Mold-free formation casting method of high-performance aluminum alloy casting

A technology of aluminum alloy castings and moldless molding, which is applied in the direction of casting molding equipment, casting molds, and casting mold components. It can solve complex and large-scale metal components and other problems, so as to improve product quality, reduce labor intensity, and make the price more reasonable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

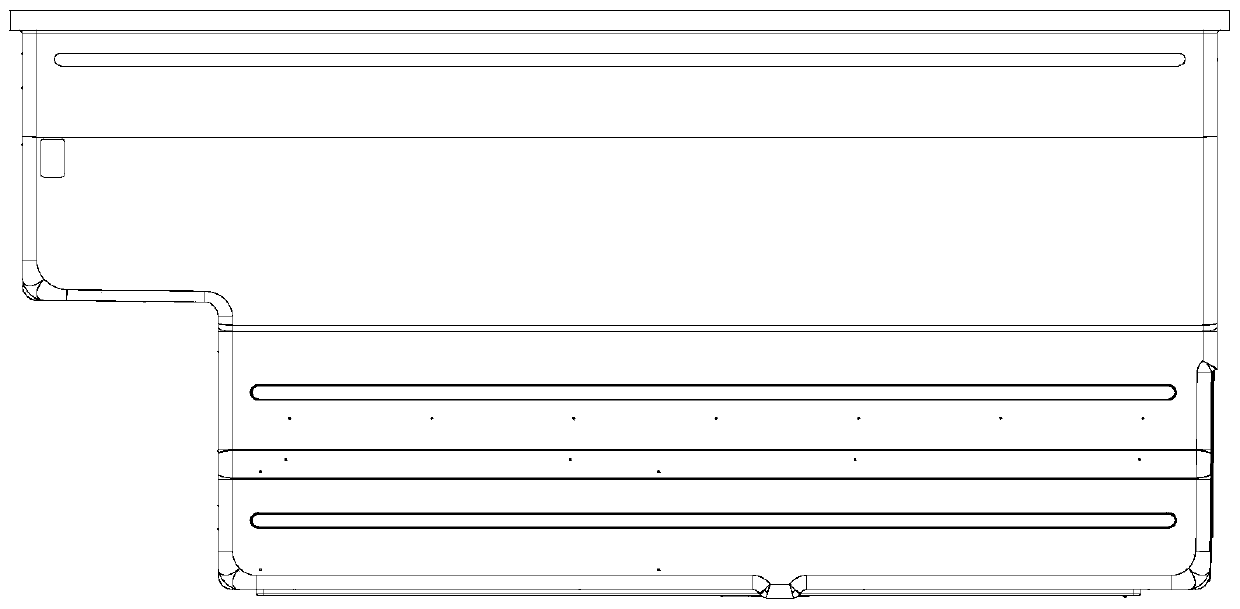

[0032] Such as figure 1 Shown is a schematic diagram of the product to be cast in this embodiment; the invention provides a method for dieless forming casting of an aluminum alloy casting, which specifically includes the following steps:

