Patents

Literature

32results about How to "Improve the manufacturing environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-nickel cathode material for lithium secondary battery

ActiveCN110137488AReduce Lithium Nickel MixingStable crystal structureCell electrodesSecondary cells servicing/maintenanceLarge capacityLithium-ion battery

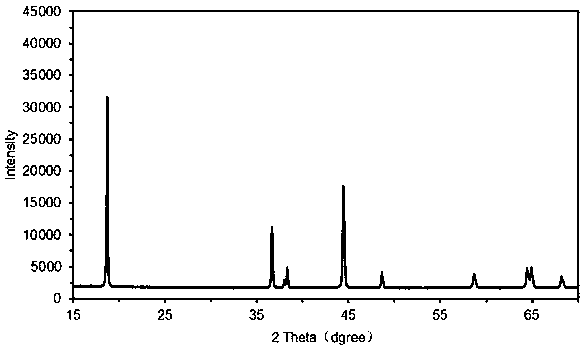

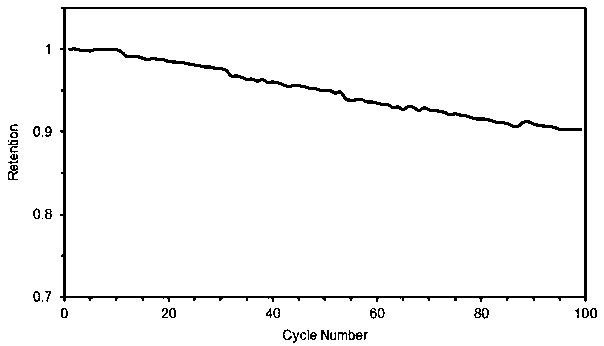

The invention discloses a method for preparing a high-nickel cathode material for a lithium secondary battery. The method comprises the steps of weighing and uniformly mixing a nickel-cobalt-manganesecompound, a lithium salt and an additive I; calcining the mixture in two stages at high temperature in an oxygen atmosphere; cooling, sieving, water-washing the mixture; and mixing the mixture with an additive II for secondary sintering so as to obtain the high-nickel ternary cathode material, wherein the lithium salt is a mixed lithium salt of lithium carbonate and lithium hydroxide, and the lithium carbonate and the lithium hydroxide can be mixed in any mixing ratio. The method can prepare a material having a large capacity and excellent cycle performance, can reduce the amount of highly-corrosive lithium hydroxide, improves the preparation environment of high-nickel materials, cancels out the impact of lithium hydroxide price fluctuation on the price of the high-nickel ternary material, and has a good application prospect.

Owner:郑州中科新兴产业技术研究院 +1

Vacuum insulation board core material and manufacturing method thereof

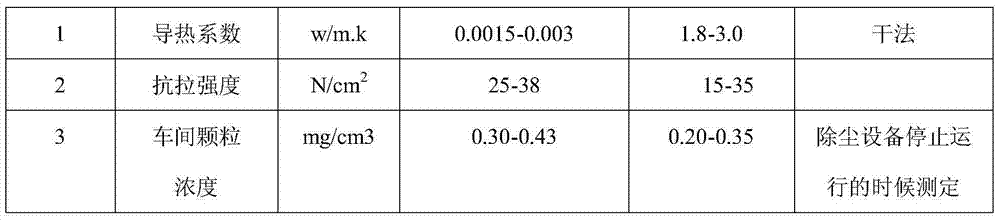

The invention discloses a vacuum insulation board core material and a manufacturing method thereof. The core material comprises the following components in parts by mass: 50-70 parts of SiO2, 0-7 parts of Al2O3, 2-15 parts of CaO, 0-6 parts of MgO, 8-20 parts of Na2O+K2O, 12-15.5 parts of B2O3, 0.1-7.0 parts of ZnO and at most 1.0 part of other components. By adopting the high-boron-content glass wool microfiber, the core material has the advantages of high fiber strength, high fiber smoothness and smooth molding process, and can be the best core material for a high-performance vacuum insulation board; and since the high-boron-content vacuum insulation board core material has the advantages of high fiber strength and high smoothness, only a small amount of the glass dust drops in the process of producing the core material and manufacturing the dry-process vacuum insulation board, thereby effectively improving the manufacturing environment of the operator and greatly reducing the dust treatment cost of the enterprise.

Owner:安徽吉曜玻璃微纤有限公司

Preparation method for grinding wheel of photosensitive resin binding agent

InactiveCN1623733AShorten production timeReduce manufacturing costGrinding devicesPolymer scienceResin adhesive

A process for preparing abrasive disk by use of photosensitive resin adhesive includes such steps as making its main body and mould, mixing the photosensitive resin adhesive with abrasive particles to obtain filler, and filling the filler in the solidifying cavity of said main body step by step while using light to irradiate it step by step for solidifying.

Owner:ZHEJIANG UNIV OF TECH

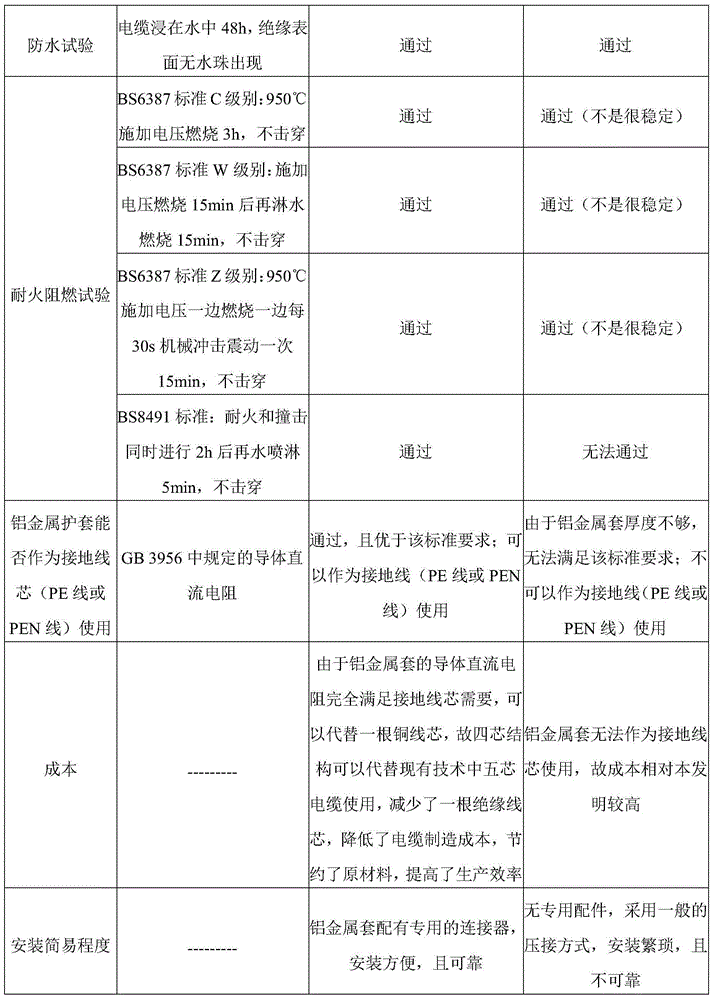

Dry vacuum insulated panel and production method thereof

InactiveCN104406009AHigh strengthImprove the manufacturing environmentThermal insulationPipe protection by thermal insulationGlass fiberPunching

The invention discloses a vacuum insulated panel and a production method thereof. The vacuum insulated panel comprises a core material and an aluminum film bag, wherein the core material consists of the following components in parts by mass: 50-70 parts of SiO2, 0-7 parts of Al2O3, 2-15 parts of CaO, 0-6 parts of MgO, 8-20 parts of Na2O+K2O, 5.5-15.5 parts of B2O3, 0.1-7.0 parts of ZnO, and not more than 1.0 part of other components. The production process of the insulated panel comprises the steps of cotton cutting, punching, drying, cotton conveying, cotton loading, packaging and rolling. The heat conductivity coefficient of the dry vacuum insulated panel is below 0.0025 w / m.k; the method improves the operator production environment, and reduces the company dust treatment cost; in addition, as the core material of the dry vacuum insulated panel is an inorganic glass fiber with a longer length, and can be directly recovered to a kiln as a raw material for recycling, the dry vacuum insulated panel is a green product having the advantages of environment protection, heat insulation, heat preservation, sound absorption and energy conservation.

Owner:安徽吉曜玻璃微纤有限公司

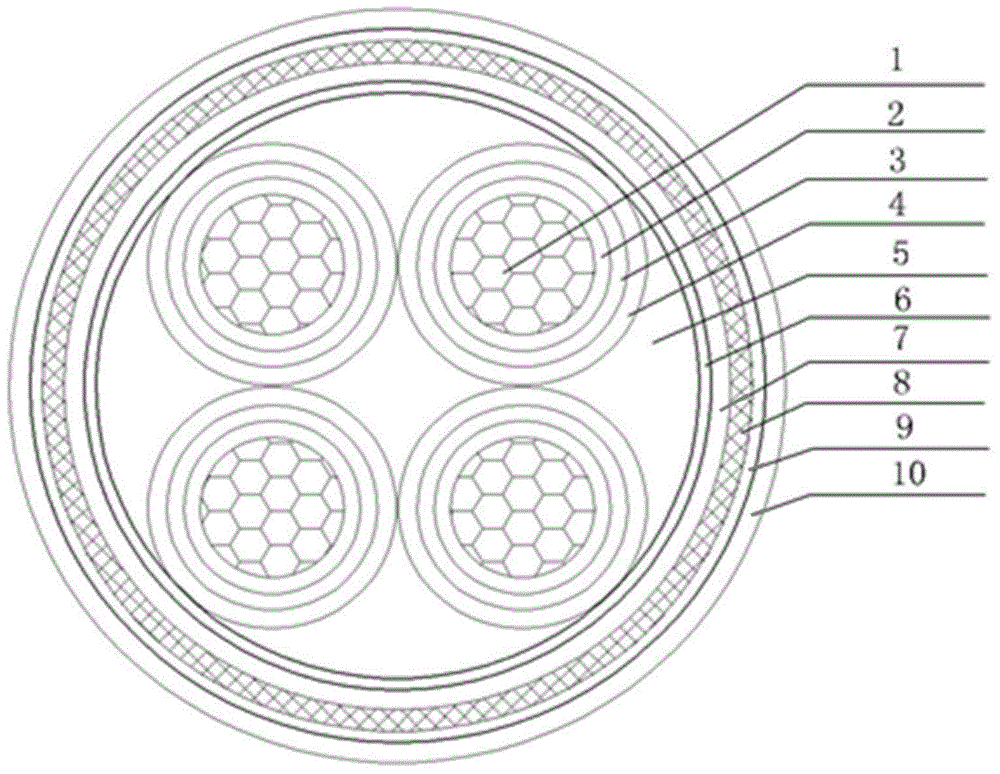

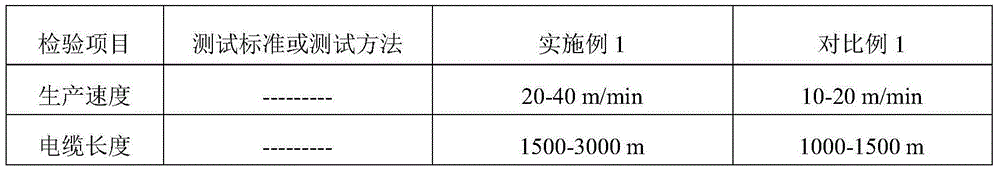

Mineral insulated metal sheath fireproof cable and preparation method thereof

PendingCN106297971AReduce diameter sizeImprove the role of external defenseInsulated cablesCable/conductor manufactureInsulation layerElectrical conductor

The invention discloses a mineral insulated metal sheath fireproof cable and a preparation method thereof. The cable comprises a cable core, a mineral matter oxygen barrier layer, an inner flame retardation layer, a mineral matter fireproof expansion layer, a metal reinforcing layer, an outer flame retardation layer and an oversheath; the cable core comprises insulating cores, and each insulating core is wrapped in an aluminum metal sheathe and an anticorrosion plastic layers successively; a mineral matter insulation layer services as an external layer of each insulating core, and internally provided with metal conductors; and the cable core is wrapped in the mineral matter oxygen barrier layer, the inner flame retardation layer, the mineral matter fireproof expansion layer, the metal reinforcing layer, the outer flame retardation layer and the oversheath successively. The cable of the invention can reach the CWZ grade of BS6387 standard, and satisfy 2h of fireproof bump test prescribed by the BS8491 standard, the production speed is high, the whole cable can be produced in a continuous and long manner, onsite installation technology is simple, and the cable can be applied to power distribution, illumination, control and alarm systems requiring for circuit completeness.

