Patents

Literature

66 results about "Potassium isocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium cyanate is used as a basic raw material for various organic syntheses, including, urea derivatives, semicarbazides, carbamates and isocyanates. For example, it is used to prepare the drug hydroxyurea. It is also used for the heat treatment of metals (e.g., Ferritic nitrocarburizing).

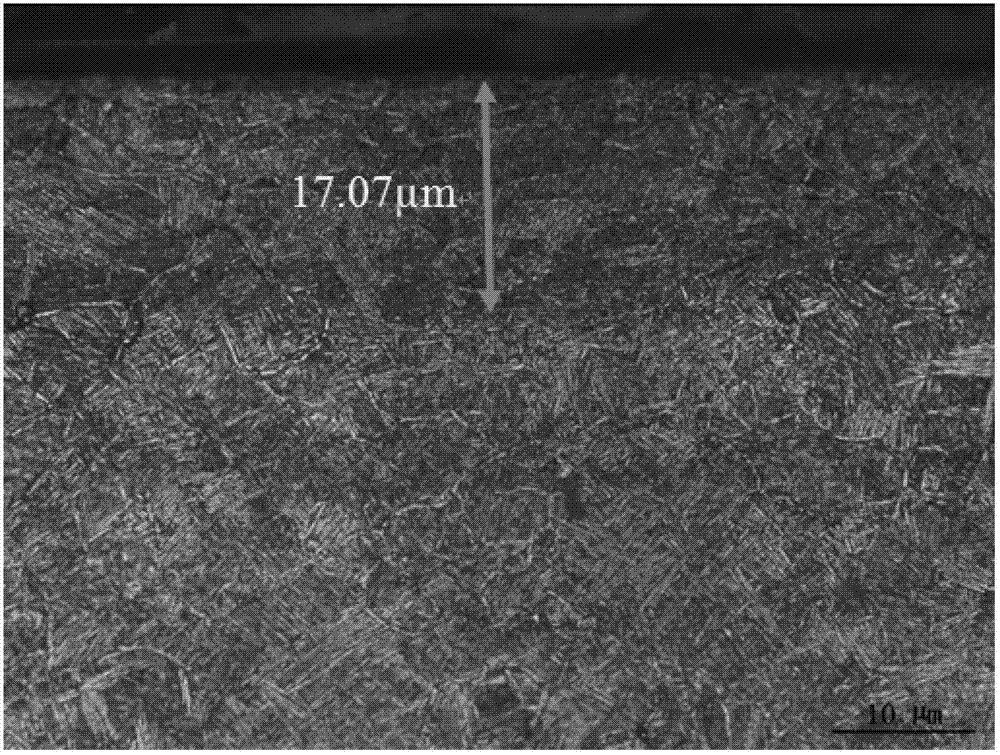

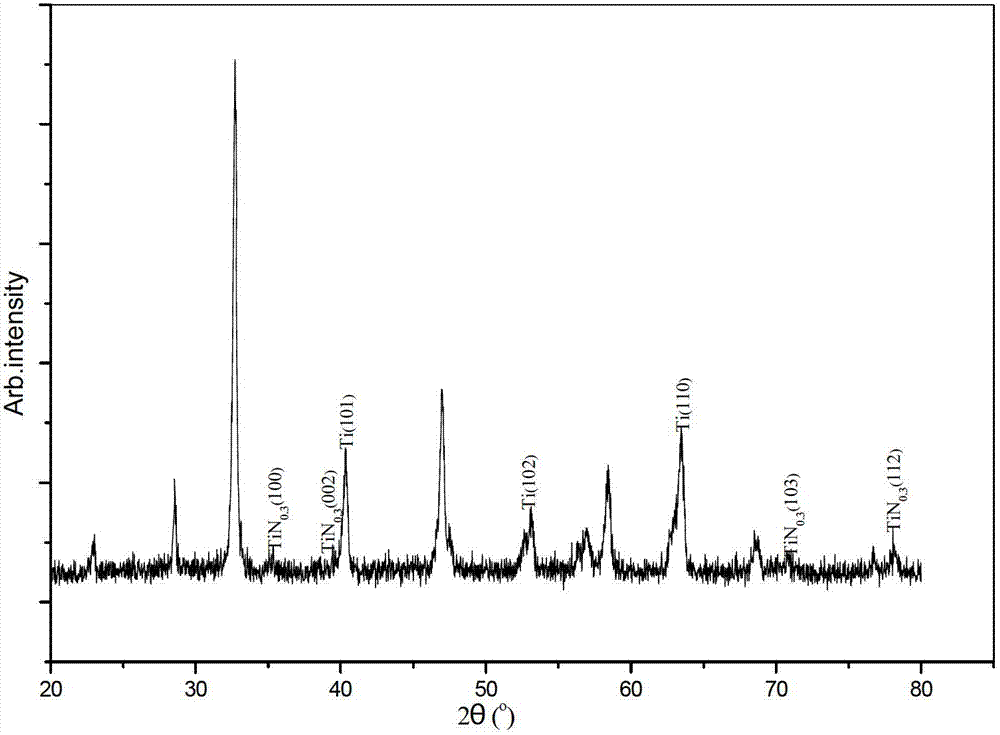

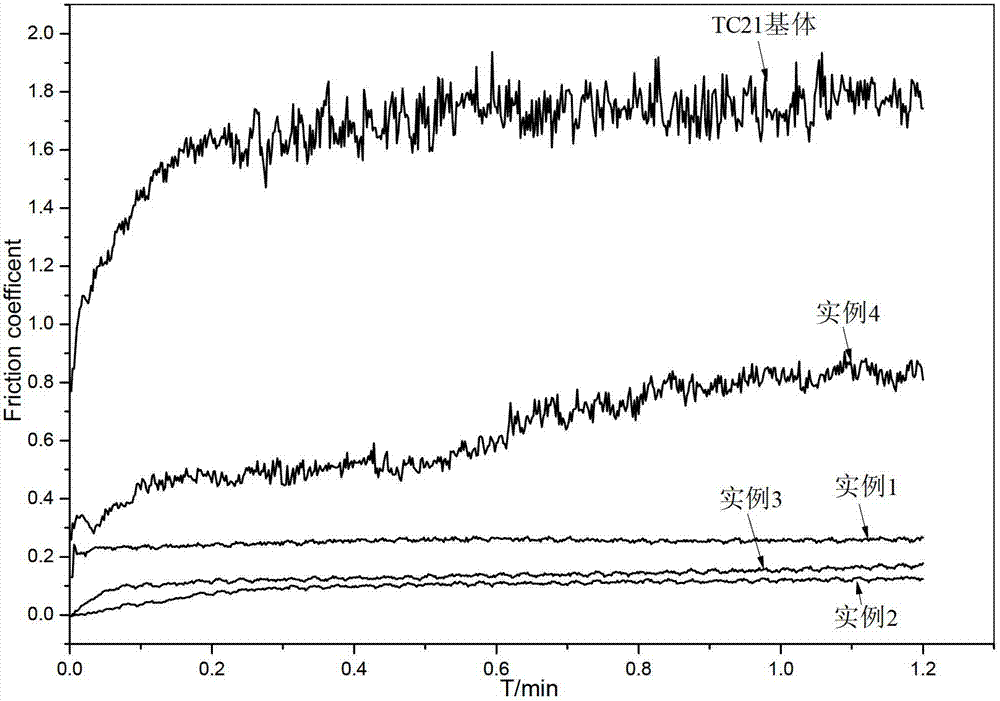

Low-temperature surface nitriding method of titanium alloy

ActiveCN102965613ASimple processImprove controllabilitySolid state diffusion coatingPtru catalystSand blasting

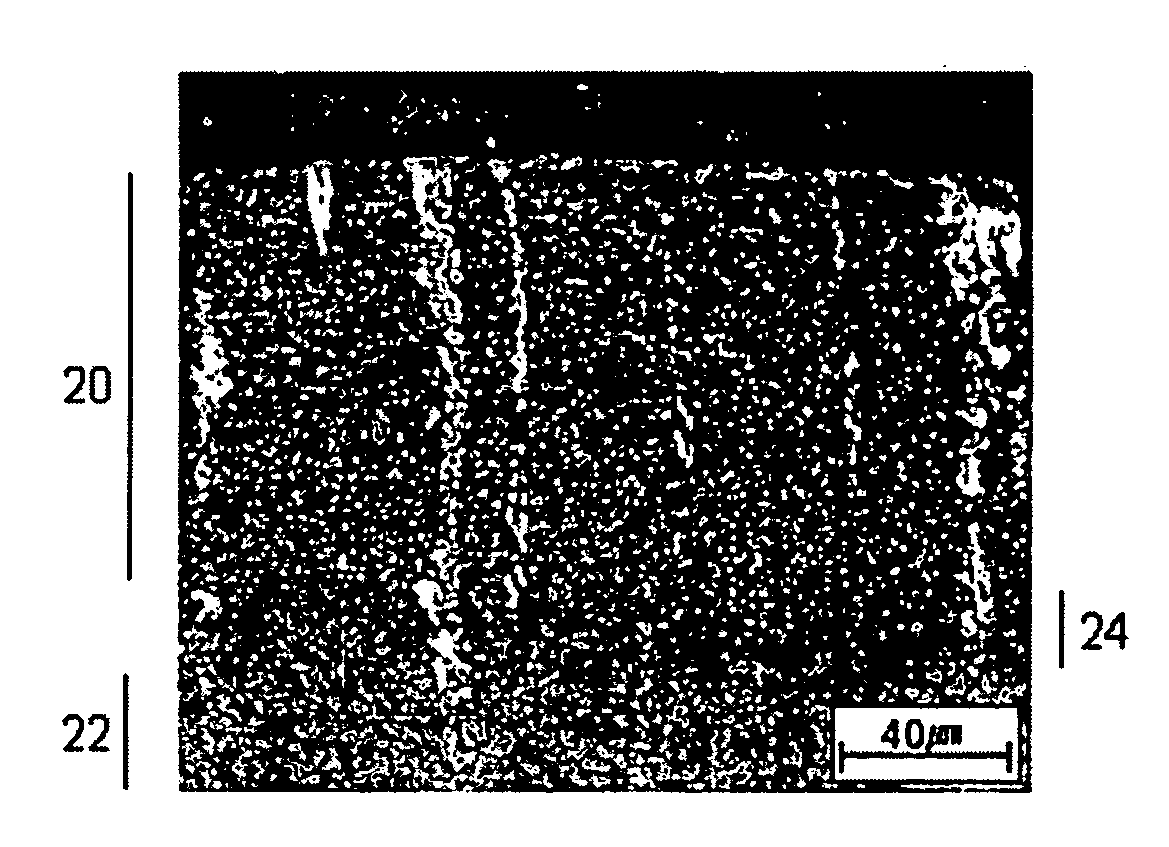

The invention discloses a low-temperature surface nitriding method of a titanium alloy, and belongs to the technical field of metal surface heat treatment and modification. The low-temperature surface nitriding method is characterized by comprising the following steps of: firstly, carrying out sand blasting cleaning on the surface of the titanium alloy, then carrying out chemical mechanical lapping and polishing, then mixing powder crystal sodium cyanate (NaCNO) and granular crystal potassium cyanate (KCNO) and rare earth CeO2 powder in a certain proportion so as to obtain a nitriding reagent, placing the nitriding reagent and the treated titanium alloy in a crucible for compacting and sealing, then drying, and placing the crucible in a high-temperature furnace for heating, wherein NaCNO and KCNO are used as nitriding sources, and rare earth CeO2 is used as a catalyst. According to the low-temperature surface nitriding method, a TiN 0.3-1 nitriding layer is formed on the surface of the titanium alloy TC21, the friction coefficient of the surface of the titanium alloy is remarkably reduced, the surface hardness is increased, and the surface property is enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Modified lime sulphur and application thereof in gold leaching technology

ActiveCN103243222AReduce dosageImprove stabilityProcess efficiency improvementLead nitrateCalcium peroxide

The invention discloses a modified lime sulphur and an application thereof in a gold leaching technology. The modified lime sulphur comprises a stabilizer sodium-hexametaphosphate, oxidants-calcium peroxide and potassium cyanate, and additives-lead nitrate and soluble bromides (such as sodium bromide, potassium bromide, calcium bromide and the like). The modified lime sulphur is used as a gold leaching agent so as to effectively recover gold from gold-containing ores, gold concentrate powder and gold-containing wastes. The modified lime sulphur has the characteristics that the modified lime sulphur is easy to synthesize; the preparation cost is low; the preparation process is environment-friendly and toxic-free; and when the prepared modified lime sulphur is used for gold leaching, the gold leaching technology is simple, and the gold leaching velocity is high; and moreover, the modified lime sulphur is suitable for more ores than cyaniding gold leaching.

Owner:CENT SOUTH UNIV

Method for preparing N-carbamyl glutamic acid

InactiveCN101168518ANo side effectsReduce feeding costsUrea derivatives preparationOrganic compound preparationPropanoic acidFiltration

The invention discloses a method for preparing N-carbamoylglutamic acid. The method comprises the following steps: a. Mixing glutamic acid, potassium cyanate, potassium hydroxide, concentrated hydrochloric acid and urea propionic acid according to 1-1.5: The molar ratio of 1-1.5:1-1.5 is fully mixed to obtain the mixture; b. The mixture obtained in step a is dissolved in 1L of distilled water per 1-1.5mol, and placed at room temperature at 20-25°C for 16-20 hours to obtain Contain the liquid of the mixture described in step a of 1-1.5mol in every unit of liquid; c. acidify each unit of liquid described in step b with 80-100ml of concentrated hydrochloric acid, then stand in 200ml of ureapropionic acid for 2-3 hours After filtering, N-carbamylglutamic acid was recrystallized from water. Compared with other existing methods for producing N-carbamylglutamic acid, the present invention has the following advantages: 1. The method uses cheap glutamic acid as a raw material, which greatly reduces the production cost. 2. The production process is carried out at room temperature, and the process is simple. 3. N-carbamoylglutamic acid recrystallized from water has no toxic and side effects. The invention provides a practical way for really realizing the use of N-carbamyl glutamic acid as arginine substitute.

Owner:印遇龙

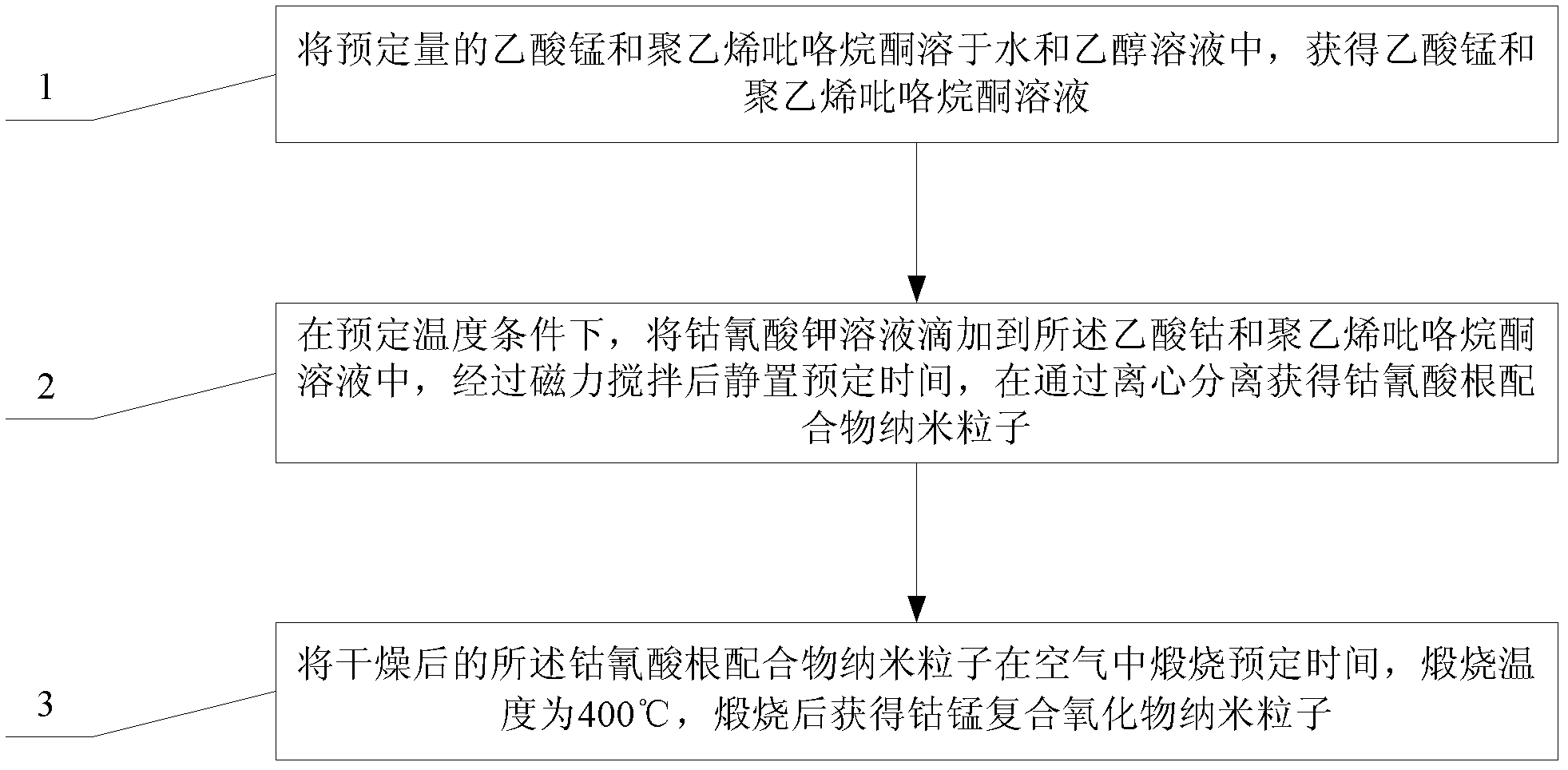

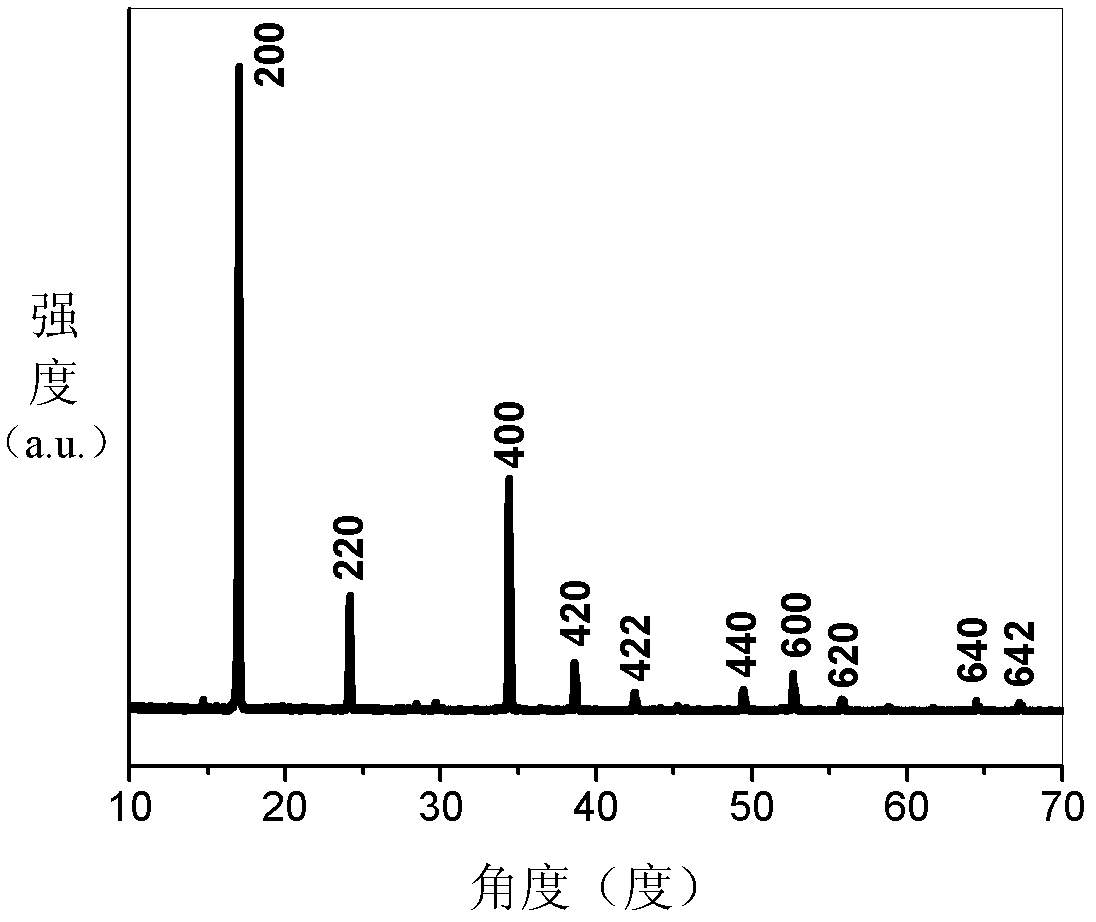

Preparation method of cobalt-manganese composite oxide nanoparticles and cobalt-manganese composite oxide nanoparticles prepared by adopting same

