Device for ironing collar badge hole

A flower hole and pinhole technology, which is applied in the field of collar ironing flower hole devices, can solve problems such as inability to meet large-scale large-scale production, unstable product quality, time-consuming and labor-intensive problems, and achieve large-scale large-scale production, consistent molding, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

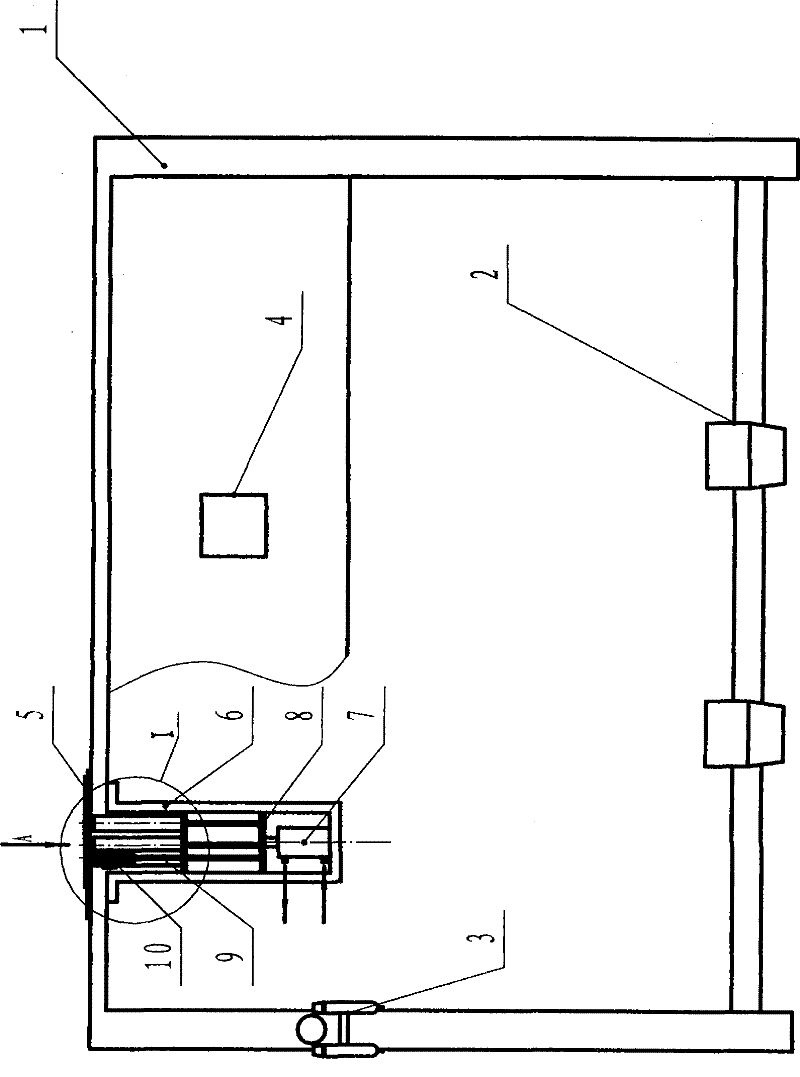

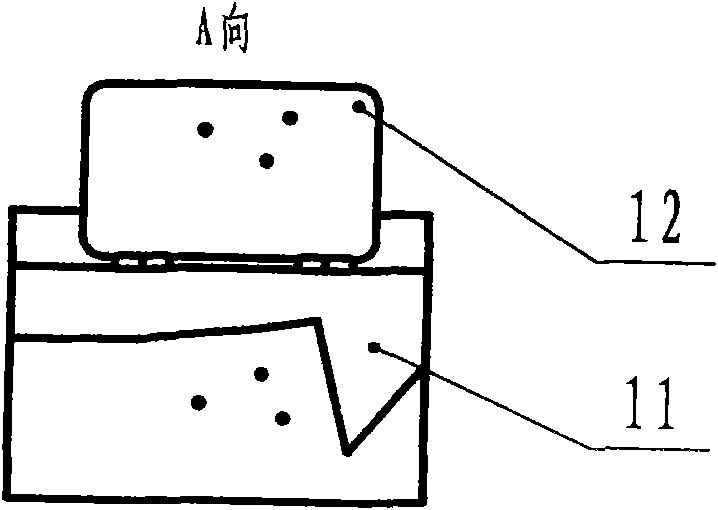

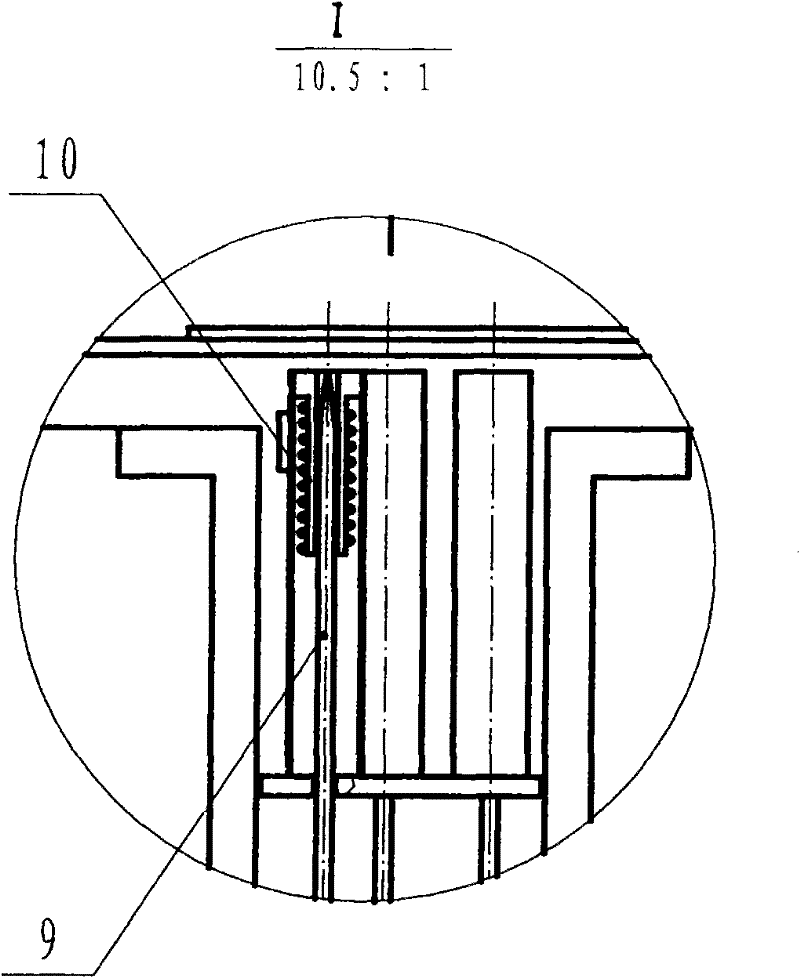

[0012] Such as figure 1 , figure 2 and image 3 As shown, a collar perforation device in this embodiment includes a frame 1, a foot switch 2 arranged at the bottom of the frame 1, a pressure reducing valve 3 and a temperature controller 4 arranged on the frame, wherein: It also includes a needle body made of cylinder 7, cylinder support 6, positioning plate 5, needle iron 9, needle support plate 8 and external heating tube 10, cylinder 7 is located at the bottom of cylinder support 6, needle support plate 8 Bottom surface and the end of piston rod of cylinder 7 are connected together by bolts, the bottom of ironing needle 9 is installed on the top surface of ironing needle support plate 8 according to the position of collar flower hole, and external heating tube 10 is sleeved on the top of ironing needle 9 and is contained in The top of the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com