Low-acidity etching production method for PCB and double-liquid type acidic etching liquid system

An acid etching solution and acid etching technology, which is applied in the field of acid etching, can solve the problems of occupational diseases caused by respiratory tract, side reactions of production tanks, and influence on conductivity, etc., so as to improve the PCB manufacturing environment, reduce the generation of chlorine gas, and increase the etching rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

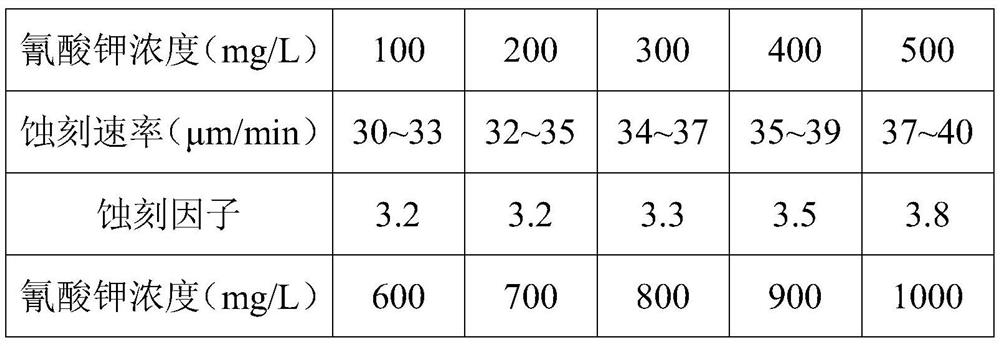

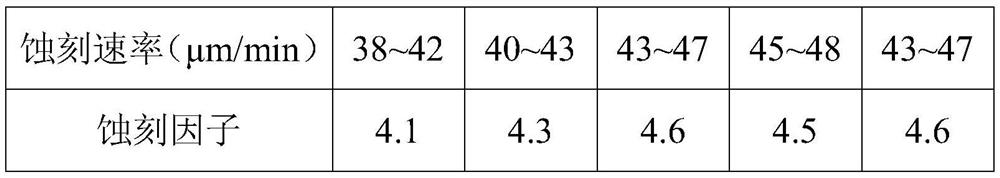

[0040] An etching production method applied to PCB boards with low tail gas and low acidity, the composition of the acid etching liquid system used in the etching production includes an oxidizing agent and an etching liquid additive;

[0041] Described oxidizing agent comprises the one of sodium chlorate, sodium hypochlorite;

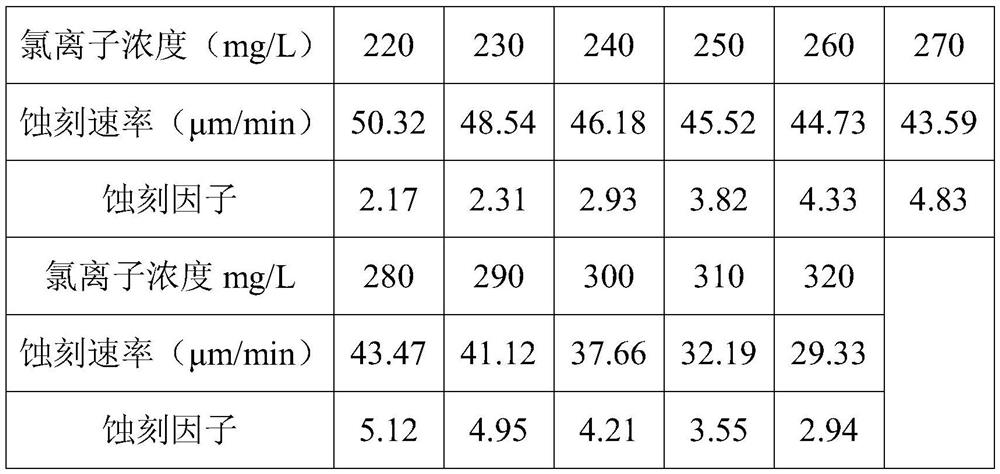

[0042]The etching solution additive includes cyanate, ammonium chloride, and sodium chloride, and its acid equivalent is 5.0 to 5.5. The use of the additive makes the formed acidic etching working bath liquid have an acid equivalent of 0.8 to 1.2 after detection, and the oxidizing agent The concentration of the solution is 320~370g / L, and the chloride ion concentration of the bath solution is 240~250g / L, which shows that compared with the traditional acid etching solution using 31% industrial concentrated hydrochloric acid, the acidity of the acid etching solution system of the present invention is lower and efficient. and safe;

[0043] The working co...

Embodiment 2

[0056] An etching production method applied to PCB boards with low tail gas and low acidity, the composition of the acid etching liquid system used in the etching production includes an oxidizing agent and an etching liquid additive;

[0057] Described oxidizing agent comprises the one of sodium chlorate, sodium hypochlorite;

[0058] The etching solution additive includes oxalic acid dihydrazide, ammonium chloride, and sodium chloride, and its acid equivalent is 4.0 to 5.0. The use of the additive makes the formed acidic etching working bath liquid have an acid equivalent of 0.4 to 5.0 after testing. 0.8, the concentration of oxidant sodium chlorate is 300-400 g / L, and the concentration of chloride ion is 260-270 g / L;

[0059] The working concentration of the ammonium chloride is 20000-30000 mg / L, and the working concentration of the sodium chloride is 5000-10000 mg / L.

[0060] The acidic etching environment is 50°C, the upper pressure is 2.2kg, the lower pressure is 2.0kg, ...

Embodiment 3

[0065] An etching production method applied to PCB boards with low tail gas and low acidity, the composition of the acid etching liquid system used in the etching production includes an oxidizing agent and an etching liquid additive;

[0066] Described etchant additive comprises acid reducing auxiliary agent, ammonium chloride, sodium chloride, and described acid reducing auxiliary agent is the sodium cyanate of 700mg / L and the oxalic acid dihydrazide mixing of 90mg / L, and its acid equivalent is 5.0-6.0, in the acid etching working bath formed after mixed use, the acid equivalent is 1.0-1.2, the concentration of oxidant is 200-300g / L, and the concentration of chloride ion in the bath is 250-260g / L;

[0067] The working concentration of ammonium chloride is 10000-15000mg / L, and the working concentration of sodium chloride is 25000-30000mg / L;

[0068] The acidic etching environment is 50°C, the upper pressure is 2.2kg, the lower pressure is 2.0kg, the oxidation-reduction potenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com