Electric silicon rubber

A conductive silicone and rubber technology, applied in the field of silicone rubber, can solve problems such as difficult dispersion, easy dusting, and low stacking density, and achieve the effects of excellent mechanical and electrical properties, improved product qualification rate, and increased stacking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

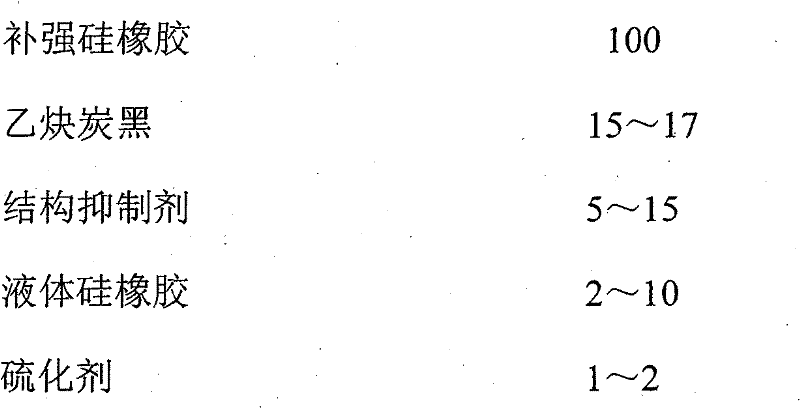

Method used

Image

Examples

Embodiment 1

[0036] 100 parts of reinforcing silicone rubber, 17 parts of granular conductive acetylene carbon black, 8 parts of hexamethylcyclotrisilazane, 4 parts of liquid silicone rubber and 1 part of DCP; mixing according to the above production process; The resistivity is 0.5Ω·m, the tensile strength is 6.5MPa, the elongation is 590%, and the tear strength is 40N / mm; it is better than the national standard.

Embodiment 2

[0038] 100 parts of reinforcing silicone rubber, 20 parts of granular conductive acetylene carbon black, 12 parts of diphenylsilanediol, 6 parts of liquid silicone rubber and 1.5 parts of double 2,5 (vulcanizing agent); mix according to the above-mentioned production process; The obtained material is tested, and the volume resistivity is 0.3Ω·m, the tensile strength is 6.8MPa, the elongation is 560%, and the tear strength is 35N / mm; it is better than the national standard.

Embodiment 3

[0040] 100 parts of reinforced silicone rubber, 22 parts of granular conductive acetylene carbon black, 10 parts of tetramethylethylenedioxydimethylsilane, 8 parts of liquid silicone rubber and 1.2 parts of DCP (vulcanizing agent); carry out according to the above production process Mixing; the obtained material is tested, and the volume resistivity is 0.2Ω·m, the tensile strength is 6.7MPa, the elongation is 550%, and the tear strength is 37N / mm; it is better than the national standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com