Furnace end of combustor

A burner and burner technology, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of unfavorable development, affecting the service life of the burner, and low working reliability, so as to reduce poor process stability and reduce The effect of unreliable quality and high work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

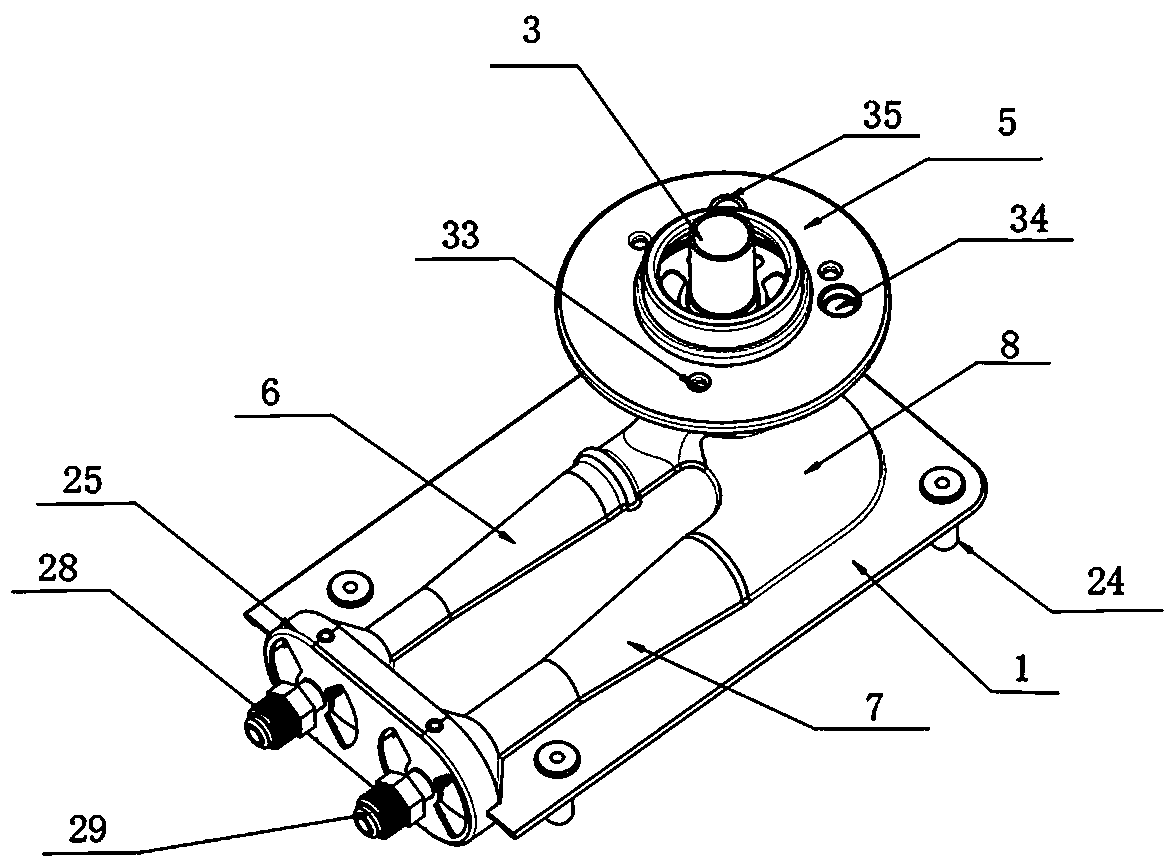

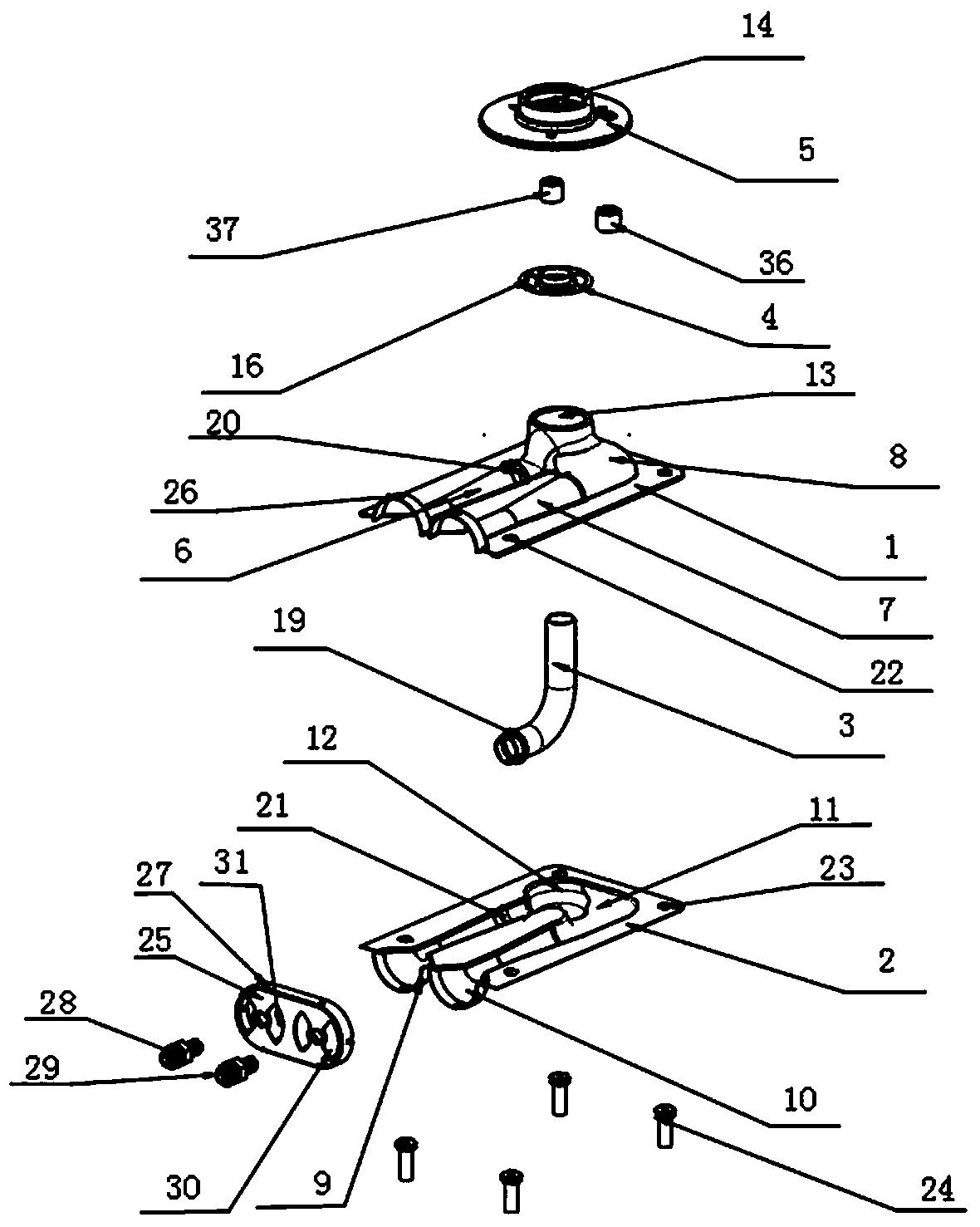

[0046] refer to Figure 1-Figure 5 , the furnace head of the burner, including the upper cover 1, the lower bottom 2, the central mixing nozzle 3, the connecting pipe fixing plate 4, the mounting flange 5, the upper cover 1 is covered on the lower bottom 2, and the upper cover 1 is provided with a central fire starter Ejector upper half 6, main fire ejector upper half 7 and main fire upper half cover 8, lower bottom 2 is provided with center fire ejector lower half 9, main fire ejector lower half 10 and The lower half cover 11 of the main fire, the upper half 6 of the center fire ejector is covered on the lower half 9 of the center fire ejector, the upper half 6 of the center fire ejector and the lower half 9 of the center fire ejector jointly constitute Central fire ejector, the main fire ejector upper half 7 is covered on the main fire ejector lower half 10, and the main fire ejector upper half 7 and the main fire ejector lower half 10 jointly constitute the main fire ejecto...

