Mineral insulated metal sheath fireproof cable and preparation method thereof

A metal sheath and mineral insulation technology, applied in the direction of insulated cables, cable/conductor manufacturing, insulated conductors, etc., can solve the problems of harsh manufacturing environment, short project length, thin aluminum metal sheath, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

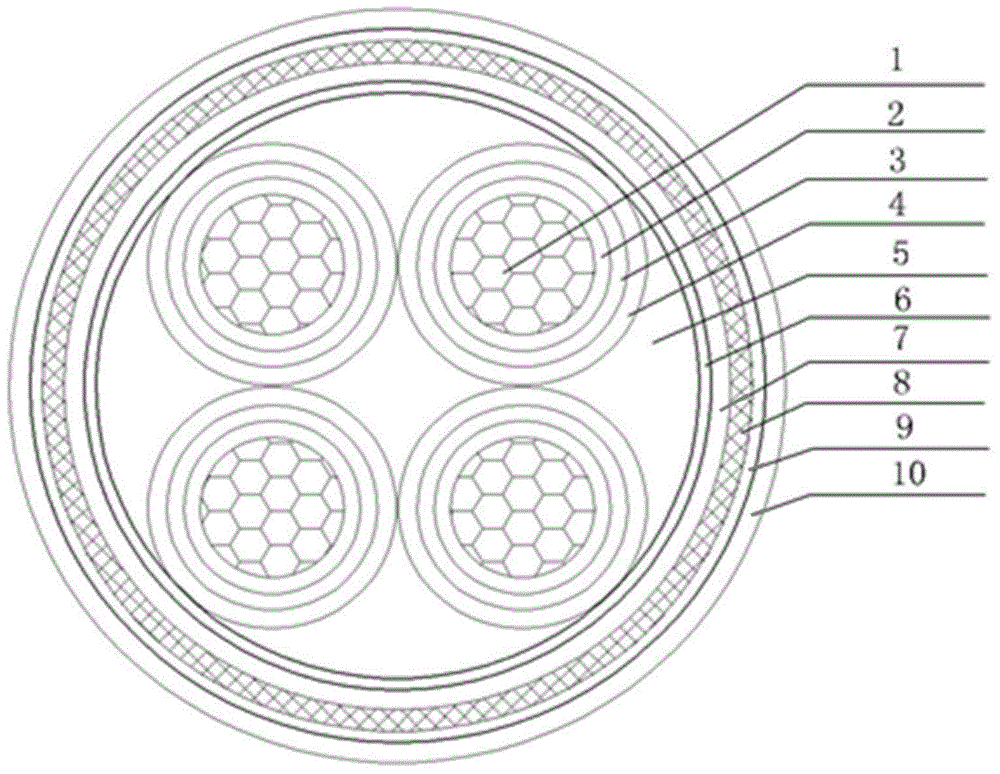

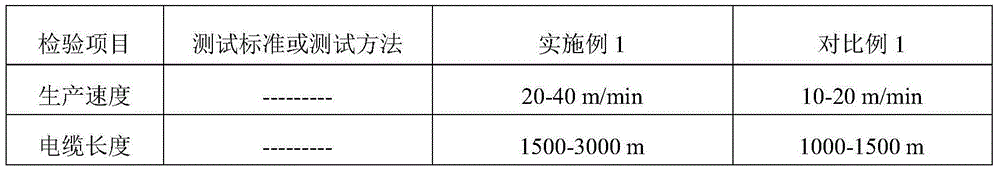

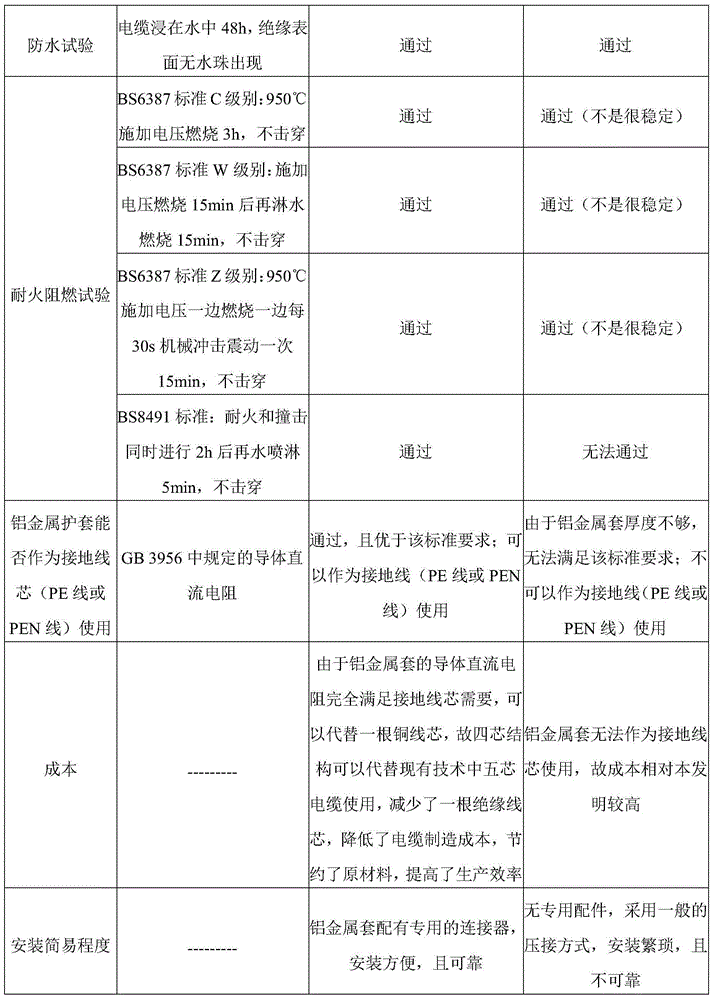

[0080] The fire-resistant cable with mineral insulated metal sheath of this embodiment, figure 1 A schematic diagram of its cross-sectional structure. It includes four insulated wire cores, the outer layer of the insulated wire cores is a mineral insulating layer 2, and a metal conductor 1 is arranged inside the mineral insulating layer 2; a metal sheath 3 is formed on the outside of each insulated wire core by extruding. The metal sheath 3 is covered with an anti-corrosion plastic layer 4, and the anti-corrosion plastic layer 4 is covered with a mineral oxygen barrier layer 5, and the mineral oxygen barrier layer 5 is coated with an inner flame-retardant layer 6, and the inner flame-retardant layer 6 is coated with a mineral refractory expansion layer 7, a metal reinforcement layer 8 is woven outside the mineral refractory expansion layer 7, an outer flame retardant layer 9 is coated on the metal reinforcement layer 8, and a Outer sheath10. Among them, the material of the m...

Embodiment 2

[0095] The material of the anti-corrosion plastic layer of the fire-resistant cable with mineral insulated metal sheath in this embodiment is polyethylene.

[0096] The preparation method of the mineral insulated metal sheath fire-resistant cable of the present embodiment comprises the following steps:

[0097] (1) Strand the copper conductor monofilament into a metal conductor, and then wrap the refractory mica tape on the outside to form a mineral insulation layer and make an insulated core; the cross-sectional area of the conductor is 630mm 2 , the thickness of the mineral insulating layer is 1.8mm;

[0098] (2) Before the operation steps of continuous extrusion of aluminum metal, the aluminum metal is pretreated according to the following steps: first, use a brush device to remove dust and other dirt on the surface of the aluminum metal, and then use an online cleaning system to wash off the oil on the surface , to clean the surface of aluminum metal. The pretreated al...

Embodiment 3

[0109] The preparation method of the mineral insulated metal sheath fire-resistant cable of the present embodiment comprises the following steps:

[0110] (1) Strand the copper conductor monofilament into a metal conductor, and then wrap the refractory mica tape on the outside to form a mineral insulation layer and make an insulated core; the cross-sectional area of the conductor is 300mm 2 , the thickness of the mineral insulating layer is 1.0mm;

[0111] (2) Before the operation steps of continuous extrusion of aluminum metal, the aluminum metal is pretreated according to the following steps: first, use a brush device to remove dust and other dirt on the surface of the aluminum metal, and then use an online cleaning system to wash off the oil on the surface , to clean the surface of aluminum metal. The pretreated aluminum metal is continuously extruded on the outside of the insulated wire core. Before extrusion, the cavity of the extruder is first placed in an oven at 600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com