Azimuthal rolling track grinding device for magnetic hanging steel ball

A suspension device and magnetic suspension technology, applied in the field of mechanical processing equipment, can solve the problems such as being unable to be used in mass industrial production, the cage is easily damaged, the existence of knife marks, etc., achieving high coaxiality, not easy to damage, and replacing steel. Ball handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

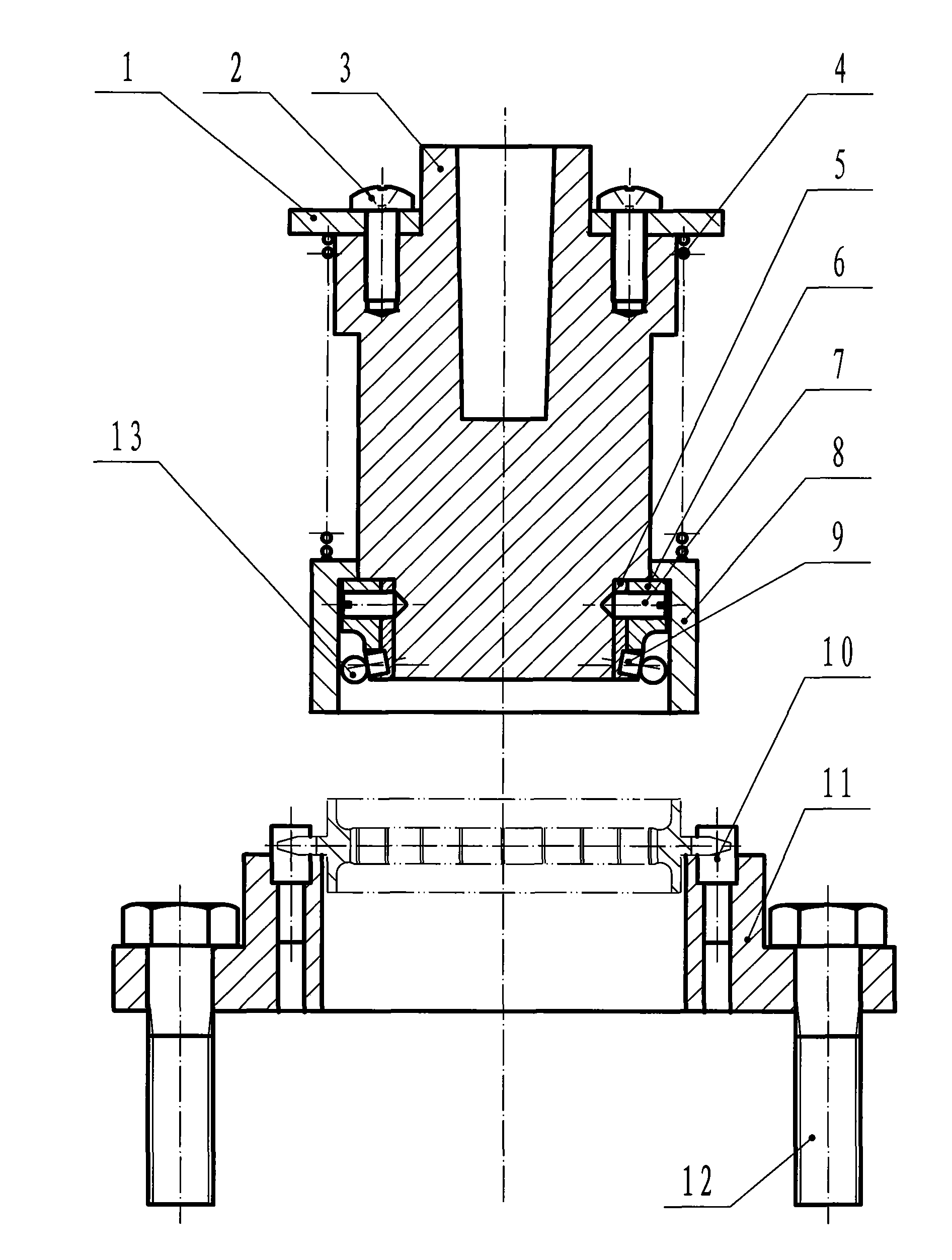

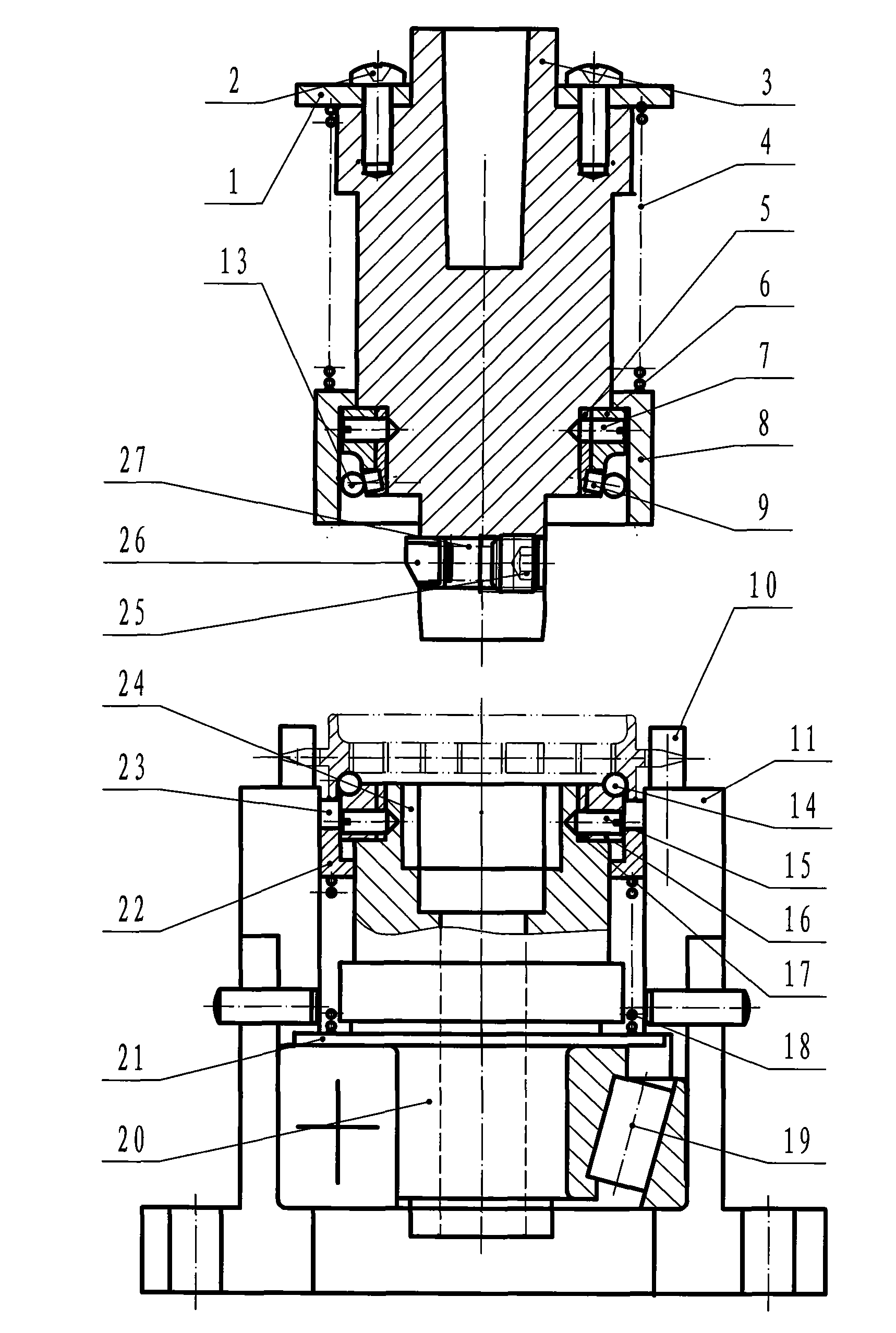

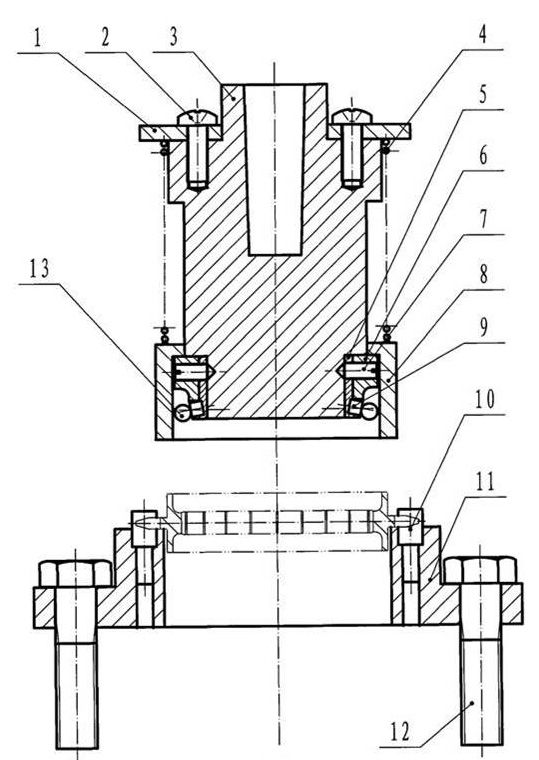

[0019] Example 1: Magnetically suspended steel ball angular raceway single-sided rolling device

[0020] The magnetically suspended steel ball angular raceway single-sided rolling device includes a connecting body 3, and the tail end of the connecting body 3 is provided with a tapered hole, which is used for connecting with the main shaft of a drilling machine. On the side wall of the working end of the connecting body 3, ten magnet seats 5 are evenly distributed in a ring shape, and the magnet seats 5 are non-magnetic materials, such as copper. The number of briquetting blocks 6 is equal to that of the magnet base 5 , and the briquetting blocks 6 are superimposed on the magnet base 5 , and the set screws 7 with slotted tapered ends fix the briquetting blocks 6 and the magnet base 5 on the connecting body 3 . A groove is formed after each pair of magnet base 5 and pressing block 6 is assembled, and a permanent magnet 9 is embedded in the groove. Steel balls 13 match the numbe...

Embodiment 2

[0022] Embodiment 2: Double-sided rolling device for magnetically suspended steel ball angular raceway

[0023] The magnetically suspended steel ball angular raceway double-sided rolling device includes a connecting body 3, and the tail end of the connecting body 3 is provided with a tapered hole, and the tapered hole is used for connecting with the main shaft of a drilling machine. The side wall of the working end of the connecting body 3 is covered with an annular magnet seat 5, which is a non-magnetic material, such as copper. The briquetting block 6 is also annular, and the briquetting block 6 is sleeved on the magnet seat 5 , and a plurality of slotted set screws 7 with tapered ends fix the briquetting block 6 and the magnet seat 5 on the connecting body 3 . Ten grooves are formed after the magnet base 5 and the pressing block 6 are assembled, the grooves are evenly distributed on an annular ring, the permanent magnets 9 are embedded in the grooves, the steel balls 13 mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com