InactiveCN102437324AShape is easy to controlOptimal Control StructureMaterial nanotechnologyCell electrodesManganeseLithium-ion battery

The invention provides a preparation method of cobalt-manganese composite oxide nanoparticles and the application of the cobalt-manganese composite oxide nanoparticles prepared by adopting the method in a lithium ion battery. The corresponding method comprises the steps that a predetermined amount of manganese acetate and polyvinylpyrrolidone are dissolved in water and an ethanol solution, and a manganese acetate and polyvinylpyrrolidone solution is obtained; under a predetermined temperature condition, a cobalt potassium cyanate solution is dropwise added into the manganese acetate and polyvinylpyrrolidone solution, is magnetically stirred and then stands still for predetermined time, and cobalt cyanic acid radical complex nanoparticles are obtained through centrifugal separation; and the dried cobalt cyanic acid radical complex nanoparticles are calcined in air for predetermined time at a calcination temperature of 400 DEG C, and the cobalt-manganese composite oxide nanoparticles are obtained after the calcination. According to the preparation method, higher temperature and longer reaction time are not needed, the shapes and the structures of the particles are easy to control, the manufacturing process is relatively simple, the requirement for equipment is not high, and large-scale popularization and application can be realized.

Owner:UNIV OF SCI & TECH OF CHINA

Salt bath formula for treating high-speed steel air conditioning compressor blade by salt bath nitriding treatment and treatment method

ActiveCN101871087ARaise the concentration ratioLow melting pointSolid state diffusion coatingAir conditioningSodium cyanate

The invention relates to a salt bath formula for treating a high-speed steel air conditioning compressor blade by salt bath nitriding treatment and a treatment method. The salt bath formula comprises the following compositions in percentage by weight: 15-25 percent of potassium cyanate, 5-20 percent of sodium cyanate, 3-10 percent of lithium carbonate, 8-20 percent of sodium carbonate, 10-40 percent of potassium carbonate and 1-10 percent of sodium chloride. The invention has the advantages that because Li ions and Cl ions are added in the formula, the melting point of salt bath is lowered, and nitridation can be carried out under lower temperature; the activity is favorable, and good appearance and good diffusion layer thickness can be achieved without introducing ammonia; and the K / Na concentration proportion is enhanced, and a white layer is not easy to form on the surface of a workpiece.

Owner:SHANGHAI JIANGKAI METAL SURFACE TREATMENT TECH +1

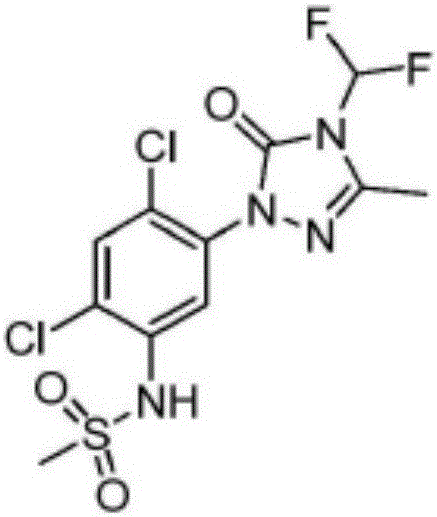

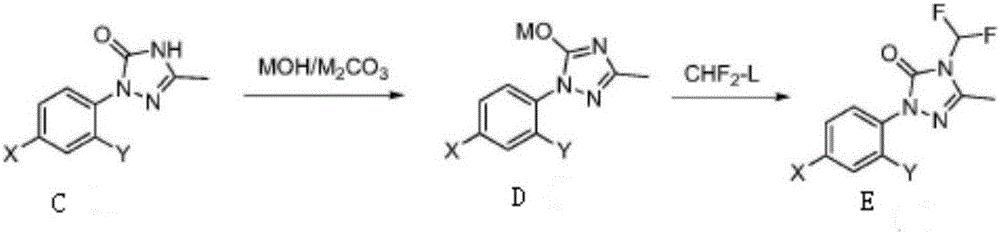

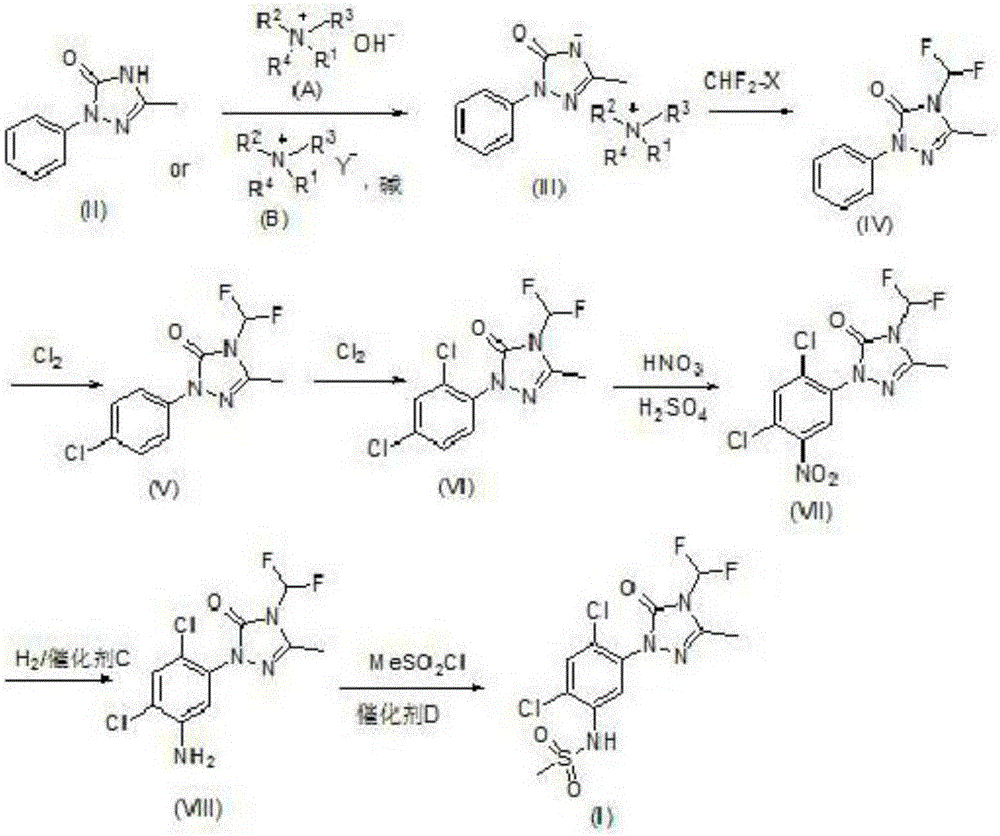

Method for synthesizing Sulfentrazone

The invention relates to a method for synthesizing Sulfentrazone. The method is characterized by comprising the steps of liberating o-chlorophenylhydrazine from o-chlorophenylhydrazine hydrochloride, which serves as a raw material, by an alkali, subjecting o-chlorophenylhydrazine to a reaction with trimethyl orthoacetate and potassium cyanate so as to obtain 1-o-chlorophenyl-3-methyl-1H-1,2,4-triazol-5-one, and then, subjecting 1-o-chlorophenyl-3-methyl-1H-1,2,4-triazol-5-one to N-alkylation, chlorination, nitration, reduction and sulfonylation, thereby obtaining the Sulfentrazone, wherein a composite catalyst and a solvent, i.e., dichloroethane are adopted in a chlorination reaction. The method for synthesizing the Sulfentrazone, disclosed by the invention, has the advantages that the o-chlorophenylhydrazine hydrochloride serves as the raw material, so that the steric hindrance of an intermediate product can be low, and the yield of the product is increased; and meanwhile, in the chlorination reaction, the composite catalyst is adopted, thus, the orientation effect on all atoms is good, and the solvent is dichloroethane, so that the recycling of the solvent is facilitated.

Owner:JIANGSU REPONT PESTICIDE FACTORY

Chemical heat treatment for solid rare earth accelerant

InactiveCN1804103AHigh surface hardnessImprove infiltration efficiencySolid state diffusion coatingChemical treatmentRare earth

The solid rare-earth energizer for chemical thermal treatment comprises: 40-90w% energizer of rare-earth chloride as any combination of La, Ce, Pr and Nd or single La or Ce; and 10-60w% auxiliary agent that contains 20-30% urea, 2-30% biamino hydride, 20-30% potassium ferrocyanide, and 20-25% KCN or NaCN; or 50-70% KCl, 20-40% NaCl, and 2-10% boric acid. This invention overcomes defects in prior art, and has high efficiency, large effect to metal phase tissue modification, and wide application range.

Owner:哈尔滨意锋稀土材料开发有限公司

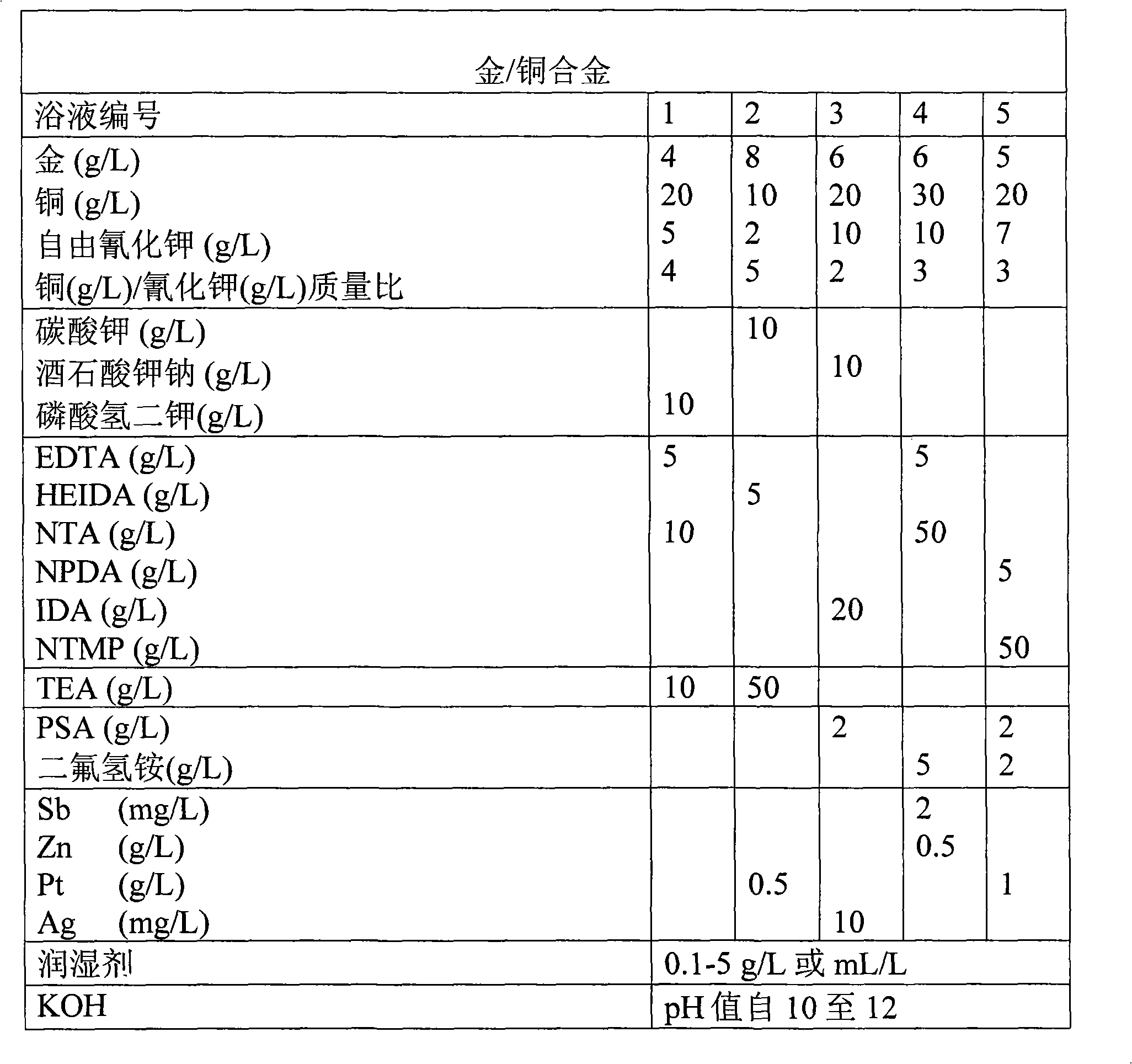

Electrolyte and method for electrolytic deposition of gold-copper alloys

This invention relates to an electrolyte as well as a method for the deposition of a gold-copper alloy on a substrate surface. With the electrolyte and method disclosed, deposition of gold-copper alloys with a value of carat in the range of 12 to 19 kt is possible. Beneath a source of gold and copper, the inventive electrolyte comprises potassium cyanate (KCN) in a concentration capable to maintain a copper to KCN ratio in the range of 3 to 7, and at least one complexing agent of the group consisting of ethylenediamine tetraacetic acid, diethylenetriamine pentaacetic acid, nitrilo-triacetic acid, ethylenediamine tetraacetic acid [EDTA], diethylenetriamine pentaacetic acid and nitrilo-triacetic acid [NTA] Hydroxyethyl imino diacetic acid [HEIDA], nitrilo propionic diacetic acid [NPDA], imino diacetic acid [IDA], nitrilo trimethylphosphoric acid [NTMA, Dequest 2000], triethanol amine [TEA].