Owner:上海市高桥电缆厂有限公司

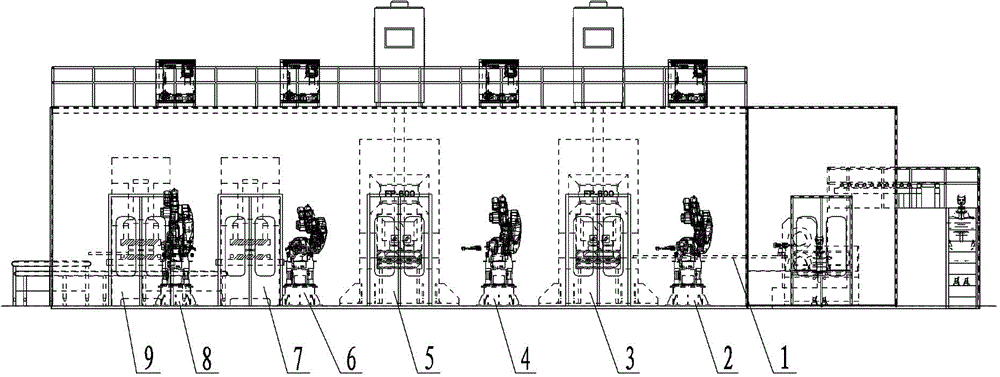

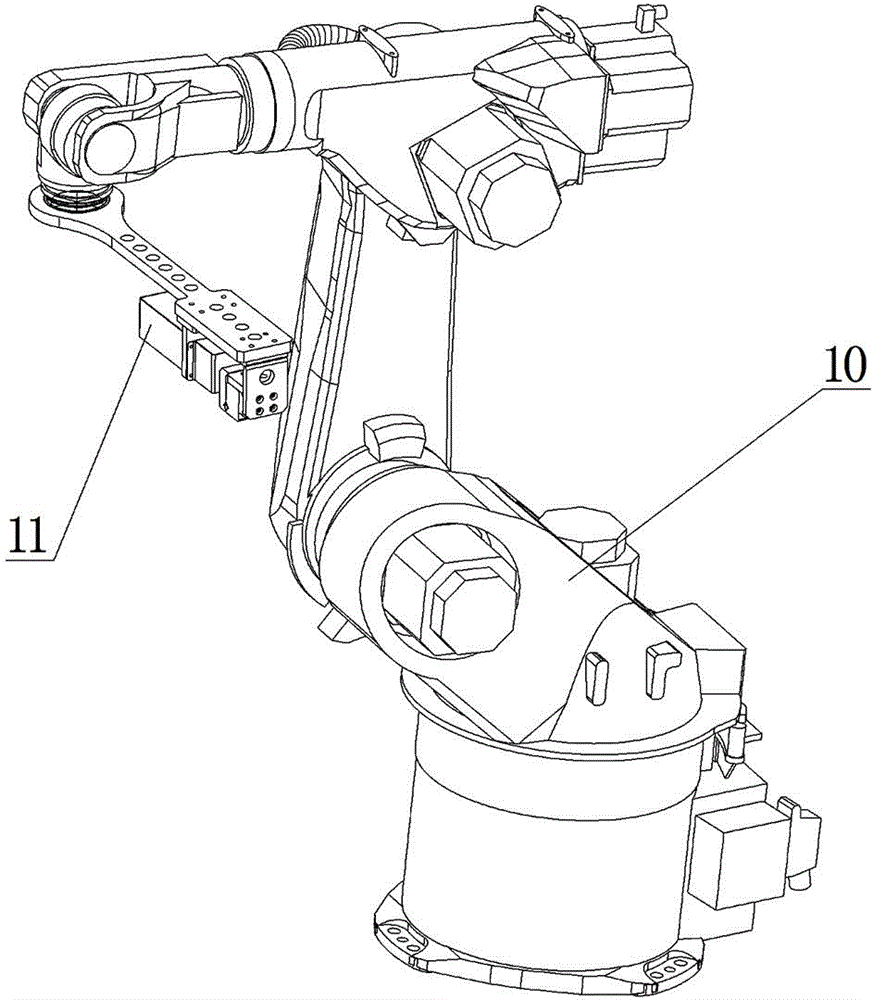

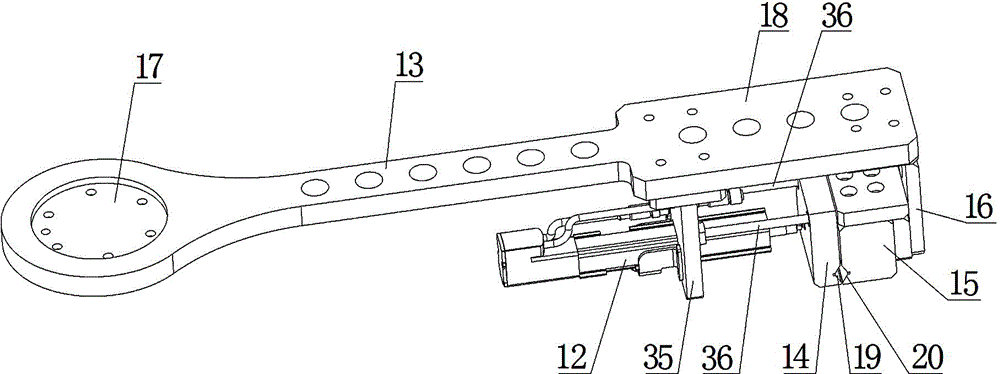

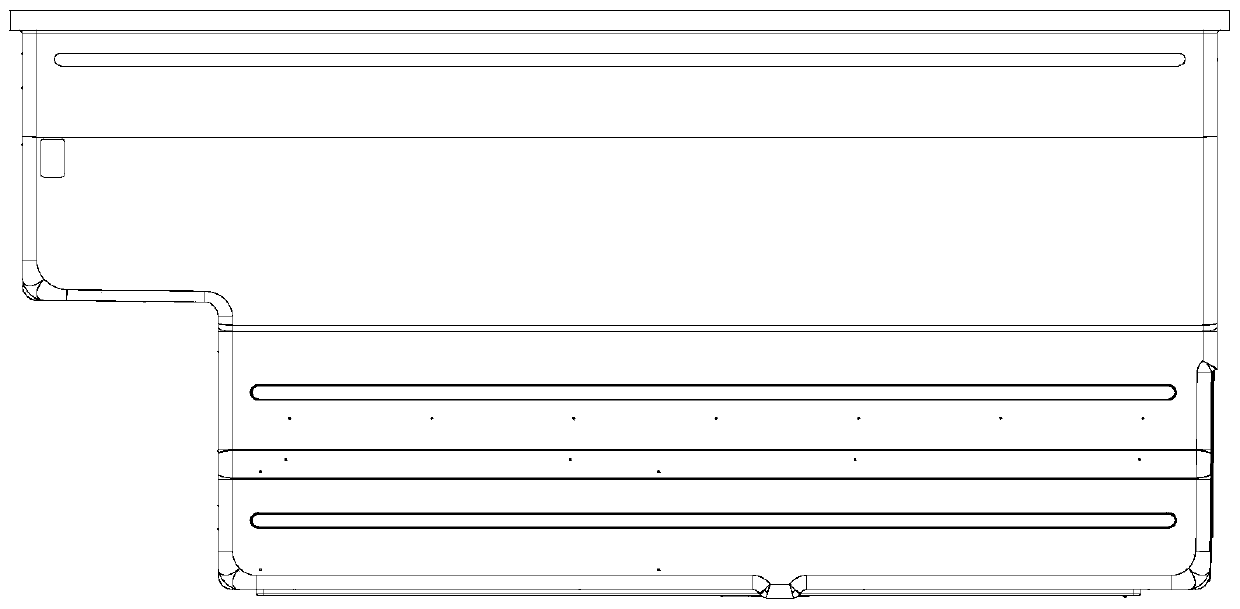

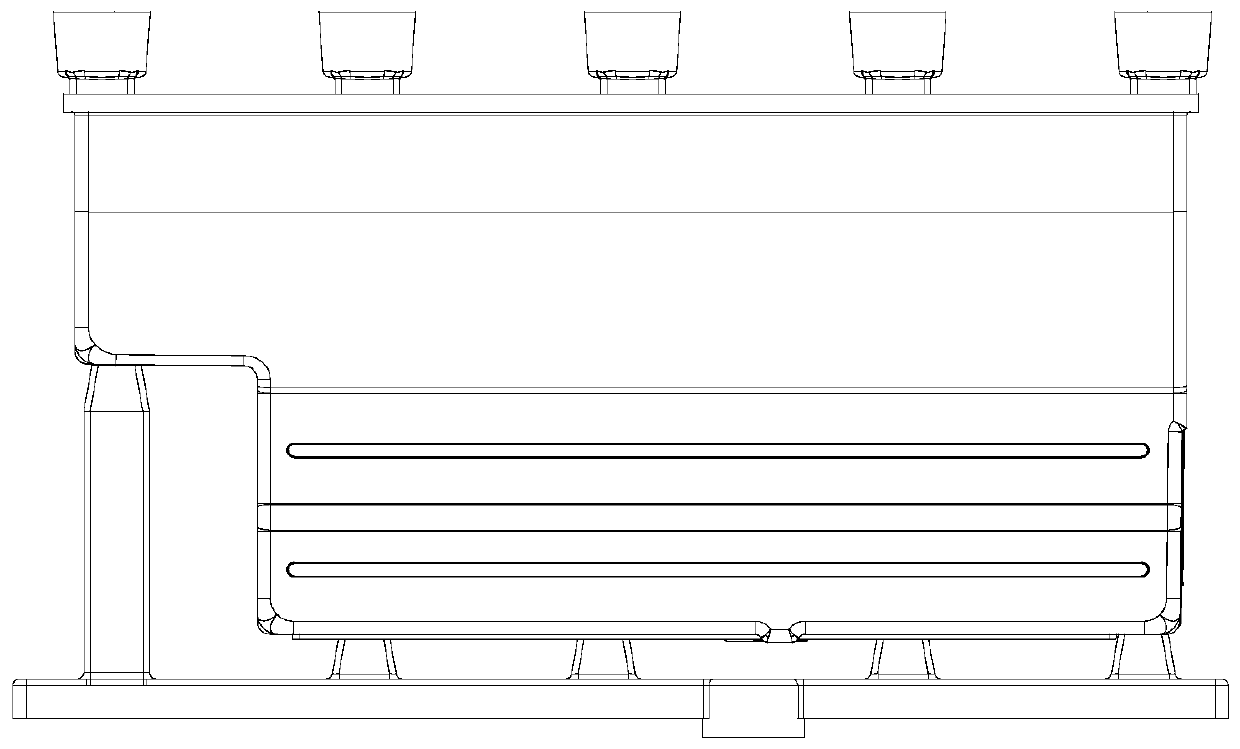

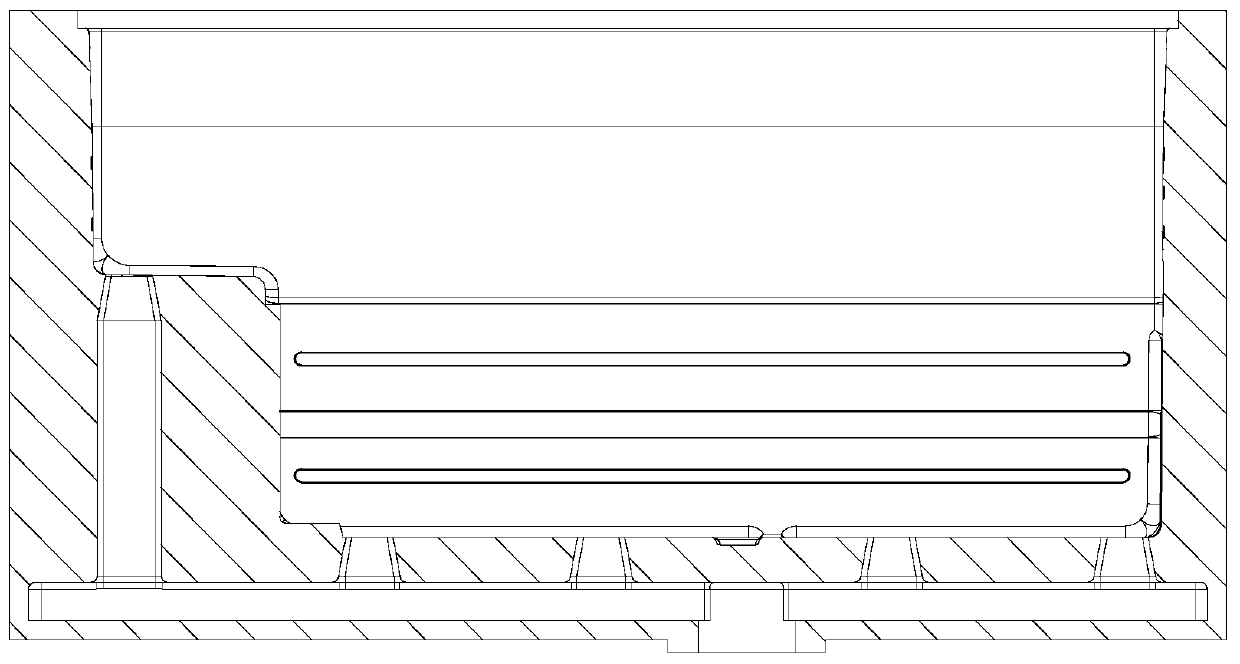

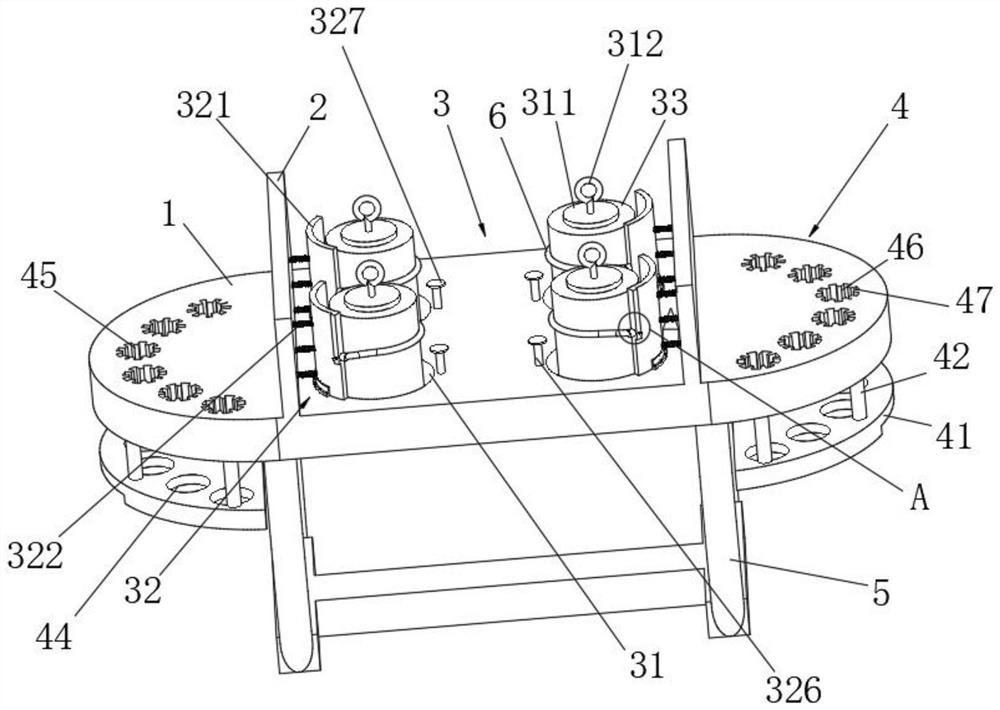

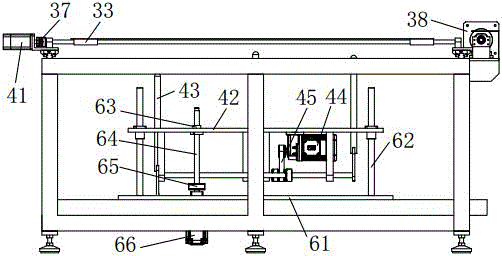

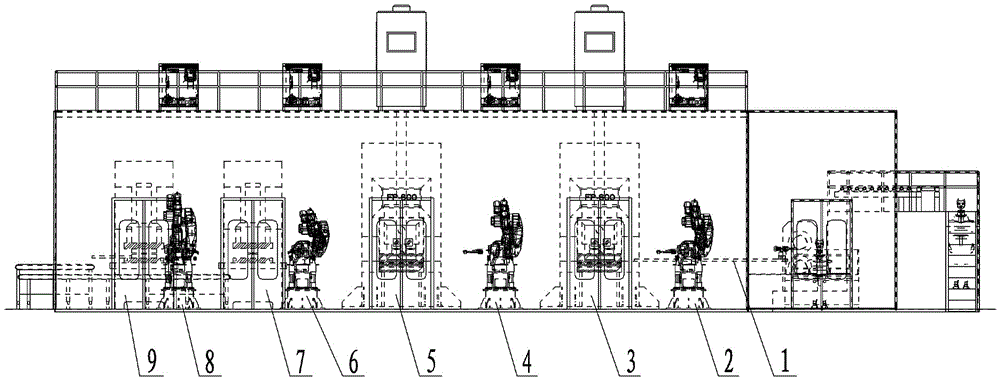

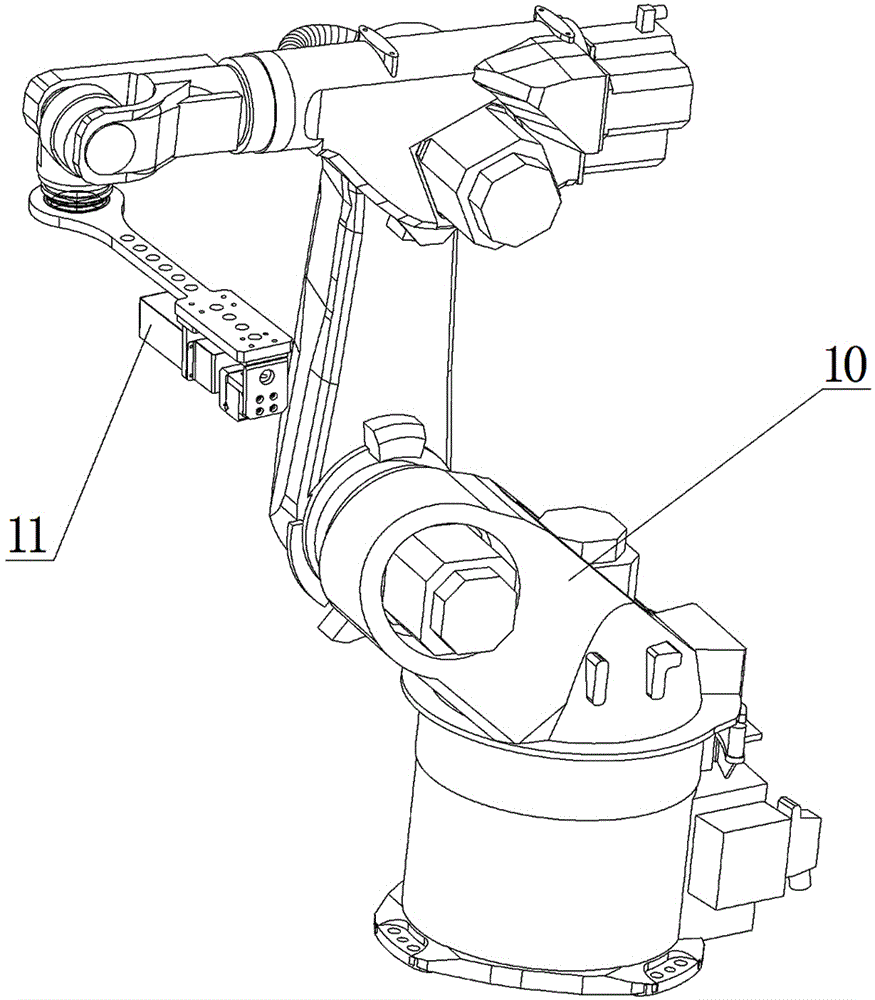

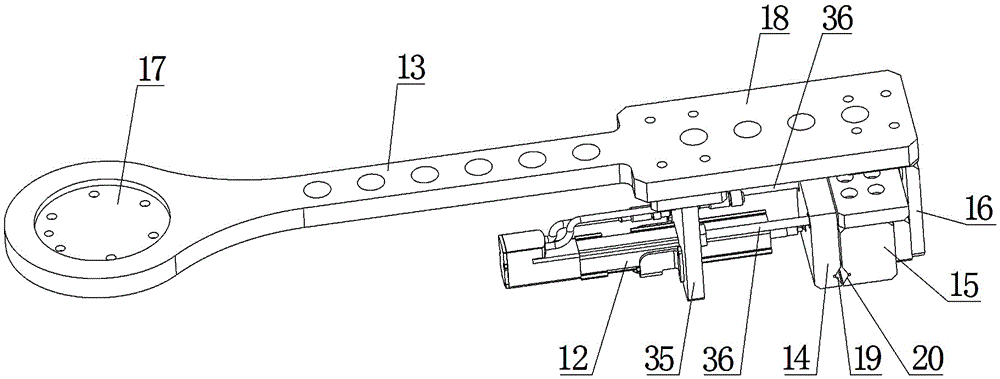

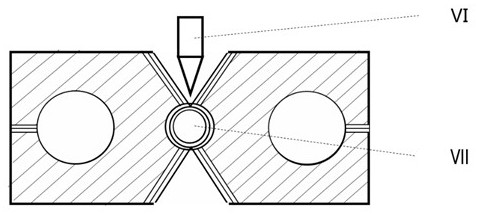

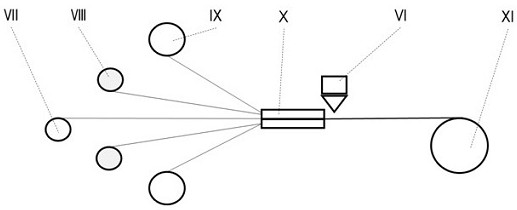

Hot-die forging system for engine connecting rod

ActiveCN104550592AGuarantee the safety of lifeProtect healthForging/hammering/pressing machinesOther manufacturing equipments/toolsEngineeringMachine press

The invention discloses a hot-die forging system for an engine connecting rod. The hot-die forging system consists of a blank getting slide table (1), a rough forging robot (2), a hot-die rough forging machine (3), a finish forging robot (4), a hot-die finish forging machine (5), a trimming robot (6), a trimming press (7), a correcting robot (8) and a correcting press (9) which are arranged in a machine room and arranged from the right to the left in sequence, wherein a high-decibel soundproof anti-noise device and a soot purifier are arranged in a room body of the machine room. The hot-die forging system has the benefits that the production efficiency is high, the labor intensity of a worker is greatly relieved, the remote operation can be safely and reliably realized, and clamping damages of the engine connecting rod are effectively avoided.

