Vacuum insulation board core material and manufacturing method thereof

A technology of vacuum insulation panels and core materials, applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of not reaching Class A combustion level, increasing energy consumption, and not being widely used, achieving less glass dust, reducing costs, The effect of high fiber strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

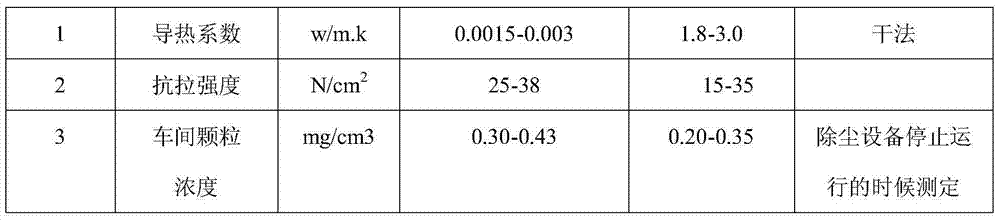

Examples

Embodiment 1

[0036] The following components in parts by mass are mixed to form a mixture:

[0037] Accurately weigh 41.8 parts of quartz powder; 7.3 parts of soda ash; 7.6 parts of lithium feldspar; 1.1 parts of calcite; 7.35 parts of dolomite; 10.3 parts of albite;

[0038] The mixture is added to the melting pool of the furnace for melting treatment to obtain uniform and clear molten glass. The melting treatment of the mixture includes 5 stages: silicate formation stage, glass liquid formation stage, and glass liquid clarification stage , Glass liquid homogenization stage and glass liquid fiber formation stage, control furnace temperature 1400 ℃, regenerator temperature 870 ℃

[0039] Control the temperature of the channel for transporting the molten glass to 1180°C, control the temperature of the molten glass to 1140°C, and control the temperature of the centrifuge disc to 980°C, put the molten glass through the channel into the leaky plate and the centrifuge disc into the centrifuge f...

Embodiment 2

[0058] The following components in parts by mass are mixed to form a mixture:

[0059] Weigh 40.6 parts of quartz powder, 7.5 parts of lithium feldspar, 9.8 parts of albite, 23.5 parts of borax, 2.9 parts of calcite, 5.2 parts of dolomite, 9.8 parts of soda ash, and 0.76 parts of fluorite; mix well to form a mixture.

[0060] The mixture is added to the melting pool of the furnace for melting treatment to obtain uniform and clear molten glass. The melting treatment of the mixture includes 5 stages: silicate formation stage, glass liquid formation stage, and glass liquid clarification stage , Glass liquid homogenization stage and glass liquid fiber formation stage, control furnace temperature 1370 ℃, regenerator temperature 870 ℃

[0061] Control the temperature of the channel for transporting the molten glass to 1160°C, control the temperature of the molten glass to 1120°C, and control the temperature of the centrifuge disc to 960°C, put the molten glass through the channel in...

Embodiment 3

[0080] The following components in parts by mass are mixed to form a mixture:

[0081] Weigh 40.2 parts of quartz powder, 9.2 parts of lithium feldspar, 9.6 parts of albite, 24.9 parts of borax, 9.6 parts of calcite, 5.2 parts of dolomite, 9.2 parts of soda ash, and 0.9 parts of fluorspar; mix them evenly to form a mixture.

[0082] The mixture is added to the melting pool of the furnace for melting treatment to obtain uniform and clear molten glass. The melting treatment of the mixture includes 5 stages: silicate formation stage, glass liquid formation stage, and glass liquid clarification stage , Glass liquid homogenization stage and glass liquid fiber formation stage, control furnace temperature 1360 ℃, regenerator temperature 870 ℃

[0083] Control the temperature of the channel for transporting the molten glass to 1150°C, control the temperature of the molten glass to 1120°C, and control the temperature of the centrifuge disc to 960°C, put the molten glass through the cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com