Lubricating device used for wheel machining

A lubricating device, wheel machine technology, applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve the problems of operator health injury, high cost of cutting fluid use, odor and odor, etc., to achieve convenient and economical operation. The effect of manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

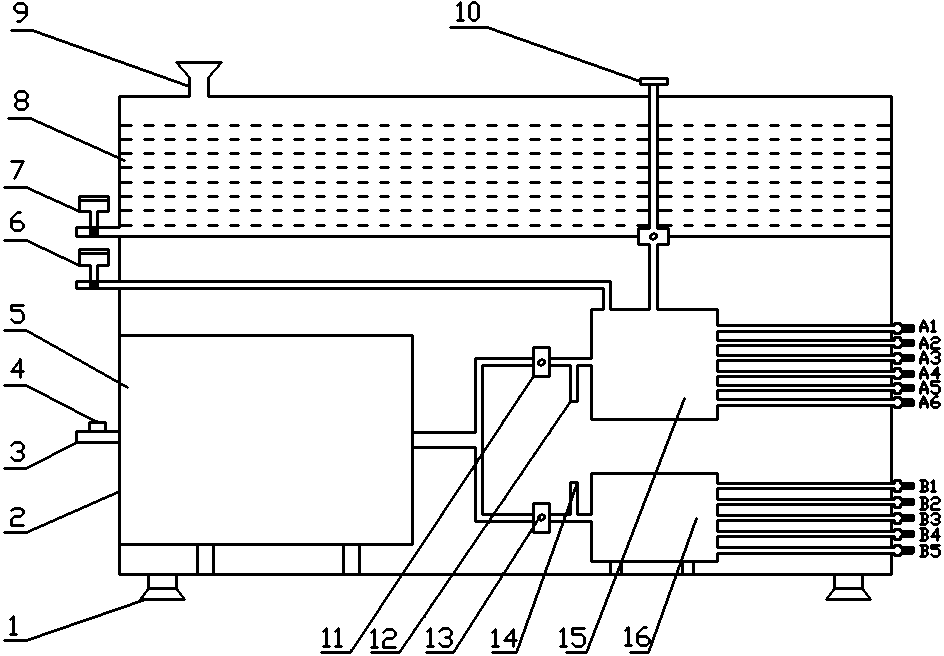

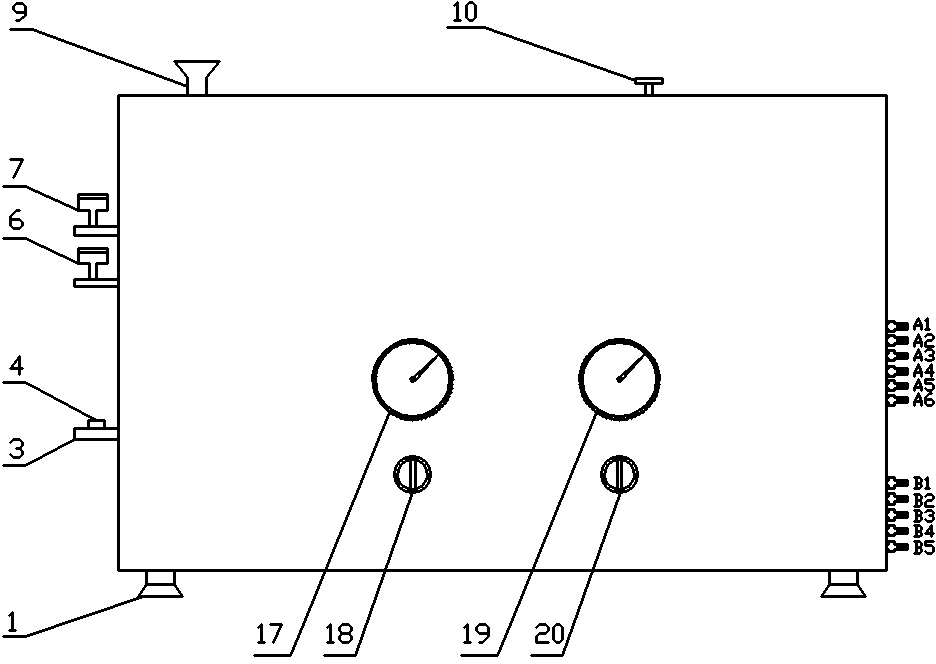

[0011] The details and working conditions of the specific device proposed by the present invention will be given below in conjunction with the description of the accompanying drawings.

[0012] A lubricating device for wheel machining, which consists of an adjustable foot 1, a frame 2, a power interface 3, a power switch 4, an air compressor 5, a safety valve 6, an oil drain valve 7, an oil tank 8, an oil filling port 9, and an oil volume adjustment Valve 10, oil mist pressure regulating valve 11, oil mist pressure gauge interface 12, air pressure regulating valve 13, air pressure gauge interface 14, oil mist generator 15, air divider 16, oil mist pressure gauge 17, oil mist pressure adjustment Knob 18, compressed air pressure gauge 19, air pressure adjustment knob 20, A1-A6 oil mist output interface and B1-B5 compressed air output interface. The air compressor 5 is fixed on the frame 2, and its output end is divided into two circuits, one is connected to the oil mist pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com