Owner:CHENGDU HUANLONG AUTOMOBILE EQUIP CO LTD

Mold-free formation casting method of high-performance aluminum alloy casting

PendingCN111408690AImprove product qualityImprove the manufacturing environmentAdditive manufacturing apparatusFoundry mouldsMetallic materialsIndustrial engineering

The invention belongs to the technical field of metal material machining and forming and particularly relates to a mold-free formation casting method of a high-performance aluminum alloy casting. Themold-free formation casting method comprises the steps that a shell mold is rapidly manufactured by the adoption of a 3D printing technology, box burying and tamping are conducted in a V-method shaping manner, and then a low-pressure technology is adopted to conduct pouring. According to the implementation scheme, the problem that by the adoption of a traditional casting technology, precise casting of a complicated large-sized metal component and a small batch of individualized products is quite difficult to achieve, a near-net forming technology is achieved, the product quality of the castingis greatly improved, the production and manufacturing environment is improved, the labor intensity is lowered, and environment-friendly casting basically can be achieved. Besides, by the adoption ofthe mold-free formation casting method of the high-performance aluminum alloy casting, the product can achieve that the structure is more complicated, the performance is more excellent, the quality ismore elaborate, manufacturing is more efficient and the cost performance ratio is more reasonable, and the product has good application prospect.

Owner:CHUZHOU JINNUO INDAL

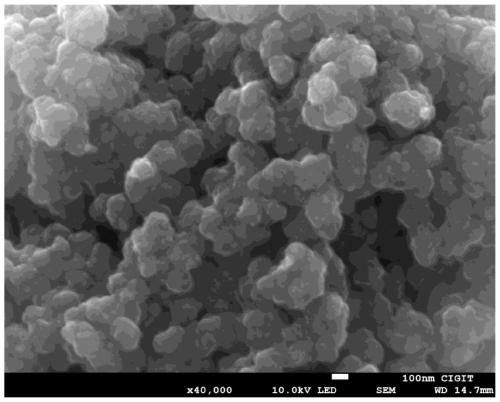

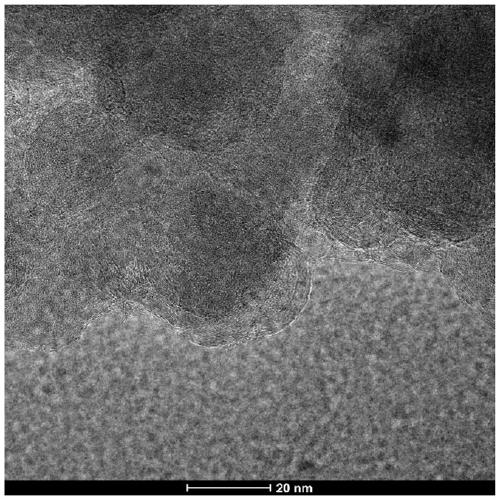

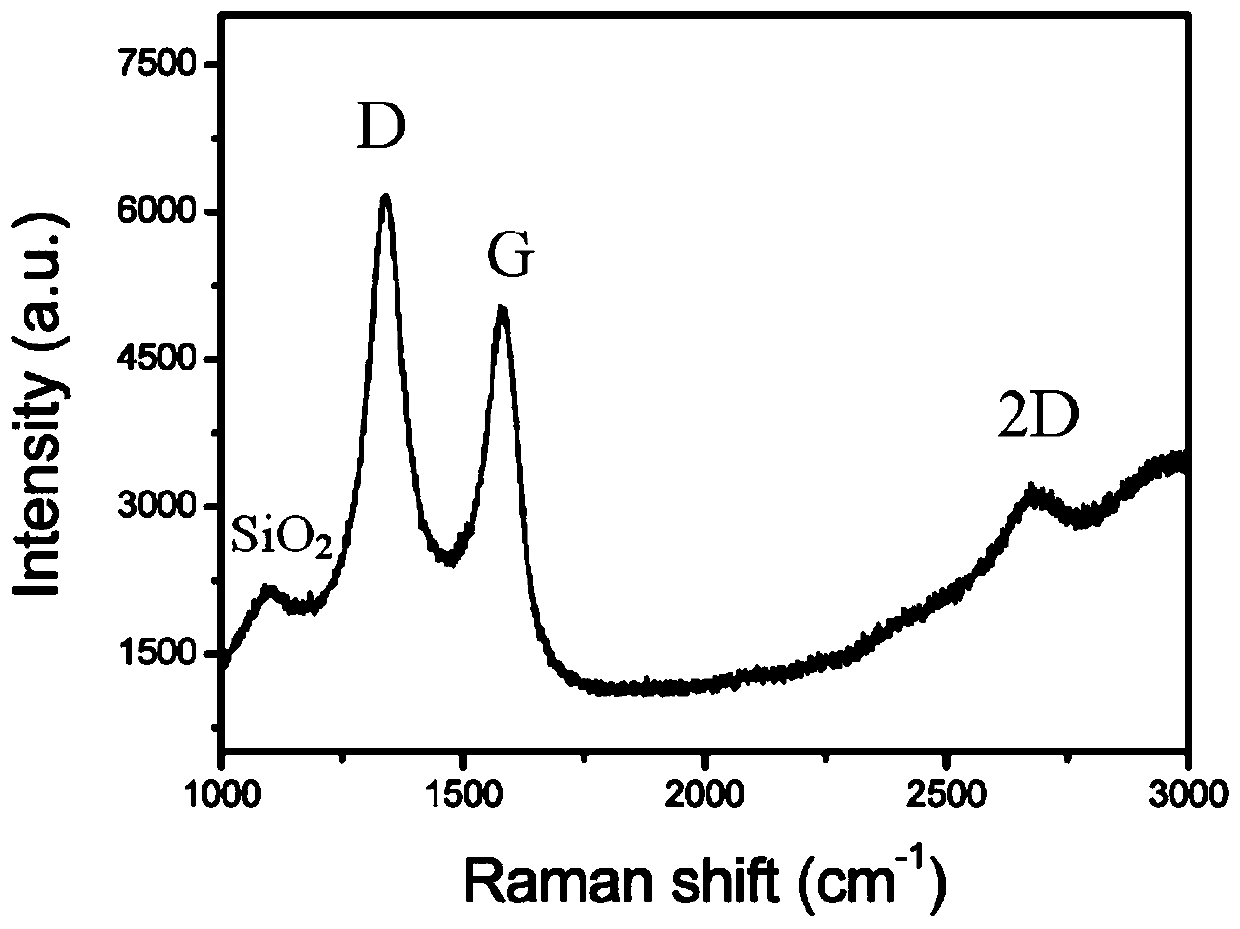

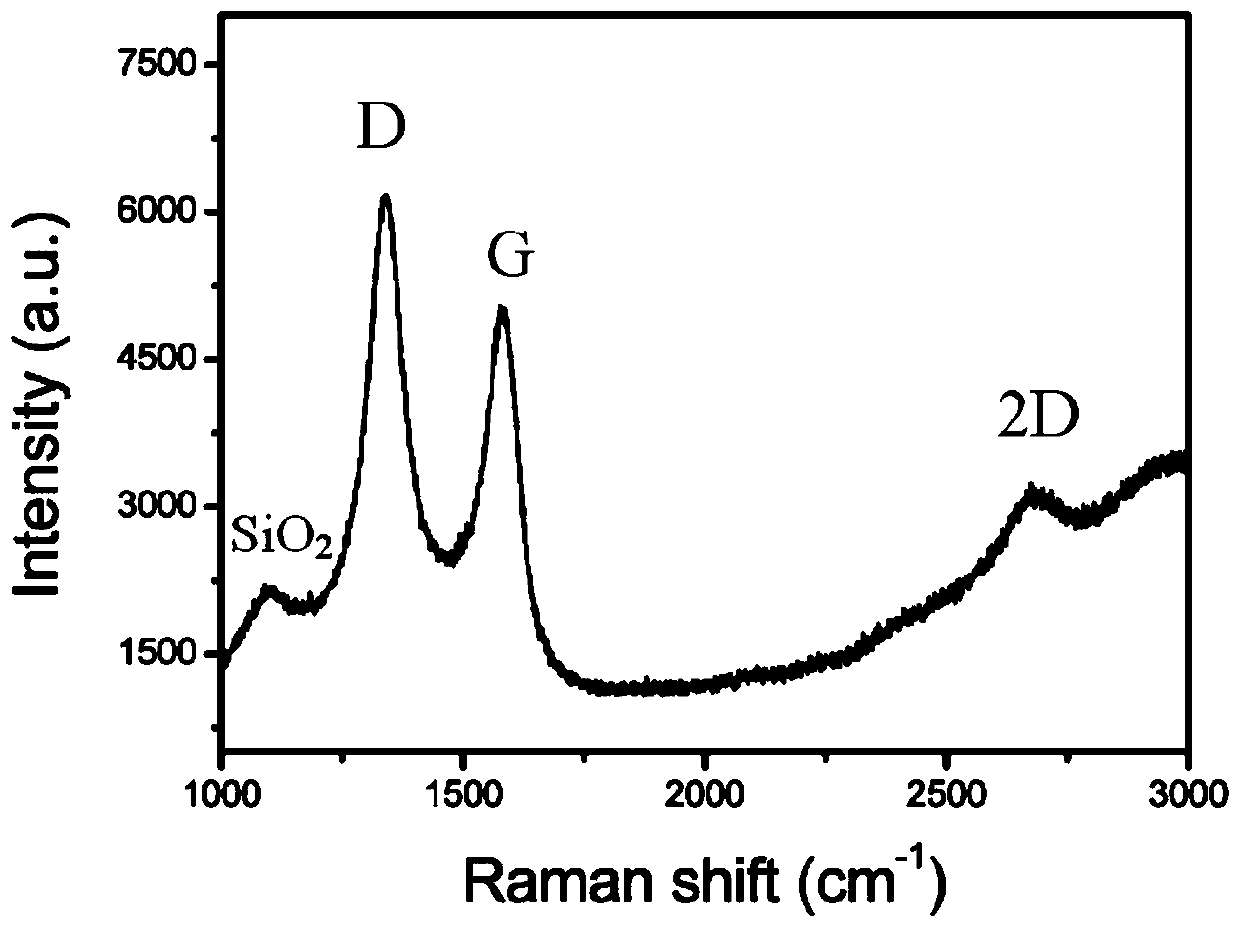

Method for preparing silicon dioxide/graphene nano composite material by microwave chemical vapor deposition and product thereof

ActiveCN109957784AThe process is simpler and more convenientReduce manufacturing costChemical vapor deposition coatingMaterials preparationMicrowave method

The invention discloses a method for preparing a silicon dioxide / graphene nano composite material by microwave chemical vapor deposition and a product thereof, and belongs to the technical field of composite material preparation. According to the method for preparing the silicon dioxide / graphene nano composite material by microwave chemical vapor deposition, a microwave vapor deposition method isadopted to prepare the silicon dioxide / graphene composite material in situ, and other pre-synthesis processes are not required, so that the preparation process is simple, and the production cost is reduced; and meanwhile, the microwave method has the characteristics of fast heating, high efficiency, low energy consumption and short production period. The silicon dioxide / graphene nano composite material is provided with a core-shell structure, and can combine the characteristics of high mechanical strength and high hardness of silicon dioxide with the advantages of high conductivity and the like of graphene, so that the composite material has high conductivity and high mechanical strength.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Preparation method of photo sensitive resin binding agent sand wheel

A process for preparing the adhesive disc with photosensitive resin as adhesive includes such steps as preparing the metallic base of abrasive disc, mixing photosensitive resin with abrasive particles, stirring, installing said metallic base onto rotary platform, rotating, coating said mixture on one surface of metallic base, optical solidifying, coating the mixture on its back, and optical solidifying.

Owner:ZHEJIANG UNIV OF TECH

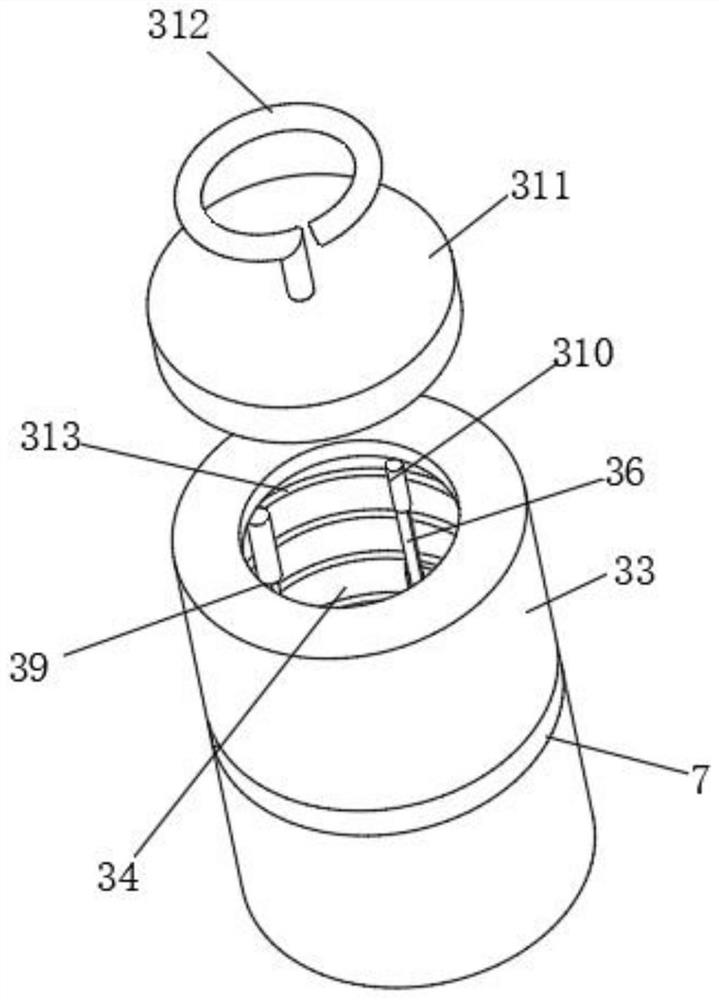

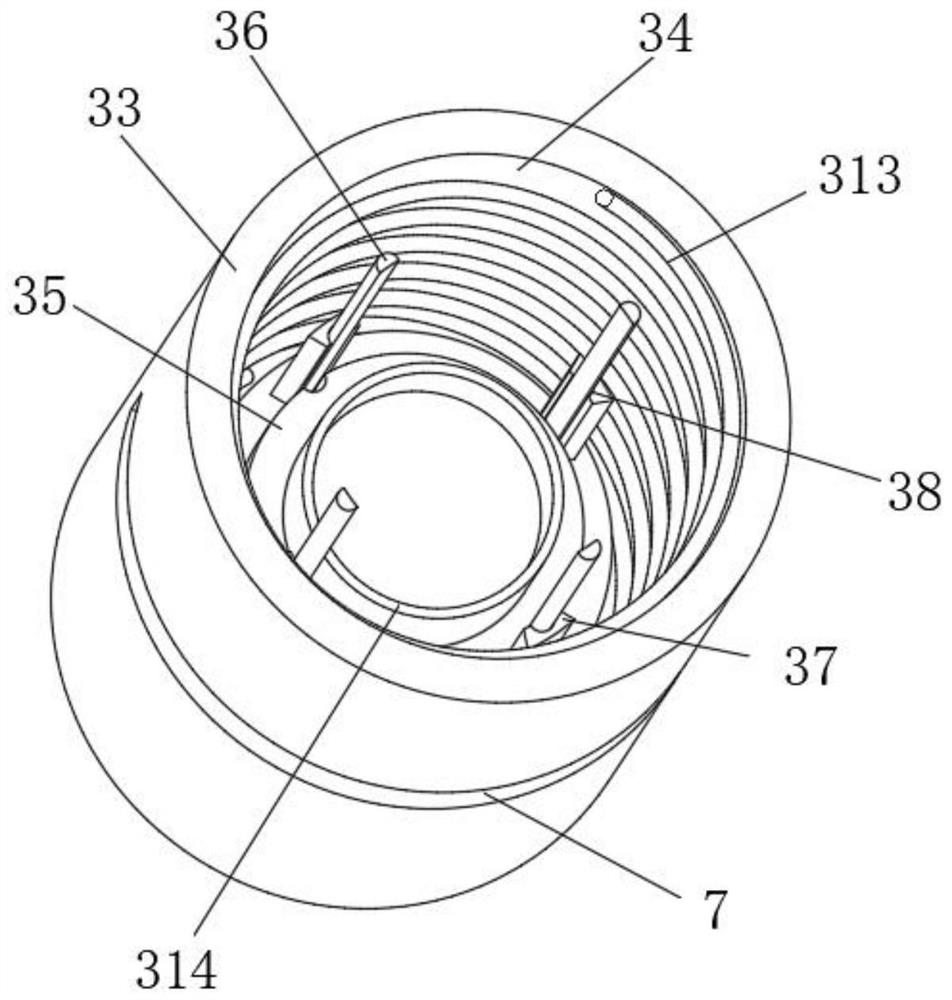

Urine stem cell preparation equipment

InactiveCN111925936AReduces the chance of humans touching the petri dishReduce the chance of contaminationBioreactor/fermenter combinationsBiological substance pretreatmentsStem like cellUrine

The invention discloses urine stem cell preparation equipment, and particularly relates to the field of stem cell preparation, the urine stem cell preparation equipment comprises a preparation workbench, two partition plates are arranged on the upper surface of the preparation workbench, a preparation mechanism is arranged between the two partition plates, two placement mechanisms are arranged onthe opposite sides of the two partition plates, and the number of the placement mechanisms is two. The preparation mechanism is arranged; a culture dish is placed in the culture barrel; a good preparation environment is provided for stem cell preparation by utilizing the leakproofness of the cavity; meanwhile, the culture dish can be conveniently taken out by pulling the limiting strips; the probability of artificial contact with the culture dish is reduced, the probability of contamination of the culture dish is further reduced, meanwhile, an inclination mechanism is arranged, a pressing threaded rod is rotated, a culture barrel is driven to incline according to the lever principle, a worker can conveniently transfer liquid to a culture medium, culture operation on urine stem cells is facilitated, and actual use is facilitated.

