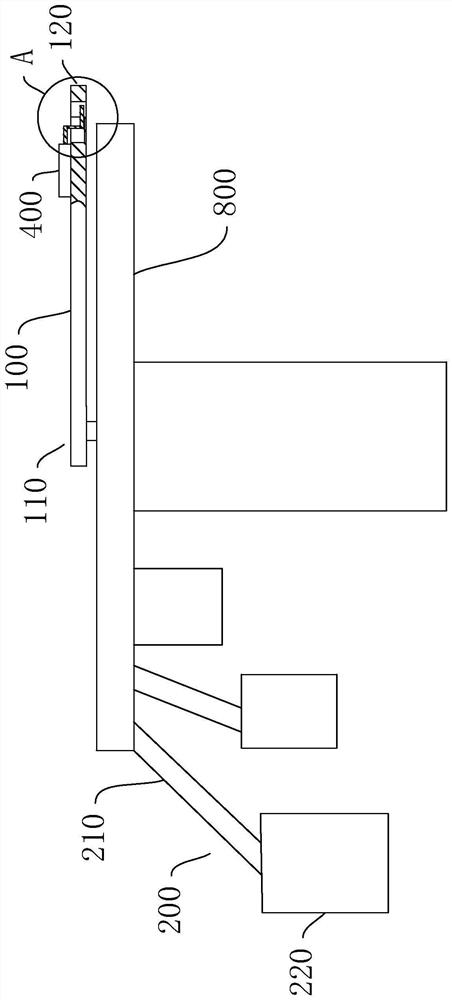

[0033] Such as Figure 1 to Figure 3 As shown, the chip frequency screening and packaging device of this embodiment includes: a packaging and rotating mechanism and a plurality of packaging and receiving mechanisms 200, wherein the packaging and rotating mechanism includes a frame 800, a turret 100, and a rotating drive assembly. The frame 100 is horizontally provided with a connection end 110 and a free end 120, the connection end 110 is rotatably connected to the frame 800, and the rotation drive assembly is in transmission connection with the connection end 110, specifically: the rotation drive assembly includes a rotation motor and a control The rotating motor is connected to the rotating shaft provided on the connecting end 110 through a transmission belt transmission structure, and the frame 800 is connected to the frame 800 through the rotating shaft, and the free end 120 is provided with a clamping device for clamping and releasing chips. structure, on the rotation pat...

Embodiment 2

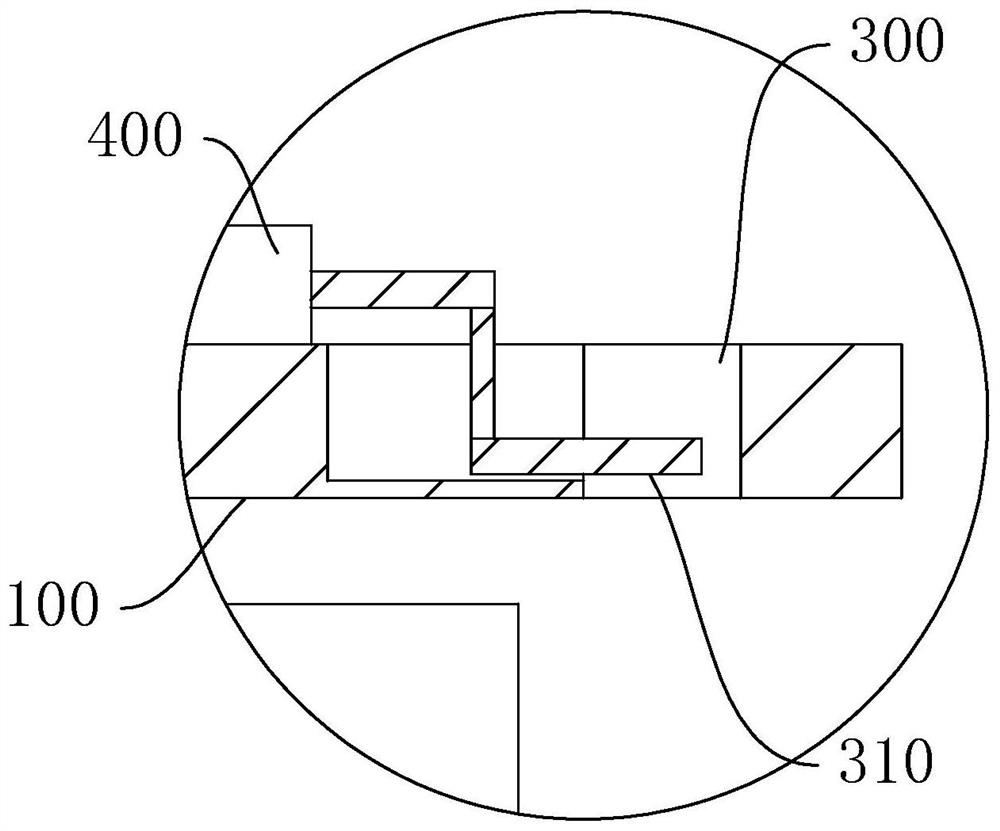

[0040] Such as Figure 4 and Figure 5 As shown, the difference between this embodiment and Embodiment 1 lies in the difference in the clamping structure. The clamping structure includes a detection material hole 300 penetrating up and down and a jacking assembly, and a stopper is arranged in the bottom of the detection material hole 300 310, the stopper 310 is an elastic member, one side of the stopper 310 is fixedly connected to the inner wall of the detection material hole 300, and the ejector assembly is provided with a push rod 500 arranged above the detection material hole 300, for The ejector drive unit drives the ejector pin 500 to move up and down, the ejector drive unit makes the lower end of the ejector pin 500 protrude into the detection material hole 300, and the chip is supported by the stopper 310 of the elastic member in this embodiment , which is equivalent to that the stopper 310 can hold the chip in the detection material hole 300, and follow the rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com