Yttrium ion modified lithium ion battery ternary positive electrode material and preparation method thereof

A technology for lithium ion batteries and positive electrode materials, applied in battery electrodes, active material electrodes, positive electrodes, etc., can solve the problems of poor rate performance and cycle stability, battery flatulence, high humidity requirements, etc., to reduce lithium The effect of nickel mixing, improving cycle performance and accelerating diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

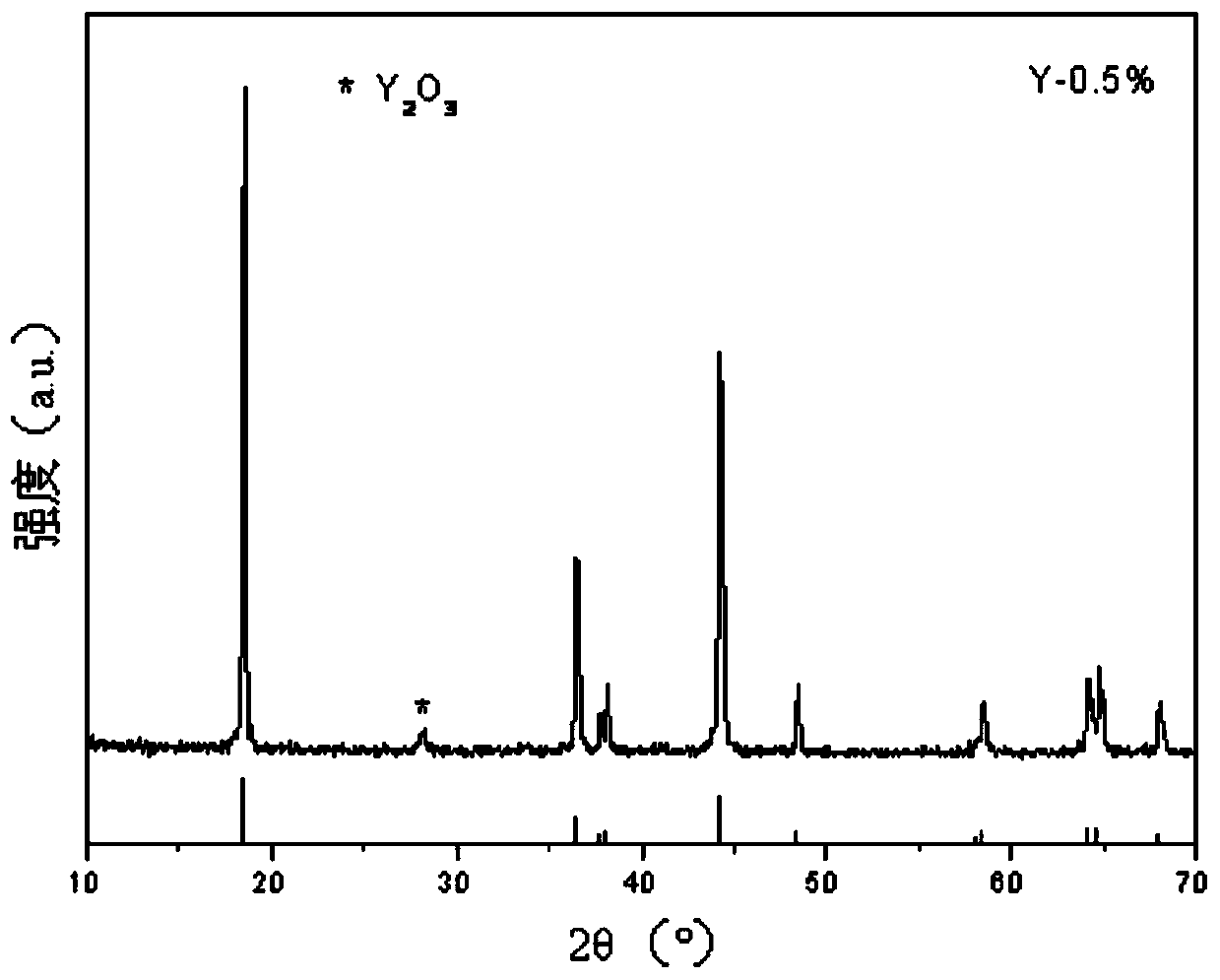

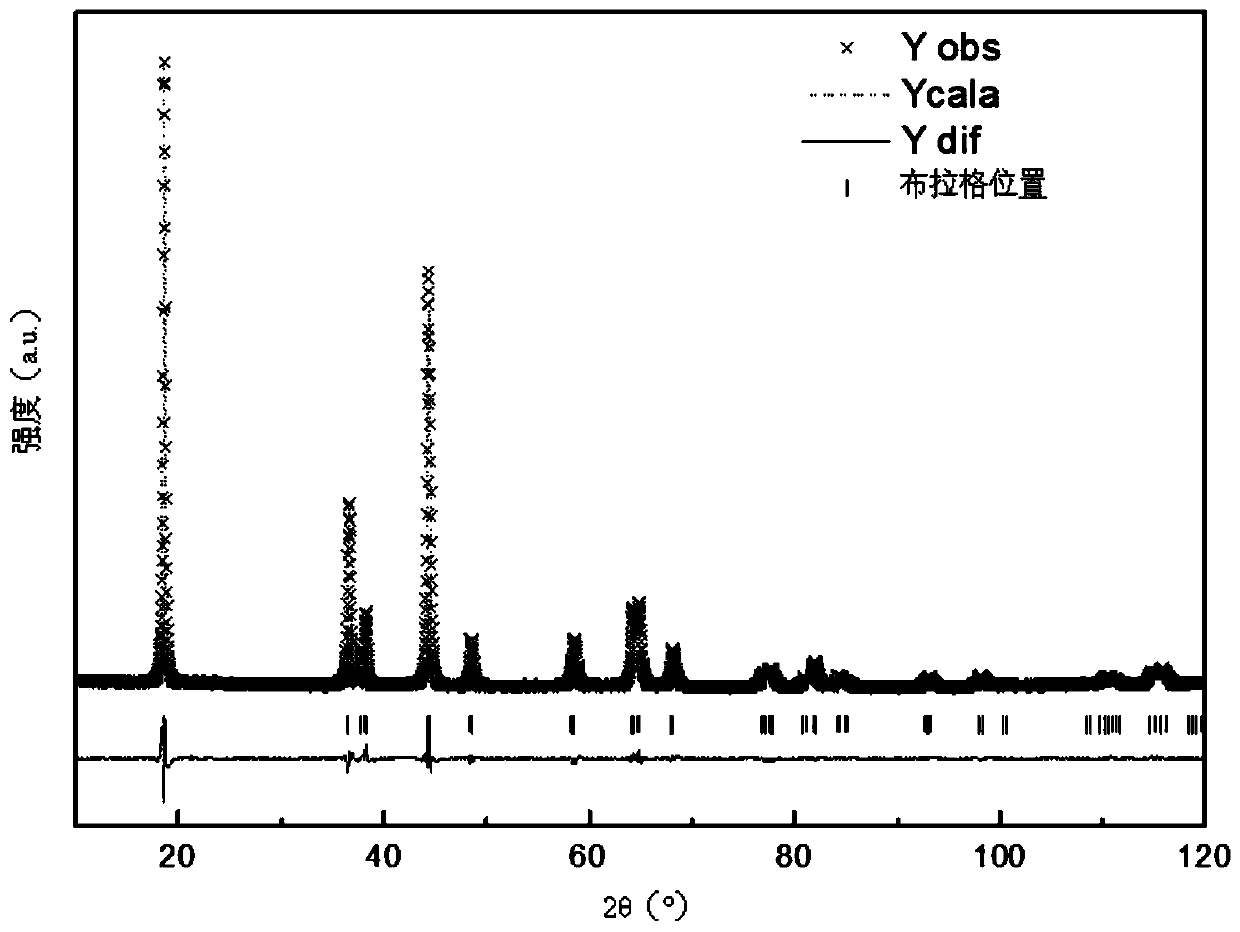

[0028] A kind of yttrium ion modified lithium ion battery ternary cathode material, the raw materials used are calculated as follows in parts by weight:

[0029] Nickel oxide: 135 parts;

[0030] Cobalt oxide: 35 parts;

[0031] Manganese dioxide: 52 parts;

[0032] Lithium carbonate: 117 parts;

[0033] Yttrium oxide: 6 parts.