Owner:陈龙刚

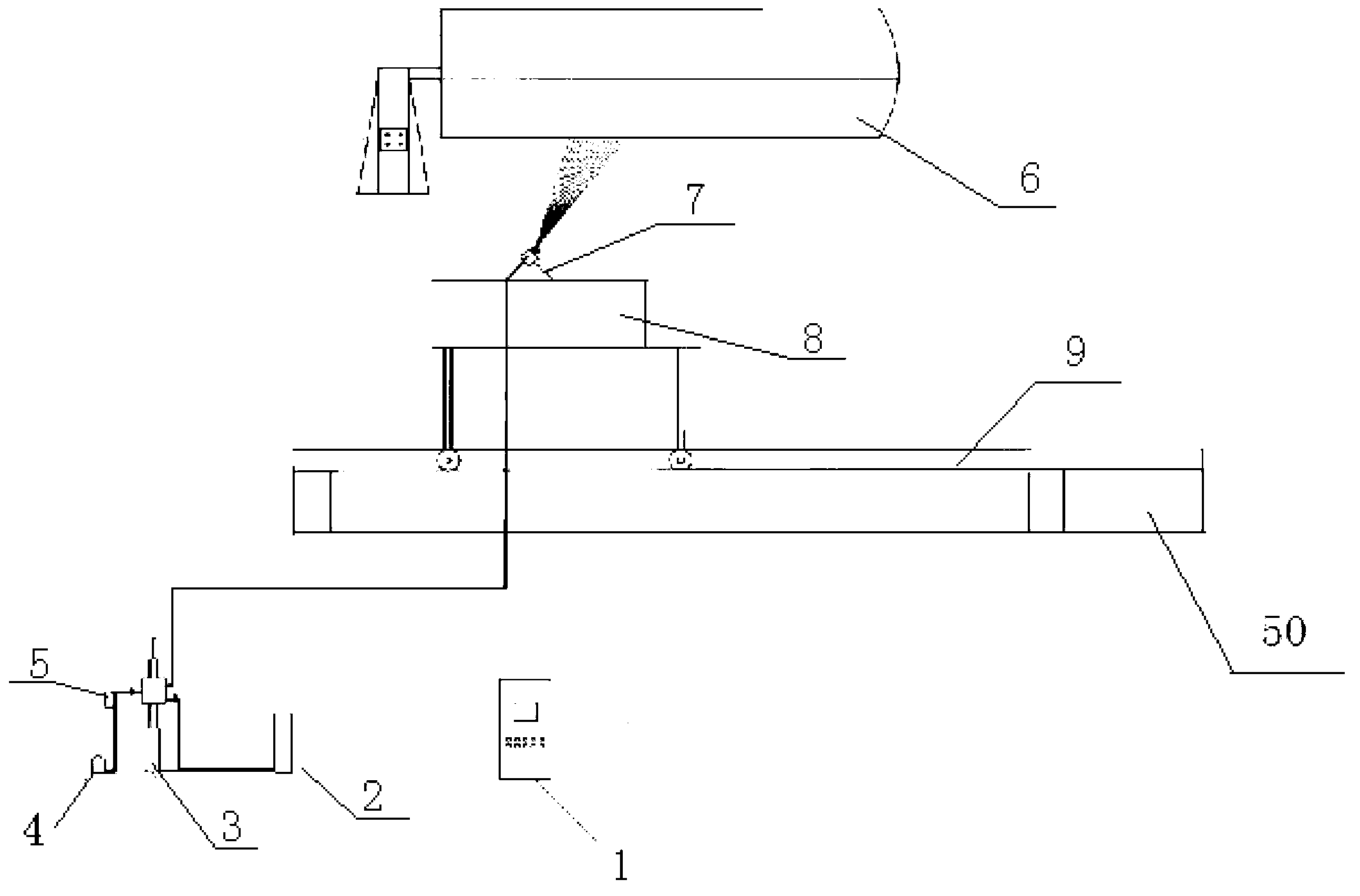

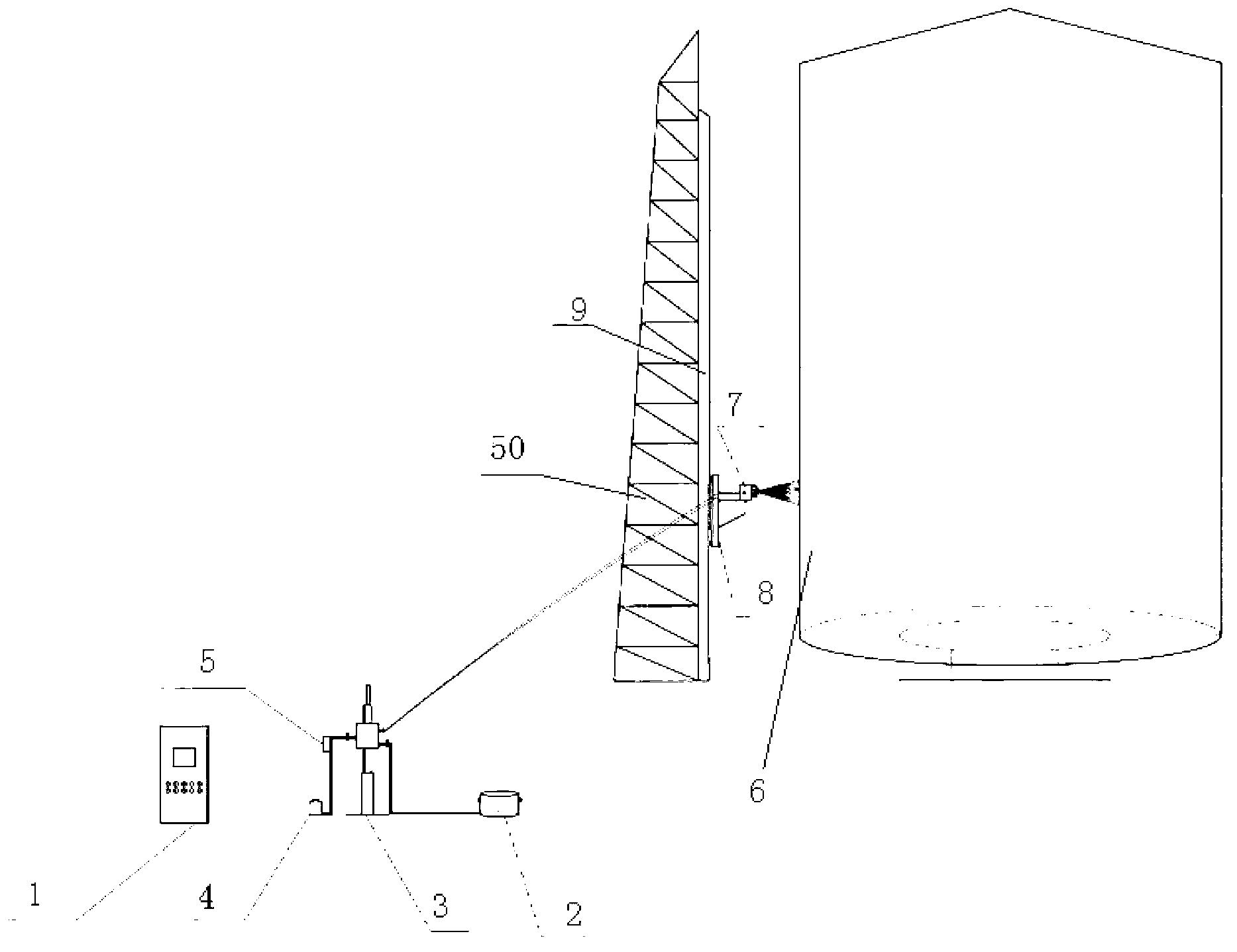

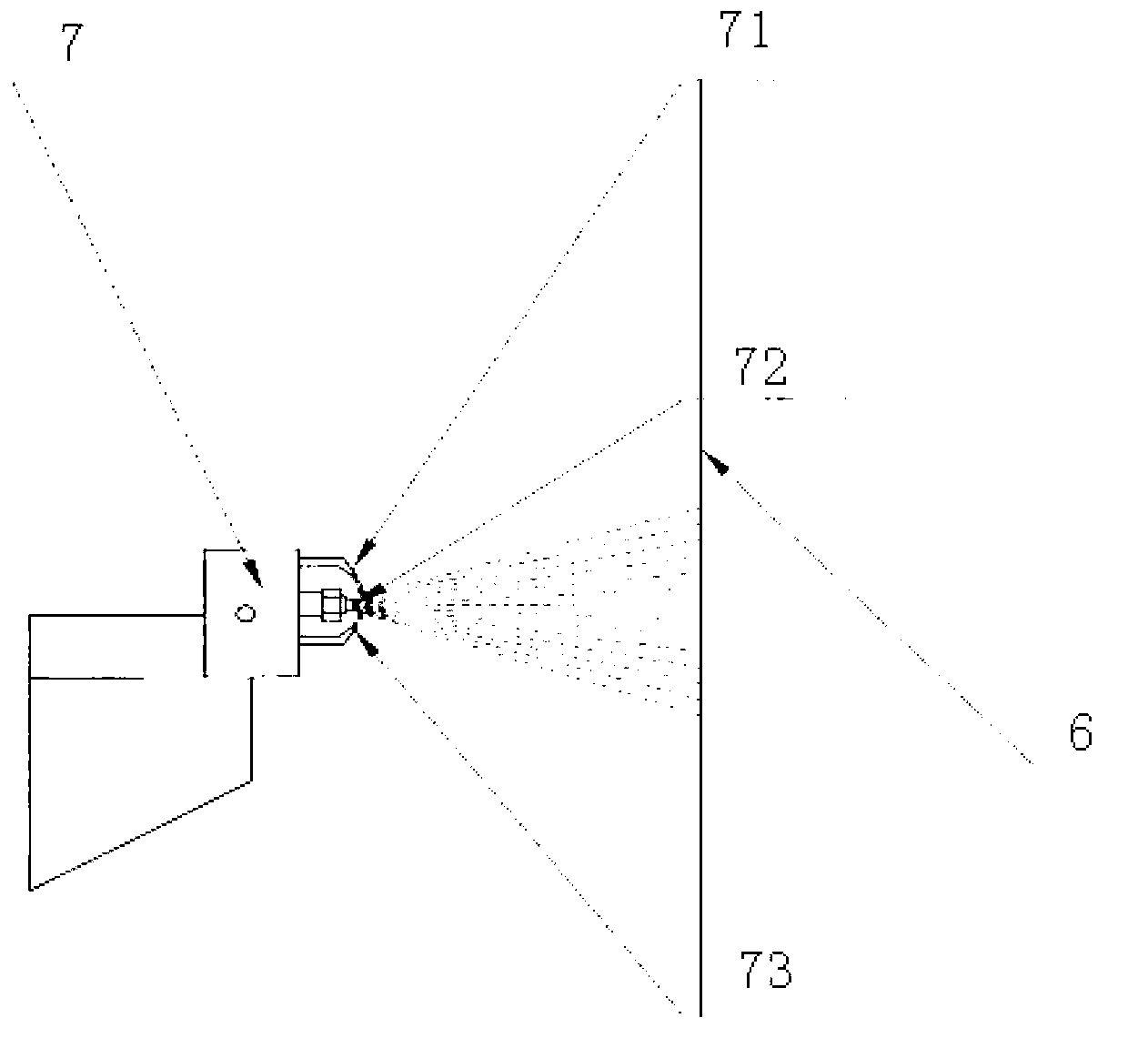

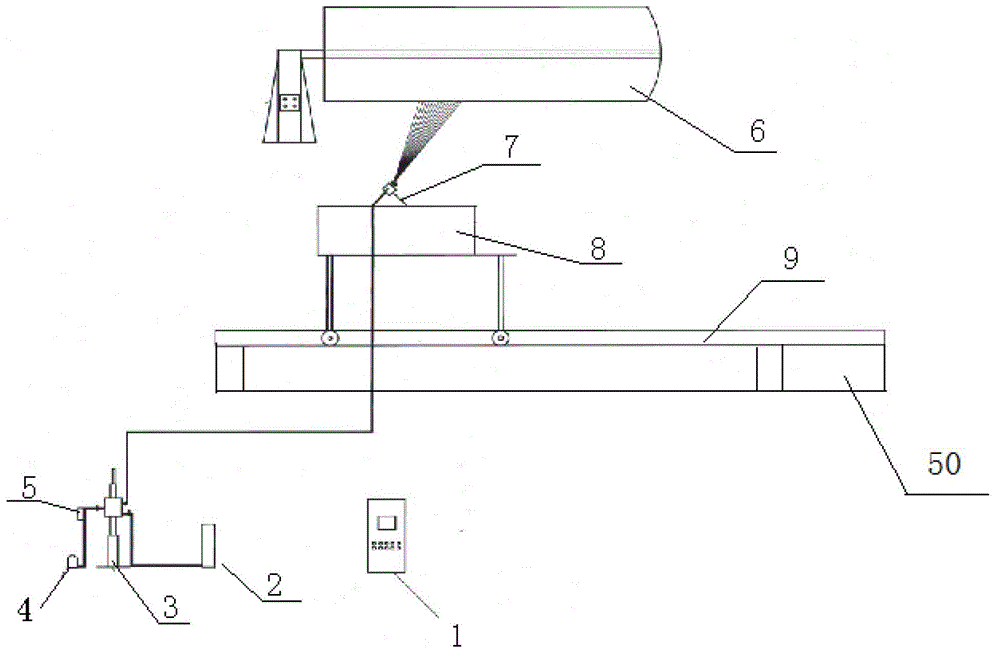

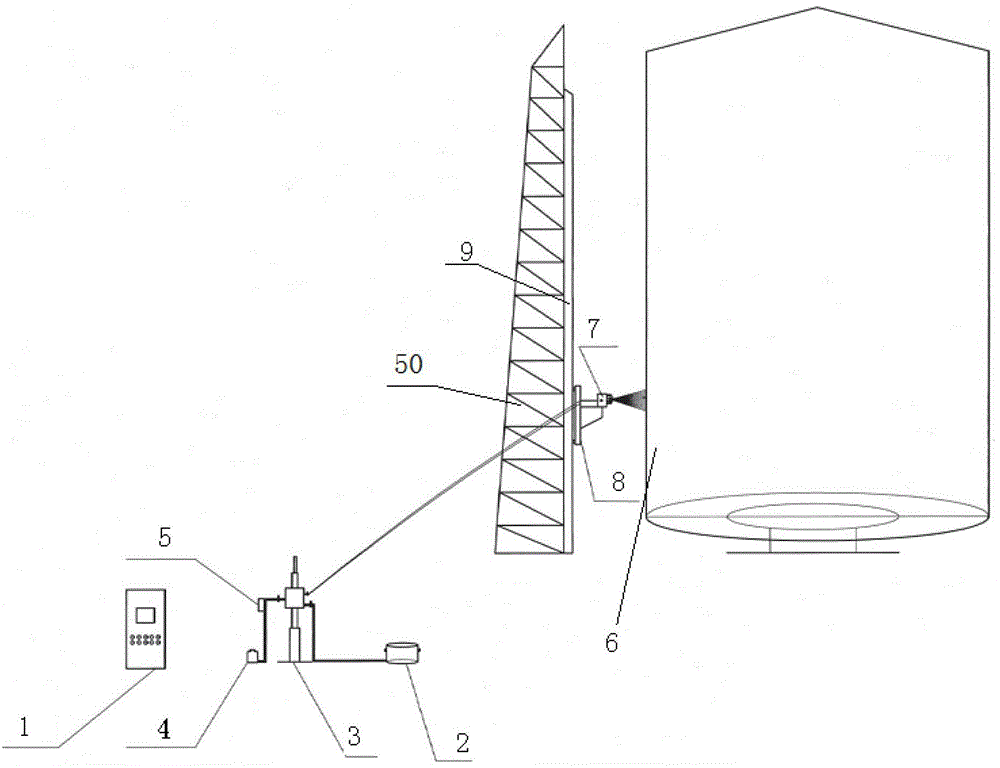

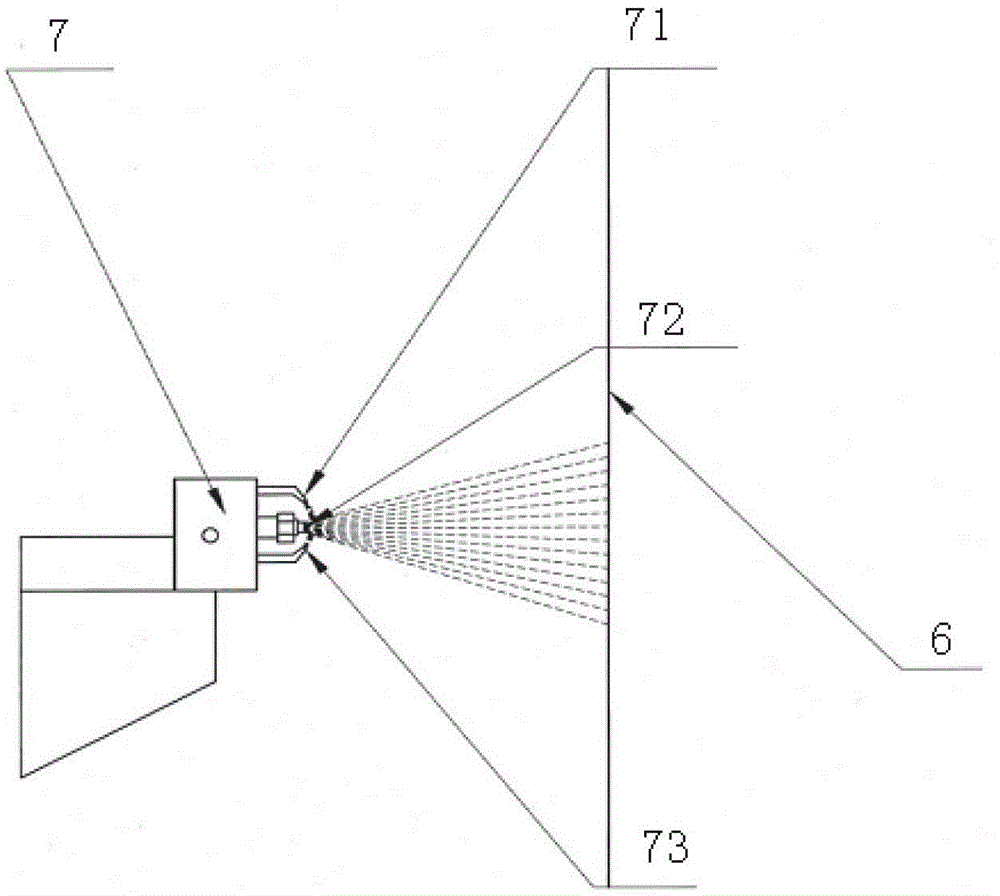

Glass reinforced plastic forming method and glass reinforced plastic forming system

