Anion doped modified lithium-excess (5:3:2) type ternary lithium ion battery cathode material

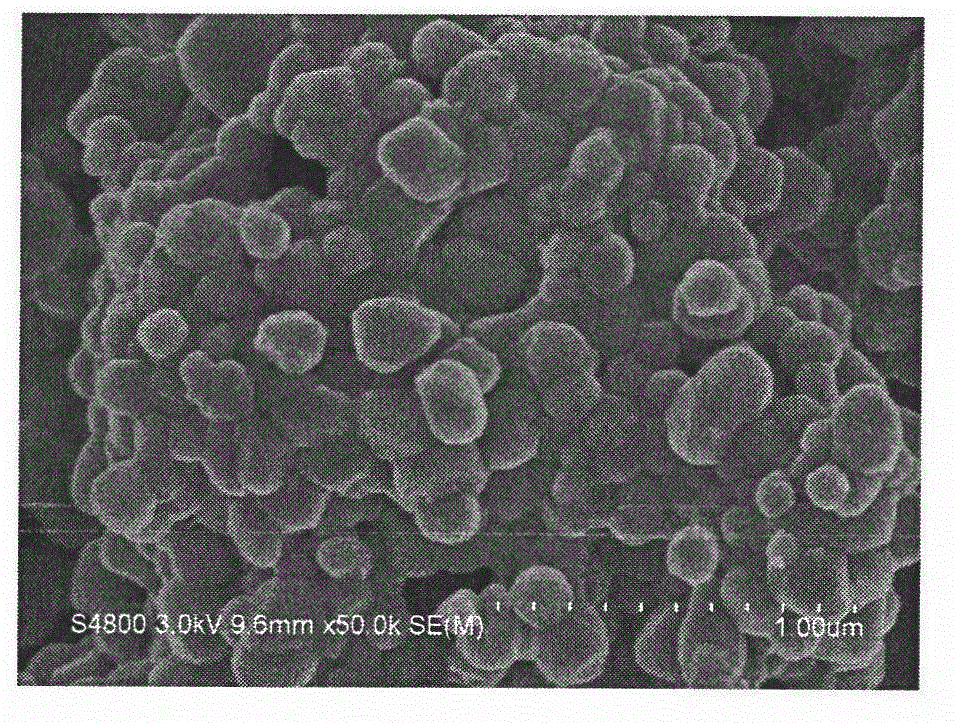

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficulty in ensuring batch stability, low material packing density, and irregular particles, and achieve improved cycle performance and magnification Good performance, cycle performance, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0041] Example 2 Li 1+0.05 (Ni 0.5 mn 0.3 co 0.2 )O 2-005 f 005

[0042] (1) Add 0.1mol Ni(NO 3 ) 2 ·6H 2 O, 0.06mol Mn(NO 3 ) 2 ·6H 2 O, 0.04mol Co(NO 3 ) 2 ·6H 2 Dissolve O in 400mL deionized water to make a solution with a metal ion concentration of 0.5mol / L;

[0043] (2) Add 0.22mol (NH 4 ) 2 ·C 2 o 4 Dissolve in 800mL deionized water to form a 0.275mol / L solution (precipitating agent (NH 4 ) 2 ·C 2 o 4 The excess coefficient is 1.1);

[0044] (3) The metal solution prepared respectively in step (1) (2), (NH 4 ) 2 ·C 2 o 4 The solution was slowly added dropwise to the continuously stirring reaction kettle, and an ammonia solution with a mass percent concentration of 15% was added dropwise to adjust the pH value of the solution to 7.0, the rotation speed of the stirrer was adjusted to 400r / min, and the reaction temperature was 50°C;

[0045] (4) The material in the reactor in the step (3) was continuously stirred for 8 hours, and after the reactio...

Embodiment 3

[0048] Example 3 Li 1+0.1 (Ni 0.5 mn 0.3 co 0.2 )O 2-0.1 f 0.1

[0049] (1) Add 0.1mol NiSO 4 4H 2 O, 0.06mol MnSO 4 ·H 2 O, 0.04mol CoSO 4 ··7H 2 O was dissolved in 300mL deionized water to prepare a solution with a metal ion concentration of 0.67mol / L;

[0050] (2) 0.24mol (NH 4 ) 2 ·C 2 o 4 Dissolve in 600mL deionized water to form a 0.4mol / L solution (precipitating agent (NH 4 ) 2 ·C 2 o 4 The excess coefficient is 1.2);

[0051] (3) The metal solution prepared respectively in step (1) (2), (NH 4 ) 2 ·C 2 o 4 Slowly add the solution dropwise into the continuously stirring reaction kettle, and add dropwise an ammonia solution with a concentration of 15% by mass to adjust the pH value of the solution to 7.5, adjust the rotation speed of the stirrer to 500r / min, and the reaction temperature to 60°C;

[0052] (4) The material in the reactor in the step (3) was continuously stirred for 6 hours, and after the reaction was completed, it was further aged fo...

Embodiment 5

[0060] Example five Li 1+0.05 (Ni 0.5 mn 0.3 co 0.2 )O 2-0.05 Cl 0.05

[0061] (1) Add 0.1mol Ni(CH 3 COOH) 2 4H 2 O, 0.06mol Mn(CH 3 COOH) 2 4H 2 O, 0.04molCo(CH 3 COOH) 2 4H 2 O was dissolved in 500mL deionized water to prepare a solution with a metal ion concentration of 0.4mol / L;

[0062] (2) Add 0.2mol (NH 4 ) 2 ·C 2 o 4 Dissolve in 1000mL deionized water to form a 0.2mol / L solution;

[0063] (3) The metal solution prepared respectively in step (1) (2), (NH 4 ) 2 ·C 2 o 4 The solution is slowly added dropwise into the continuously stirring reaction kettle, and an ammonia solution with a mass percent concentration of 15% is added dropwise to adjust the pH value of the solution to 6.5, the rotation speed of the stirrer is adjusted to 300r / min, and the reaction temperature is 40°C;

[0064] (4) The material in the reactor in step (3) was continuously stirred for 10 hours, and after the reaction was completed, it was further aged for 6 hours to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com