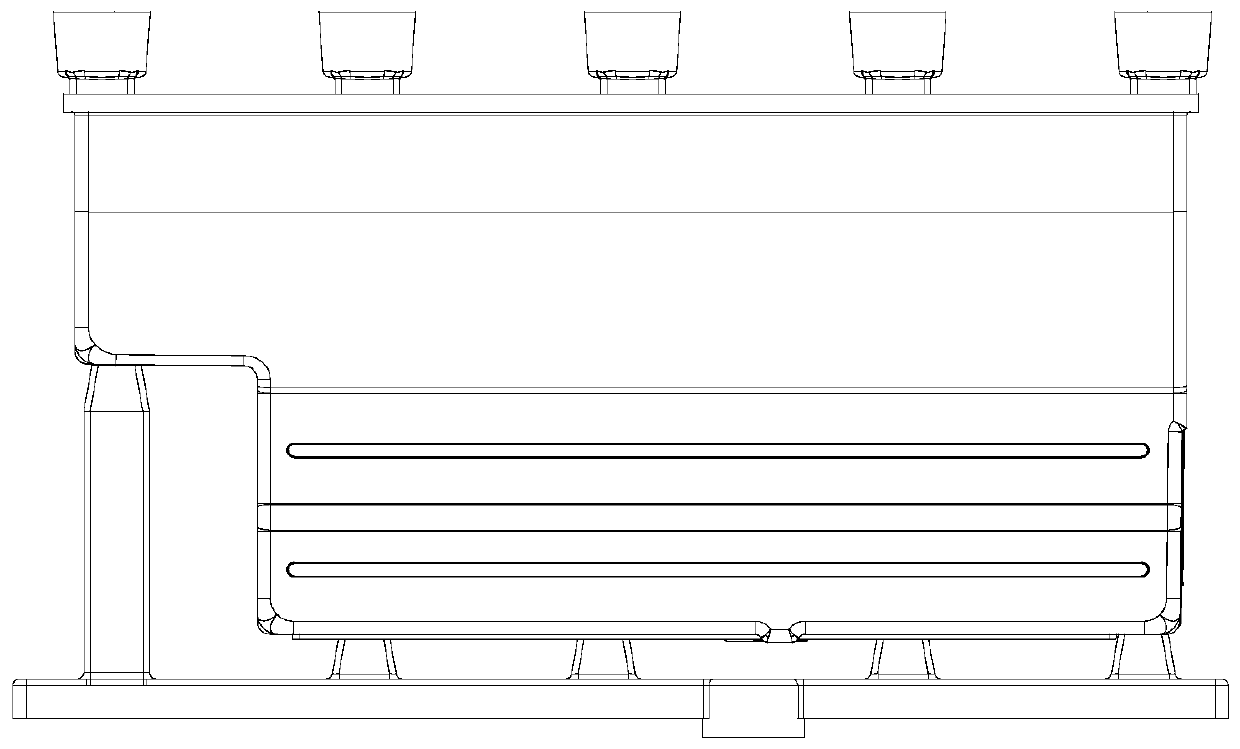

[0033] (1) Preprocess the three-dimensional image of the product, that is, to figure 1 Carry out preprocessing, delete the subtle features that cannot be cast and form, increase the machining allowance on the processing surface, shrink the model as a whole, design the gating system according to the product structure characteristics and complete the three-dimensional graphics drawing of the gating system, and obtain the casting process diagram of the product, such as figure 2 shown;

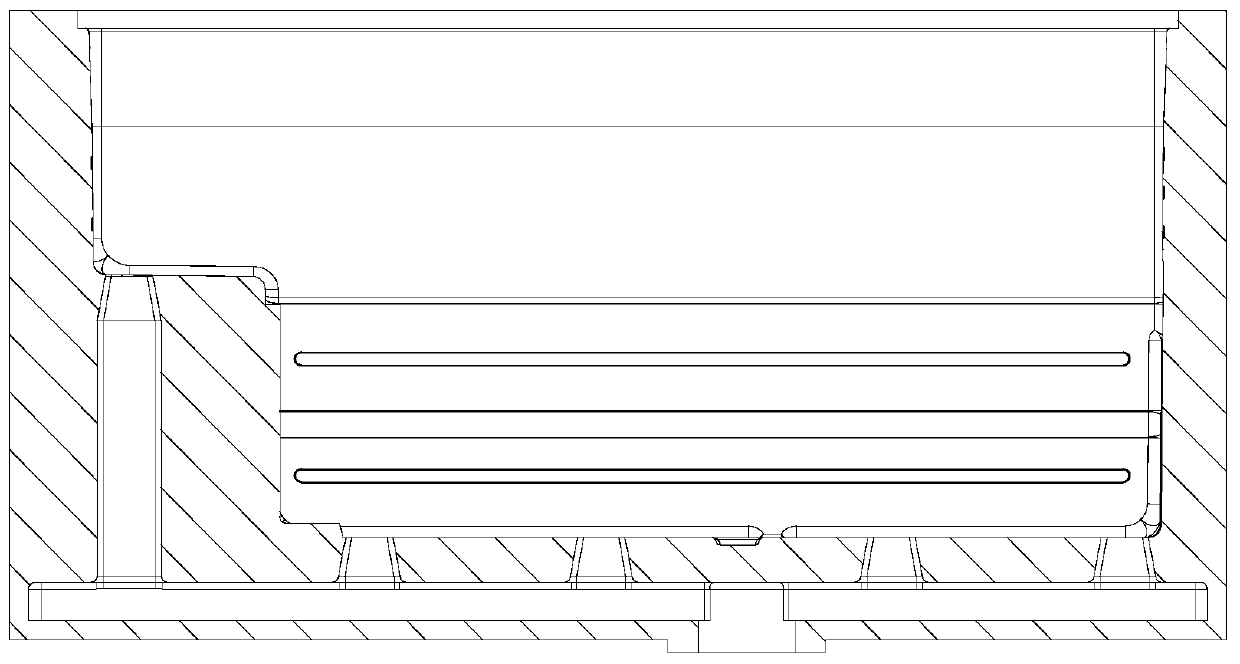

[0034] Then use the 3D software to draw the 3D model of the sand shell;

[0035] (2) Use a 3D printer to print out the drawn casting sand molds, as follows image 3 The 3D printing sand mold for the product to be cast is shown; as Figure 4 The upper mold o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com