ActiveCN103302866AImprove production efficiency and product qualityImprove the production environmentCoatingsSpray nozzleEngineering

The invention discloses a glass reinforced plastic forming method and a glass reinforced plastic forming system. The method comprises the following steps of: respectively pressurizing a phenolic resin feed liquid, a solidified agent and a glass fiber so as to spurt in a shape of fans and converge through three nozzlesof a spraying gun, wherein the fan-shaped injection surfaces of the solidified agent and the glass fiber are respectively positioned on the two sides of the injection surface formed by phenolic resin so as to spurt; injecting the solidifying feed liquid after converging under the propulsion of the injection pressure of the bakelite feed liquid in a fan shape to the target injection surface, and curing and forming the solidifying feed liquid on the target injection surface. The glass reinforced plastic forming method and the glass reinforced plastic forming system provided by the invention have the advantages that a purpose that the spraying gun is used for injecting so as to uniformly mix the phenolic resin, the solidified agent and the glass fiber is achieved through regulating the viscosity of the bakelite feed liquid, the bakelite forming efficiency is improved, the manufacture environment of employees is improved, and a gummosis condition meets a field injecting liner manufacturing process.

Owner:ZHONGYI GLASS FIBER REINFORCED PLASTICS

Catalyst and preparation process of tert-butyl isothiocyanate

ActiveCN111450857AEasy to separateImprove the manufacturing environmentPhysical/chemical process catalystsOrganic chemistryButyl isothiocyanatePtru catalyst

The invention discloses a catalyst and a preparation process of tert-butyl isothiocyanate. The catalyst is dry hydrogen chloride gas. The preparation method comprises the following steps: taking 70-85parts by mass of ammonium thiocyanate, 200 parts by mass of water, 65-90 parts by mass of 85% tert-butyl alcohol and 200-250 parts by mass of 30% hydrochloric acid, dissolving ammonium thiocyanate inwater, adding 85% tert-butyl alcohol, heating, dropwise adding 30% hydrochloric acid, standing for layering, taking an upper-layer material, transferring the upper-layer material into a drying container, heating to 50-60 DEG C, carrying out vacuumizing operation, introducing dry hydrogen chloride gas into a vacuumizing drying container, closing a valve until the drying container returns to normalpressure, maintaining for 30+ / -5 minutes, and carrying out nitrogen replacement to obtain tert-butyl isothiocyanate. According to the method, the dried hydrogen chloride gas is used as the catalyst for preparing tert-butyl isothiocyanate, hydrogen chloride is easy to separate, no by-product is generated, the prepared tert-butyl isothiocyanate reaches 98% or above, and meanwhile, the preparation environment of tert-butyl isothiocyanate can be effectively improved.

Owner:江苏再拓生物科技有限公司

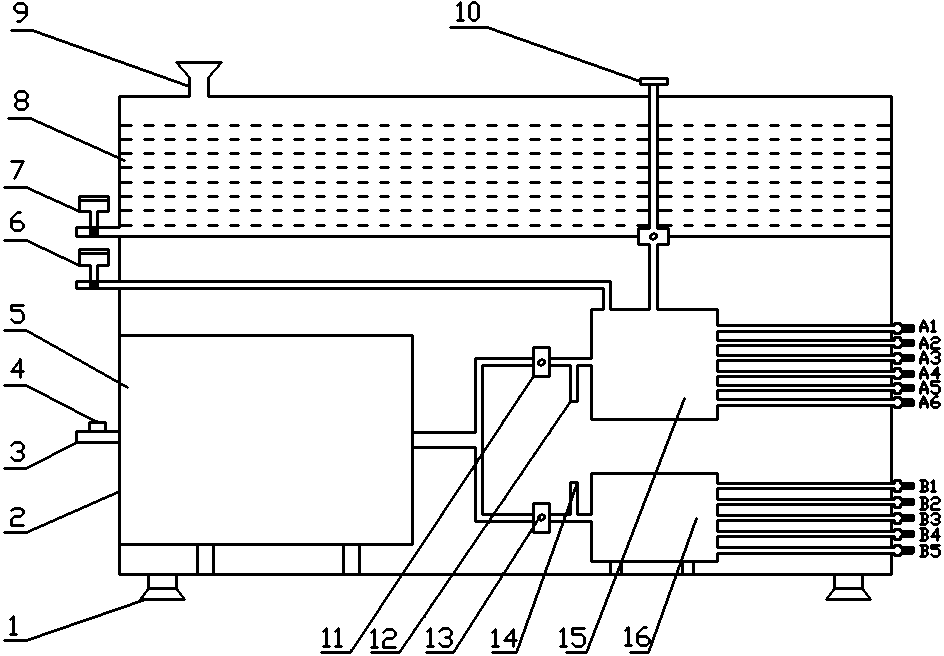

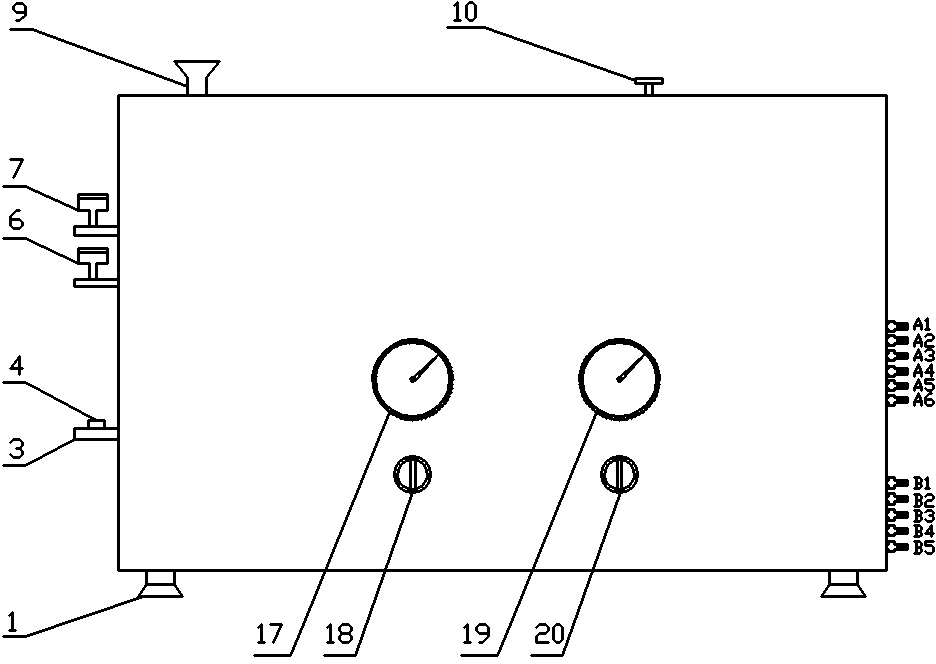

Lubricating device used for wheel machining

InactiveCN107685253AMeet the lubrication process requirementsReduce manufacturing costMaintainance and safety accessoriesFuel tankAir compressor

The invention provides a lubricating device used for wheel machining. The lubricating device used for wheel machining is composed of an air compressor, a safety valve, an oil drain valve, an oil tank,an oil filling port, an oil quantity regulation valve, an oil mist pressure regulation valve and the like. The air compressor is fixed to a rack. The output end of the air compressor is divided intotwo paths, one path is connected with the oil mist pressure regulation valve, and the oil mist pressure regulation valve is externally connected with an oil mist pressure regulation knob; and the other path is connected with an air pressure regulation valve, and the air pressure regulation valve is externally connected with an air pressure regulation knob. An oil mist pressure gauge connector is arranged between the oil mist pressure regulation valve and an oil mist generator and externally connected with an oil mist pressure gauge. An air pressure gauge connector is arranged between the air pressure regulation valve and an air separator and externally connected with a compressed air pressure gauge. According to the lubricating device used for wheel machining, the lubrication technologicalrequirements of wheel machining can be met, a traditional lubricating method based on cutting fluid can be completely replaced by the lubricating device, the manufacturing cost is greatly reduced, and the manufacturing environment is improved; and the lubricating device has the characteristics of being simple in structure, easy to manufacture, convenient and fast to operate and the like.

Owner:CITIC DICASTAL

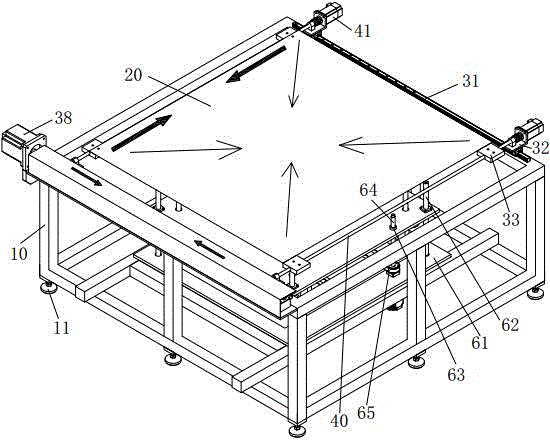

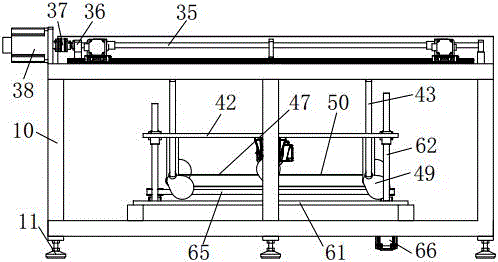

Fresh jasmine flower maintaining device for jasmine flower tea and use method of fresh jasmine flower maintaining device

PendingCN106387226ASimple structurePromotes opening and puffingTea substituesClimate change adaptationEngineeringCam

The invention relates to a fresh jasmine flower maintaining device for jasmine flower tea and a use method of the fresh jasmine flower maintaining device. The device comprises spreading and cooling cloth arranged on a machine frame, and a retraction and extension system for horizontally and longitudinally retracting and extending the spreading and cooling cloth, a cam vibrating system is arranged on the lower side of the spreading and cooling system, and a lifting mechanism for driving the cam vibrating system to life is also arranged at the lower part of the machine frame. The use method comprises the following steps of (1) separately enabling a sliding plate and cloth surface fixing plates to move in contrary directions through a first driving mechanism and a second driving mechanism, so that the spreading and cooling cloth is spread; (2) placing jasmine flower petals on the spreading and cooling cloth which is spread; (3) enabling lifting rods of cam mechanisms to realize lifting reciprocating movement through a third driving mechanism, so that the spreading and cooling cloth generates vibration at different places to achieve the purpose of flatly spreading the jasmine flower petals; and (4) after the jasmine flower petals are spread and cooled, separately enabling the sliding plate and the cloth surface fixing plates to realize opposite movement to retract the spreading and cooling cloth through the first driving mechanism and the second driving mechanism. The device is simple in structure and convenient used for performing spreading and cooling treatment on jasmine flower piles.

Owner:FUJIAN AGRI & FORESTRY UNIV

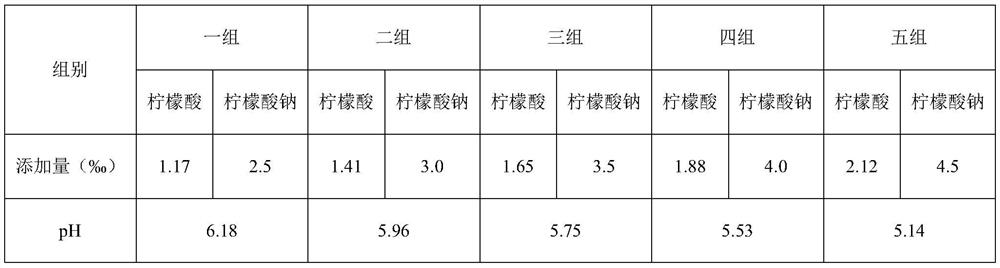

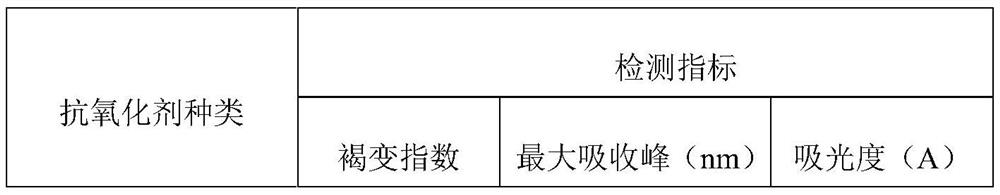

Preparation method of multi-color red beet concentrated juice

ActiveCN112385803ASimple processAvoid loss and fadingFood freezingFood preservationUltrafiltrationSugar beet

The invention discloses a preparation method of multi-color red beet concentrated juice. The preparation method includes washing, enzyme inactivation by electron beams, crushing, color protection, squeezing, centrifugation, ultrafiltration, concentration, sterilization, aseptic filling and irradiation treatment. The preparation method is simple in technology, has no damage to materials and abandons conventional high temperature enzyme inactivation methods; through the adoption of enzyme inactivation by electron beams, the loss and fading of the materials due to high temperature can be avoided;through electron-beam energy, enzyme inactivation effects can be precisely controlled, browning index can be decreased, and the color and nutrient compositions in red beets can be reserved to a greatextent; and products with multiple colors are prepared through different radiation doses, so that market application scope can be expanded, the demands for multiple colors can be provided, each colorcan be accurately monitored through a color difference meter, and therefore, the uniformity of color difference between finished products can be guaranteed.

