Method for preparing silicon dioxide/graphene nanocomposite material by microwave chemical vapor deposition and product thereof

A nano-composite material and silicon dioxide technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems that affect the research and application of graphene-based composite materials, low-density specific surface area, difficult performance, etc. problems, to achieve the effect of excellent mechanical properties, high utilization rate of heat energy, and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

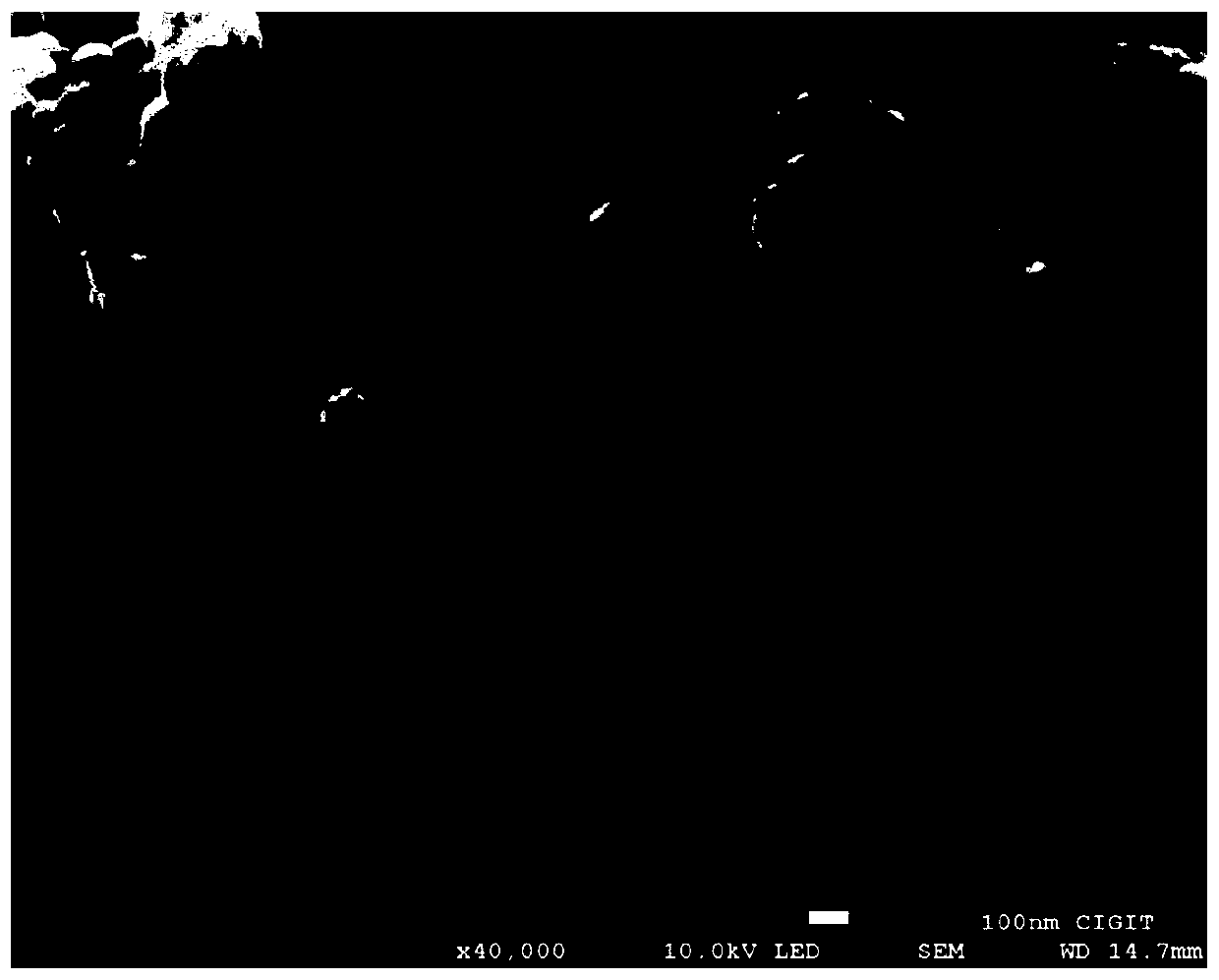

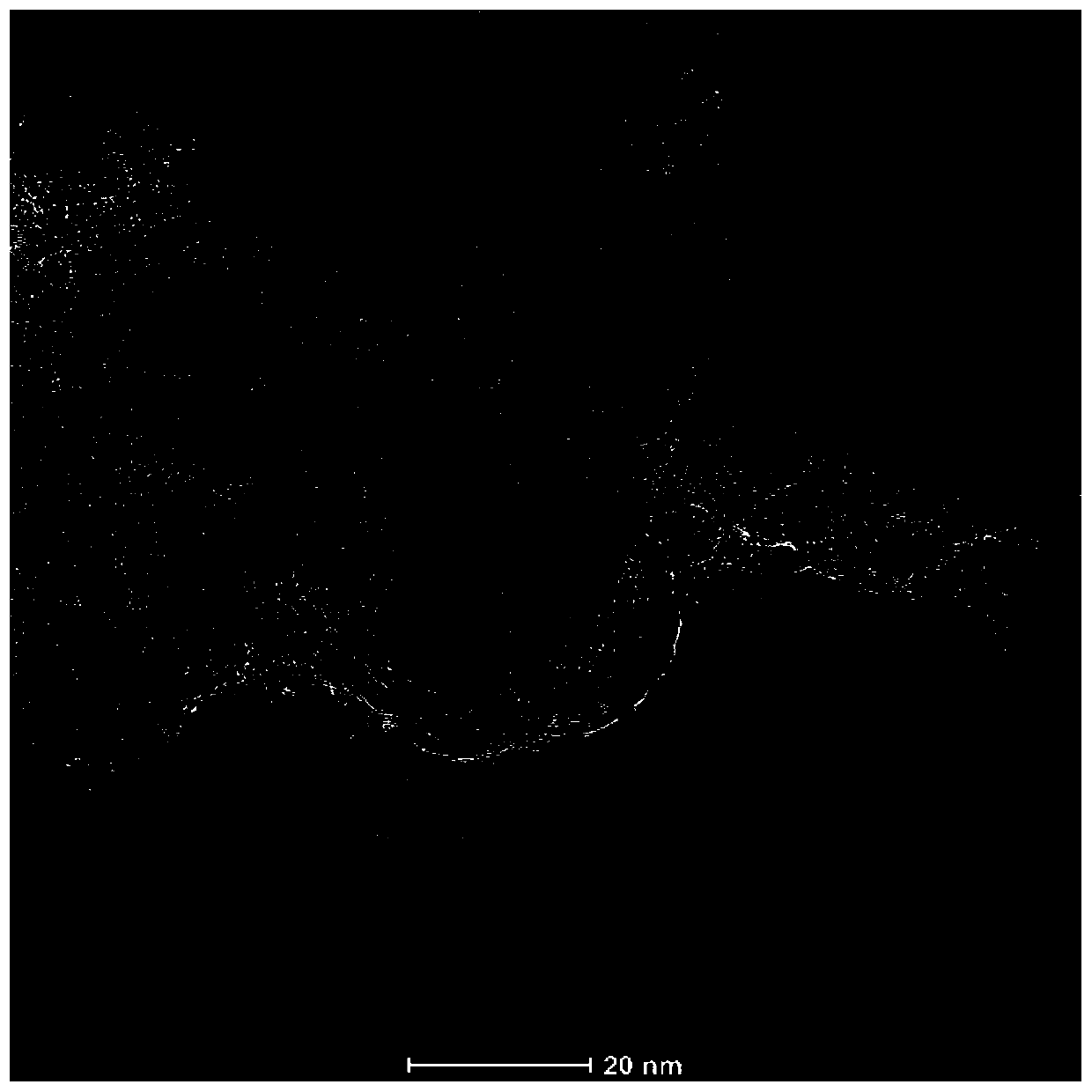

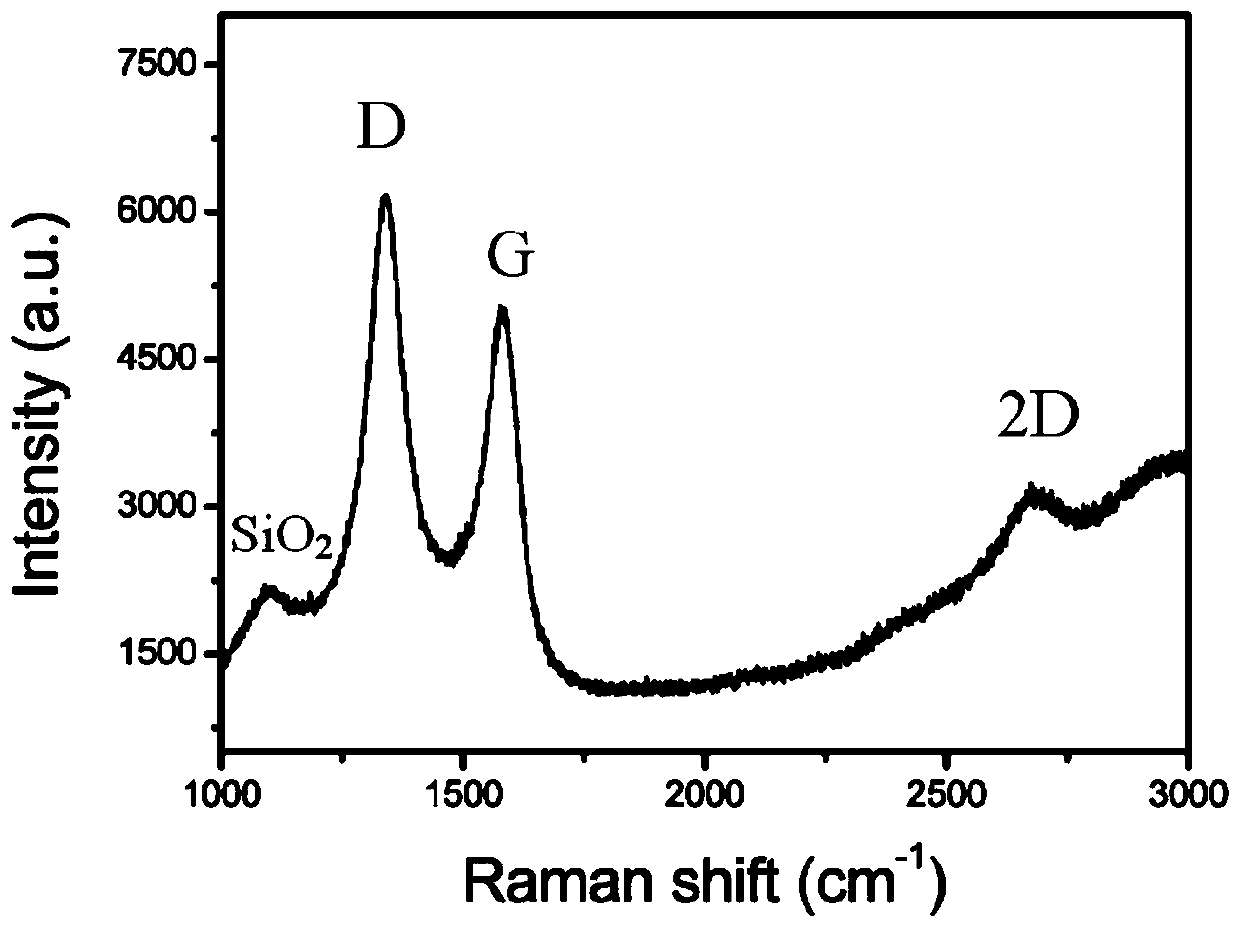

[0034] A method for preparing silicon dioxide / graphene nanocomposites by microwave chemical vapor deposition, comprising the following steps:

[0035] (1) Place 0.1 g of silicon dioxide in the microwave plasma reaction chamber, feed nitrogen gas at a flow rate of 200 sccm as a protective gas, and heat at a heating rate of 35° C. / min for 20 minutes to make the microwave plasma reaction chamber The temperature reaches 700°C;

