Method for preparing high-nickel cathode material for lithium secondary battery

A lithium secondary battery, cathode material technology, applied in secondary batteries, secondary battery repair/maintenance, battery electrodes, etc., can solve the problems of human injury, strong corrosion of raw materials, etc., and achieve long cruising range and stable crystal structure. , the effect of reducing the amount of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

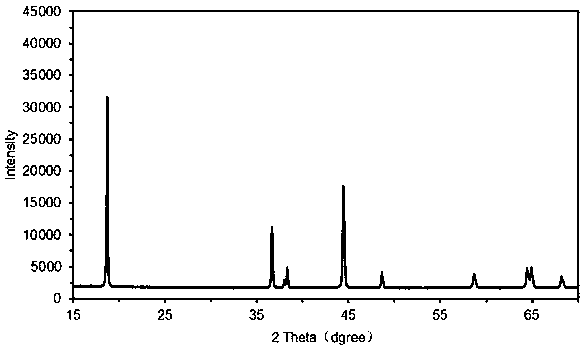

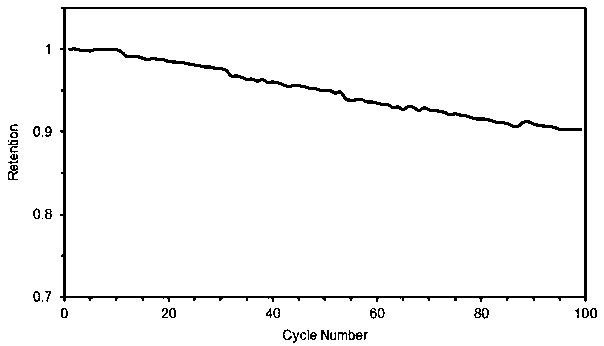

[0025] Take D50 as Ni of 12 μm 0.80 co 0.10 mn 0.10 (OH) 2 Precursor, lithium salt adopts the mixed lithium salt that is made up of lithium carbonate and lithium hydroxide monohydrate, and wherein lithium carbonate provides lithium salt and lithium hydroxide monohydrate provides the molar ratio of lithium salt to be 1:1, but total amount of lithium (in the form of The molar ratio) is Li / (Ni+Co+Mn)=1.08. The additive is 20 nm nano-zirconia, and the proportion of zirconium element is 0.005 mol. Calcined under the atmosphere for 10 hours, then roasted at 810°C for 15 hours in an oxygen atmosphere, crushed the calcined product through a 200-mesh sieve, and carried out under the conditions of washing temperature of 25°C, washing time of 40 minutes, and washing times of 1 times water. Washed with water, and then mixed with 20nm nano-zirconia evenly, the proportion of zirconium element added is 0.001mol, and after sintering at 700°C for 8 hours in an oxygen atmosphere, Li 1.08 Ni...

Embodiment 2

[0030] Take D50 as Ni of 8 μm 0.80 co 0.10 mn 0.10 (OH) 2 Precursor, lithium salt adopts the mixed lithium salt that is made up of lithium carbonate and monohydrate lithium hydroxide, and wherein lithium carbonate provides lithium salt and monohydrate lithium hydroxide provides the mol ratio of lithium salt to be 7:3, but total amount of lithium (in the form of The molar ratio) is Li / (Ni+Co+Mn)=1.06. The additive is 20 nm nano-magnesium hydroxide, and the proportion of magnesium element is 0.001 mol. Roast under oxygen atmosphere for 10 hours, and then roast under oxygen atmosphere at 790°C for 15 hours, crush the roasted product through a 200-mesh sieve, wash with water at a temperature of 25°C, a washing time of 20 minutes, and a washing ratio of 5 times , and then mixed evenly with 20nm nano-boron oxide, the amount of boron added was 0.015mol, and after sintering at 700°C for 8 hours in an oxygen atmosphere, Li 1.06 Ni 0.80 co 0.10 mn 0.10 Mg 0.001 B 0.01 5 o 2 ....

Embodiment 3

[0034] In embodiment 2, lithium salt adopts the mixed lithium salt that is made up of lithium carbonate and lithium hydroxide monohydrate, and wherein lithium carbonate provides lithium salt and lithium hydroxide monohydrate provides the mol ratio of lithium salt to be 9:1, but total lithium The amount (by molar ratio) is Li / (Ni+Co+Mn)=1.06. The additive is 20 nm nano-cerium fluoride, and the proportion of cerium element added is 0.001 mol. After mixing evenly with a ball mill, first Low temperature 720 °C under an oxygen atmosphere for 10 hours, and then at 785 °C for 15 hours under an oxygen atmosphere, followed by water washing, mixing with additives, and secondary sintering processes were the same as in Example 2 to obtain Li 1.06 Ni 0.80 co 0.10 mn 0.10 Ce 0.001 B 0.015 o 2 , The specific discharge capacity of the material obtained at 0.2C is 195 mAh / g, and the cycle retention rate is 88% after 80 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com