Owner:湖北紫鑫生物科技有限公司

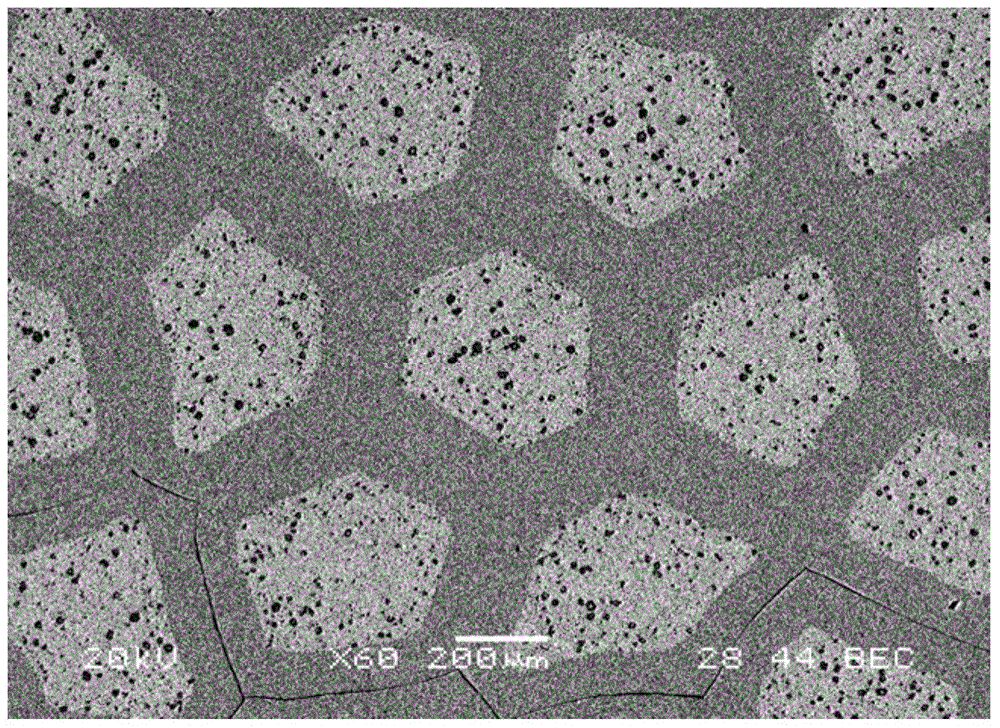

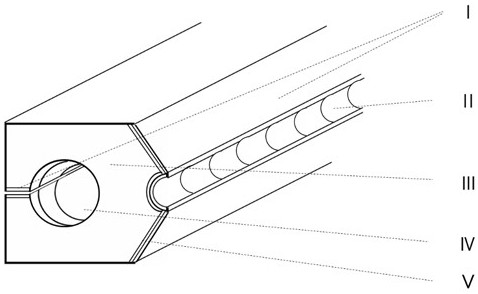

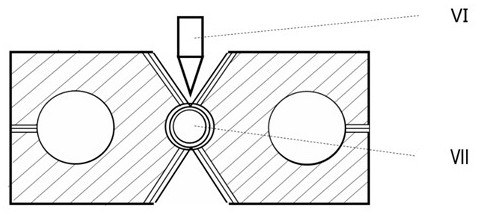

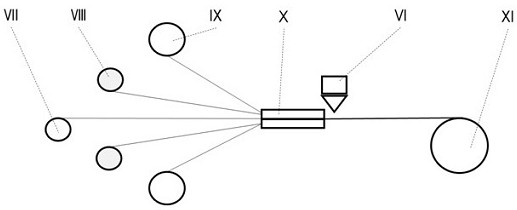

a kind of agsno 2 Preparation method of multi-core composite wire

ActiveCN104867622BEvenly distributedOrganizational structure is stableCable/conductor manufactureWire rodSoldering

The invention discloses a preparation method of an AgSnO2 multi-core composite wire rod. The method comprises the following steps: step 1, preparing a single-core composite sheath; step 2, soldering and sealing; step 3, carrying out hot extrusion treatment; step 4, drawing and acquiring a single-core composite wire rod; step 5, straightening, sizing, cutting off, carrying out acid pickling and drying; step 6, bundling and assembling the single-core composite wire rod, repeating processing technologies of the step 2, the step3 and the step 4 and acquiring a n-core composite wire rod; step 7, bundling and assembling the n-core composite wire rod, repeating the processing technologies of the step 2, the step3 and the step 4 and acquiring a n2-core composite wire rod; step 8, bundling and assembling the n2-core composite wire rod, carrying out the hot extrusion treatment and acquiring a n3-core composite wire rod whose cross section is round; step 9, drawing and acquiring the AgSnO2 multi-core composite wire rod. Through multiple times of bundling and assembling processes, uniform distribution of core threads and stability of an organization structure in the AgSnO2 multi-core composite wire rod are realized. An average size of the core threads is about dozens of nanometers. Combined with the heat treatment, a good Ag / SnO2 interface combination effect is formed.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

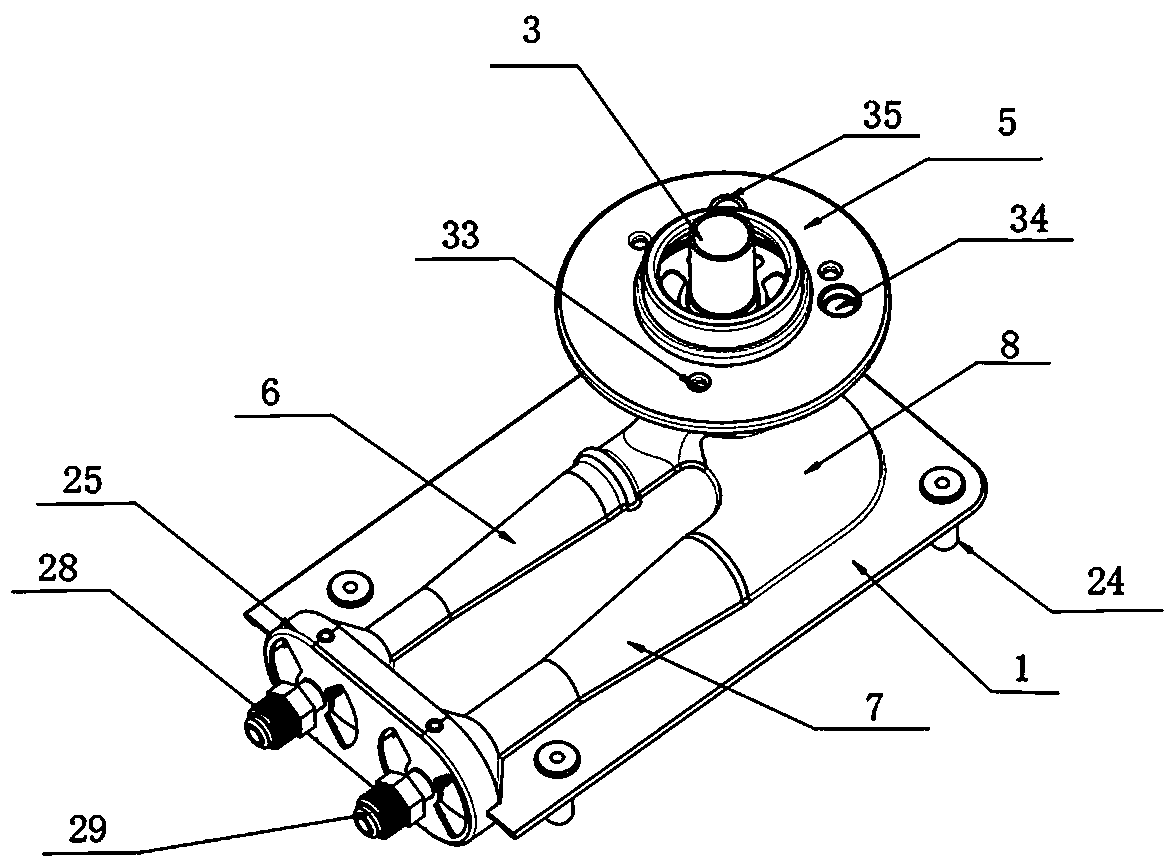

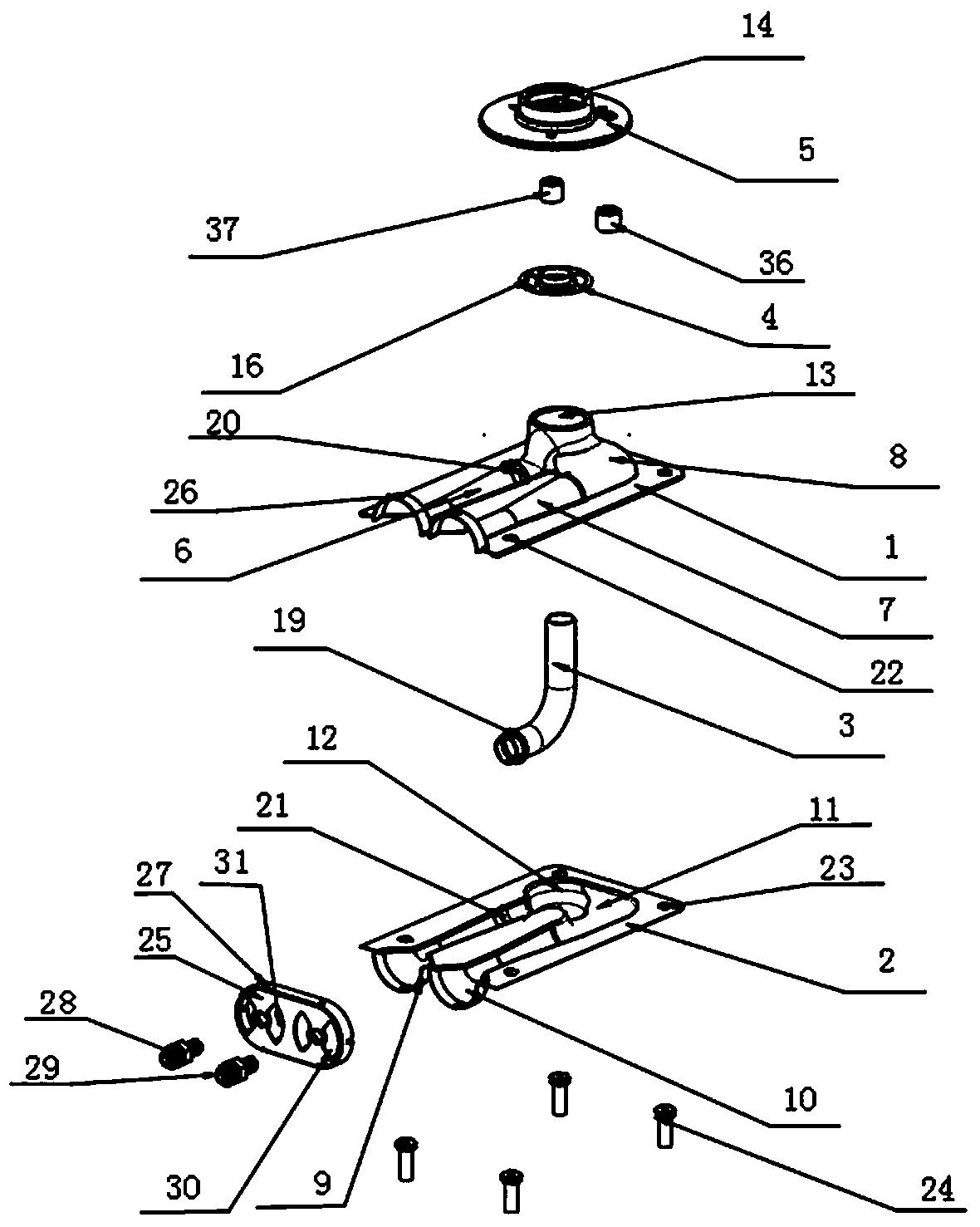

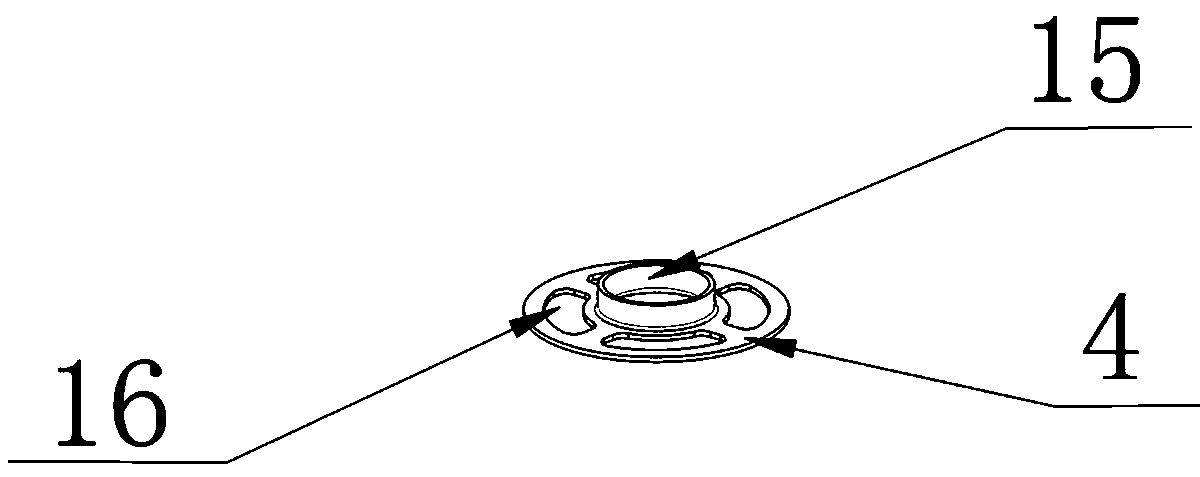

Furnace end of combustor

PendingCN110894946AHigh working reliabilityCompact structureGaseous fuel burnerThermodynamicsCombustor

The invention discloses a furnace end of a combustor, which comprises an upper cover, a lower bottom, a central mixing connecting pipe, a connecting pipe fixing disc and a mounting flange, wherein theupper cover covers the lower bottom; the upper cover is provided with a central fire ejector upper half part, a main fire ejector upper half part and a main fire upper half cover; the lower bottom isprovided with a central fire ejector lower half part, a main fire ejector lower half part and a main fire lower half cover; the central fire ejector upper half part and the central fire ejector lowerhalf part jointly form a central fire ejector; the main fire ejector upper half part and the main fire ejector lower half part jointly form a main fire ejector; a cavity defined by the main fire upper half cover and the main fire lower half cover is a main fire mixing cavity; the lower end of the center mixing connecting pipe penetrates through the main fire mixing cavity and then stretches intothe outlet end of the center fire ejector; and the upper end of the center mixing connecting pipe sequentially penetrates through a through hole in the main fire upper half cover, a center through hole of the connecting pipe fixing disc and a center through hole of the mounting flange from bottom to top and then stretches out to the position above the center through hole of the mounting flange. The space utilization rate is high, and the working reliability is high.

Owner:陈毅

Method for preparing silicon dioxide/graphene nanocomposite material by microwave chemical vapor deposition and product thereof

ActiveCN109957784BThe process is simpler and more convenientReduce manufacturing costChemical vapor deposition coatingGraphene nanocompositesMicrowave method

The invention discloses a method for preparing a silicon dioxide / graphene nano composite material by microwave chemical vapor deposition and a product thereof, and belongs to the technical field of composite material preparation. According to the method for preparing the silicon dioxide / graphene nano composite material by microwave chemical vapor deposition, a microwave vapor deposition method isadopted to prepare the silicon dioxide / graphene composite material in situ, and other pre-synthesis processes are not required, so that the preparation process is simple, and the production cost is reduced; and meanwhile, the microwave method has the characteristics of fast heating, high efficiency, low energy consumption and short production period. The silicon dioxide / graphene nano composite material is provided with a core-shell structure, and can combine the characteristics of high mechanical strength and high hardness of silicon dioxide with the advantages of high conductivity and the like of graphene, so that the composite material has high conductivity and high mechanical strength.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

A hot die forging system for engine connecting rod

ActiveCN104550592BGuarantee the safety of lifeProtect healthForging/hammering/pressing machinesOther manufacturing equipments/toolsEngineeringMachine press

The invention discloses a hot-die forging system for an engine connecting rod. The hot-die forging system consists of a blank getting slide table (1), a rough forging robot (2), a hot-die rough forging machine (3), a finish forging robot (4), a hot-die finish forging machine (5), a trimming robot (6), a trimming press (7), a correcting robot (8) and a correcting press (9) which are arranged in a machine room and arranged from the right to the left in sequence, wherein a high-decibel soundproof anti-noise device and a soot purifier are arranged in a room body of the machine room. The hot-die forging system has the benefits that the production efficiency is high, the labor intensity of a worker is greatly relieved, the remote operation can be safely and reliably realized, and clamping damages of the engine connecting rod are effectively avoided.

