Butterfly-shaped optical cable, sheath strip for forming same, forming method and forming device

A technology for butterfly optical cables and sheaths, applied in the field of butterfly optical cables, forming methods and devices, and sheath strips for forming, can solve problems such as cracking, reduction of optical fiber unit protection capabilities, aging, etc., so as to prolong service life, Improve the manufacturing environment and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

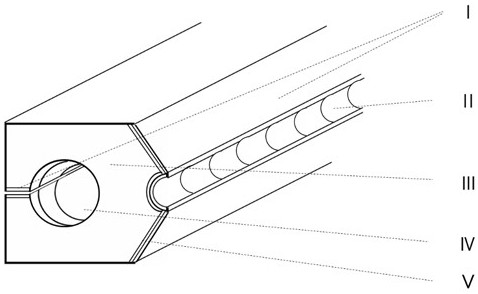

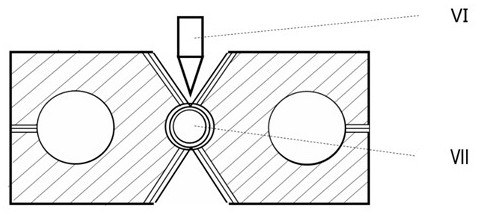

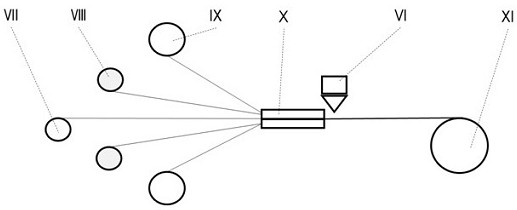

[0065] The butterfly optical cable provided by this embodiment, such as Figure 7 As shown, it includes a sheath solder layer I, a sheath flame-retardant layer III and an optical fiber unit VII; the sheath solder layer I is close to the optical fiber unit VII on one side, and has a sheath flame-retardant layer III on the other side;

[0066] The sheath solder layer I has a groove arranged longitudinally and continuously with the optical cable, and the groove is used as an easy-to-tear opening for peeling off the optical fiber unit VII, and the groove points to the optical fiber unit VII; the cross section of the groove is V-shaped;

[0067] The flame-retardant layer III of the sheath is arranged symmetrically with respect to the optical fiber unit VII in a butterfly shape, and is arranged continuously along the longitudinal direction of the optical cable with a symmetrical circular tunnel IV, and a strengthening member is arranged in the tunnel IV .

[0068] The optical fib...

Embodiment 2

[0077] The butterfly optical cable provided by this embodiment, such as Figure 8 As shown, it includes a sheath solder layer I, a sheath flame-retardant layer III and an optical fiber unit VII; the sheath solder layer I is close to the optical fiber unit VII on one side, and has a sheath flame-retardant layer III on the other side;

[0078] The sheath solder layer I has a groove arranged longitudinally and continuously with the optical cable, and the groove is used as an easy-to-tear opening for peeling off the optical fiber unit VII, and the groove points to the optical fiber unit VII; the cross section of the groove is V-shaped;

[0079] The flame-retardant layer III of the sheath is arranged symmetrically with respect to the optical fiber unit VII, and is butterfly-shaped. A symmetrical circular tunnel IV is arranged continuously along the longitudinal direction of the optical cable, and a reinforcing member VIII is arranged in the tunnel IV.

[0080] The optical fiber un...

Embodiment 3

[0089] The butterfly optical cable provided by this embodiment, such as Figure 11 As shown, it includes a sheath solder layer I, a sheath flame-retardant layer III, a bonding layer V and an optical fiber unit VII; the sheath solder layer I is close to the optical fiber unit VII on one side, and has a sheath on the other side Flame retardant layer III;

[0090] The sheath solder layer I has a groove arranged longitudinally and continuously with the optical cable, and the groove is used as an easy-to-tear opening for peeling off the optical fiber unit VII, and the groove points to the optical fiber unit VII; the cross section of the groove is V-shaped;

[0091] There is an adhesive layer V between the sheath solder layer I and the sheath flame-retardant layer III; the peeling force between the adhesive layer V and the sheath solder layer I is 14N / 15mm, and the bonding The peeling force between layer V and the flame-retardant layer III of the sheath is 13N / 15mm.

[0092] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com