Preparation method of photo sensitive resin binding agent sand wheel

A photosensitive resin and binder technology, applied in grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high production energy consumption and long time, and achieve increased grinding wheel strength, reduced manufacturing time, and improved manufacturing. The effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

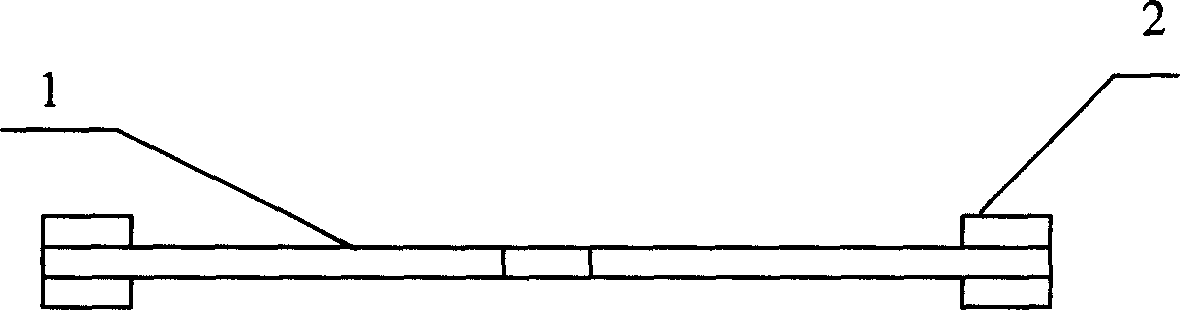

[0016] refer to figure 1 , a preparation method of photosensitive resin bond grinding wheel, the method comprises the following steps:

[0017] (1), making the grinding wheel base 1: metal base size: diameter 75mm, thickness: 0.15mm; overall size of the grinding wheel: diameter 75mm, thickness 0.4mm;

[0018] (2), material mixing: formula, with 15g commercially available photosensitive resin bonding agent, the artificial diamond 2.29g that abrasive grain size specification is 6-12 μ m stirs above-mentioned material with mixer, and abrasive tool concentration is 25%;

[0019] (3) Curing molding: install the evenly stirred mixture 2 and the substrate 1 on a self-made rotating platform, rotate the platform, and evenly spin coat the surface of the outer ring of the metal substrate (65mm-75mm range), using Japanese HOYO -EX250 ultraviolet irradiation device produced by SCHOTT company, the wavelength distribution range is 200nm to 500nm, the light intensity is 2.4w / cm, the curing...

Embodiment 2

[0022] 1. Making the grinding wheel base 1: metal base size: diameter 75mm, thickness: 0.15mm; overall size of the grinding wheel: diameter 75mm, thickness 0.4mm;

[0023] 2. Mixing: formula, mix 15g of commercially available photosensitive resin binder, 4.9g of silicon dioxide micropowder with an abrasive grain size of 6-12μm, stir the above materials evenly with a mixer, and the abrasive concentration is 50%;

[0024] 3. Curing molding: install the evenly stirred mixture 2 and substrate 1 on a self-made rotating platform, rotate the platform, and evenly spin coat the surface of the outer ring of the metal substrate (65mm-75mm range), using Japanese HOYO-SCHOTT The EX250 ultraviolet irradiation device produced by the company has a wavelength distribution range of 200nm to 500nm, a light intensity of 2.4w / cm, and a curing time of 15s. Light curing molding.

[0025] Grinding wheel use: precision cutting of glass, ceramics and silicon wafers.

Embodiment 3

[0027] refer to figure 1 , a preparation method of photosensitive resin bond grinding wheel, the method comprises the following steps:

[0028] (1), making the grinding wheel base 1: metal base size: diameter 75mm, thickness: 0.15mm; overall size of the grinding wheel: diameter 75mm, thickness 0.4mm;

[0029] (2), mixing: formula, 15g of commercially available photosensitive resin binder, 7.19g of silicon carbide with an abrasive particle size specification of 6-12 μm, stir the above materials evenly with a mixer, and the abrasive concentration is 75%;

[0030] (3) Curing molding: install the evenly stirred mixture 2 and the substrate 1 on a self-made rotating platform, rotate the platform, and evenly spin coat the surface of the outer ring of the metal substrate (65mm-75mm range), using Japanese HOYO -EX250 ultraviolet irradiation device produced by SCHOTT company, the wavelength distribution range is 200nm to 500nm, the light intensity is 2.4w / cm, the curing time is 15s, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com