Owner:ENTHONE INC

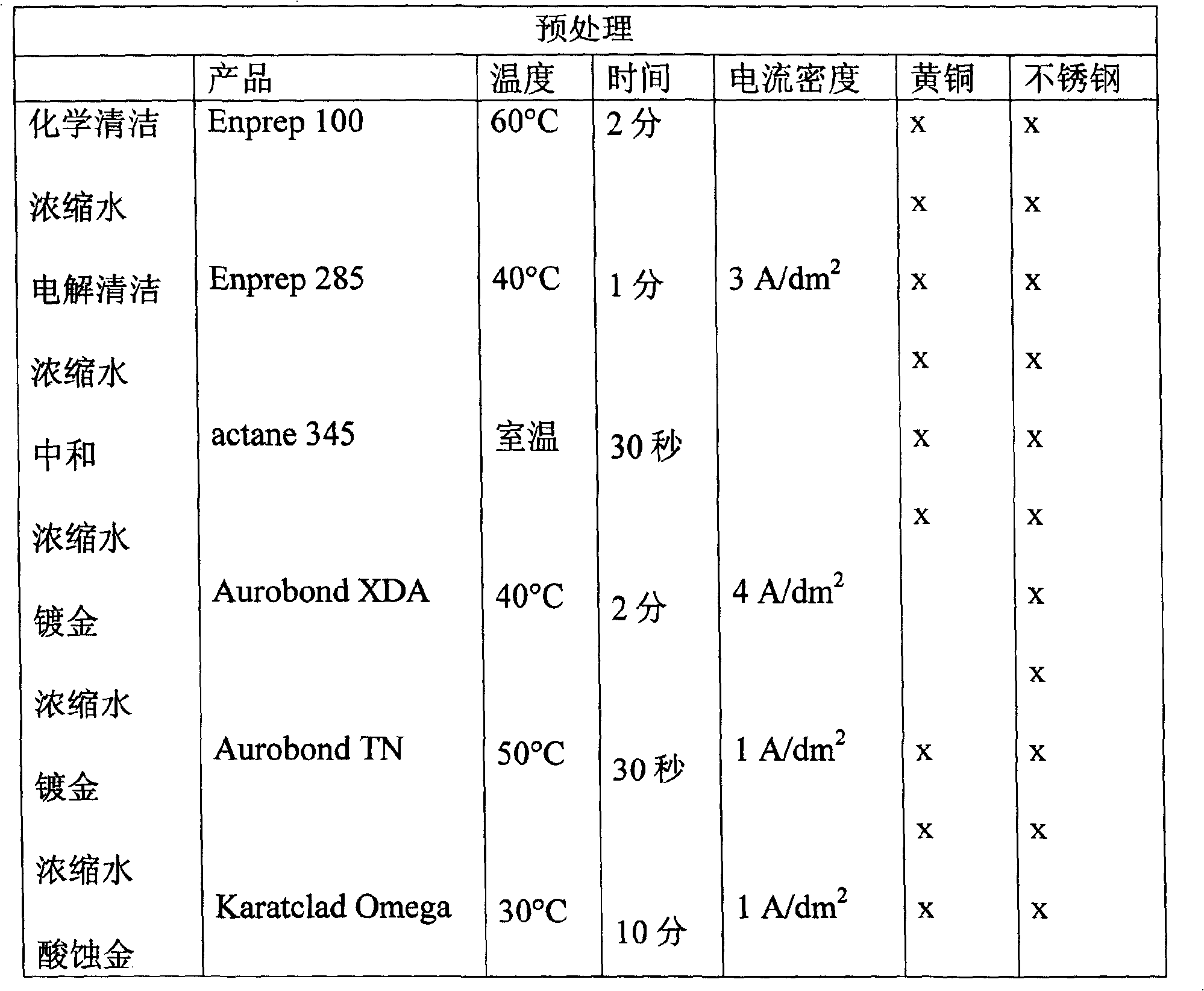

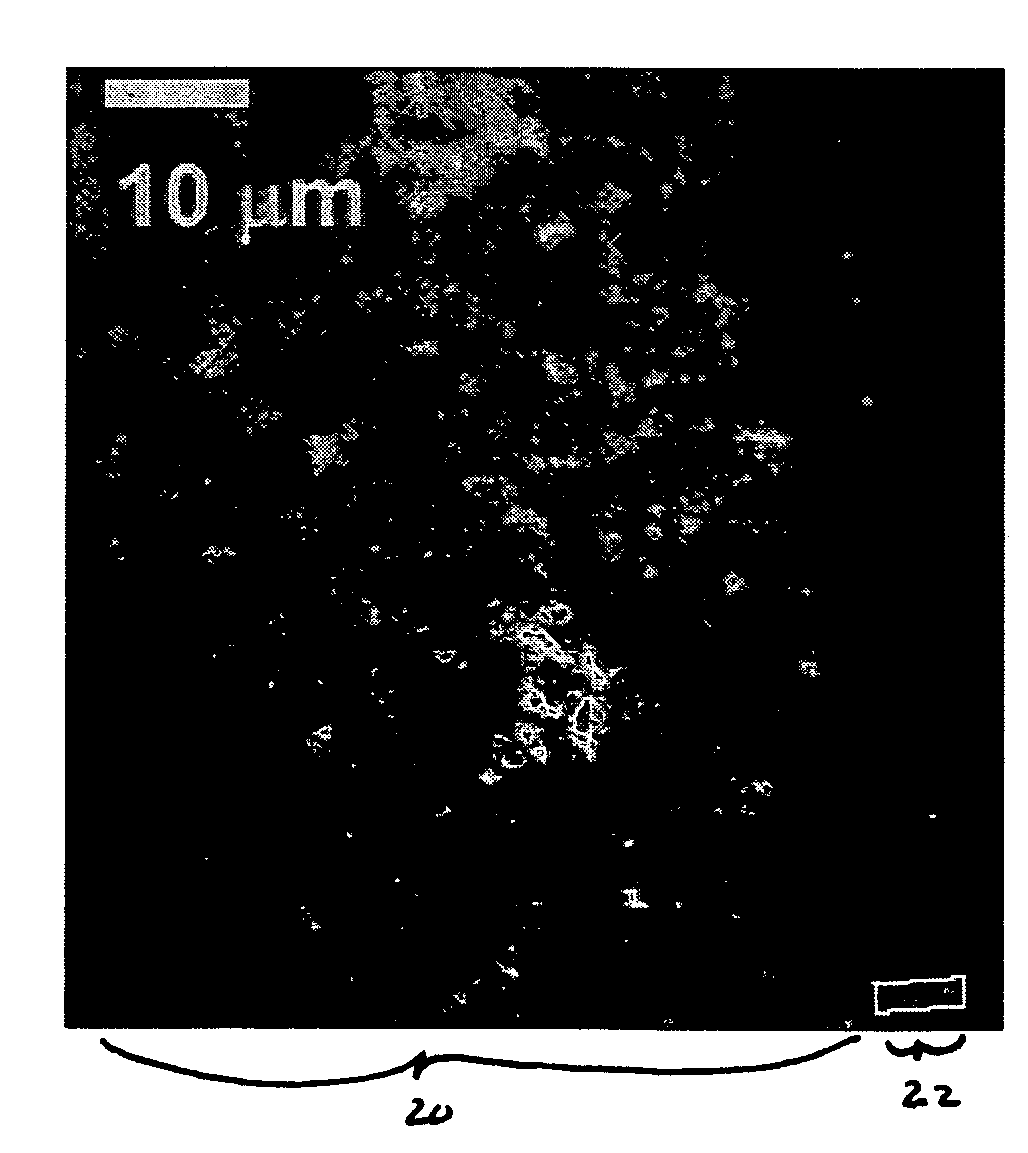

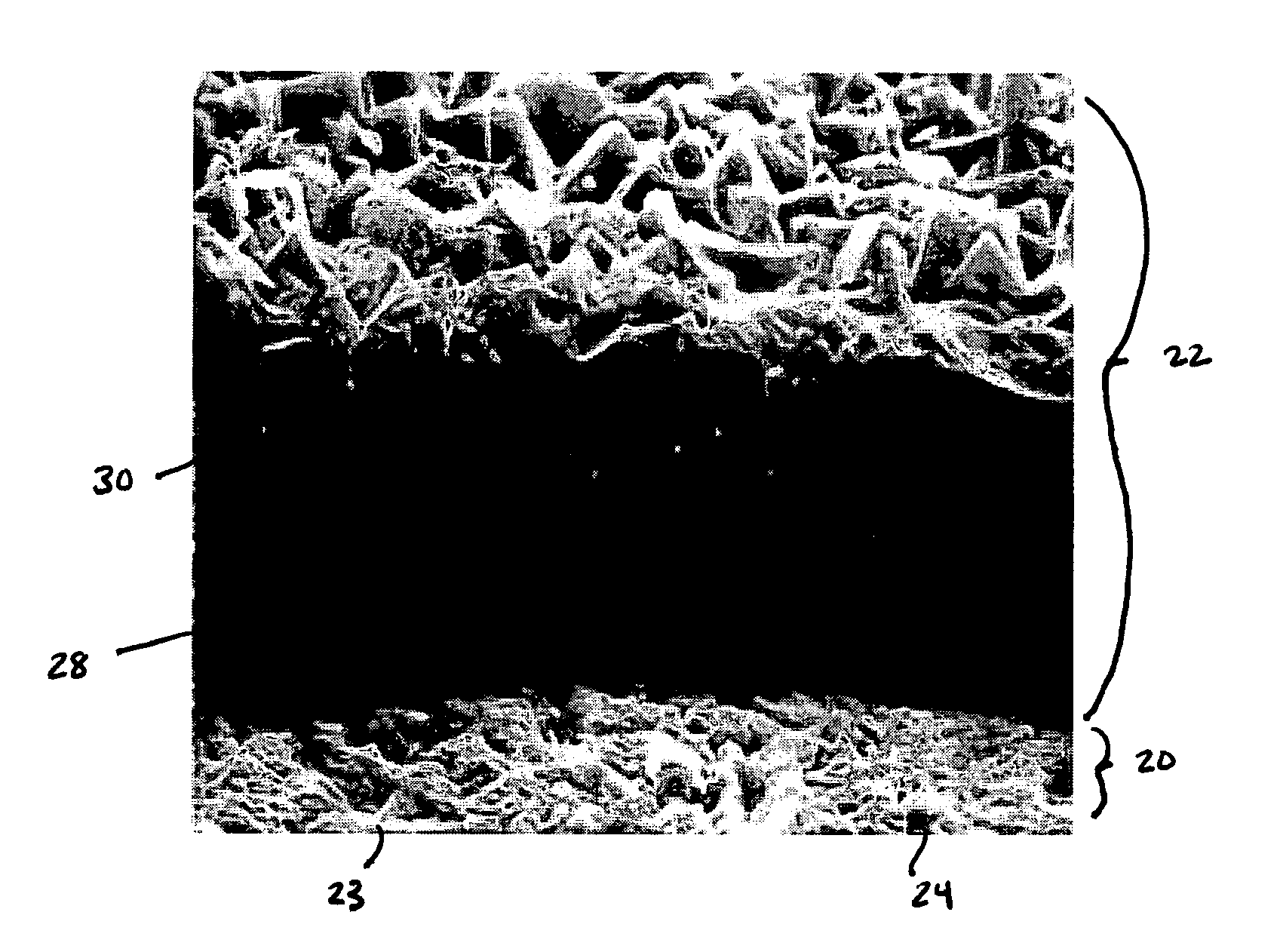

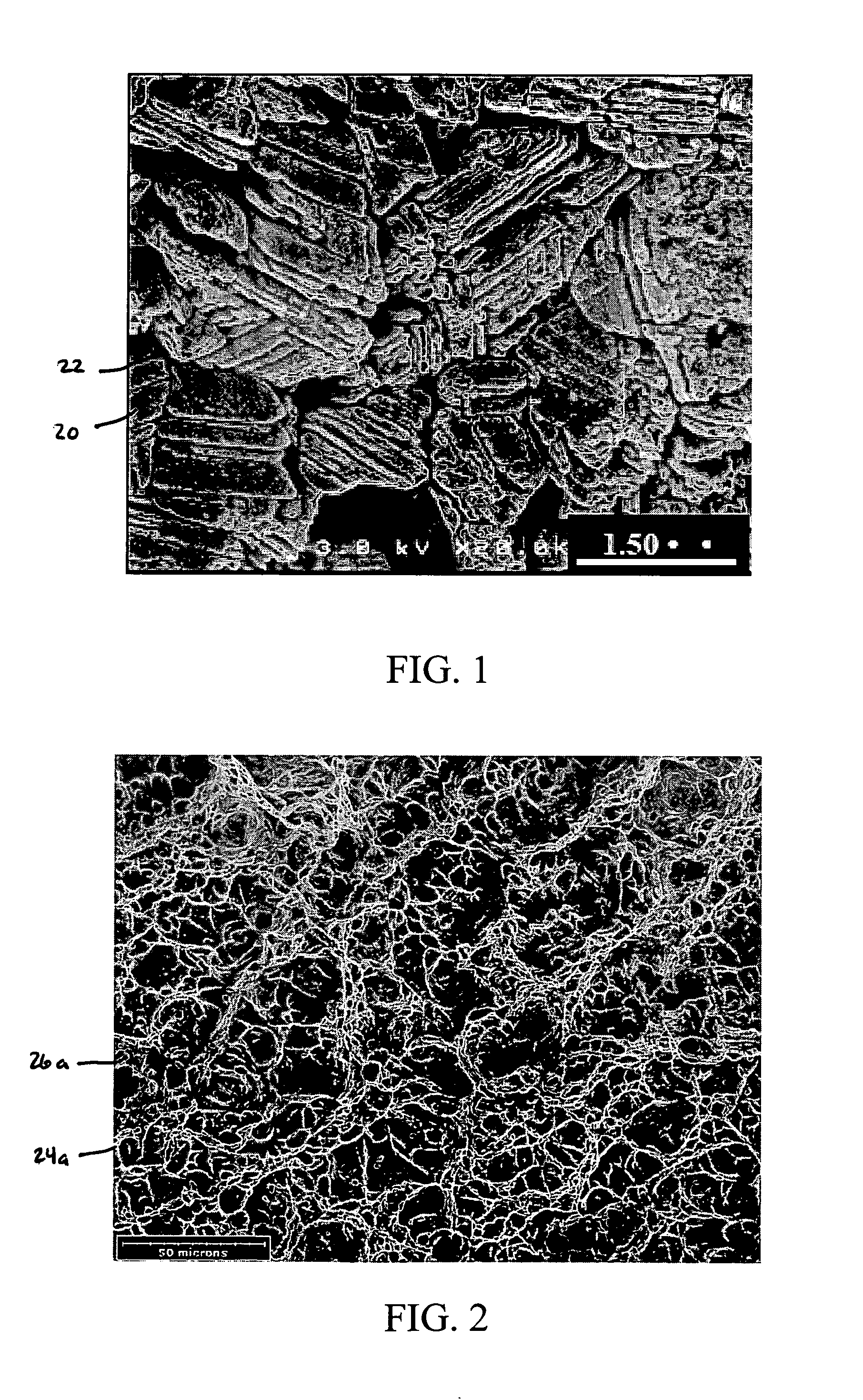

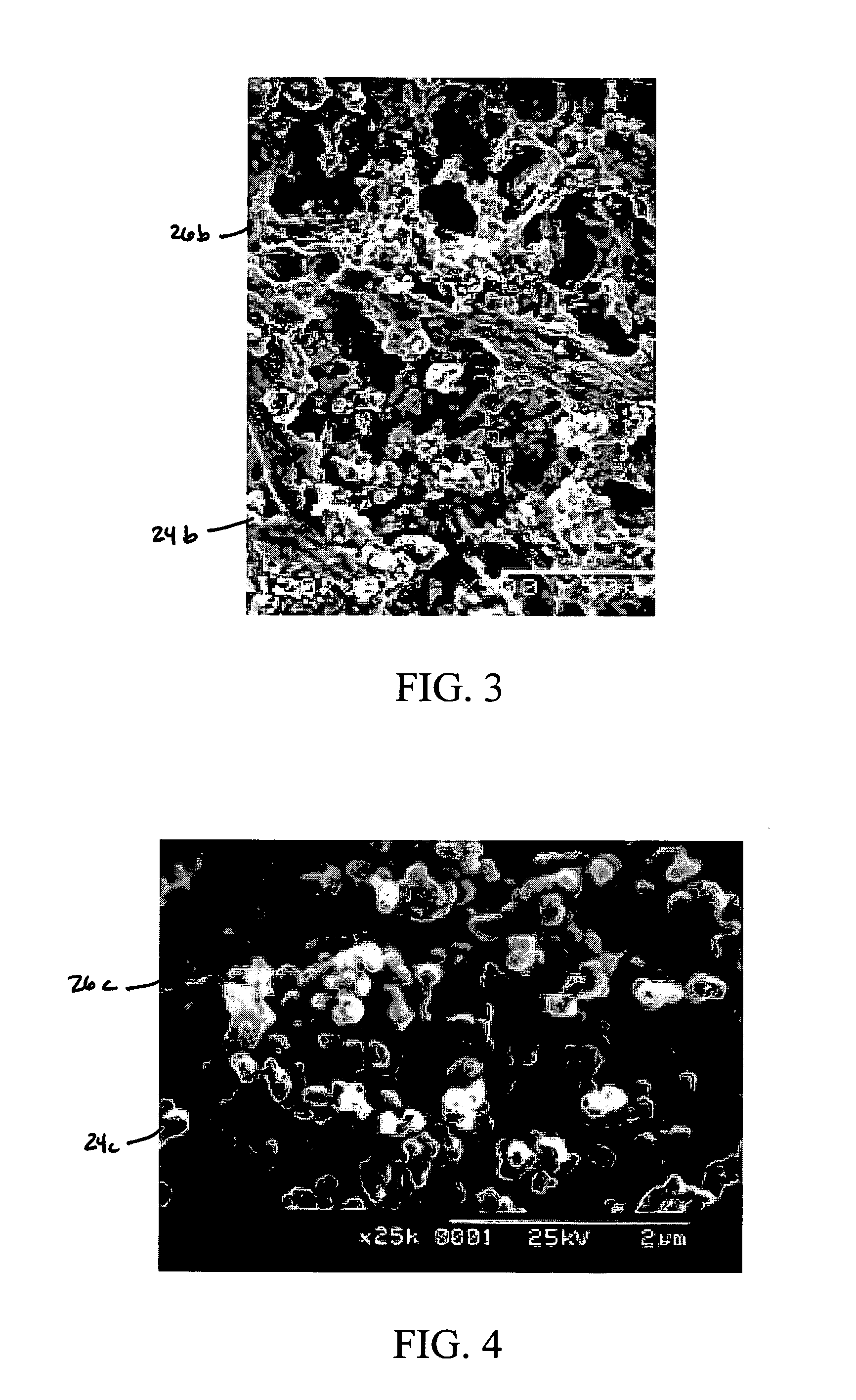

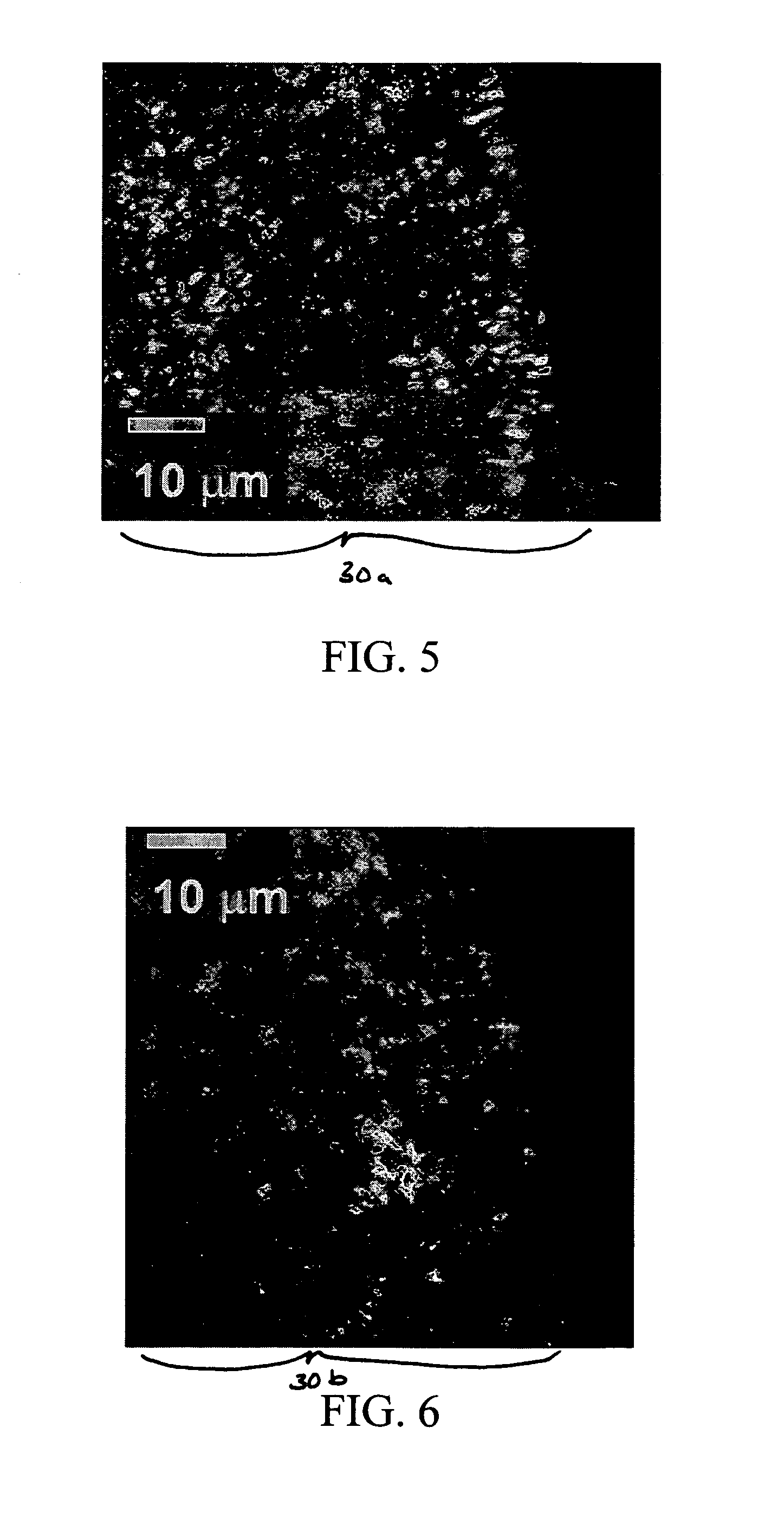

Process for diffusing titanium and nitride into a material having a coating thereon

