Ultrahigh-nickel polycrystalline positive electrode material as well as preparation method and application thereof

A positive electrode material and ultra-high technology, applied in the field of ultra-high nickel polycrystalline positive electrode material and its preparation, can solve the problems of difficult to achieve industrialization, poor cycle performance, poor specific capacity, etc., to improve the discharge specific capacity, stabilize the structure, improve Effect of Rate Capability and Cycle Retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

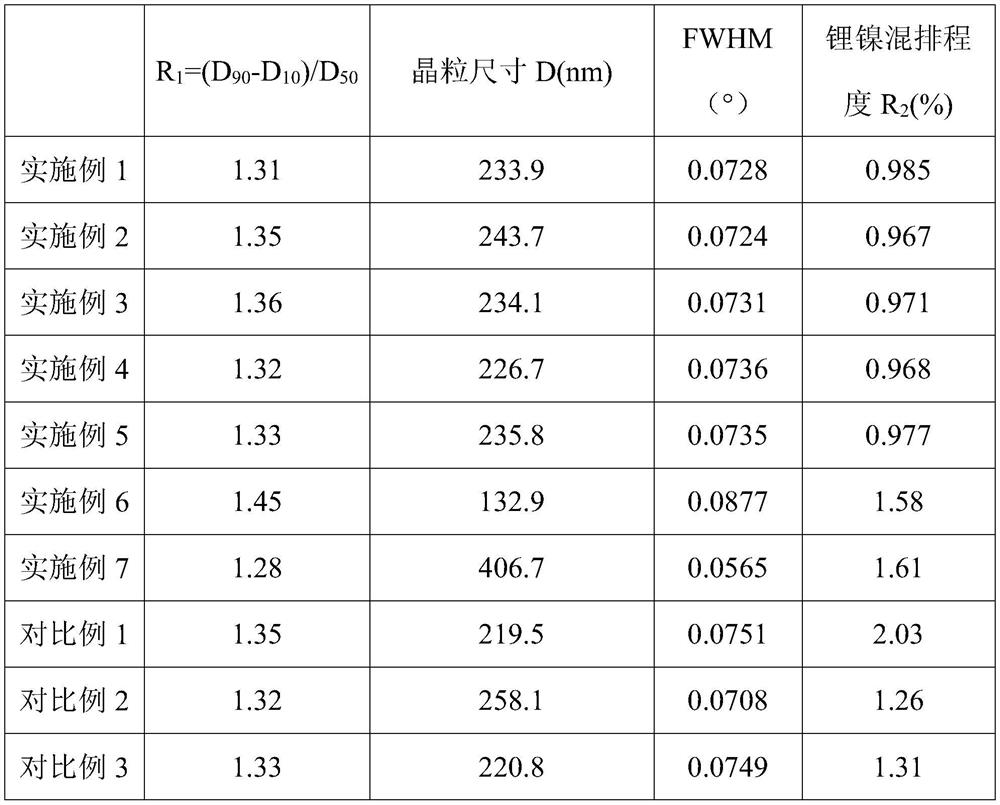

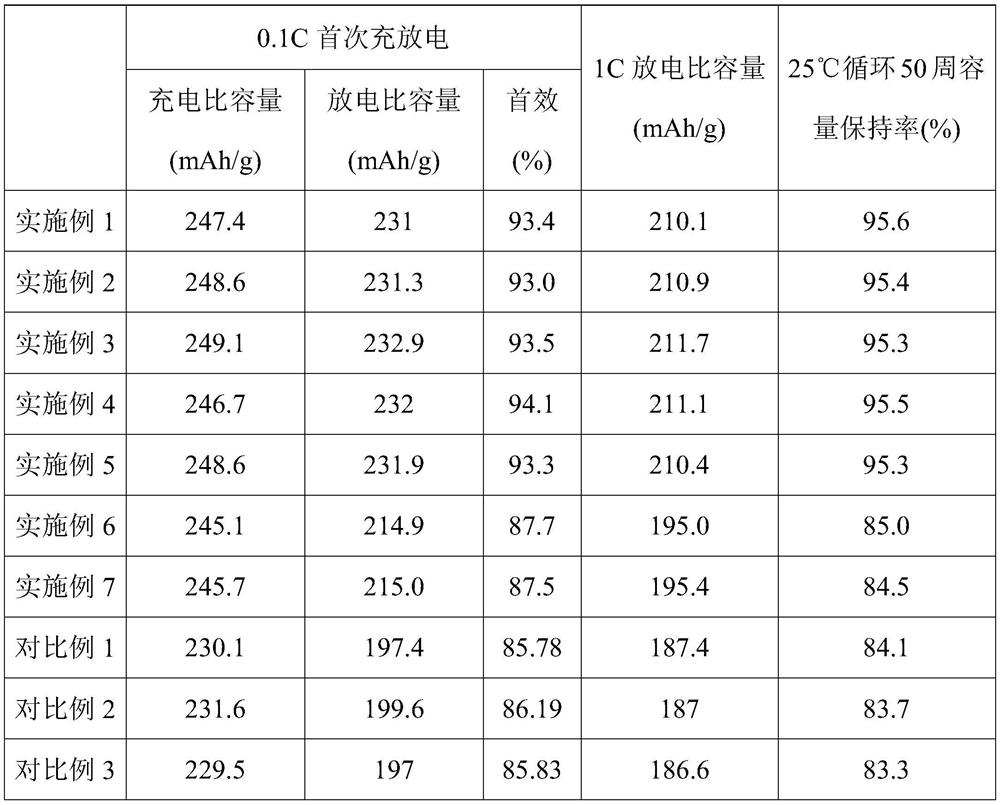

Examples

Embodiment 1

[0041] This embodiment provides an ultra-high nickel polycrystalline positive electrode material, and the ultra-high nickel polycrystalline positive electrode material is prepared by the following method:

[0042] (1) Dry mixing nickel hydroxide, zirconia, tantalum pentoxide and lithium source in a molar ratio of 0.976:0.02:0.004:1.06, and after mixing uniformly, at 715 ° C, O 2 (purity 99.99%) atmosphere, after sintering for 12 hours, cooling and sieving to obtain a sintered material (Li 1.06 Ni 0.976Zr 0.02 Ta 0.004 O 2 );

[0043] (2) the primary sintered material obtained in step (1) and cobalt oxide are uniformly mixed according to the molar ratio of 1:0.008, and in 0 2 (purity 99.99%) atmosphere, heat treatment at 650℃ for 12h, cooling and sieving (400 mesh screen) to obtain cobalt-coated ultra-high nickel polycrystalline nickel zirconium lithium tantalate cathode material (Li 1.06 Ni 0.976 Zr 0.02 Ta 0.004 O 2 ﹒ (Co 2 O 3 ) 0.008 ).

