Hole site detection jig for plastic products

A technology for detecting jig and hole position, applied in sorting and other directions, which can solve problems such as offset, long time consumption, low assembly efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

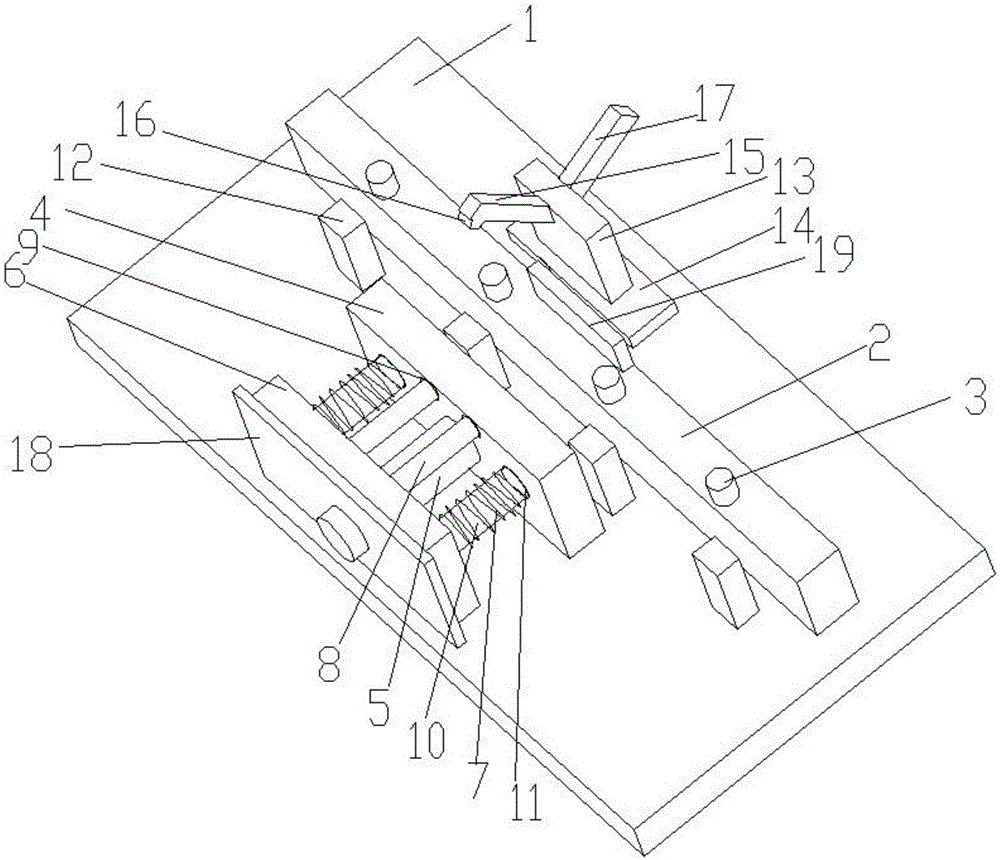

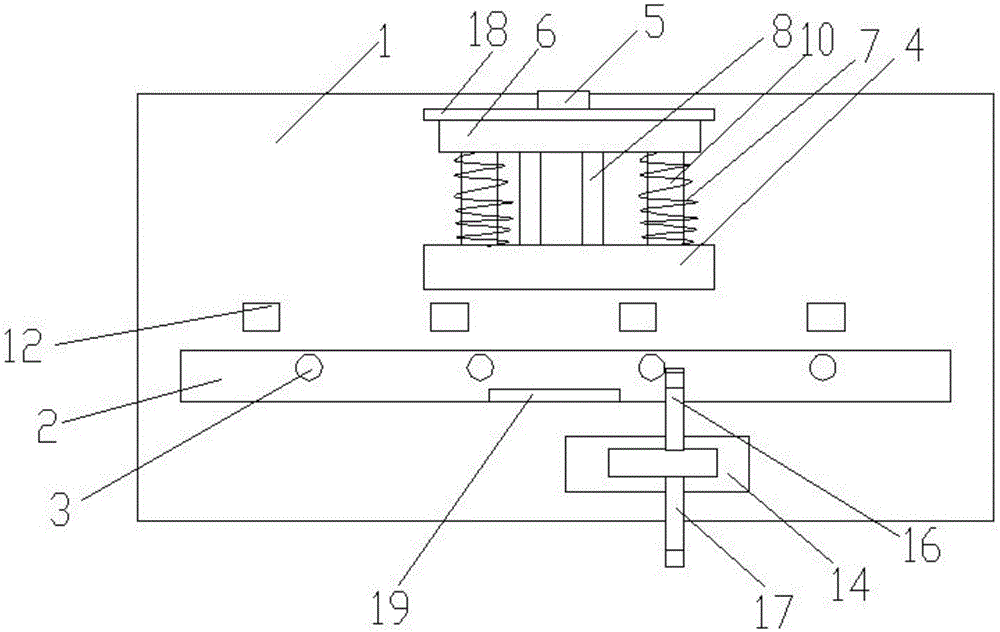

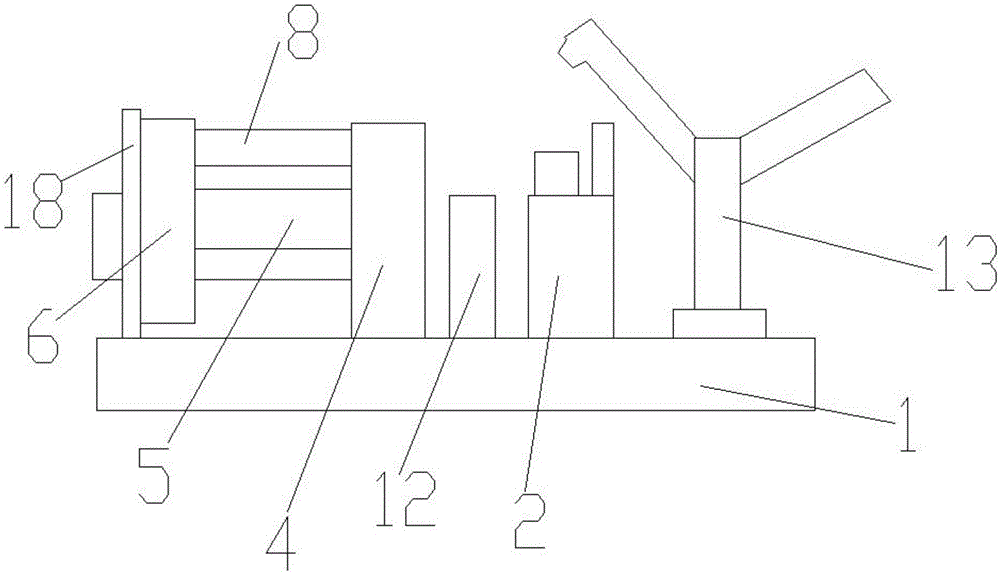

[0018] Embodiment: a plastic product hole position detection jig, including a bottom plate 1 and a positioning block 2, the positioning block is horizontally fixed on the bottom plate, and a number of positioning columns 3 are fixed at even intervals on the upper end of the positioning block, so that A fixed block 4 is fixed on the base plate, the fixed block is positioned at one side of the positioning block, a support column 5 is fixed horizontally on the fixed block, and a movable block 6 is set horizontally on the support column, A number of springs 7 are fixedly connected laterally between the movable block and the fixed block, the movable block is located on the side of the fixed block away from the positioning block, and the movable block is transversely facing the side of the positioning block A hole position detection needle 8 is fixed, and an opening 9 for the hole position detection needle to pass through is arranged on the fixed block. When in use, the plastic prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com