Owner:CHENGDU HUANLONG AUTOMOBILE EQUIP CO LTD

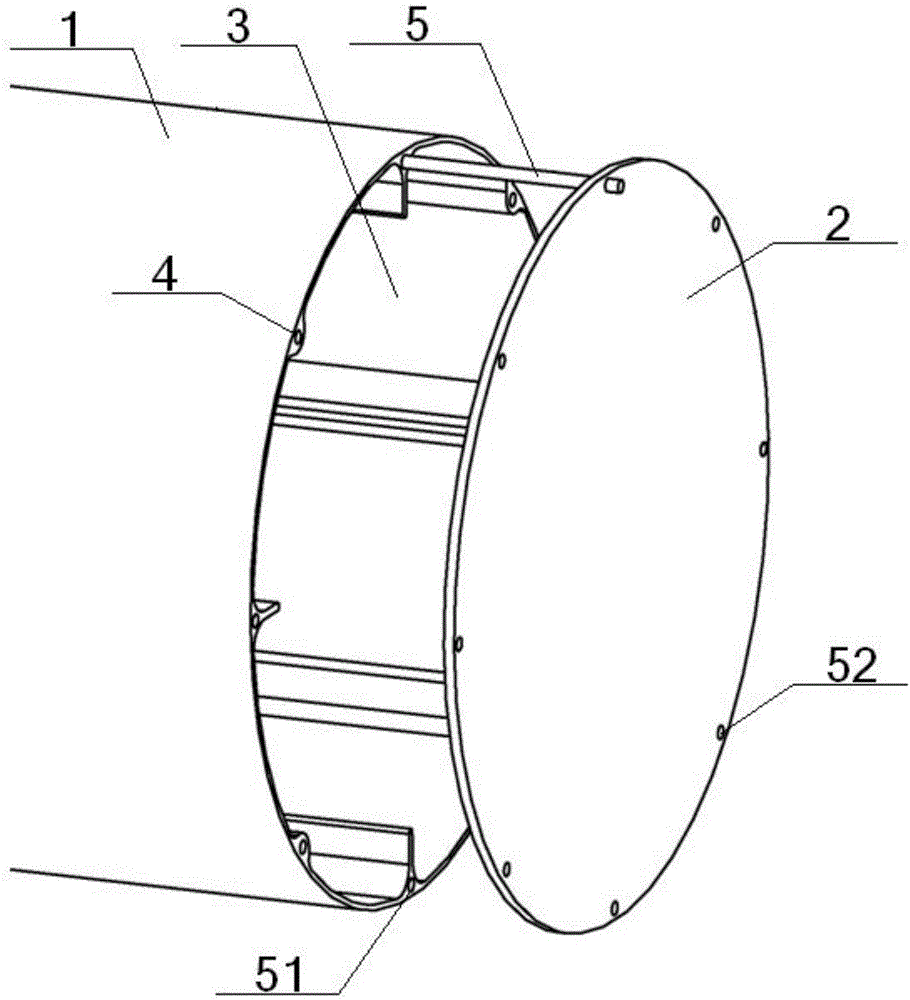

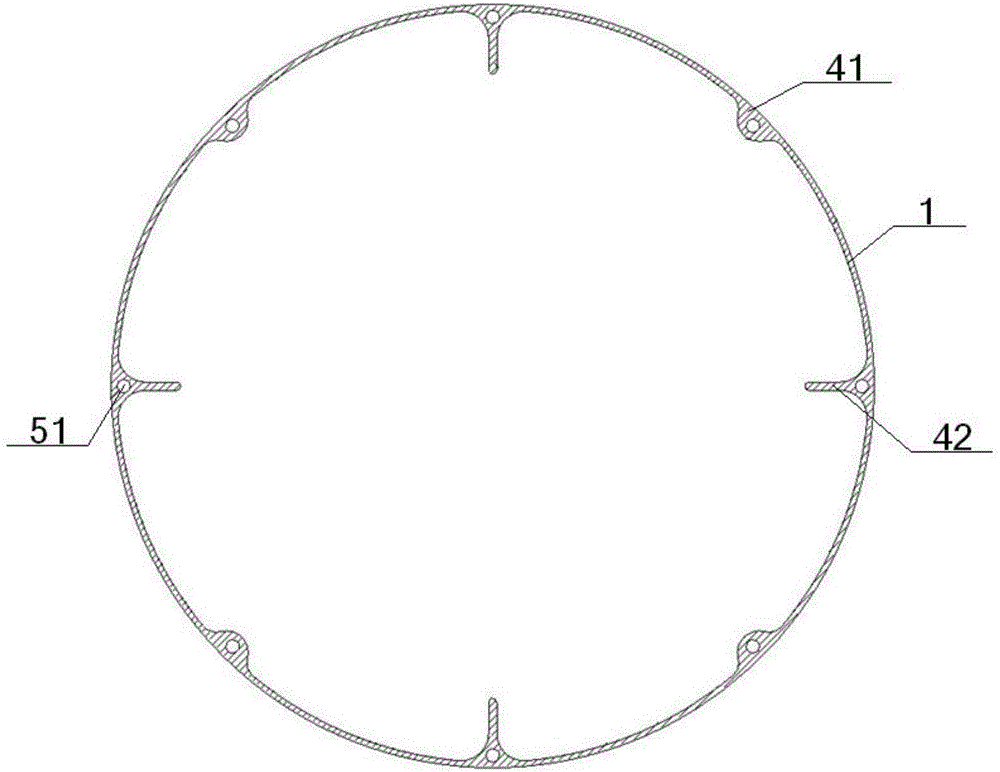

A kind of aluminum alloy air storage tank for vehicle

ActiveCN105674043BAchieve interconnectionStrong pressure resistanceVessel geometry/arrangement/sizeVessel wallsEngineeringWeld seam

The invention discloses an aluminum alloy air reservoir for a vehicle. The aluminum alloy air reservoir comprises a reservoir body, an end cover, reinforcing ribs and connecting rods, wherein the inner wall of the reservoir body is provided with the plurality of reinforcing ribs along the axis direction of the reservoir body; the bottoms of the reinforcing ribs are connected with the inner wall of the reservoir body, and the tops of the reinforcing ribs extend towards the inside of the reservoir body; rib threaded hole cavities are formed in parts close to the bottoms of the reinforcing ribs and are correspondingly connected with coverthreaded holes in the end cover through the connecting rods; the cross section of each reinforcing rib is boss-shaped, I-shaped or T-shaped; and the connecting rods are bolts, screws or rivets. Due to the adoption of the design, welding seams can be avoided, the pressure resistance and the safety can be improved, the stability of a manufacturing process can be improved, the utilization ratio of a material can be increased, the reject rate can be reduced, and the part manufacturing environment can also be improved.

Owner:DONGFENG COMML VEHICLE CO LTD

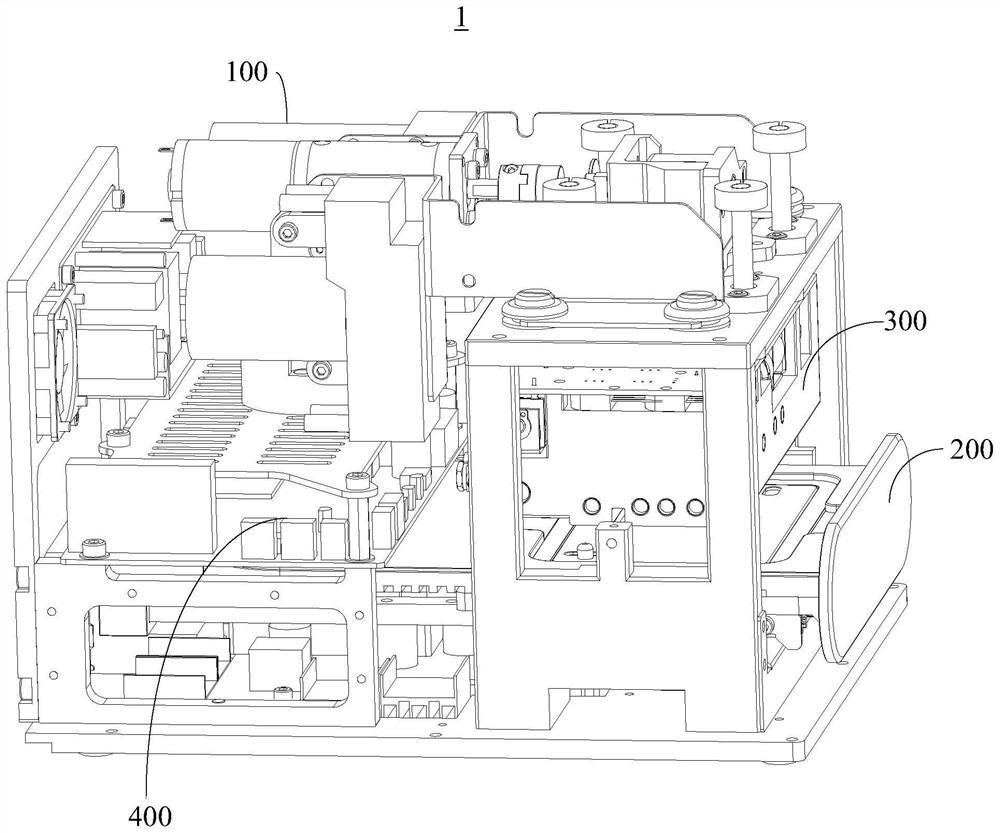

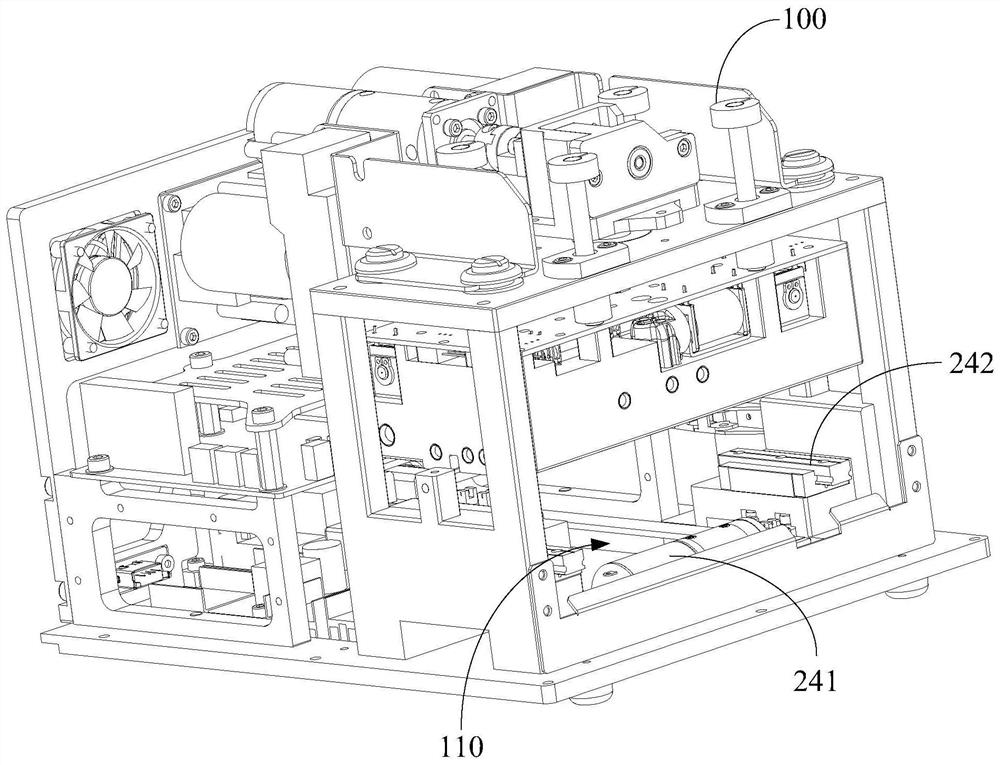

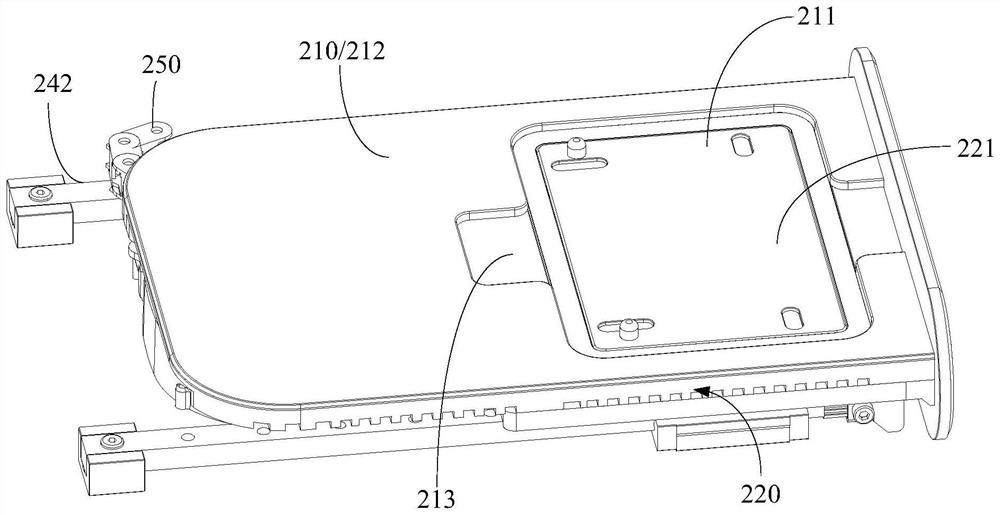

In-out warehouse assembly and single cell library preparation system

PendingCN114672884AImprove applicabilityImprove the manufacturing environmentLaboratory glasswaresLibraries apparatusTemperature controlProcess engineering

The invention discloses an in-and-out bin assembly and a single cell library preparation system, the in-and-out bin assembly comprises an in-and-out bin and a temperature control mechanism, and the in-and-out bin defines a mounting area for mounting a microfluidic chip; the temperature control mechanism is arranged in the in-out bin and at least acts on the micro-fluid chip in the installation area so as to control the temperature of the micro-fluid chip to be maintained within the target temperature interval. According to the invention, the in-out bin can be used for fixedly installing the microfluidic chip, and drives the microfluidic chip to enter and exit from the inner cavity of the housing of the single cell preparation library; the temperature control mechanism is arranged in the in-out bin and at least can adjust the temperature of the microfluidic chip, so that the microfluidic chip is always maintained in a target temperature range no matter whether the in-out bin and / or the single cell library preparation system is applied in a scene with a relatively high temperature or a relatively low temperature, a good preparation environment is ensured, and the applicability of the whole machine is improved.

Owner:BEIJING SEEKGENE BIOSCIENCES CO LTD

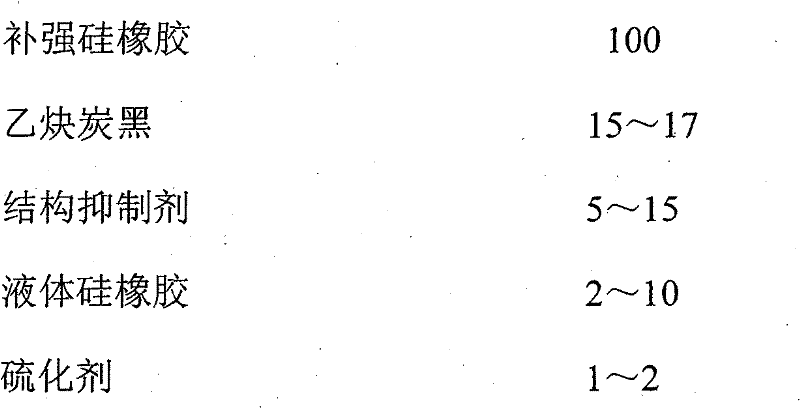

Electric silicon rubber

ActiveCN101260238BImprove conductivityGood for healthNon-conductive material with dispersed conductive materialHigh rateVolumetric Mass Density

A conductive silicon rubber relates to a material used in the accessories of electric wire and cable, and comprises reinforced silicon rubber, acetylene carbon black, structural inhibitor, liquid silicon rubber and vulcanizing agent, wherein the acetylene carbon black is granular. The making process of the conductive silicon rubber is as follows: the acetylene carbon black, hydroxyl silicon oil and water are mixed according to the proportion of 100:4.5-5.5:0.2-0.5, and then are added in a granulator to be made into granules. The conductive silicon rubber has the advantages that: because acetylene carbon black, the main raw material of the conductive silicon rubber, is turned into spheric granules with the diameter approximately equal to 1 mm from the original powdery state after pretreatment, the conductive silicon rubber has increased stacking density and is nondusty and easy to disperse, thereby substantially improving manufacturing environment and doing good to the physical health of operation staff; moreover, the acetylene carbon black has good conductive effect and can meet the requirements of electrical property with a small amount of addition (15 to 22 percent). In addition, due to the addition of gluing auxiliary agent, liquid silicon rubber, the conductive silicon rubber can be well glued to insulating glue, thereby obtaining higher rate of qualified product as well as mechanical property and electrical property superior to the requirements of national standards.

Owner:ZHEJIANG WANMA GROUP ELECTRIC

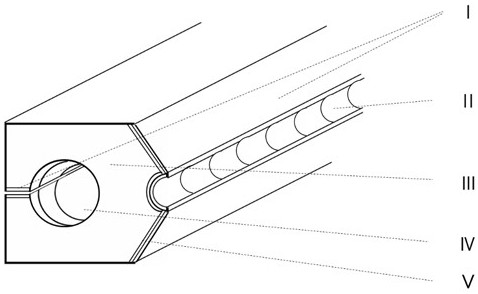

Butterfly-shaped optical cable, sheath strip for forming same, forming method and forming device

ActiveCN113467020AEasy maintenanceExtended service lifeFibre mechanical structuresForming faceEngineering

The invention discloses a butterfly-shaped optical cable, a sheath strip for forming the same, a forming method and a forming device. The butterfly-shaped optical cable comprises a sheath welding layer, a sheath flame-retardant layer and an optical fiber unit; wherein one side of the sheath welding layer is tightly attached to the optical fiber unit, and the other side of the sheath welding layer is provided with a sheath flame-retardant layer. The sheath strip comprises a flame-retardant layer component and a welding layer component, the flame-retardant layer component is provided with an arc-shaped matching surface matched with the optical fiber unit, and the welding layer component at least wraps the arc-shaped matching surface; and groove forming faces are arranged on the two sides of the arc-shaped matching face. According to the butterfly-shaped optical cable provided by the invention, the welding flux layer is adopted to form the longitudinally and continuously arranged grooves on the surface of the butterfly-shaped optical cable, and the grooves are used as tear-away lines. The structure not only can be conveniently and continuously prepared through the prefabricated sheath strip, but also can be recovered through the softening energy source when the optical cable is damaged, thereby facilitating the maintenance of the optical cable and prolonging the service life of the optical cable.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