[0034] The preparation process specifically includes the following steps:

[0035] 1) Weigh 135 parts by weight of nickel oxide, 35 parts by weight of cobalt oxide, 52 parts by weight of manganese dioxide, 117 parts by weight of lithium carbonate, and 6 parts by weight of yttrium oxide, add 1000 parts by weight of deionized water and stir evenly, A homogeneous mixture was obtained.

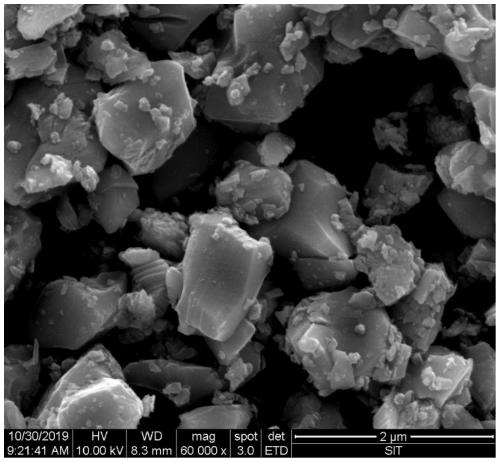

[0036] 2) Add the mixed liquid obtained in step 1) into a nano sand mill and ball mill for 1 hour, take out the slurry and spray dry it at 170° C. to obtain yttrium ion-modified lithium ion battery ternary cathode material precursor powder.

[0037] 3) Treat the pow...

Embodiment 2

[0043] A kind of yttrium ion modified lithium ion battery ternary cathode material, the raw materials used are calculated as follows in parts by weight:

[0044] Nickel oxide: 135 parts;

[0045] Cobalt oxide: 35 parts;

[0046] Manganese dioxide: 52 parts;

[0047] Lithium carbonate: 117 parts;

[0048] Yttrium oxide: 6 parts.

[0049] The preparation process specifically includes the following steps:

[0050] 1) Weigh 135 parts by weight of nickel oxide, 35 parts by weight of cobalt oxide, 52 parts by weight of manganese dioxide, 117 parts by weight of lithium carbonate, and 6 parts by weight of yttrium oxide, add 1000 parts by weight of deionized water and stir evenly, A homogeneous mixture was obtained.

[0051] 2) Add the mixed liquid obtained in step 1) into a nano sand mill and ball mill for 1 hour, take out the slurry and spray dry it at 170° C. to obtain yttrium ion-modified lithium ion battery ternary cathode material precursor powder.

[0052] 3) Treat the pow...

Embodiment 3

[0055] A kind of yttrium ion modified lithium ion battery ternary cathode material, the raw materials used are calculated as follows in parts by weight:

[0056] Nickel oxide: 135 parts;

[0057] Cobalt oxide: 35 parts;

[0058] Manganese dioxide: 52 parts;

[0059] Lithium carbonate: 117 parts;

[0060] Yttrium oxide: 6 parts.

[0061] The preparation process specifically includes the following steps:

[0062] 1) Weigh 135 parts by weight of nickel oxide, 35 parts by weight of cobalt oxide, 52 parts by weight of manganese dioxide, 117 parts by weight of lithium carbonate, and 6 parts by weight of yttrium oxide, add 1000 parts by weight of deionized water and stir evenly, A homogeneous mixture was obtained.

[0063] 2) Add the mixed liquid obtained in step 1) into a nano sand mill and ball mill for 1 hour, take out the slurry and spray dry it at 170° C. to obtain the precursor powder of the ternary cathode material for lithium ion battery.

[0064] 3) Treat the powder ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com