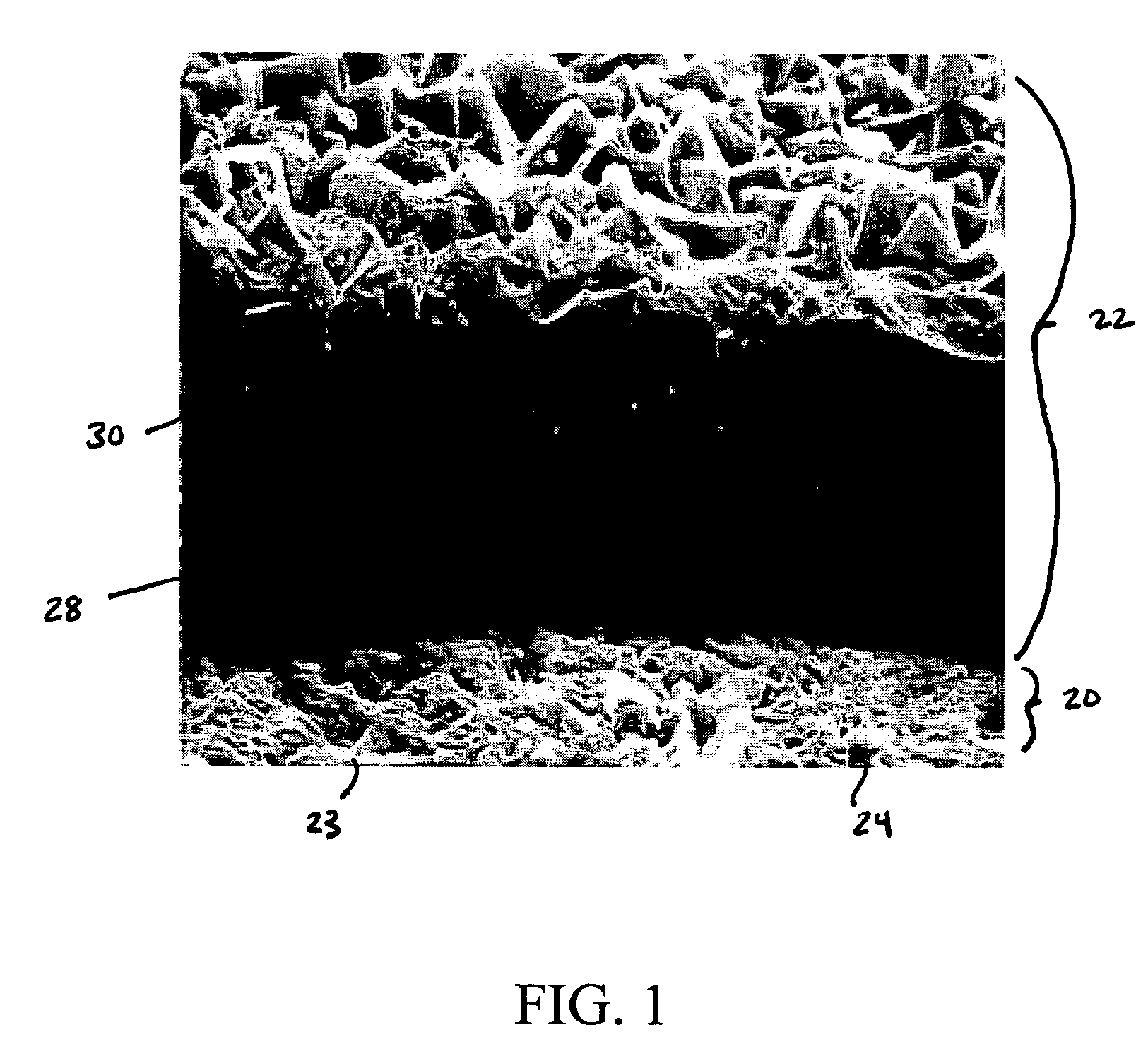

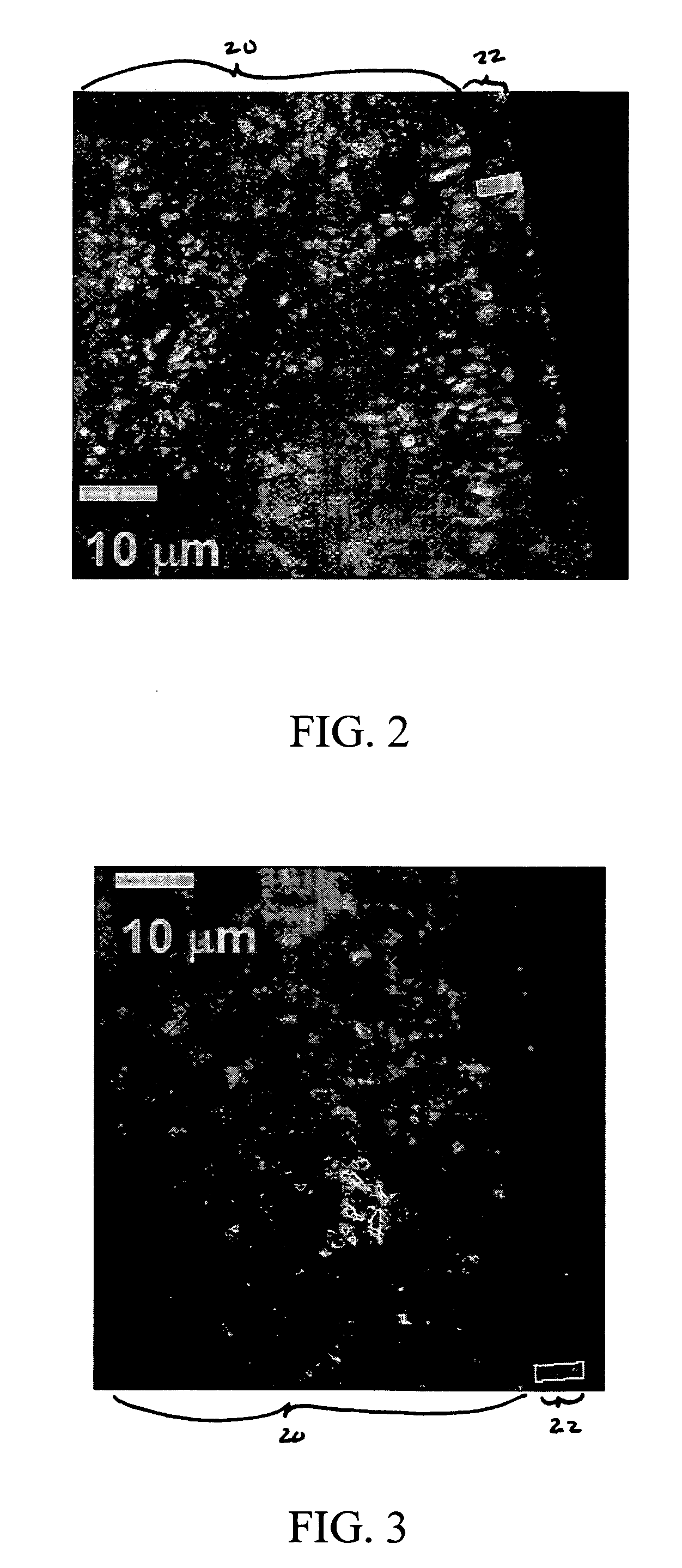

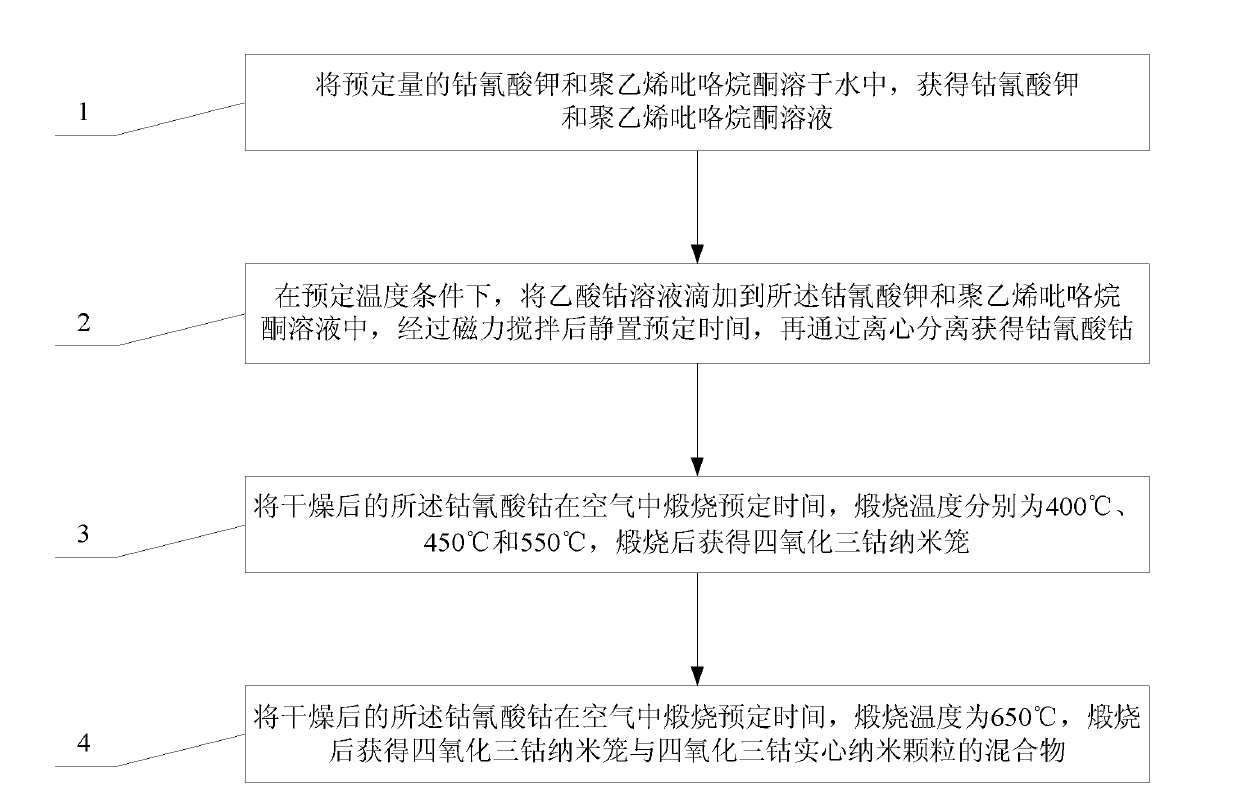

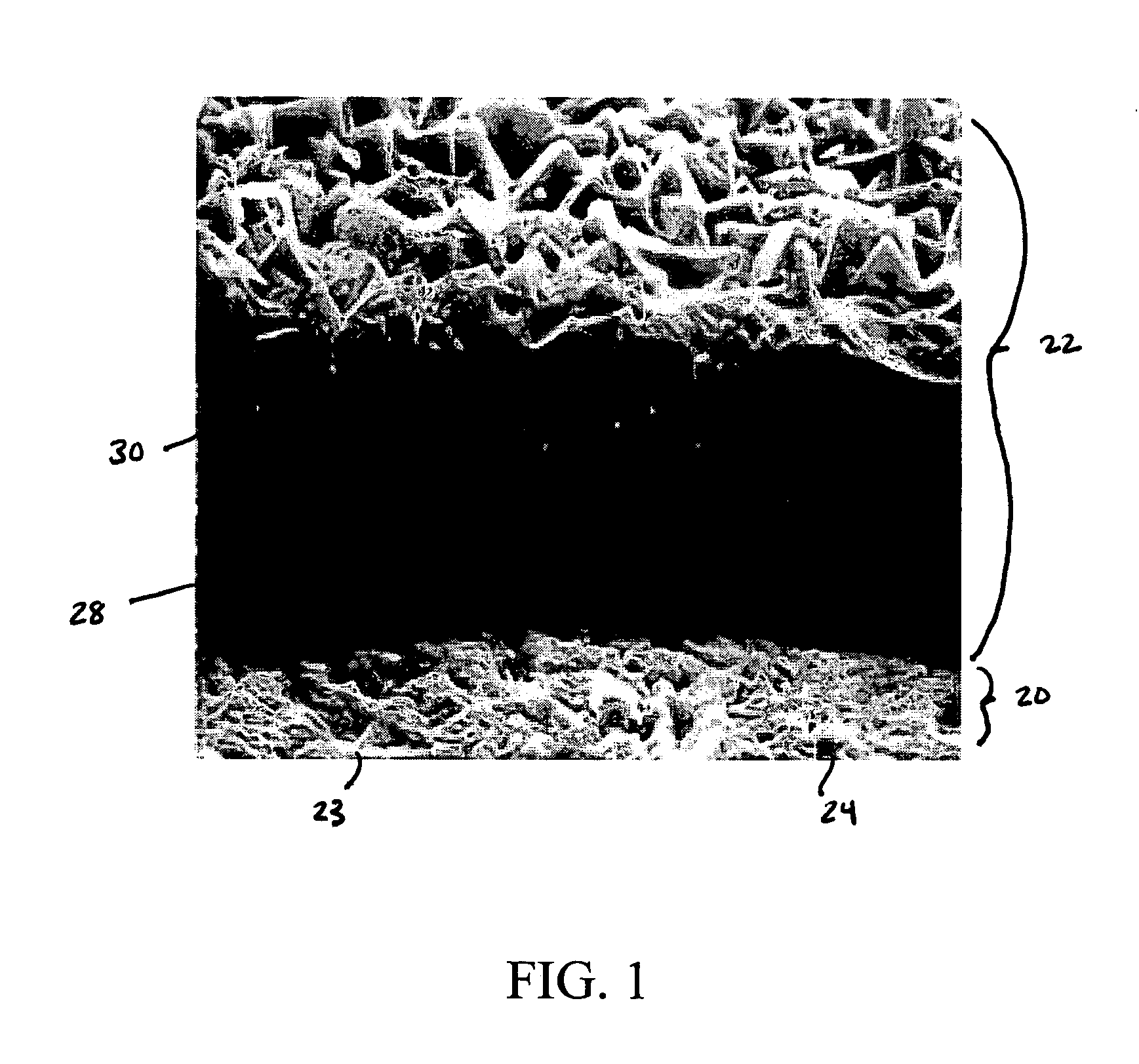

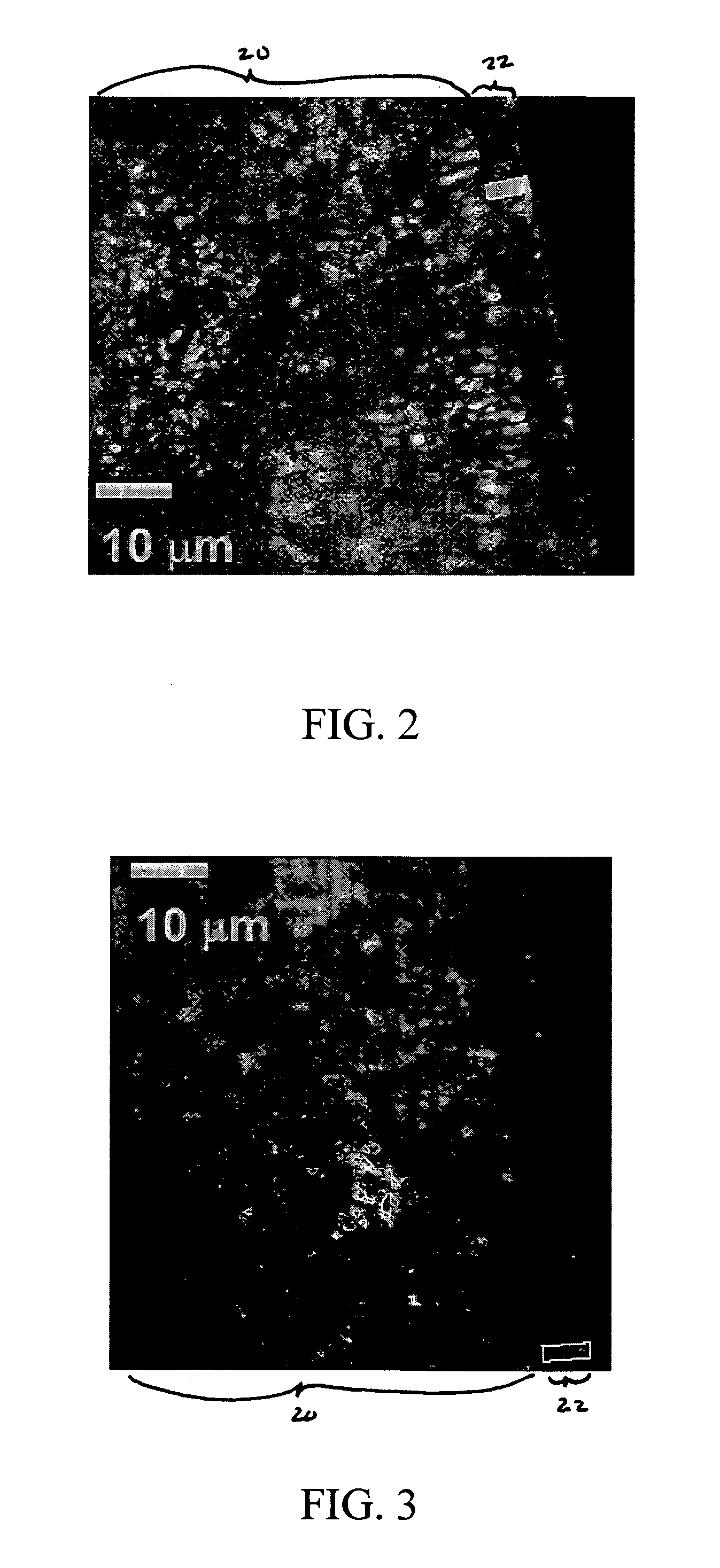

InactiveUS7438769B2Improve propertiesImprove adhesionHot-dipping/immersion processesPretreated surfacesElectrolysisTitanium

A method for diffusing titanium and nitride into a base material having a coating thereon using conventional surface treatments or coatings. The method generally includes the steps of providing a base material having a coating thereon; providing a salt bath which includes sodium dioxide and a salt selected from the group consisting of sodium cyanate and potassium cyanate; dispersing metallic titanium formed by electrolysis of a titanium compound in the bath; heating the salt bath to a temperature ranging from about 430° C. to about 670° C.; and soaking the base material in the salt bath for a time of from about 10 minutes to about 24 hours. In accordance with another aspect of the present invention, titanium and nitride may be diffused into a base material without a coating. The treated base material may further be treated with conventional surface treatments or coatings.

Owner:KO PHILOS JONGHO +1

Salt bath formula for treating stainless air conditioning compressor blade by salt bath nitriding treatment and treatment method

ActiveCN101871088ALow melting pointHigh activitySolid state diffusion coatingPotassium hydroxideAir conditioning

The invention relates to a salt bath formula for treating a stainless air conditioning compressor blade by salt bath nitriding treatment and a treatment method. The salt bath formula comprises the following compositions in percentage by weight: 5-20 percent of potassium cyanate, 15-25 percent of sodium cyanate, 3-10 percent of lithium carbonate, 8-25 percent of sodium carbonate, 10-30 percent of potassium carbonate, 1-3 percent of sodium hydroxide, 1-5 percent of potassium hydroxide and 1-15 percent of sodium chloride or sodium fluoride. The invention has the advantages that because Li ions and Cl ions are added in the formula, a melting point of salt bath is lowered, and nitridation can be carried out under lower temperature; the activity is favorable, and good appearance and good diffusion layer thickness can be achieved without introducing ammonia; and air cooling can be adopted after salt bath nitridation without adopting the traditional oil cooling mode.

