Manufacturing method of arsenic rod for molecular beam epitaxy

A technology of molecular beam epitaxy and a manufacturing method, which is applied in the field of manufacturing arsenic rods for molecular beam epitaxy, can solve problems such as affecting the production of arsenic element rods, and achieve the effects of avoiding poor molding effect and improving qualification rate and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

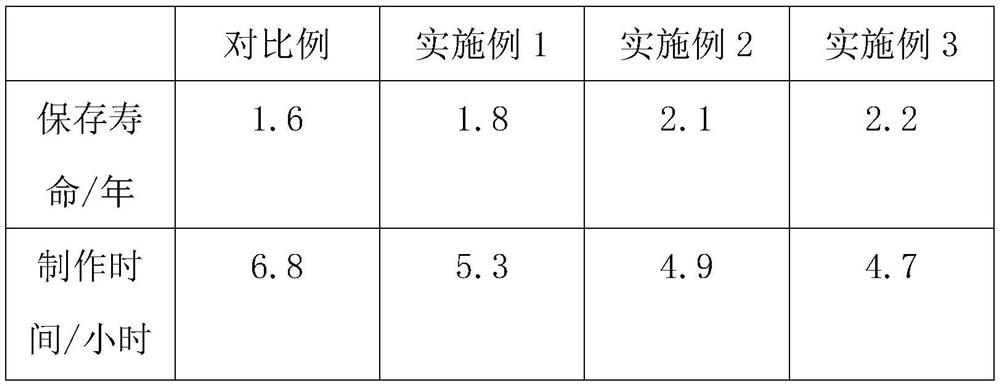

Embodiment 1

[0029] Step 1: Basic treatment of related equipment: Clean the inside and outside of the quartz tube with distilled water. After cleaning, dry it, and then use hydrofluoric acid to quickly clean the quartz tube to completely clean the silica powder on the surface of the quartz tube. Then use distilled water to clean the quartz tube while soaking. After the comprehensive cleaning is completed, wipe the inner and outer surfaces of the quartz tube clean, and then fully rotate and dry;

[0030] Step 2: Basic operation of the quartz tube: put the quartz tube in a helium-protected environment, then load arsenic particles into the quartz tube, then use a vacuum machine to vacuum the quartz tube, and then seal the quartz tube;

[0031] Step 3: Initial processing of arsenic particles: place the quartz tube loaded with arsenic particles in a sealed high-temperature and high-pressure furnace, raise the temperature in the furnace to 700 degrees Celsius, the arsenic particles are initially ...

Embodiment 2

[0036] Step 1: Basic treatment of related equipment: Clean the inside and outside of the quartz tube with distilled water. After cleaning, dry it, and then use hydrofluoric acid to quickly clean the quartz tube to completely clean the silica powder on the surface of the quartz tube. Then use distilled water to clean the quartz tube while soaking. After the comprehensive cleaning is completed, wipe the inner and outer surfaces of the quartz tube clean, and then fully rotate and dry;

[0037] Step 2: Basic operation of the quartz tube: put the quartz tube in a helium-protected environment, then load arsenic particles into the quartz tube, then use a vacuum machine to vacuum the quartz tube, and then seal the quartz tube;

[0038]Step 3: Initial processing of arsenic particles: place the quartz tube loaded with arsenic particles in a sealed high-temperature and high-pressure furnace, raise the temperature in the furnace to 725 degrees Celsius, the arsenic particles are initially s...

Embodiment 3

[0043] Step 1: Basic treatment of related equipment: Clean the inside and outside of the quartz tube with distilled water. After cleaning, dry it, and then use hydrofluoric acid to quickly clean the quartz tube to completely clean the silica powder on the surface of the quartz tube. Then use distilled water to clean the quartz tube while soaking. After the comprehensive cleaning is completed, wipe the inner and outer surfaces of the quartz tube clean, and then fully rotate and dry;

[0044] Step 2: Basic operation of the quartz tube: put the quartz tube in a helium-protected environment, then load arsenic particles into the quartz tube, then use a vacuum machine to vacuum the quartz tube, and then seal the quartz tube;

[0045] Step 3: Initial processing of arsenic particles: place the quartz tube loaded with arsenic particles in a sealed high-temperature and high-pressure furnace, raise the temperature in the furnace to 750 degrees Celsius, the arsenic particles are initially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com