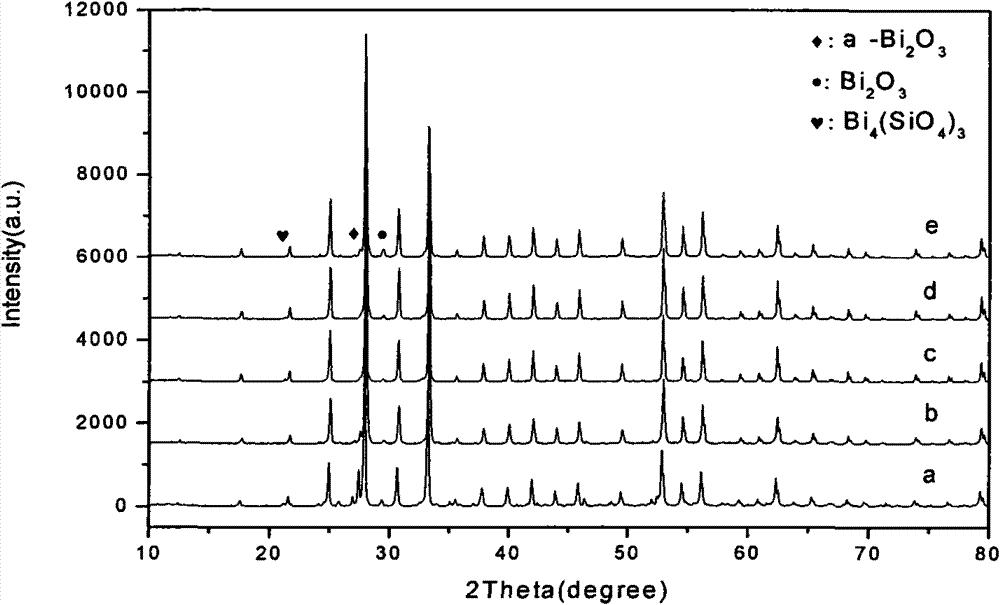

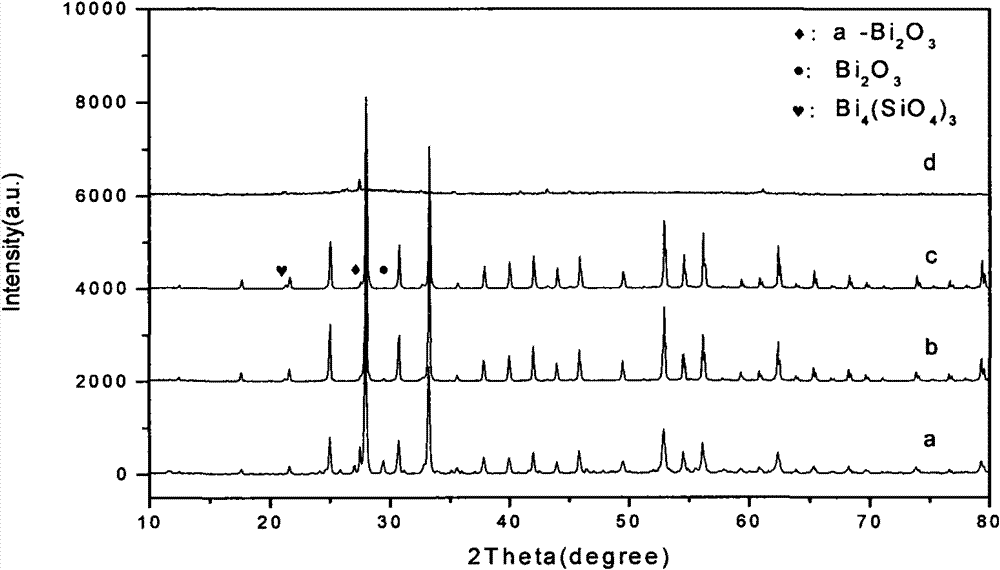

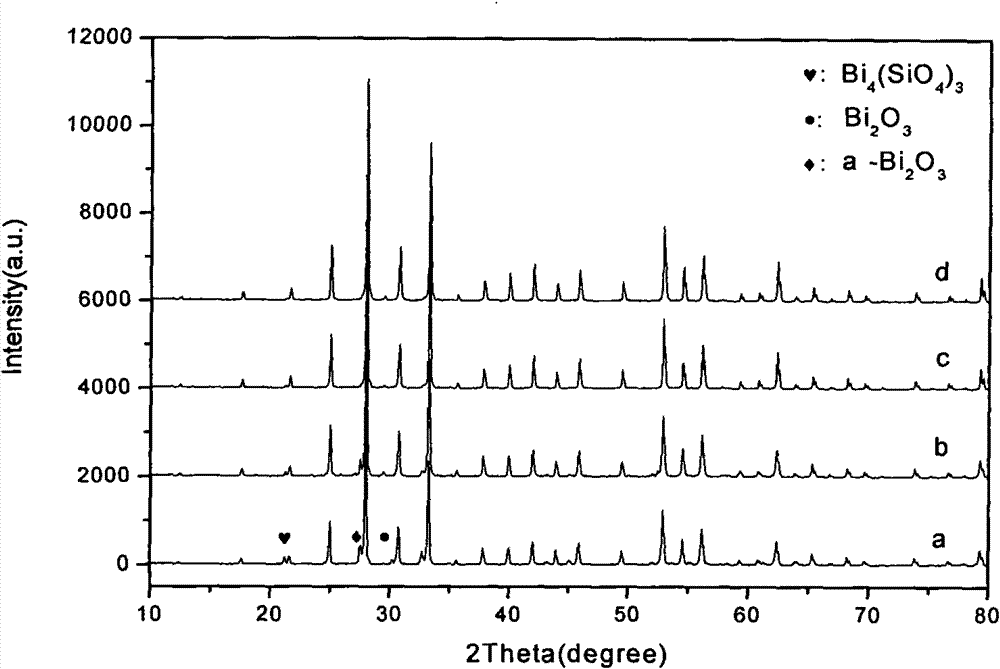

New preparation method of Bi12SiO20

InactiveCN102249252BImprove the manufacturing environmentReduce pollutionSilicon compoundsSpectral responseMuffle furnace

The invention discloses a preparation method of Bi12SiO20, which comprises the following steps: firstly dropwisely adding etraethyl orthosilicate into a glacial acetic acid solution of bismuth nitrate, adjusting the viscosity of the dropwisely added product by anhydrous alcohol, preheating in a muffle furnace at 350 DEG C for 10 min, heating to 700-800 DEG C and calcining for 180 min, cooling to room temperature to obtain the finished product. The molar ratio of bismuth nitrate, etraethyl orthosilicate, and glacial acetic acid is 12:1.2:620; the molar ratio of bismuth nitrate and anhydrous alcohol is 12:145. By introducing a new cosolvent and providing new raw material ratios and new preparation process conditions required by the preparation, the invention prepares Bi12SiO20 with a wider spectral response range, effectively reduces the environment pollution during the preparation, and reduces the manufacturing cost.

Owner:YANTAI UNIV

Glass reinforced plastic forming method and glass reinforced plastic forming system

The invention discloses a glass reinforced plastic forming method and a glass reinforced plastic forming system. The method comprises the following steps of: respectively pressurizing a phenolic resin feed liquid, a solidified agent and a glass fiber so as to spurt in a shape of fans and converge through three nozzlesof a spraying gun, wherein the fan-shaped injection surfaces of the solidified agent and the glass fiber are respectively positioned on the two sides of the injection surface formed by phenolic resin so as to spurt; injecting the solidifying feed liquid after converging under the propulsion of the injection pressure of the bakelite feed liquid in a fan shape to the target injection surface, and curing and forming the solidifying feed liquid on the target injection surface. The glass reinforced plastic forming method and the glass reinforced plastic forming system provided by the invention have the advantages that a purpose that the spraying gun is used for injecting so as to uniformly mix the phenolic resin, the solidified agent and the glass fiber is achieved through regulating the viscosity of the bakelite feed liquid, the bakelite forming efficiency is improved, the manufacture environment of employees is improved, and a gummosis condition meets a field injecting liner manufacturing process.

Owner:ZHONGYI GLASS FIBER REINFORCED PLASTICS

Preparation method of glass slides for xrf analysis with release aid

InactiveCN108982563BPrevent volatilizationAvoid gatheringMaterial analysis using wave/particle radiationLithium metaboratePhysical chemistry

The invention relates to a preparation method for an XRF analysis glass sheet with a demolding assistant function. The preparation method is characterized by comprising the following steps: blending according to a mass ratio of ammonium iodide to a demolding assistant to water of 1:(2-3):5, and uniformly mixing, to obtain solution containing the demolding assistant; mixing 67wt% of lithium tetraborate and 33wt% of lithium metaborate, to obtain a mixed fluxing agent; uniformly mixing 6.000-8.000 g of the mixed fluxing agent and 0.1000-1.0000 g of oxide powder, to obtain a mixture; placing the mixture in a platinum crucible, dropwise adding 2-5 drops of the solution containing the demolding assistant to the mixture; placing the platinum crucible filled with the mixture in a high-temperaturefurnace, melting for 15-25 min in a condition of 980-1050 DEG C; and taking out the platinum crucible filled with the molten mixture, naturally cooling, stripping, and demolding, to obtain the XRF analysis glass sheet with the demolding assistant function. The preparation method is low in production cost and good in preparation environment, and the prepared XRF analysis glass sheet is capable of reducing an analysis lower limit of Al.

Owner:WUHAN UNIV OF SCI & TECH +1

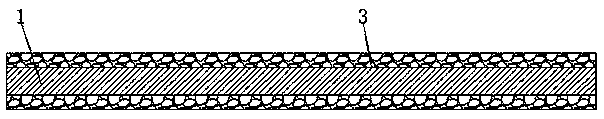

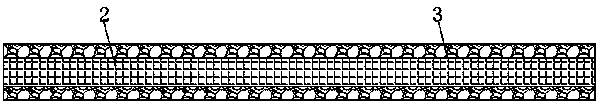

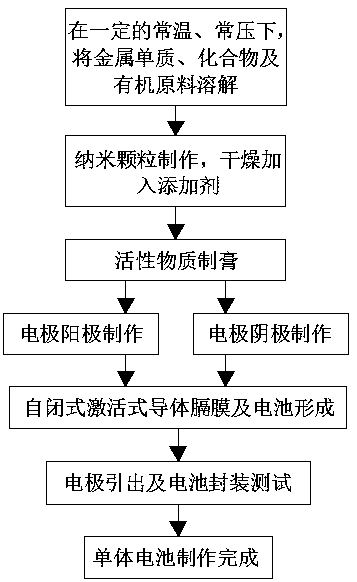

Self-closing activation-type semiconductor cell and production flow

InactiveCN108336414AGood material selection, processing and productionSimple manufacturing processFinal product manufactureElectrode carriers/collectorsCopper foilBiological activation

The invention discloses a self-closing activation-type semiconductor cell. The self-closing activation-type semiconductor cell comprises a copper foil and an aluminium foil, the top and the bottom ofthe copper foil as well as the top and the bottom of the aluminium foil are coated with an active substance, a production flow comprises the following steps: selecting a corresponding metal simple substance, a compound and an organic raw material, selecting a container with a certain size, selecting the corresponding metal simple substance, the compound and the organic raw material and respectively placing the materials in the container, adding dissolving liquid in the container, sealing the container through a seal cover, controlling temperature and pressure in the container by people so thatthe internal part of the container is in normal temperature and normal pressure states, and dissolving and mixing the selected corresponding metal simple substance, the compound and the organic raw material in the container, wherein the production flow belongs to the technical field of the cell. The self-closing activation-type semiconductor cell and the production flow are greatly convenient forpeople usage, the current self-closing activation-type semiconductor cell making technology can be simplified, the preparation environment is optimized, and the cost of the materials is low.

Owner:王云燕

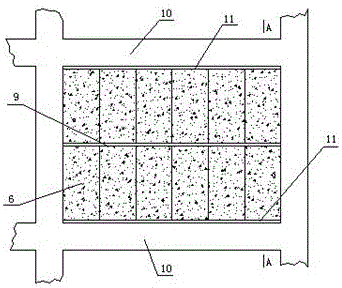

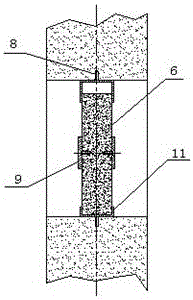

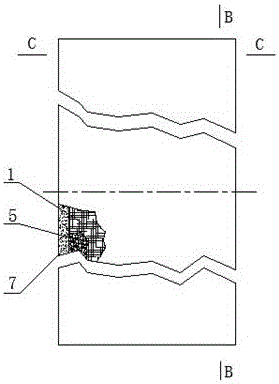

Prefabricated light partition board

InactiveCN106401055AGuaranteed stiffnessGuaranteed StrengthBuilding componentsSheet steelEngineering

The invention provides a prefabricated light partition board. The prefabricated light partition board is characterized in that the partition board (6) comprises a framework and a straw coal ash and fine aggregate concrete layer (7) which is poured on the framework; and the framework is composed of a corrugated foam insulation plate (5) which is located in the middle and punched steel plates (1) which are fixed to the two sides of the corrugated foam insulation plate (5) through bolts (3). The thickness of each punched steel plate (1) is 0.5-2 mm, the diameters of holes in the punched steel plates (1) are 10-15 mm, and the distance between the centers of every two adjacent holes is 20-40 mm. According to the prefabricated light partition board, the punched steel plates which have certain rigidity and extremely high strength are adopted, so that the rigidity and strength of the prefabricated light partition board in the manufacturing process are guaranteed, the bearing capacity of the partition board under a load is improved, expansion of cracks in the wall forming process is limited, and generation and development of cracks in the using process are restrained.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A butterfly optical cable, a sheath strip for forming it, a forming method and a forming device

ActiveCN113467020BEasy maintenanceExtended service lifeFibre mechanical structuresEngineeringEnergy source

The invention discloses a butterfly optical cable, a sheath strip for forming it, a forming method and a forming device. The butterfly optical cable includes a sheath welding layer, a sheath flame-retardant layer and an optical fiber unit; one side of the sheath welding layer is close to the optical fiber unit, and the other side has a sheath flame-retardant layer. The sheath strip includes a flame-retardant layer member and a welding layer member, the flame-retardant member has an arc-shaped mating surface matched with the optical fiber unit, and the welding layer member at least covers the arc-shaped mating surface; Both sides of the arc-shaped mating surface have groove-forming surfaces. The butterfly optical cable provided by the present invention adopts the solder layer to form the longitudinal continuous arrangement grooves on the surface of the butterfly optical cable, which is used as an easy-to-tear opening, which can be conveniently and continuously prepared through prefabricated sheath strips, and can When the energy source is restored by softening, it is convenient for the maintenance of the optical cable and prolongs the service life of the optical cable.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

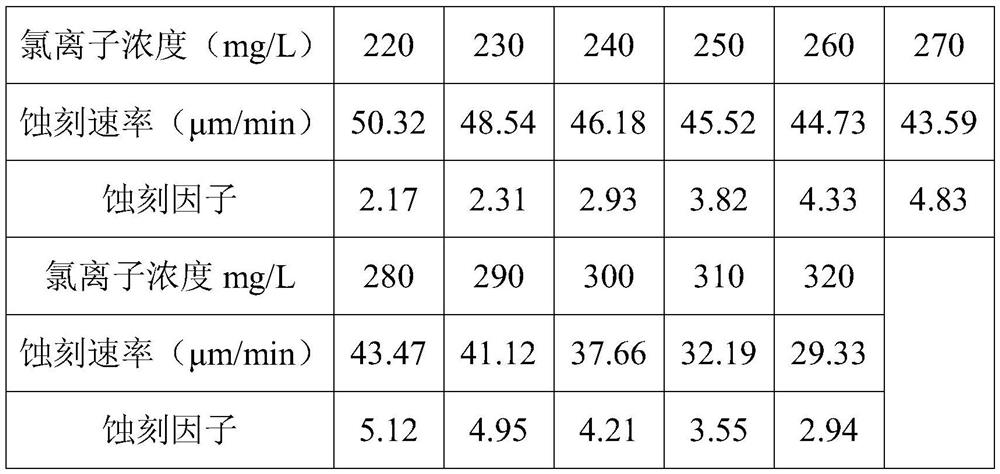

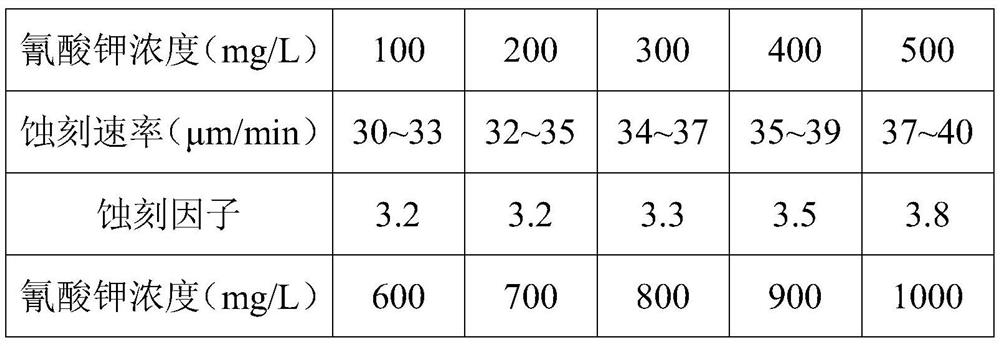

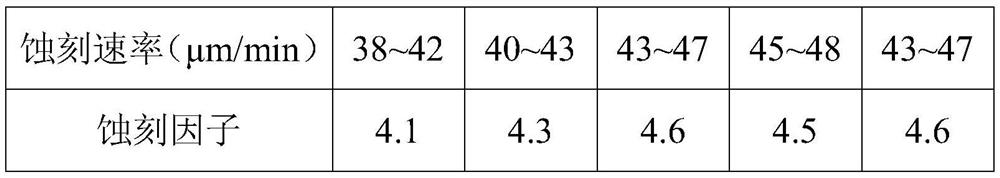

Low-acidity etching production method for PCB and double-liquid type acidic etching liquid system

The invention belongs to the technical field of acid etching, and particularly relates to a low-acidity etching production method for a PCB (printed circuit board) and a double-liquid type acid etching liquid system. An acid-reducing auxiliary agent of an acid etching liquid adopted in etching production comprises one or two of cyanate and oxalic acid dihydrazide; and the cyanate comprises sodium cyanate, potassium cyanate or ammonium cyanate. The cyanate and the oxalic acid dihydrazide are used as the etching liquid deacidification auxiliary agent, and an additive is formed by the auxiliary agent and is applied to the PCB acid etching liquid, so that the etching rate can be increased, and the etching factor can be increased; and after the acid etching liquid for PCB production is mixed with the etching liquid additive, the concentration of the adopted oxidant is reduced, and the acid equivalent of the whole system is reduced. The used etching liquid additive can replace 31% industrial concentrated hydrochloric acid adopted traditionally, the etching rate reaches 40-50 microns / min, the etching factor reaches 4.0-5.0, and the additive is greatly superior to a traditional double-solution type acid etching solution.

Owner:深圳市泓荣辉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com