Owner:SHANGHAI JIANGKAI METAL SURFACE TREATMENT TECH +1

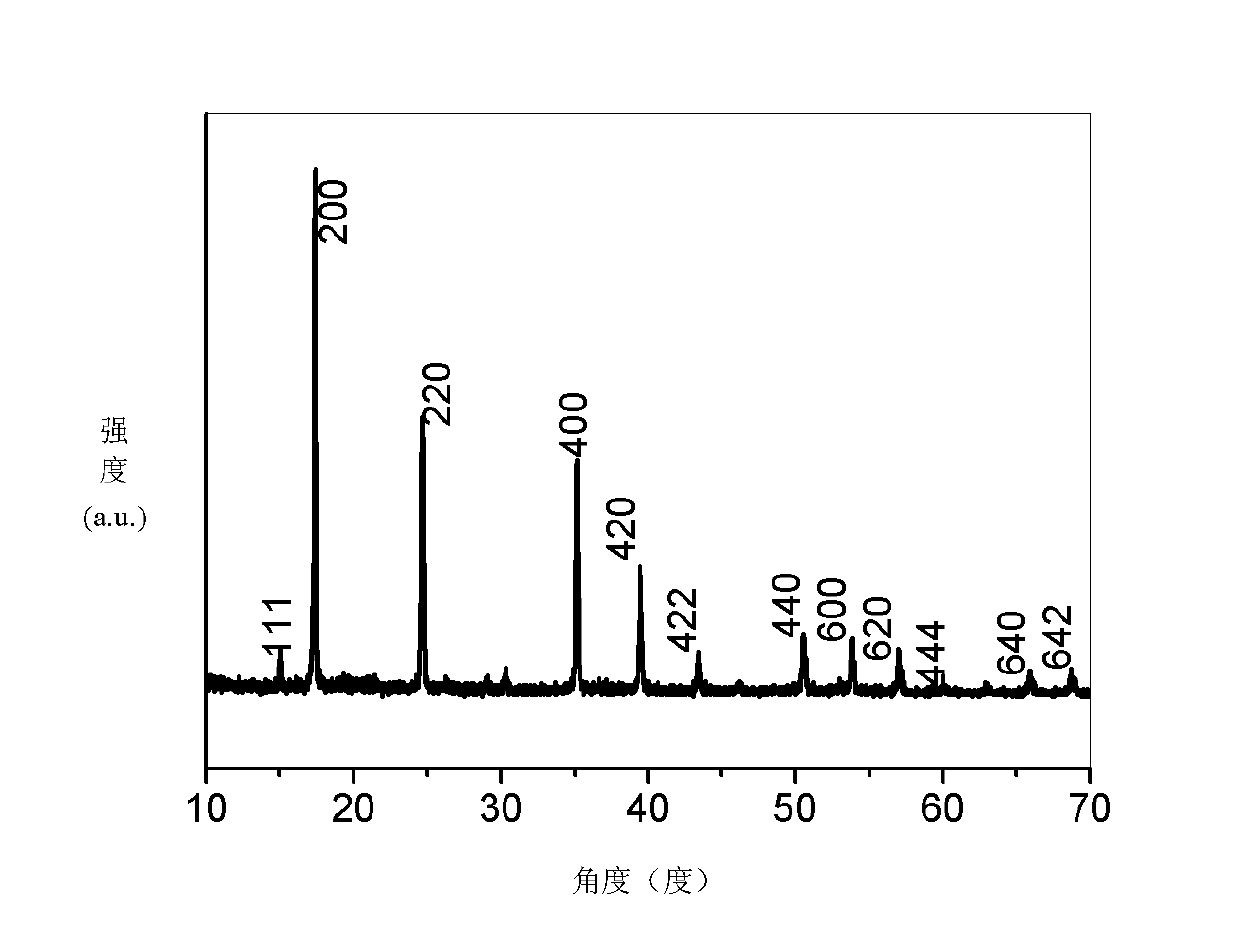

Preparation method of cobaltosic oxide nano cage and cobaltosic oxide nano cage prepared by adopting same

InactiveCN102437325ASimple preparation processAchieve mass productionMaterial nanotechnologyCell electrodesHigh pressureLithium-ion battery

The invention provides a preparation method of a cobaltosic oxide nano cage and the application of the cobaltosic oxide nano cage prepared by adopting the method in a lithium ion battery. The corresponding method comprises the steps that a predetermined amount of cobalt potassium cyanate and polyvinylpyrrolidone are dissolved in distilled water, and a cobalt potassium cyanate and polyvinylpyrrolidone solution is obtained; a cobaltous acetate solution is dropwise added to the cobalt potassium cyanate and polyvinylpyrrolidone solution, is magnetically stirred and then stands still for predetermined time, and then cobalt cyanate cobalt is obtained through centrifugal separation; the dried cobalt cyanate cobalt is calcined in air respectively at the calcination temperatures of 400 DEG C, 450 DEG C and 550 DEG C, and the cobaltosic oxide nano cage is obtained after the calcination; the dried cobalt cyanate cobalt is calcined in air for predetermined time at a calcination temperature of 650 DEG C, and a mixture of the cobaltosic oxide nano cage and cobaltosic oxide solid nanoparticles is obtained after the calcination. According to the preparation method, high temperature and high pressure are not needed, the manufacturing process is relatively simple, the requirement for equipment is not high, an operator only needs to use conventional equipment, and large-scale production can be realized.

Owner:UNIV OF SCI & TECH OF CHINA

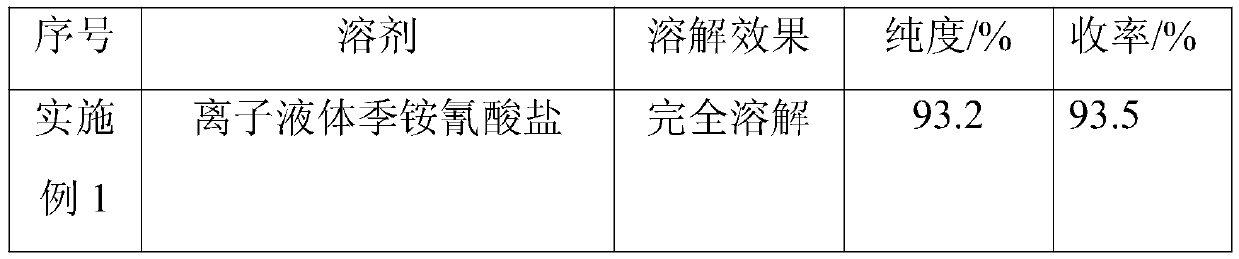

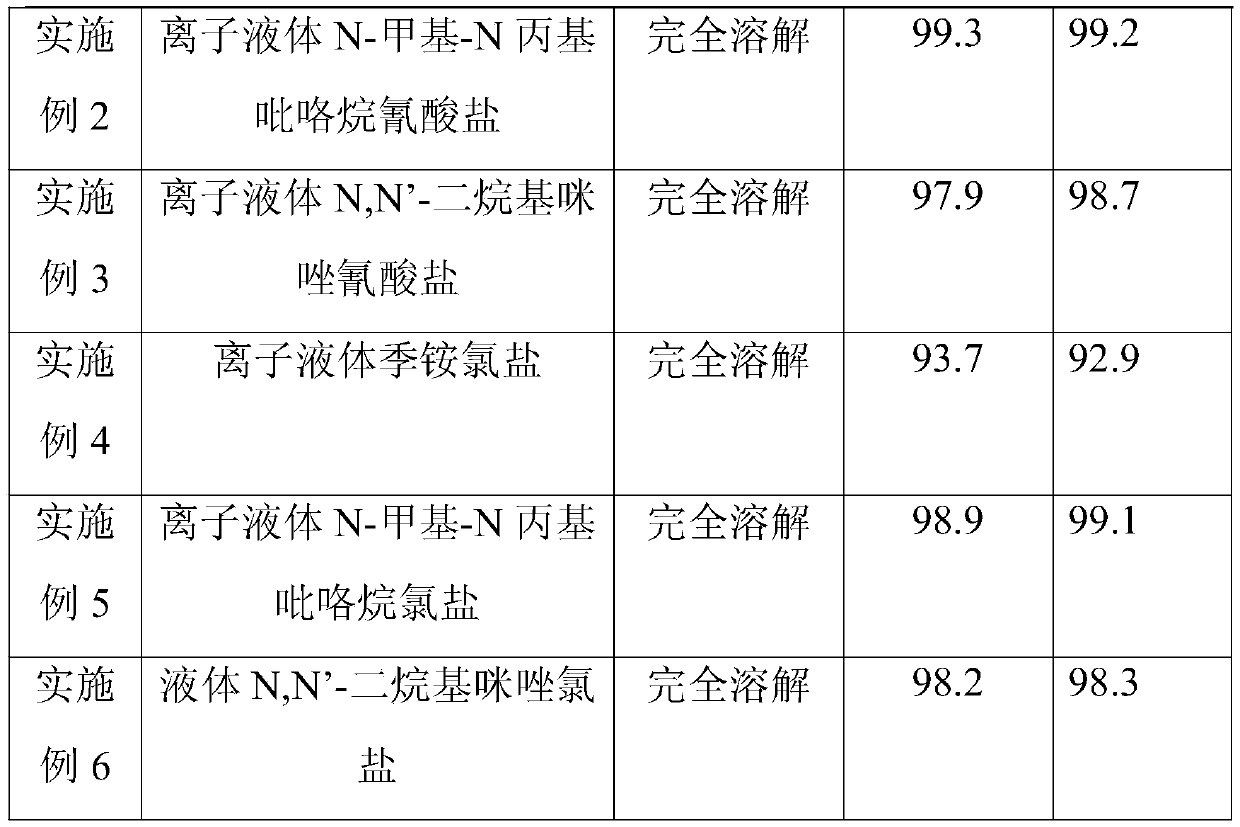

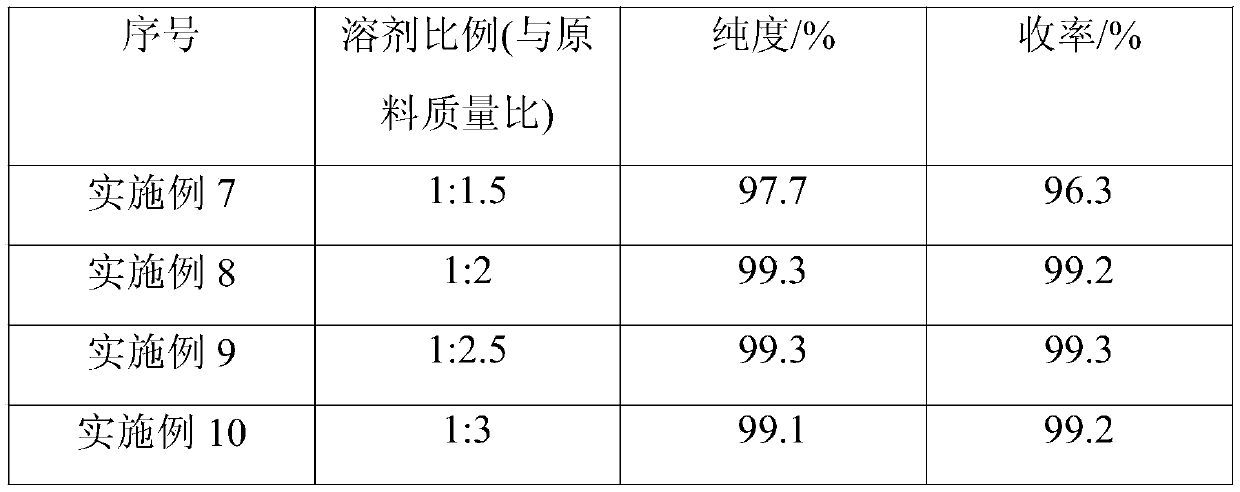

Preparation of high-purity potassium cyanate

The invention discloses a method for preparing high-purity potassium cyanate, which belongs to preparation of the potassium cyanate. The method takes industrial urea and potassium carbonate as raw materials and dimethyl sulfoxide or dimethyl formamide as a solvent, and adopts proper technological conditions: the reaction temperature is 130 DEG C, the reaction time is 8 hours, the mol ratio of the urea to the potassium carbonate is 3.5 to 1, and the mass ratio of the solvent to the urea is 7 to 1; the product with 96 percent (mass fraction) of the potassium cyanate can be obtained, and the obtained potassium cyanate is washed by adopting anhydrous alcohol as a detergent, wherein the amount of the detergent is 3 to 4 times of the volume of the potassium cyanate; and the potassium cyanate after washing is dried, and the potassium cyanate with the purity of more than 98 percent (mass fraction) can be obtained. The method has the advantages that the technology is simple and easy and the purity of the prepared potassium cyanate is as high as more than 98 percent (mass fraction).

Owner:XUZHOU COLLEGE OF INDAL TECH

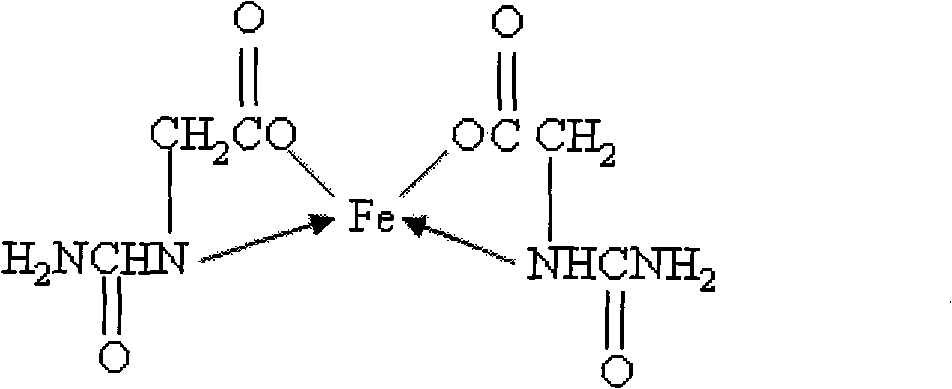

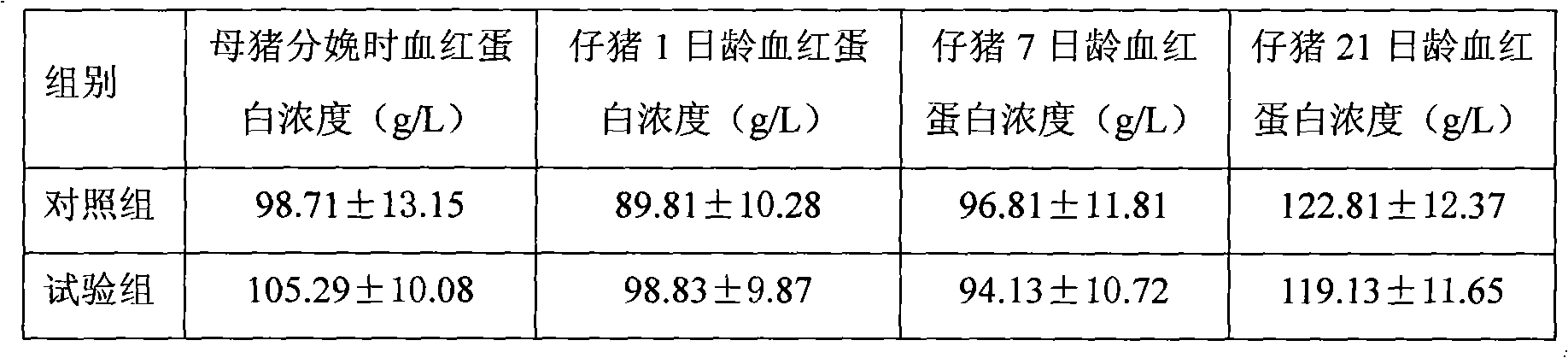

Dipeptide iron chelate for feed additives and preparation method thereof

ActiveCN102093467AImprove protectionShort process routeAnimal feeding stuffAccessory food factorsFood additiveGlycine

The invention provides a method for preparing carbamyl glycine dipeptide iron chelate, which comprises the following steps: preparing carbamyl glycine dipeptide by utilizing glycine and potassium cyanate, preparing carbamyl glycine dipeptide iron chelate by utilizing the carbamyl glycine dipeptide and ferrous sulfate, and the like. The invention also provides carbamyl glycine dipeptide iron chelate prepared by the method, which is used for preparing feeds or additives for preventing baby pigs or pregnant sows from anemia. The product provided by the invention can effectively increase the hemoglobin concentration in the blood of sows and baby pigs during the parturition of the sows; and the method provided by the invention can replace the traditional method for complementing iron by injecting newborn baby pig muscle injections, thereby saving the labor force and being convenient to use.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI +1

Process for diffusing titanium and nitride into a material having a coating thereon and products produced thereby

InactiveUS20070243398A1Improve propertiesImprove adhesionHot-dipping/immersion processesPretreated surfacesElectrolysisTitanium

A method for diffusing titanium and nitride into a base material having a coating thereon using conventional surface treatments or coatings. The method generally includes the steps of providing a base material having a coating thereon; providing a salt bath which includes sodium dioxide and a salt selected from the group consisting of sodium cyanate and potassium cyanate; dispersing metallic titanium formed by electrolysis of a titanium compound in the bath; heating the salt bath to a temperature ranging from about 430° C. to about 670° C.; and soaking the base material in the salt bath for a time of from about 10 minutes to about 24 hours. In accordance with another aspect of the present invention, titanium and nitride may be diffused into a base material without a coating. The treated base material may further be treated with conventional surface treatments or coatings.