Embodiment 2

[0065] The difference between this embodiment and embodiment 1 is:

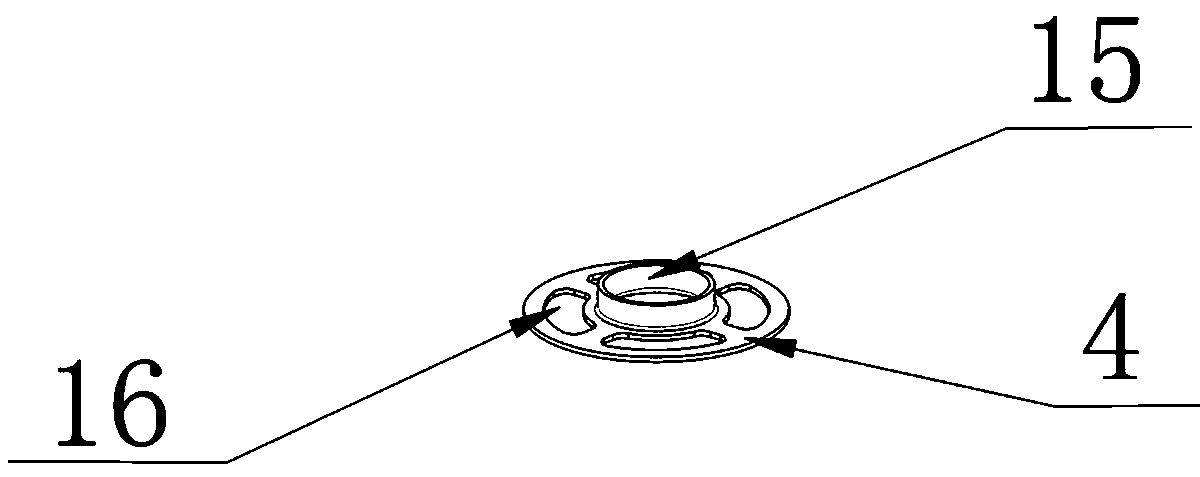

[0066] refer to Figure 6-Figure 11 , in this embodiment, the upper half cover 8 of the main fire is connected with the installation flange 5 through the flange seat 17, the flange seat 117 is arranged between the installation flange 5 and the upper half cover 8 of the main fire, and the flange seat 17 is fixed on On the upper half cover 8 of the main fire, the mounting flange 5 is covered on the flange seat 17, and the center of the flange seat 17 has a through hole 18, and the center through hole 18 of the flange seat 17 is connected with the upper half cover 8 of the main fire. The through hole 13 communicates, and the fixed plate 4 is arranged on the inner wall top of the central through hole 18 of the flange seat 17. The central through hole 15 of the fixed plate 4 and the air-distributing through hole 16 all pass through the central through hole 18 of the flange seat 17 and The through hole 13 on the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com