Prefabricated light partition board

A lightweight partition board and partition board technology, applied in the field of filling wall boards or partition boards, can solve the problems of affecting the appearance quality and strength, easy to cause deflection due to poor stacking, and easy falling off of the wall plastering layer. Easy to carry and install manually, good thermal insulation and sound insulation, light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

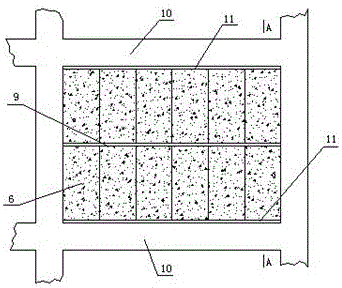

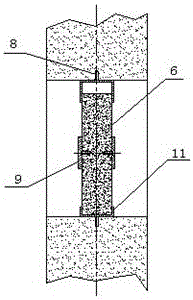

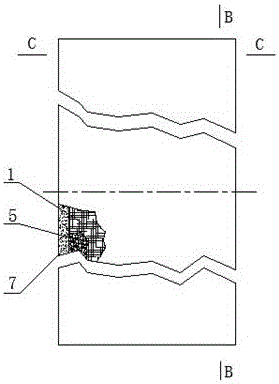

[0020] Such as Figure 1-Figure 5 , a prefabricated lightweight partition wall panel, characterized in that: the partition wall panel 6 includes a skeleton and a straw fly ash fine stone concrete layer 7 poured on the skeleton, and the skeleton is composed of a corrugated foam insulation board 5 in the middle and through The bolt 3 is fixed on the punched steel plate 1 on both sides of the corrugated foam insulation board 5 .

[0021] The average thickness of the corrugated foam board 5 is 50~80mm, the thickness is adjustable, the rib groove depth is 15mm, and the rib groove spacing is 50mm. The rib groove can be used for pipelines and buried wire grooves. deformation of the board during fabrication.

[0022] The horizontal and vertical spacing of the bolts 3 in the plane is 200mm, the diameter is 8mm, and the two ends are exposed 20mm outside the plane of the punche...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com