Owner:KO PHILOS JONGHO +1

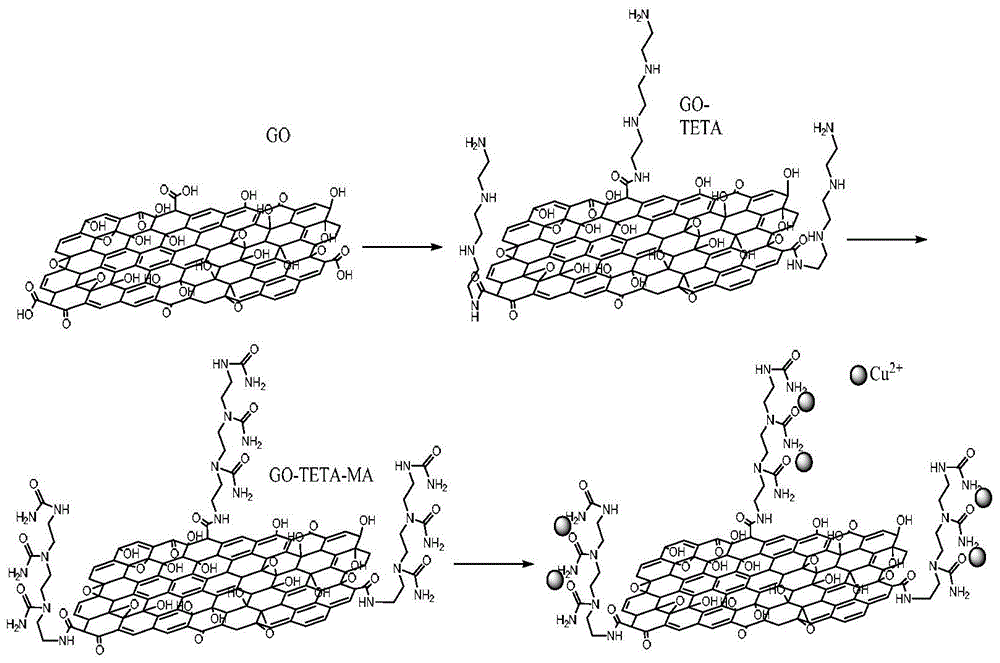

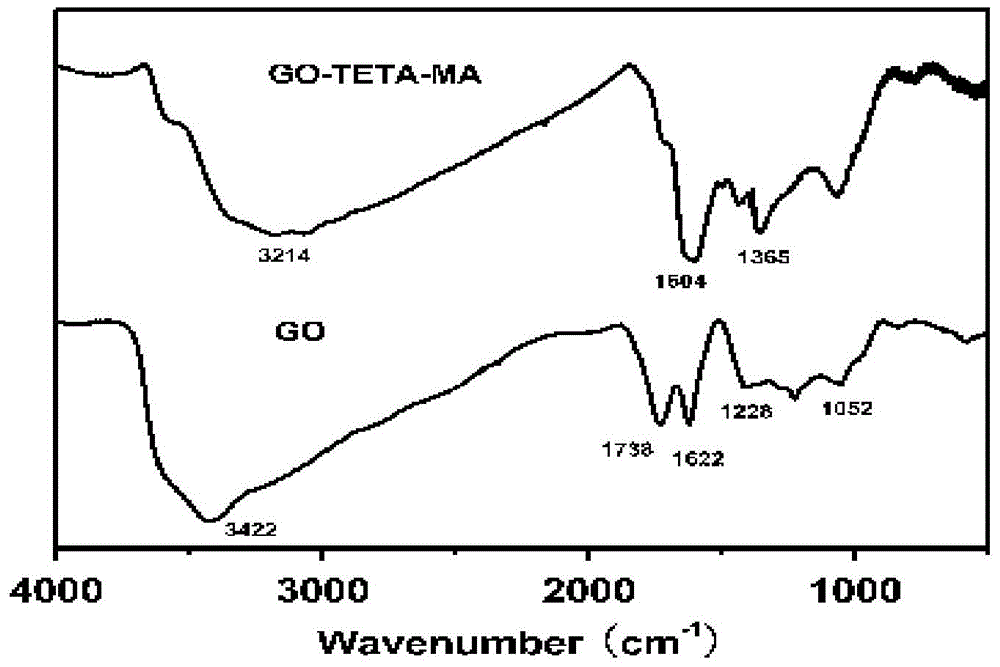

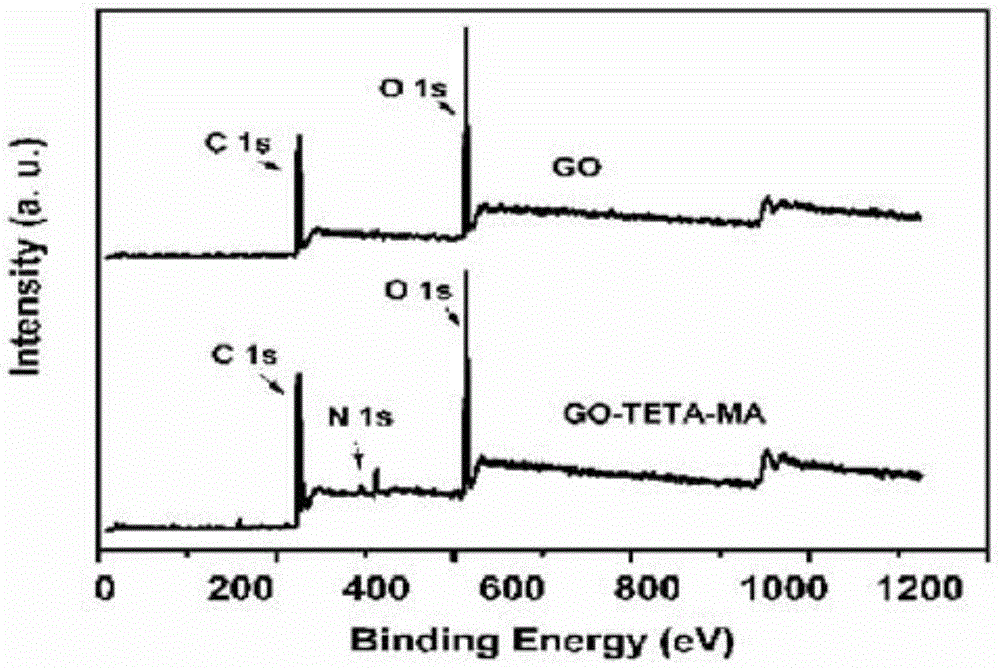

Preparation method of graphene oxide adsorption material adsorbing copper ions

The invention relates to a preparation method of a graphene oxide adsorption material adsorbing copper ions, and particularly relates to a preparation method of a graphene oxide adsorption material. The invention aims to solve the problem of low adsorption capacity of modified graphene oxide for copper ions. According to the preparation method, water is used as a solvent, and graphene oxide is grafted with triethylene tetramine and then is modified with potassium cyanate, so as to obtain a solid copper ion adsorption material with multiple adsorption sites. The material prepared by using the preparation method has a good adsorption effect on copper ions and can reach the hygienic standard of domestic drinking water after adsorption, the adsorbent is stable in properties and is not influenced by acid and alkaline, and the situations of secondary pollution and the like cannot occur; the synthetic method is simple and is suitable for industrial production. The preparation method is used in the field of treating heavy metal pollutants in water.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

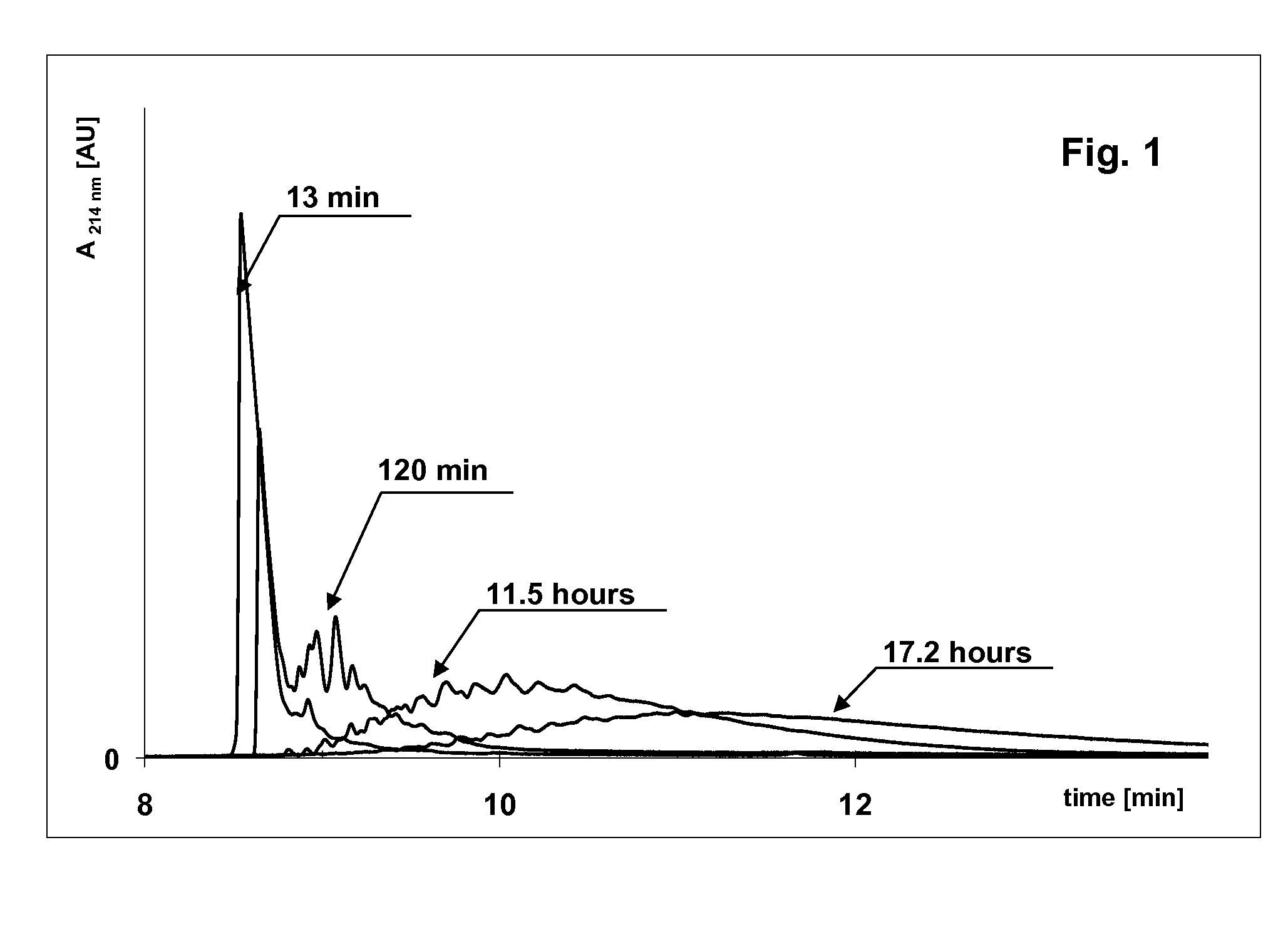

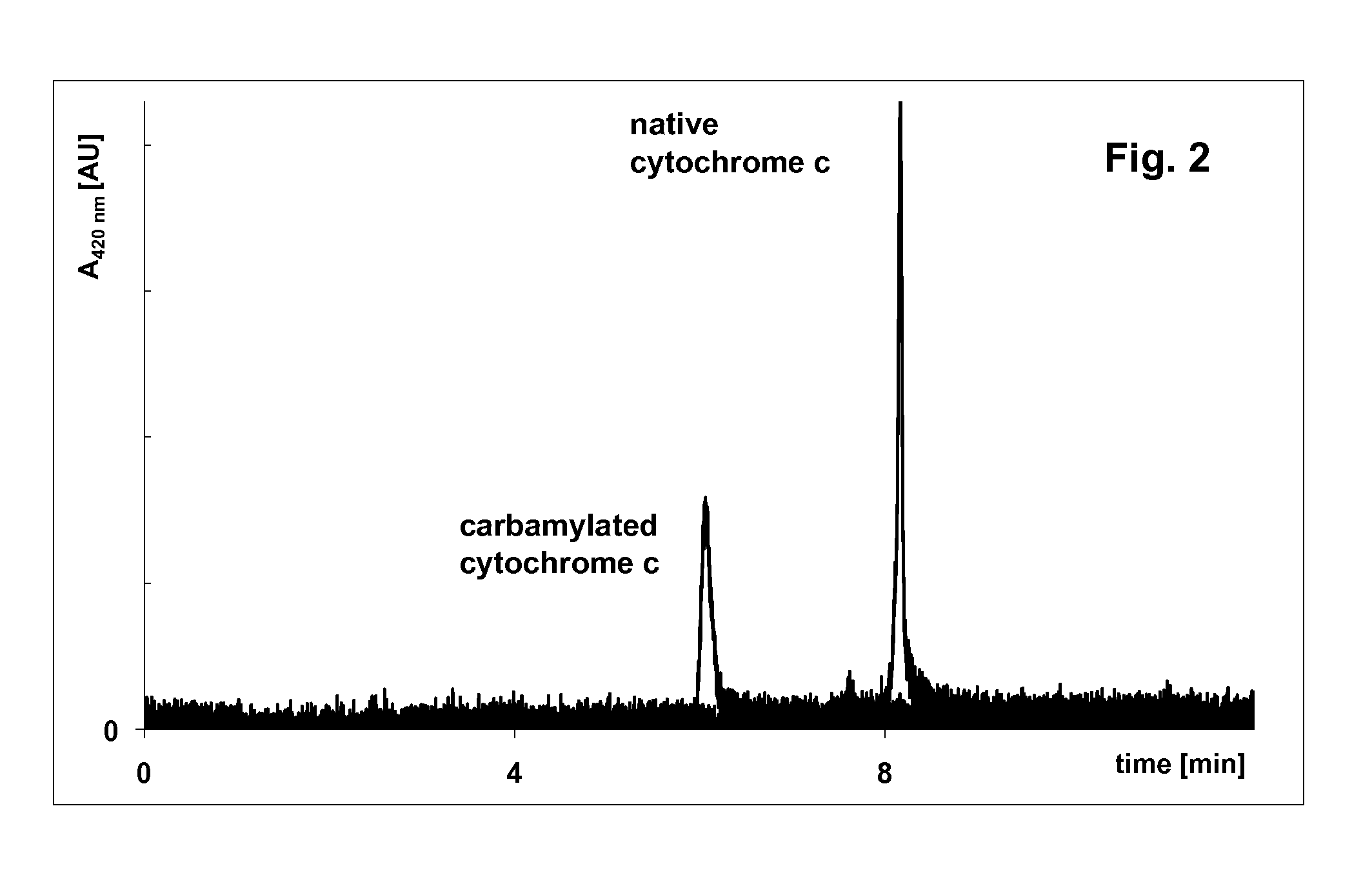

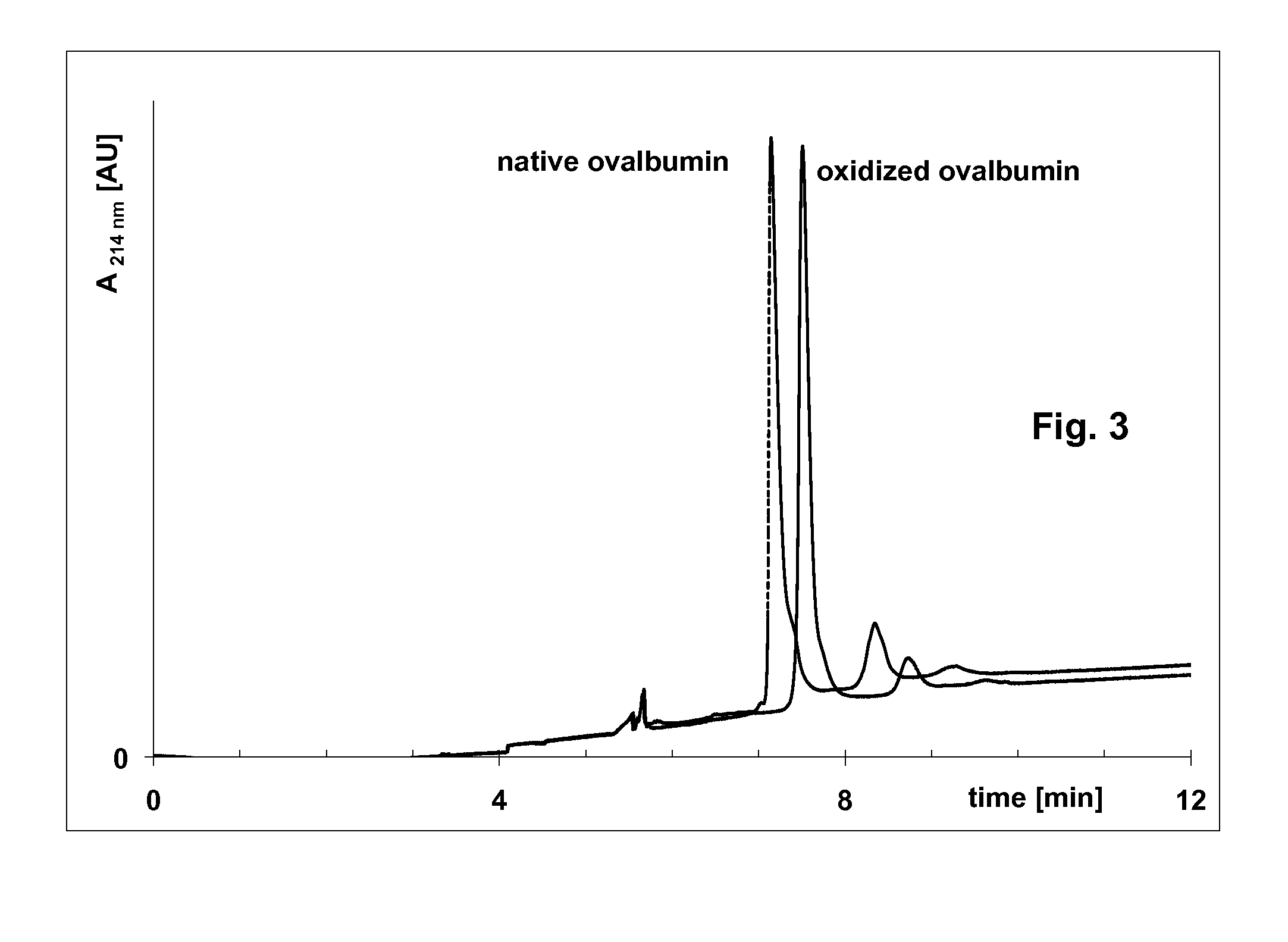

Chemical modification of proteins for their more accurate molecular-weight determination by electrophoresis

InactiveUS20120125775A1Improve accuracyElectrolysis componentsPeptide/protein ingredientsElectrophoresisChemical modification

Disclosed herein is a composition and method for sample preparation of proteins for their size separation by electrophoresis, suitable for molecular-weight determination of proteins in the range between about 14,000 and 500,000. In an embodiment, proteins, particularly those exhibiting biased migration, are modified to change their intrinsic charge, or carbohydrate component to improve accuracy of their molecular weights as determined by electrophoretic size separation via their interaction with ionic surfactants. In a preferred embodiment, the proteins are carbamylated with potassium cyanate and their carbohydrate components are oxidized with sodium periodate.

Owner:DOLNIK VLADISLAV +1

Preparation method of 3-isocyanate propyltriethoxysilane

ActiveCN110437273AWide variety of sourcesLow costGroup 4/14 element organic compoundsBulk chemical productionTriethoxysilaneSolvent

The invention relates to a preparation method of 3-isocyanate propyltriethoxysilane, belonging to the field of fine chemical synthesis. The method comprises synthesizing the 3-isocyanate propyltriethoxysilane from chloropropyltriethoxysilane and potassium cyanate through one-step synthesis in an ionic liquid adopted as a solvent under a catalysis function. An isocyanate process is adopted, and aiming at disadvantages, of the process, that reaction raw materials are difficult to dissolve and yields are low, the preparation method of the 3-isocyanate propyltriethoxysilane based on the ionic liquid is provided.

Owner:ZHEJIANG HUANGMA TECH +3

Process for diffusing titanium and nitride into a steel or steel alloy by altering the content of such

InactiveUS20080226831A1Speed up the processLiquid surface applicatorsElectrolysis componentsElectrolysisAlloy

An improved method is provided for diffusing titanium and nitride into a base material comprising a steel or steel alloy. The composition of the base material generally comprises at least one of the following: more than about 1.95% vanadium, less than about 4.1% chromium, and a presence of cobalt. The method generally includes the steps of providing such a base material; providing a salt bath which includes sodium dioxide and a salt selected from the group consisting of sodium cyanate and potassium cyanate; dispersing metallic titanium formed by electrolysis of a titanium compound in the bath; heating the salt bath to a temperature ranging from about 430° C. to about 670° C.; and soaking the base material in the salt bath for a time of from about 10 minutes to about 24 hours.

