a kind of agsno 2 Preparation method of multi-core composite wire

A composite wire and composite rod technology, which is used in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of poor uniformity, poor plasticity and ductility, and difficult processing of electrical contact materials, and achieve stable structure and improved electrical conductivity. , Excellent effect of preparation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

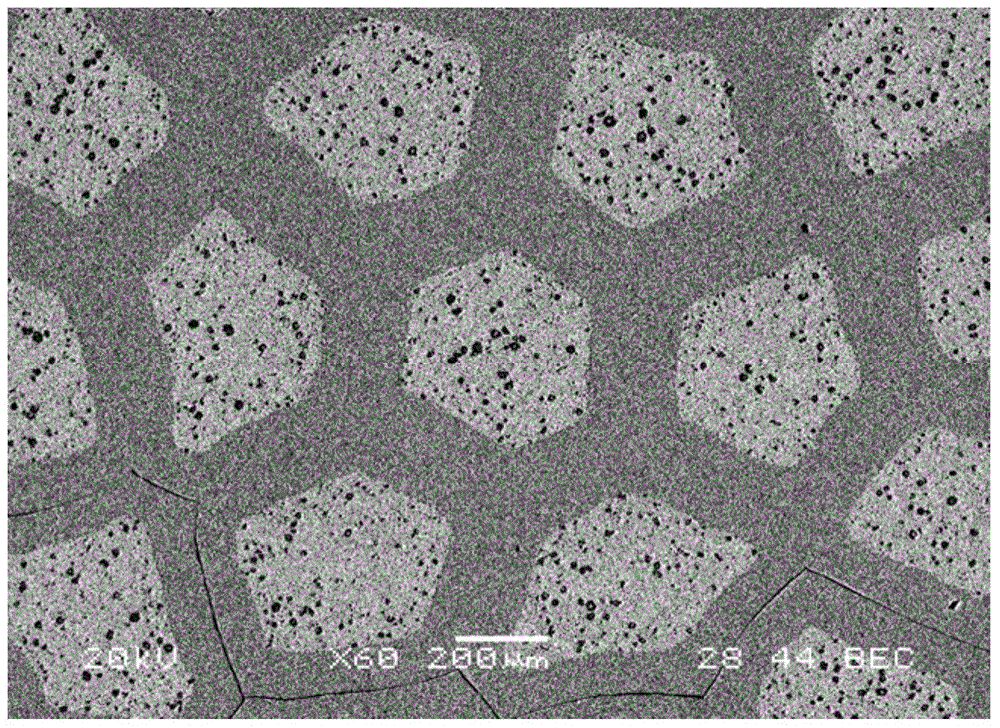

Image

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

[0031]Step 1, put the tin bar into the first silver sheath to obtain a single-core composite sheath; the mass content of the tin bar in the single-core composite sheath is 89.7%, and the balance is silver; the mass content of the tin bar The purity is 99.95%, the cross-sectional diameter is 39 mm, the outer diameter of the first silver sheath is 45.0 mm, and the inner diameter is 40.0 mm;

[0032] Step 2, using a vacuum electron beam welder to respectively carry out vacuum electron beam welding to the two ends of the single-core composite sheath described in step 1;

[0033] Step 3, heat-extrude the single-core composite sheath welded and sealed in step 2 for 6 hours at a temperature of 150° C. to obtain a single-core composite rod with a cross-sectional diameter of 14.36 mm; The extrusion ratio of the extrusion treatment is 9.8;

[0034] Step 4. The single-core composite rod described in step 3 is drawn for 43 passes to...

Embodiment 2

[0043] This embodiment includes the following steps:

[0044] Step 1, put the tin rod into the first silver sheath to obtain a single-core composite sheath; the mass content of the tin rod in the single-core composite sheath is 82.3%, and the balance is silver; the mass content of the tin rod The purity is 99.95%, the cross-sectional diameter is 28 mm, the outer diameter of the first silver sheath is 32.0 mm, and the inner diameter is 30.0 mm;

[0045] Step 2, using a vacuum electron beam welder to respectively carry out vacuum electron beam welding to the two ends of the single-core composite sheath described in step 1;

[0046] Step 3, heat-extrude the single-core composite sheath welded and sealed in step 2 for 4 hours at a temperature of 200° C. to obtain a single-core composite rod with a cross-sectional diameter of 10.67 mm; The extrusion ratio of the extrusion treatment is 9;

[0047] Step 4. The single-core composite rod described in step 3 is drawn 36 times to obtai...

Embodiment 3

[0055] This embodiment includes the following steps:

[0056] Step 1, put the tin rod into the first silver sheath to obtain a single-core composite sheath; the mass content of the tin rod in the single-core composite sheath is 90.7%, and the balance is silver; the mass content of the tin rod The purity is 99.95%, the cross-sectional diameter is 27 mm, the outer diameter of the first silver sheath is 33.0 mm, and the inner diameter is 30.0 mm;

[0057] Step 2, using a vacuum electron beam welder to respectively carry out vacuum electron beam welding to the two ends of the single-core composite sheath described in step 1;

[0058] Step 3, heat-extrude the single-core composite sheath welded and sealed in step 2 for 2 hours at a temperature of 220° C. to obtain a single-core composite rod with a cross-sectional diameter of 11.22 mm; The extrusion ratio of the extrusion treatment is 8.65;

[0059] Step 4. The single-core composite rod described in step 3 is drawn 48 times to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com