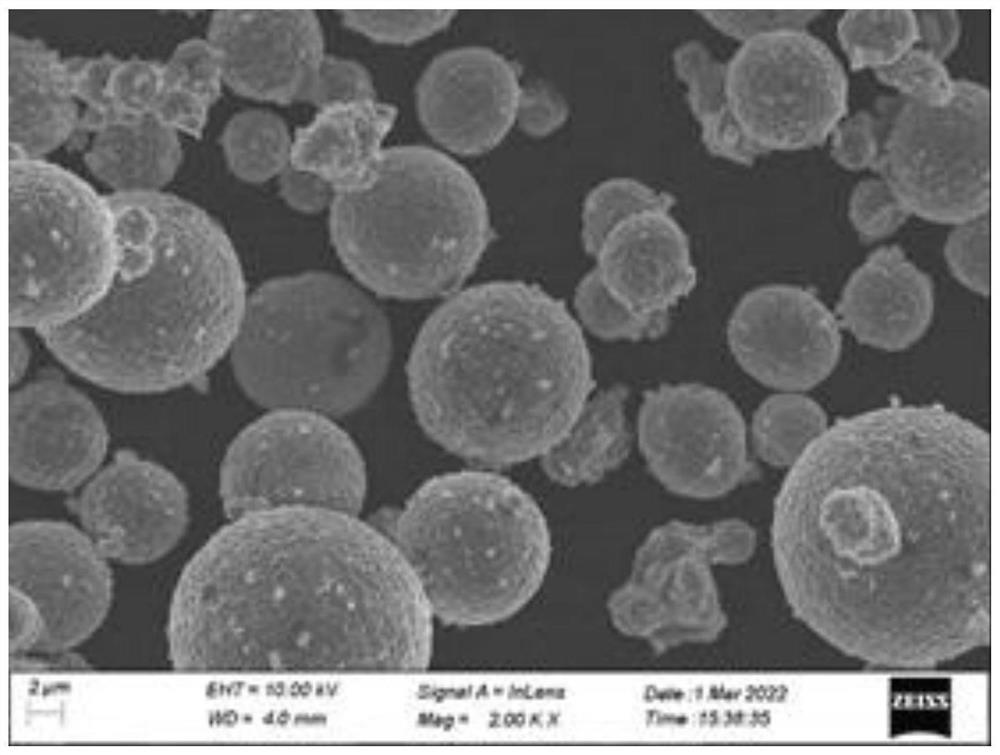

[0044] The SEM image...

Embodiment 2

[0046] This embodiment provides an ultra-high nickel polycrystalline positive electrode material, and the ultra-high nickel polycrystalline positive electrode material is prepared by the following method:

[0047] (1) Dry mixing nickel hydroxide, zirconia, tantalum pentoxide and lithium source in a molar ratio of 0.988:0.01:0.003:1.06, and after mixing uniformly, at 715 ° C, O 2 (purity 99.99%) atmosphere, after sintering for 12 hours, cooling and sieving to obtain a sintered material (Li 1.06 Ni 0.988 Zr 0.01 Ta 0.003 O 2 );

[0048] (2) the primary sintered material obtained in step (1) and cobalt oxide are uniformly mixed according to the molar ratio of 1:0.008, and in 0 2 (purity 99.99%) atmosphere, heat treatment at 650℃ for 12h, cooling and sieving (400 mesh screen) to obtain cobalt-coated ultra-high nickel polycrystalline nickel zirconium lithium tantalate cathode material (Li 1.06 Ni 0.988 Zr 0.01 Ta 0.003 O 2 ﹒ (Co 2 O 3 ) 0.008 ).

Embodiment 3

[0050] This embodiment provides an ultra-high nickel polycrystalline positive electrode material, and the ultra-high nickel polycrystalline positive electrode material is prepared by the following method:

[0051] (1) Dry mixing nickel hydroxide, zirconium oxide, tantalum pentoxide and lithium source in a molar ratio of 0.965:0.03:0.005:1.06, and after mixing uniformly, at 715 ° C, O 2 (purity 99.99%) atmosphere, after sintering for 12 hours, cooling and sieving to obtain a sintered material (Li 1.06 Ni 0.965 Zr 0.03 Ta 0.005 O 2 );

[0052] (2) the primary sintered material obtained in step (1) and cobalt oxide are uniformly mixed according to the molar ratio of 1:0.008, and in 0 2 (purity 99.99%) atmosphere, heat treatment at 650℃ for 12h, cooling and sieving (400 mesh screen) to obtain cobalt-coated ultra-high nickel polycrystalline nickel zirconium lithium tantalate cathode material (Li 1.06 Ni 0.965 Zr 0.03 Ta 0.005 O 2 ﹒ (Co 2 O 3 ) 0.008 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com