[0036] (2) Pass the mixed gas of hydrogen gas and methane gas into the reaction chamber of microwave plasma with the flow velocity of 200sccm, carry out in-situ growth on the silicon dioxide surface and form the graphene coating layer, stop feeding mixed gas after 1min, cool The silicon dioxide / graphene nanocomposite material can be obtained at room temperature, wherein the volume ratio of hydrogen gas and methane gas introduced is 1:8.

[0037] During the whole preparation process, the air pressure of the microwave plasma was kept at 40 Torr, and the pow...

Embodiment 2

[0044] A method for preparing silicon dioxide / graphene nanocomposites by microwave chemical vapor deposition, comprising the following steps:

[0045] (1) Place 0.1 g of silicon dioxide in the reaction chamber of microwave plasma, feed argon gas at a flow rate of 150 sccm as a protective gas, and heat at a heating rate of 25° C. / min for 20 minutes to make the reaction chamber of microwave plasma The temperature in the medium reaches 500°C;

[0046](2) Pass the mixed gas of hydrogen gas and ethylene gas into the reaction chamber of microwave plasma with the flow velocity of 150sccm, carry out in-situ growth on the silicon dioxide surface and form the graphene coating layer, stop feeding mixed gas after 30min, cool The silicon dioxide / graphene nanocomposite material can be obtained at room temperature, wherein the volume ratio of hydrogen gas and ethylene gas is 1:5.

[0047] During the whole preparation process, the air pressure of the microwave plasma was kept at 30 Torr, and...

Embodiment 3

[0050] A method for preparing silicon dioxide / graphene nanocomposites by microwave chemical vapor deposition, comprising the following steps:

[0051] (1) Place 0.1g of silicon dioxide in the microwave plasma reaction chamber, feed helium gas at a flow rate of 250sccm as a protective gas, and heat at a heating rate of 30°C / min for 30min to make the microwave plasma reaction chamber The temperature in the medium reaches 600°C;

[0052] (2) Pass the mixed gas of hydrogen gas and propyne gas into the reaction chamber of microwave plasma with the flow velocity of 250sccm, carry out in-situ growth on the silicon dioxide surface and form the graphene coating layer, stop feeding mixed gas after 60min, Cool to room temperature to obtain silicon dioxide / graphene nanocomposite material, wherein the volume ratio of hydrogen and propyne gas is 1:10.

[0053] During the whole preparation process, the air pressure of the microwave plasma was kept at 20 Torr, and the power of the microwave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com