New preparation method of Bi12SiO20

A technology of bismuth nitrate and glacial acetic acid, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of unsatisfactory photoresponse ability, high environmental harm and high price, and improve the preparation environment. , Wide spectral response range, the effect of reducing the degree of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The first step: 20.382g of bismuth nitrate is dissolved in 125ml of glacial acetic acid, then 0.875g of ethyl orthosilicate is added dropwise in the glacial acetic acid solution of bismuth nitrate;

[0025] The second step: adjust the viscosity of the first step product with 30ml absolute ethanol;

[0026] Step 3: Preheat the product of the second step in a muffle furnace at 350°C for 10 minutes, then heat it to 700°C for 180 minutes;

[0027] The fourth step: cooling to room temperature to obtain the finished product.

Embodiment 2

[0029] The first step: 20.382g of bismuth nitrate is dissolved in 125ml of glacial acetic acid, then 0.875g of ethyl orthosilicate is added dropwise in the glacial acetic acid solution of bismuth nitrate;

[0030] The second step: adjust the viscosity of the first step product with 30ml absolute ethanol;

[0031] Step 3: Preheat the product of the second step in a muffle furnace at 350°C for 10 minutes, heat to 800°C and bake for 180 minutes;

[0032] The fourth step: cooling to room temperature to obtain the finished product.

[0033] Determination of the optimal ratio of reactants bismuth nitrate and ethyl orthosilicate:

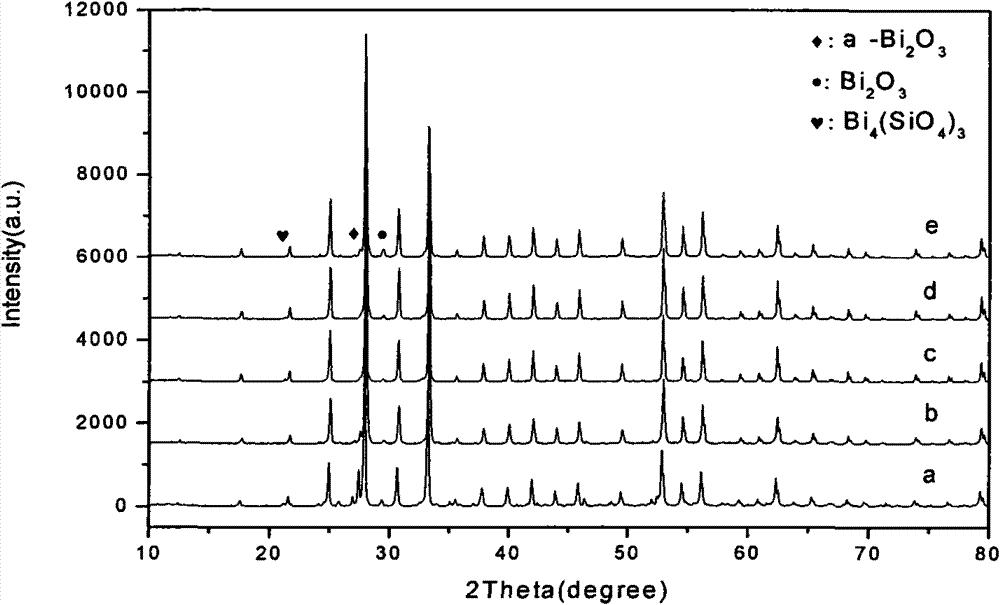

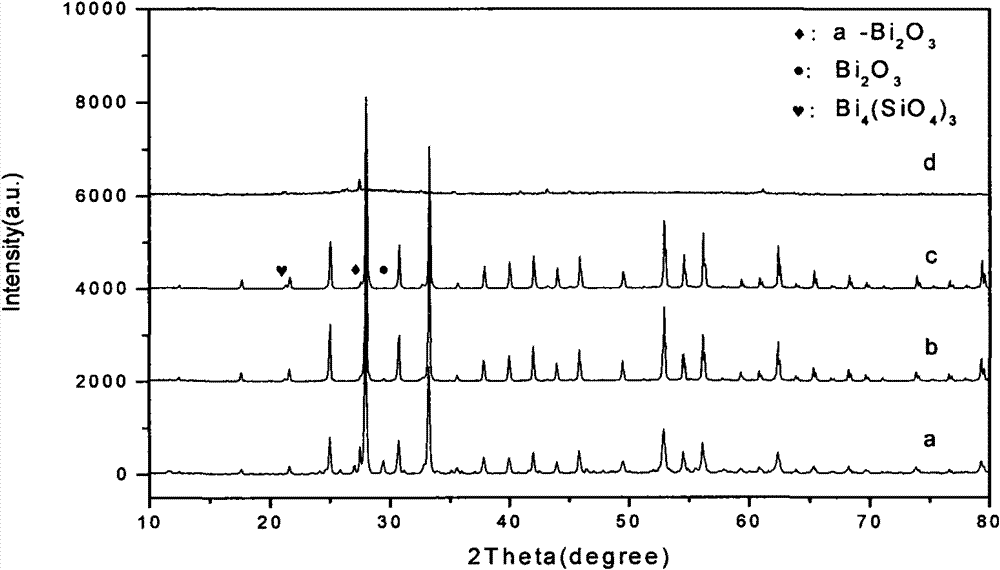

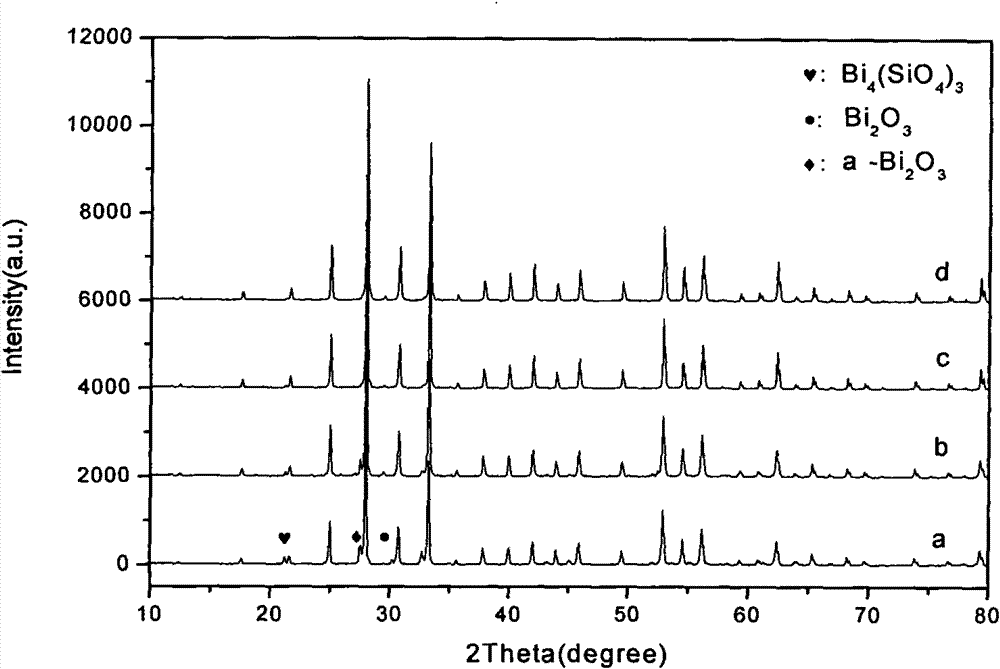

[0034] Such as figure 1 , a, b, c, d and e are that the consumption of fixing bismuth nitrate, dehydrated alcohol and glacial acetic acid is respectively 20.382g, 30ml and 125ml, and the proportioning (mol ratio) of bismuth nitrate and tetraethyl orthosilicate is 12: 1.0, 12:1.1, 12:1.2, 12:1.3 and 12:1.4, the XRD spectrum of the products calcined at 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com