Wear-resistant and corrosion-resistant mouth ring device for water pump

A corrosion-resistant, mouth-ring technology, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, can solve problems such as flow reduction, reduce impact pressure, improve wear resistance, and improve corrosion resistance The effect of wear-resistant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

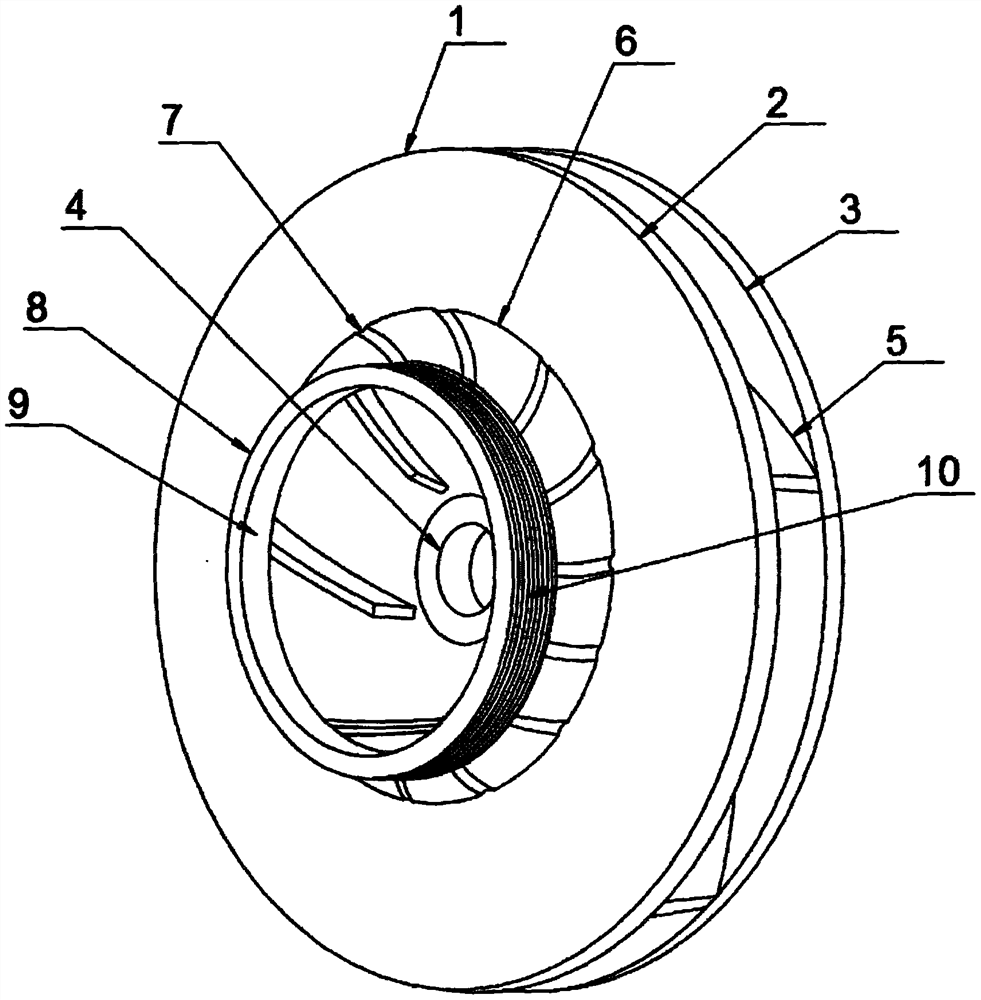

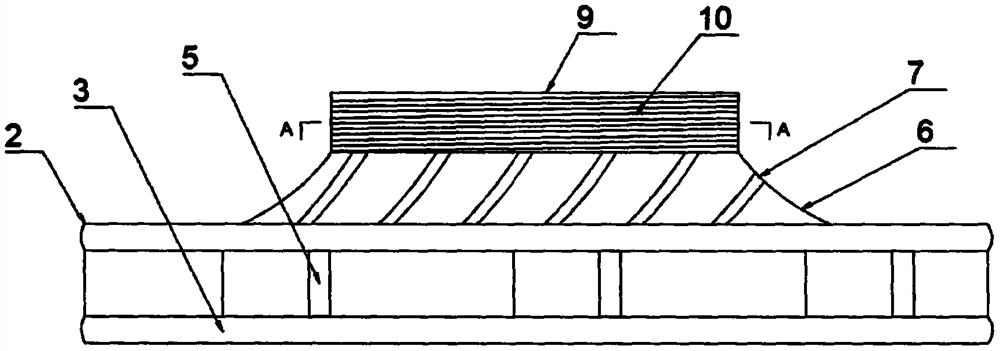

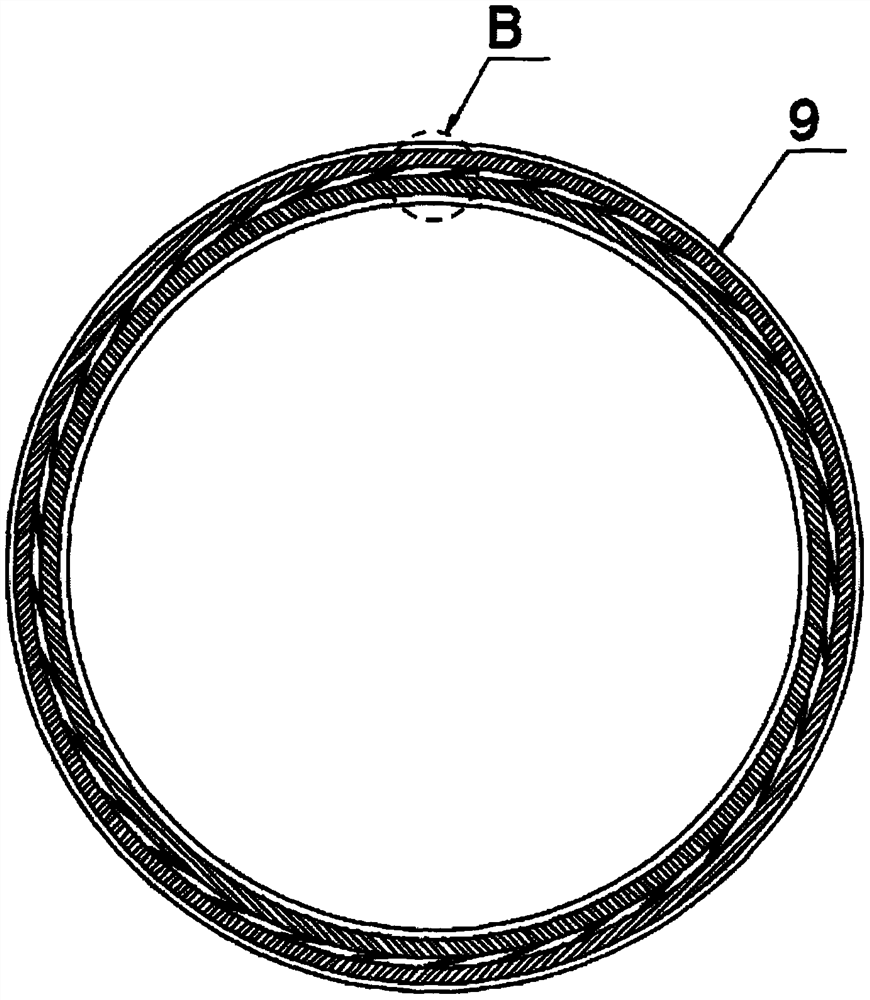

[0040]The embodiment is specifically: when a large amount of fluid passes through the mouth ring body 9 under the condition of high-speed flow, a strong impact pressure will be formed on the inner wall of the mouth ring body 9. Since the mouth ring body 9 adopts a multi-layer structure, and the first outer surface The toughness of the buffer layer 11 and the first inner buffer layer 15 is less than the toughness of the second outer buffer layer 12 and the second inner buffer layer 14, when the first outer buffer layer 11 and the first inner buffer layer 15 are subjected to impact pressure, a certain deformation, so as to feed back to the second outer buffer layer 12 and the second inner buffer layer 14 for buffer dilution, and then the second outer buffer layer 12 and the second inner buffer layer 14 conduct the force of deformation to the memory metal material. The connecting rod 13 makes the connecting rod 13 dilute and buffer the remaining impact force, thereby reducing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com