Owner:KO PHILOS JONGHO +1

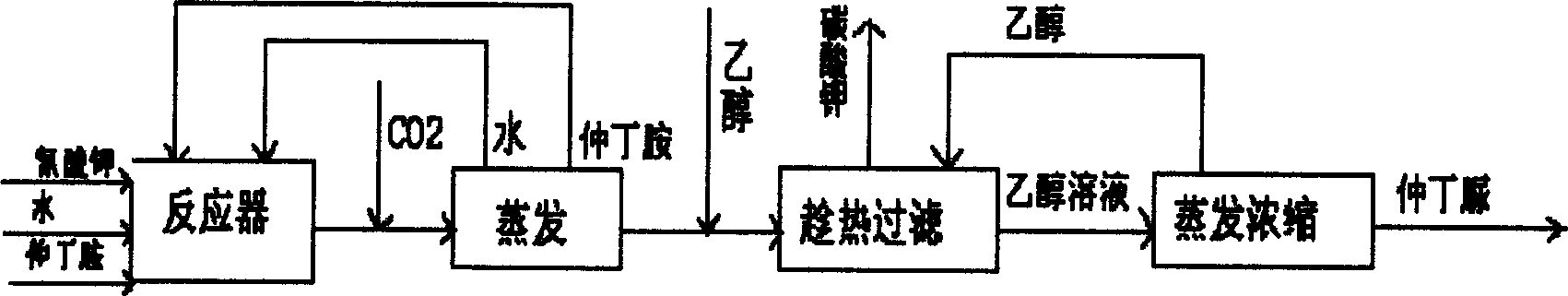

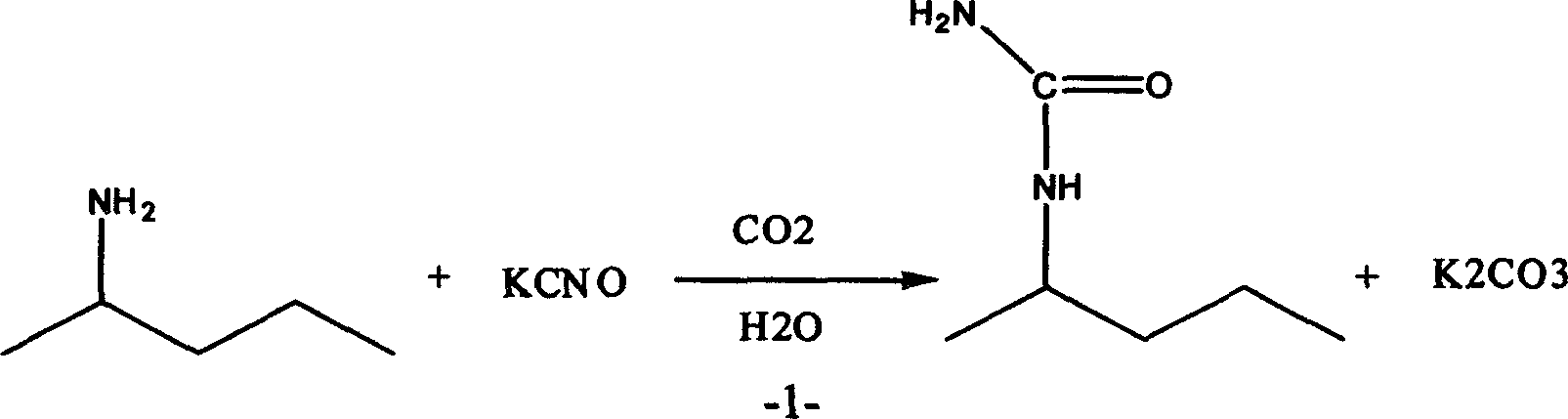

Process for synthesizing sec-butyl urea

InactiveCN1827594ALow costHigh market valueUrea derivatives preparationProductsAlcoholAqueous solution

The invention discloses a method for synthesizing the secondary butyl urea adopting catalytic processes of carbon dioxide. It includes the following steps: preparing aqueous solution by potassium cyanate dissolved by water; putting the secondary butyl amine into the reactor and diluting them by water; adding the potassium cyanate solution into the secondary butyl amine and intimately mixing them; drumming gas of carbon dioxide to the said solution and reacting; distilling the water and the excess econdary butyl amine; filtering while the system is in a high temperature to obtain the by-product of potasium carbonate; decompressing and concentrating to the mixture to remove the alcohols and obtaining the product of secondary butyl urea. The invention is of low cost, simple method, cheap stock, and higher market value of by-product of potasium carbonate. The invention is extensively used in synthesizing the secondary butyl urea of chemical intermediate and is of broad market outlook.

Owner:NANJING UNIV

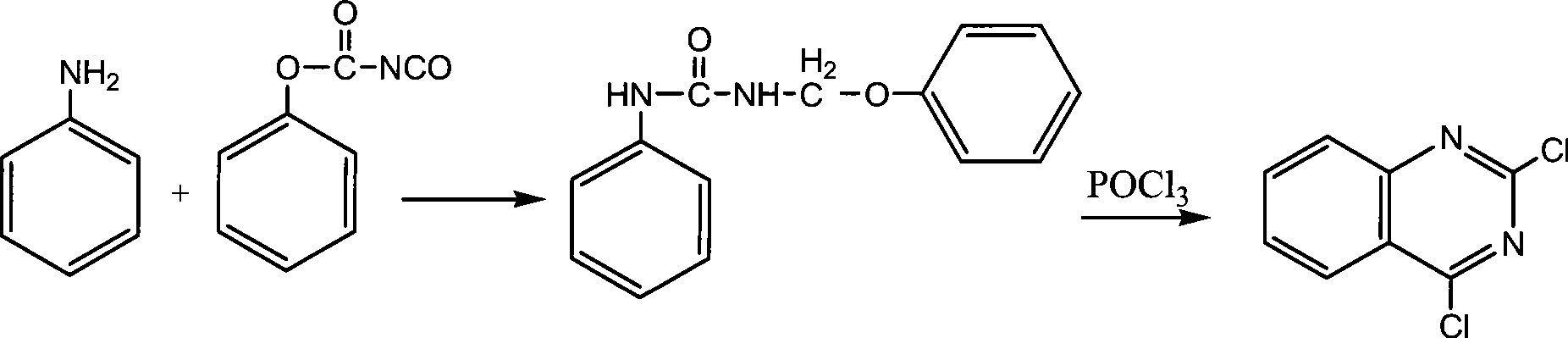

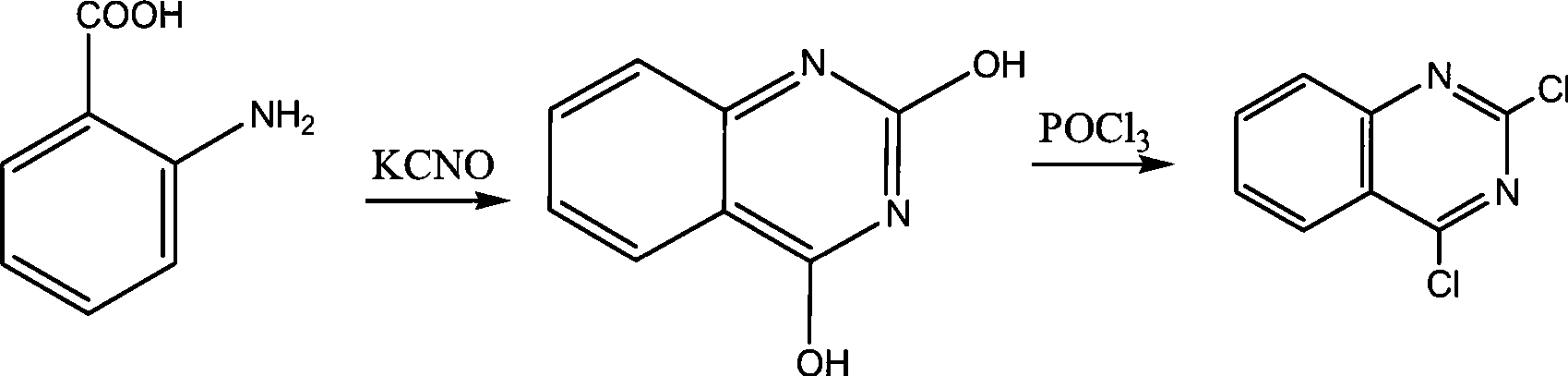

Preparation of 2,4-dichloroquinazoline

The invention relates to a method for preparing 2,4-dichloroquinazoline. The method comprises the following steps that: (1) ortho-aminobenzoic acid reacts with potassium cyanate to generate 2,4-quinazoline diones; and (2) the 2,4-quinazoline diones and a chlorinating agent undergo a chlorination reaction to generate the 2,4-dichloroquinazoline. Particularly, in step (1), the mass ratio of the ortho-aminobenzoic acid to the potassium cyanate is 1:1-3, the reaction uses water as a solvent, and is performed at a temperature of between 20 and 100 DEG C with pH of between 9 and 12; and in step (2), the chlorination reaction uses fatty amine as a solvent. The method uses non-toxic solvent and accessible raw materials, has high reaction yield, and is applicable to industrial production.

Owner:太仓浦源医药原料有限公司

Salt bath formula and treatment method in salt bath nitriding treatment of stainless steel air-conditioning compressor blades

InactiveCN102296266ALow melting pointPromote infiltrationPump componentsSolid state diffusion coatingPotassiumAcid washing

The present invention relates to a salt bath formula and treatment method in the salt bath nitriding treatment of stainless steel air-conditioning compressor blades. The salt bath formula of the present invention is composed of the following components and proportioned by weight percentage: potassium cyanate and cyanic acid 25%-50% of sodium, 8%-25% of sodium carbonate, 10%-30% of potassium carbonate, 20%-40% of sodium chloride or potassium chloride; The process makes the passivation film on the surface of the blade removed by pickling, which is easy to infiltrate nitrogen during salt bath nitriding; because the concentration of Cl (7-17%) is increased in the formula, the melting point in the salt bath is reduced, and the formula does not contain Li And K2S can still be nitrided at lower temperature.

Owner:SHANGHAI JIANGKAI METAL SURFACE TREATMENT TECH

Method for cleanly producing high-purity cyanate at low temperature

ActiveCN102336416ARealize continuous productionSave manpower and material resourcesCyanic/isocyanic acidSocial benefitsSodium cyanate

The invention discloses a method for cleanly producing high-purity cyanate at a low temperature, which comprises the following steps of: mixing urea and carbonate for 10-20 min for standby; adding cyanate bottom materials into a reactor, adding a mixture of the urea and the carbonate after the cyanate bottom materials are preheated to 140-150 DEG C; completely reacting the urea and the carbonate at a temperature of 160-180 DEG C; and obtaining a cyanate product after reacted materials are crushed. The invention also can adopt a continuous production manner. In the invention, potassium cyanate (sodium cyanate) is adopted as bottom materials so as to improve the dispersion of the reacted materials, more completely react the reacted materials, improve the product purity and generate no pollution; the reaction is conducted under the closed low-temperature environment so as to generate no toxic byproducts and greatly improve the safety; and the produced gas almost can be completely recovered without three-waste pollution. The high-purity cyanate has remarkable economic benefit and social benefit.

Owner:HUBEI DELI NEW MATERIALS

Process for diffusing titanium and nitride into a material having a coating thereon and products produced thereby

InactiveUS20090035481A1Improve propertiesImprove adhesionHot-dipping/immersion processesVacuum evaporation coatingElectrolysisTitanium

A method for diffusing titanium and nitride into a base material having a coating thereon using conventional surface treatments or coatings. The method generally includes the steps of providing a base material having a coating thereon; providing a salt bath which includes sodium dioxide and a salt selected from the group consisting of sodium cyanate and potassium cyanate; dispersing metallic titanium formed by electrolysis of a titanium compound in the bath; heating the salt bath to a temperature ranging from about 430° C. to about 670° C.; and soaking the base material in the salt bath for a time of from about 10 minutes to about 24 hours. In accordance with another aspect of the present invention, titanium and nitride may be diffused into a base material without a coating. The treated base material may further be treated with conventional surface treatments or coatings.

Owner:KO PHILOS JONGHO +1

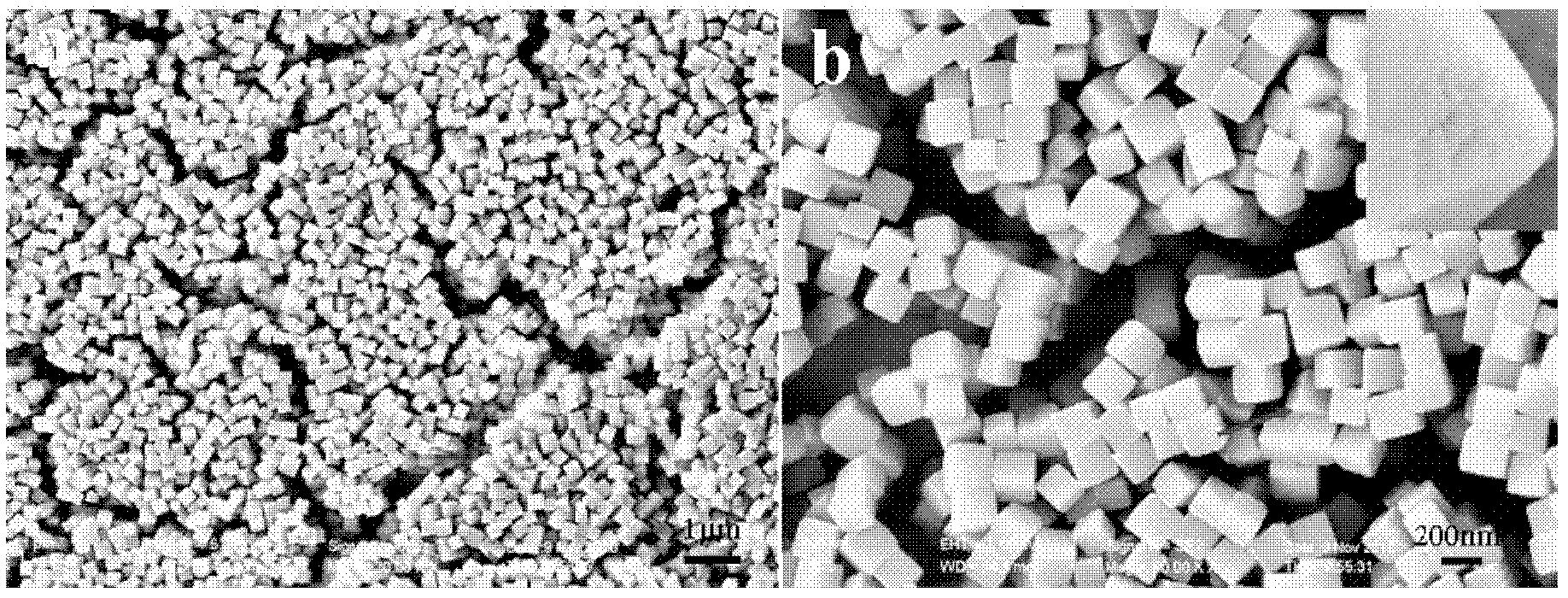

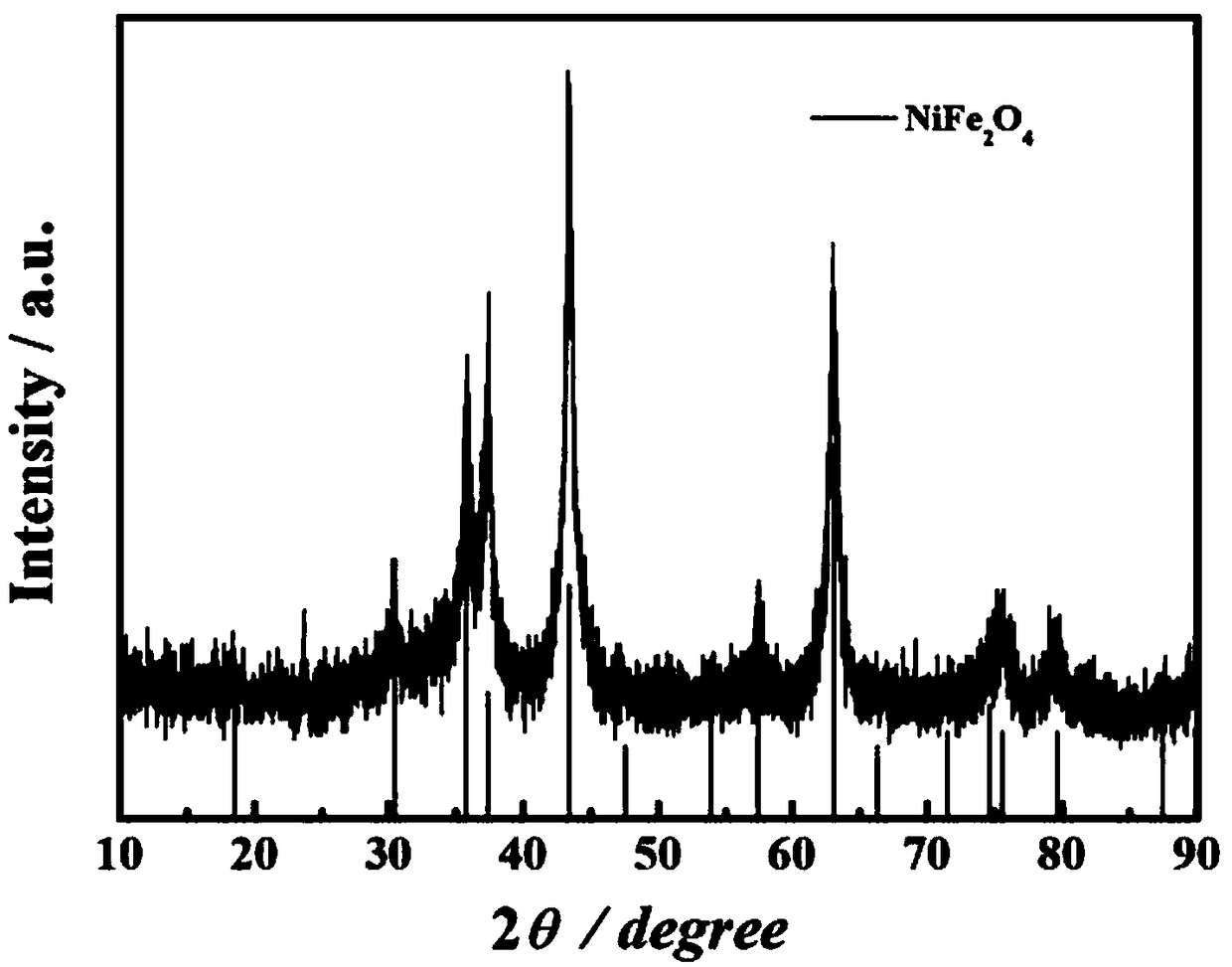

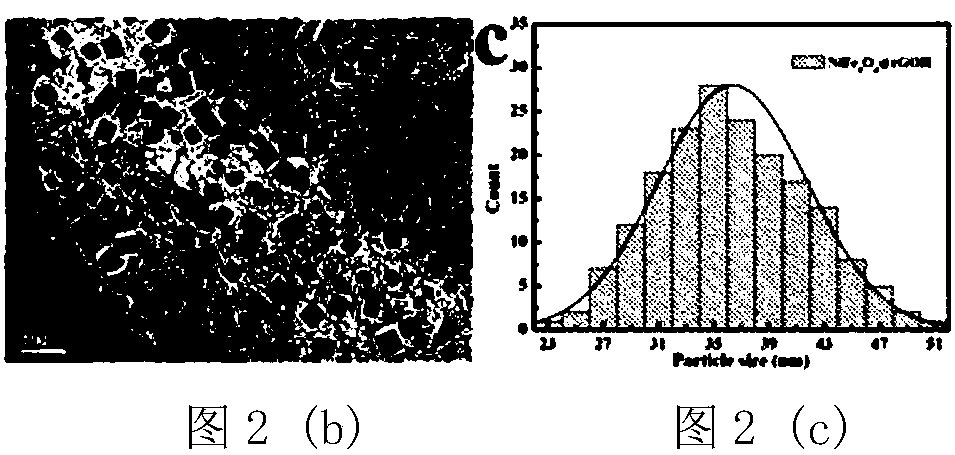

Bimetal oxide and graphene composite material and preparation method thereof

ActiveCN108597895ARegular nanocube morphologyAvoid destructionHybrid capacitor electrodesHybrid/EDL manufactureHigh pressureCalcination

The invention provides a bimetal oxide and graphene composite material and a preparation method thereof. The method comprises the steps of 1: preparing a dispersion from a graphene oxide, and adding ametal chloride salt thereto to obtain a solution 1; preparing a solution 2 having the same concentration as the metal chloride salt from a metallic potassium cyanate salt; 2: stirring the solution 1and the solution 2 uniformly separately, and then dripping the solution 2 into the solution 1 at a ratio of 2:3 by volume; and 3: transferring the mixed solution to a high-temperature and high-pressure reaction vessel, and hydrothermally reacting at 120 DEG C for 6 h; continuing to control the temperature to 180 to 220 DEG C, hydrothermally reacting for 18 h, and performing natural cooling to obtain the bimetal oxide and graphene composite material. In-situ growth of the bimetal oxide on the surface of the carbon material can be realized without high-temperature calcination, and the molar ratio of the two metals in the bimetal oxide can be accurately controlled. The prepared bimetal oxide has regular nanocube morphology.

