Preparation method of multi-color red beet concentrated juice

A technology of red beet and concentrated juice, which is applied in the field of preparation of multi-color red beet concentrated juice, can solve the problems of inability to meet the diversified needs of the market, the quality of products between batches, and the unstable color tone, so as to avoid loss and fading, Ensure uniformity and reduce the effect of browning index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of preparation method of multi-color system red beet concentrated juice of the present embodiment comprises the following steps:

[0056] (1) Cleaning: select high-quality red beets, and wash away the surface soil with flowing water;

[0057] (2) Electron beam deactivation: take 62.56 kg of cleaned red beets and use an electron beam to deactivate enzymes, the energy of the electron beam is 8 MeV, and the scanning width is 800mm~1000mm;

[0058] (3) Fragmentation: the red beets after the enzyme removal are crushed by a crusher, and the crushing particle size is 2mm-4mm;

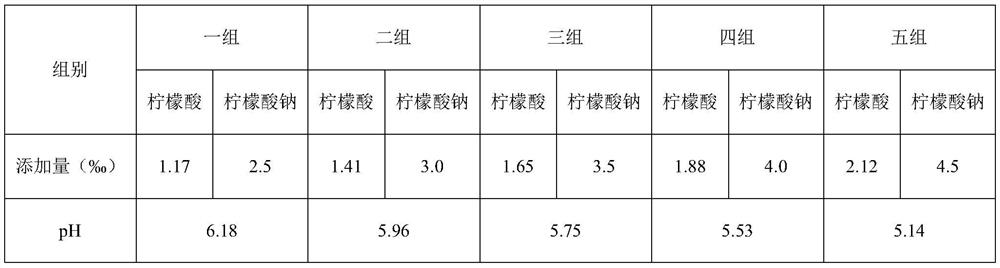

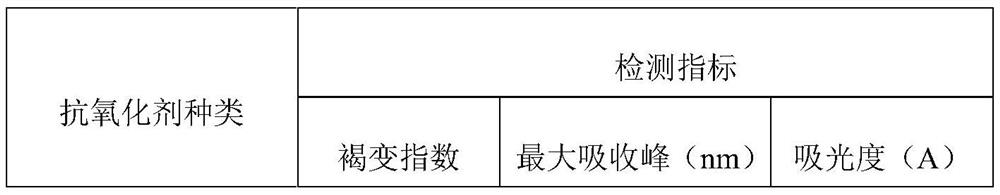

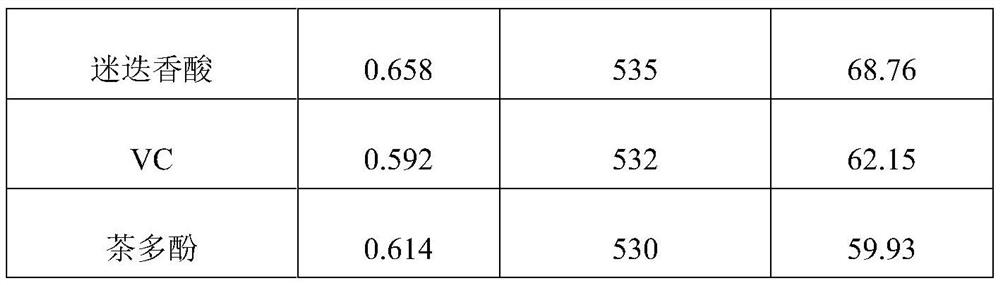

[0059] (4) Color protection: the red beet after crushing is put into the 62.56kg aqueous solution containing citric acid-sodium citrate immediately of 187.7g, adds 15.64g rosmarinic acid simultaneously and carries out color protection, after mixing evenly, carry out impact crushing, Obtain red beet slurry after leaching for 30min;

[0060] (5) Squeeze: use a squeezer to squeeze and filter the r...

Embodiment 2

[0073] A kind of preparation method of multi-color system red beet concentrated juice of the present embodiment comprises the following steps:

[0074] (1) Cleaning: select high-quality red beets, and wash away the surface soil with flowing water;

[0075] (2) Electron beam deactivation: take 70.35 kg of cleaned red beet and use an electron beam to deactivate enzymes, the energy of the electron beam is 6 MeV, and the scanning width is 800mm~1000mm;

[0076] (3) Fragmentation: the red beets after the enzyme removal are crushed by a crusher, and the crushing particle size is 2mm-4mm;

[0077] (4) Color protection: Immediately put the crushed red beets into 70.35 kg of aqueous solution containing 149.1 g of citric acid-sodium citrate, and at the same time add 17.6 g of rosmarinic acid for color protection. After mixing evenly, carry out impact crushing , obtain red beet slurry after leaching for 30min;

[0078] (5) Squeeze: use a squeezer to squeeze and filter the red beet slur...

Embodiment 3

[0086] A kind of preparation method of multi-color system red beet concentrated juice of the present embodiment comprises the following steps:

[0087] (1) Cleaning: select high-quality red beets, and wash away the surface soil with flowing water;

[0088] (2) Electron beam deactivation: take 66.21 kg of cleaned red beet and use an electron beam to deactivate enzymes, the energy of the electron beam is 10 MeV, and the scanning width is 800mm~1000mm;

[0089] (3) Fragmentation: the red beets after the enzyme removal are crushed by a crusher, and the crushing particle size is 2mm-4mm;

[0090] (4) Color protection: put the crushed red beet immediately into the 66.21kg aqueous solution containing 298g citric acid-sodium citrate, add 16.6g rosmarinic acid to protect the color, after mixing evenly, carry out impact crushing, Obtain red beet slurry after leaching for 30min;

[0091] (5) Squeeze: use a squeezer to squeeze and filter the red beet slurry to obtain a filtrate;

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com