Owner:HARBIN ENG UNIV

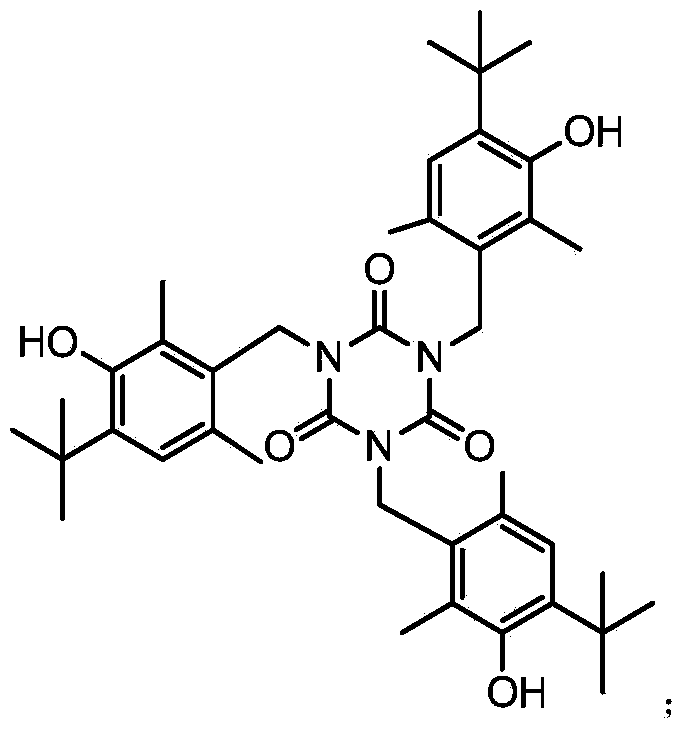

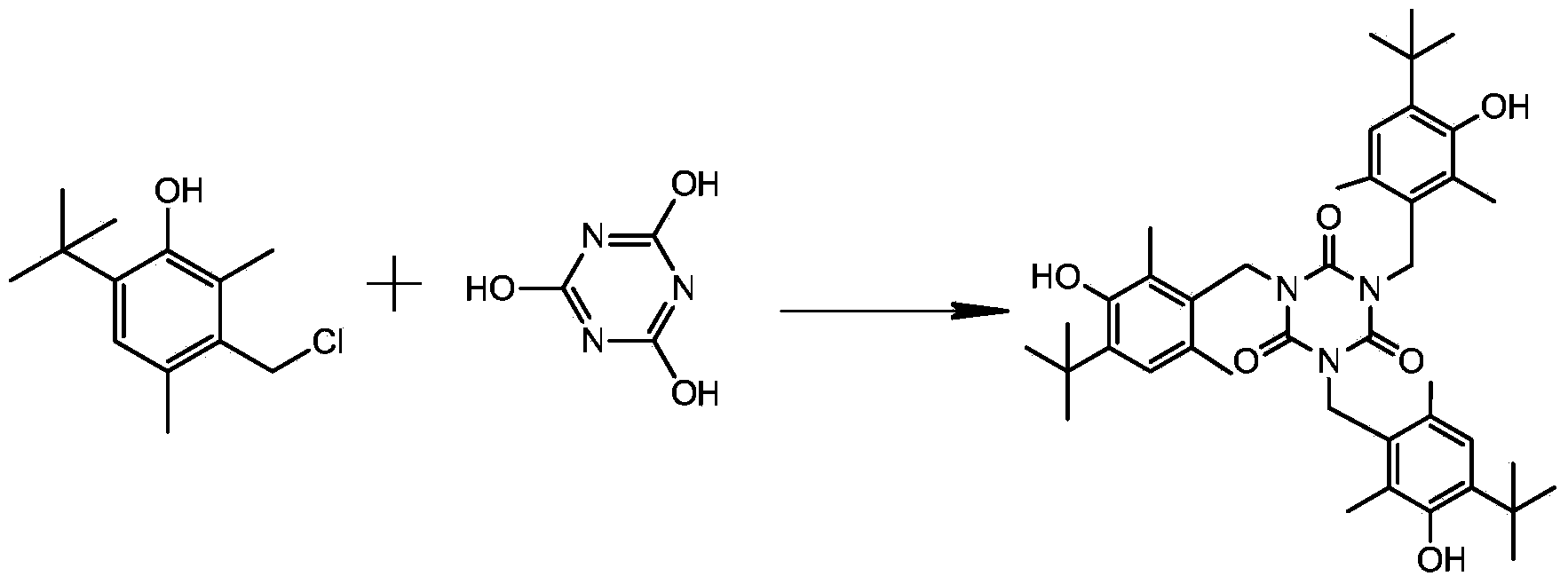

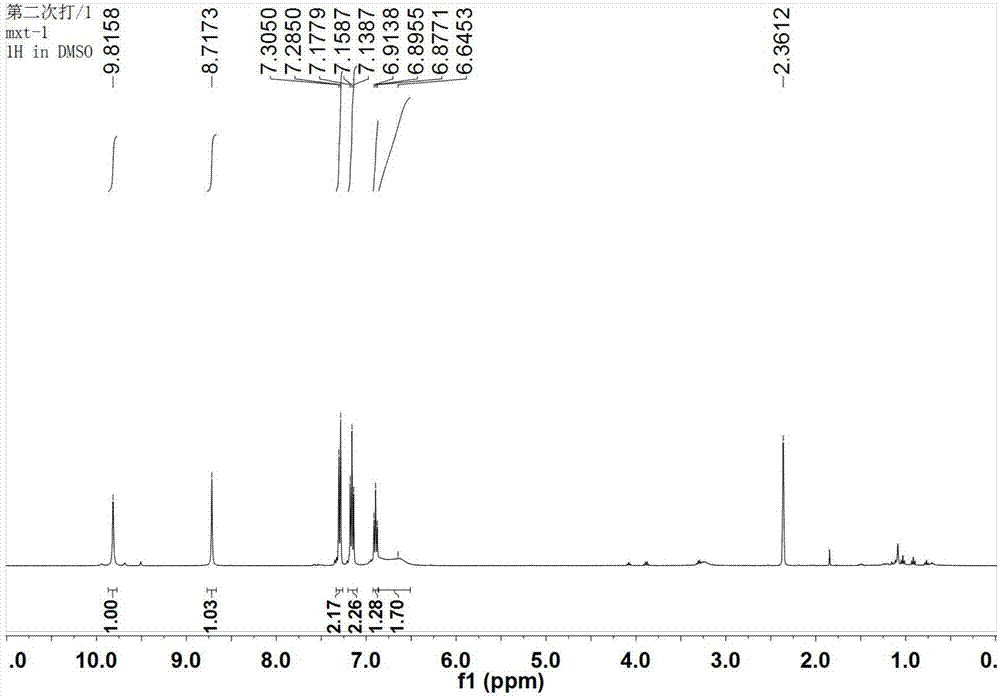

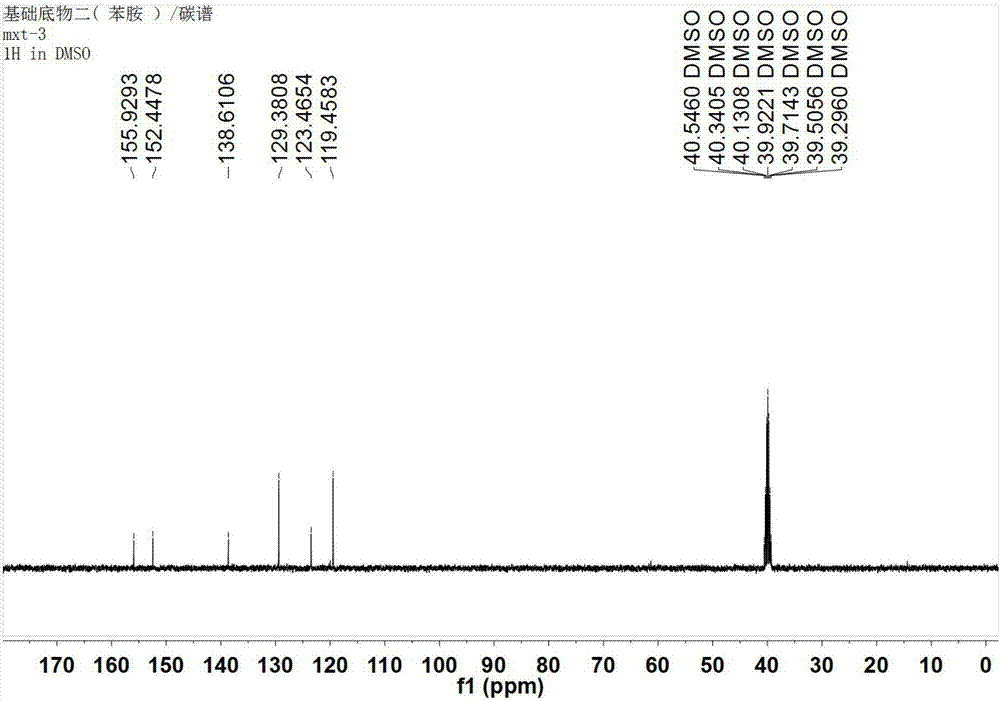

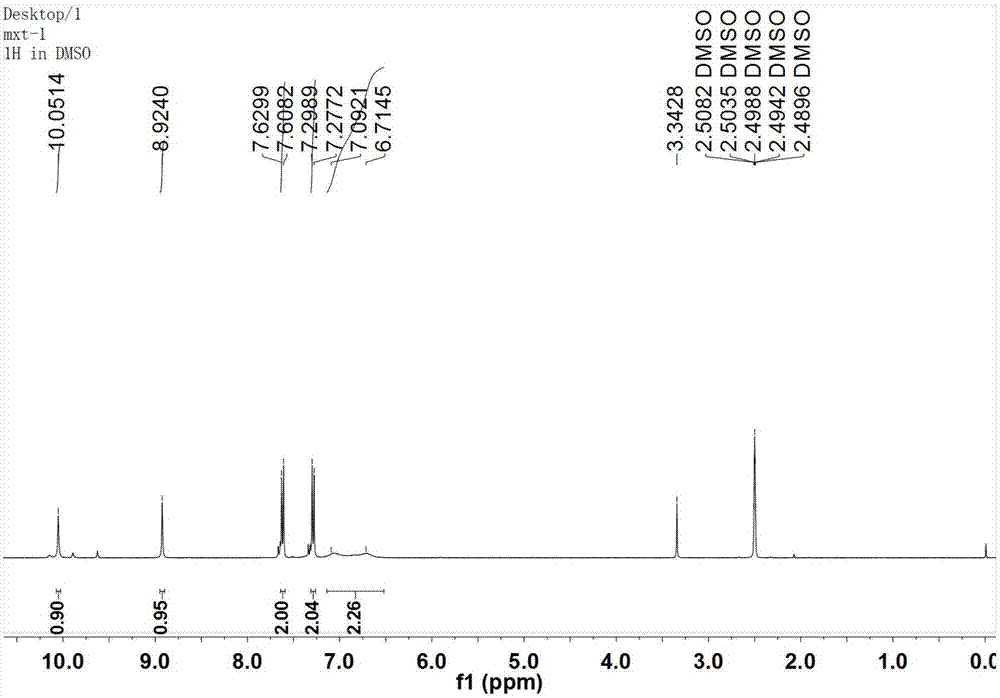

Synthesis method for antioxidant 1790

The invention discloses a synthesis method for antioxidant 1790. Raw materials include potassium cyanate, aprotic polar solvent, 2,6-dimethyl-4-tertiary butyl-5-hydroxy benzyl chloride and catalysts, wherein the molar ratio between the potassium cyanate and the 2,6-dimethyl-4-tertiary butyl-5-hydroxy benzyl chloride is 1-2: 1. Firstly, the potassium cyanate is added to aprotic polar solvents, the catalysts are added, heating is carried out until the temperature is 80-140 DEG C, the 2,6-dimethyl-4-tertiary butyl-5-hydroxy benzyl chloride is added, reaction continues for 8-14 hours, pressure is reduced after the reaction is finished, the aprotic polar solvents are removed, water is added, a crude product is obtained after filtering, washing is carried out, the crude product is recrystallized through ethyl alcohol and water, and finally the antioxidant 1790 is obtained. The synthesis method for the antioxidant 1790 is simple in process, relatively moderate in condition, short in reaction time, high in product purity, high in yield, low in cost, little in generated waste water, and beneficial to the environment and industrial production.

Owner:RIANLON

Synthetic method of omega-substituted biuret compound

InactiveCN107573263AReduce riskReduce pollutionUrea derivatives preparationOrganic compound preparationAcetic acidNitrogen

The invention belongs to the field of organic matter synthetic methods, and specifically relates to a synthetic method of an omega-substituted biuret compound. The synthetic method comprises the following steps: (1) condensation: adding substituted arylamine and potassium cyanate into a mixed solution of water and acetonitrile, warming, dropwise adding a part of acetic acid at the temperature of 45 to 100 DEG C, then adding remaining acetic acid 1 h later, and then reacting for 6 to 12 h; and (2) aftertreatment: carrying out recrystallization or column chromatography on an obtained product toobtain the omega-substituted biuret compound. The synthetic method overcomes the disadvantage that a nitrogen nitryl compound with dangerousness needs to be used in an existing synthetic process, anda one-pot method is adopted for replacing an existing two-step reaction with low yield.

Owner:DALIAN UNIV OF TECH

Process for diffusing titanium and nitride into a material having a generally compact, granular microstructure and products produced thereby

InactiveUS20070243412A1Improve propertiesImprove adhesionLiquid surface applicatorsVacuum evaporation coatingElectrolysisCarbide

A method for diffusing titanium and nitride into a base material having a generally compact, granular microstructure (e.g., carbide). The method generally includes the steps of providing a base material having a generally compact, granular microstructure; providing a salt bath which includes sodium dioxide and a salt selected from the group consisting of sodium cyanate and potassium cyanate; dispersing metallic titanium formed by electrolysis of a titanium compound in the bath; heating the salt bath to a temperature ranging from about 430° C. to about 670° C.; and soaking the base material in the salt bath for a time of from about 10 minutes to about 24 hours. In accordance with another aspect of the present invention, the base material may further be treated with conventional surface treatments or coatings.

Owner:KO PHILOS JONGHO +1

Method for cleanly producing high-purity cyanate at low temperature

ActiveCN102336416BRealize continuous productionSave manpower and material resourcesCyanic/isocyanic acidSocial benefitsEngineering

The invention discloses a method for cleanly producing high-purity cyanate at a low temperature, which comprises the following steps of: mixing urea and carbonate for 10-20 min for standby; adding cyanate bottom materials into a reactor, adding a mixture of the urea and the carbonate after the cyanate bottom materials are preheated to 140-150 DEG C; completely reacting the urea and the carbonate at a temperature of 160-180 DEG C; and obtaining a cyanate product after reacted materials are crushed. The invention also can adopt a continuous production manner. In the invention, potassium cyanate(sodium cyanate) is adopted as bottom materials so as to improve the dispersion of the reacted materials, more completely react the reacted materials, improve the product purity and generate no pollution; the reaction is conducted under the closed low-temperature environment so as to generate no toxic byproducts and greatly improve the safety; and the produced gas almost can be completely recovered without three-waste pollution. The high-purity cyanate has remarkable economic benefit and social benefit.

Owner:HUBEI DELI NEW MATERIALS

Salt bath composition in salt bath nitridation treatment of compressor blades and treatment method

InactiveCN111979512AExtended service lifeImprove stabilitySolid state diffusion coatingPotassium hydroxideSodium cyanate

The invention discloses a salt bath composition in salt bath nitridation treatment of compressor blades and a treatment method. The salt bath composition is composed of and prepared from the followingcomponents in percentage by weight: 6%-12% of naphthalenetrisulfonic acid sodium, 16%-24% of urea, 10%-12% of difluoro bromobenzene, 5%-10% of potassium cyanate, 12%-18% of sodium cyanate, 3%-6% oflithium carbonate, 8%-12% of sodium carbonate, 10%-18% of potassium carbonate, 1%-3% of sodium hydroxide, 2%-5% of potassium hydroxide and 1%-15% of sodium chloride. The salt bath composition has thebeneficial effects that naphthalenetrisulfonic acid sodium and urea are added to the salt bath composition, the melting point in salt bath is reduced, nitridation can be performed at a lower temperature, the activity is good, the nitrogen concentration in a nitriding furnace is effectively controlled, the stability of blades is improved, the rejection rate of subsequent processing is reduced, andthe application prospects are good.

Owner:BENGBU AIPU COMPRESSOR MACHINERY

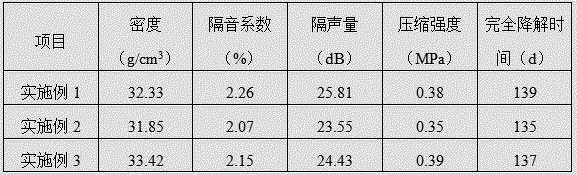

High performance foam plastic

The invention discloses a high performance foam plastic which comprises: polyether polyol, vinyl tris (Beta-methoxyethoxy) silane, glycerol triacetate, polyester resin, mung bean protein powder, modified starch, carbon black, titanium dioxide, jute fiber, polyamide fiber, glass fiber , Polyethylene wax, maleic anhydride, dibutyltin dilaurate, ethylene-ethyl acrylate copolymer, isopentane, potassium isocyanate, polyvinyl acetate emulsion, dimethyl silicone oil, triethanolamine, initiator, crosslinking agents, catalysts, accelerators, plasticizers, toughening agents, foaming agents, foaming control agents, foam stabilizers, antibacterial agents, degradation agents, antioxidants and stabilizers. The foam plastic can totally degrade into carbon dioxide and water with negligible harm to the environment. Moreover the foam plastic has the advantages of low disintegration speed and prolonged service period of foam plastic. The foam plastic also has good soundproof effects.

Owner:广西南宁桂尔创环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com