A kind of aluminum alloy air storage tank for vehicle

An aluminum alloy and gas storage tank technology, applied in the field of gas storage tanks, can solve problems such as cracking and weak pressure resistance, and achieve the effects of eliminating welding, strong pressure resistance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

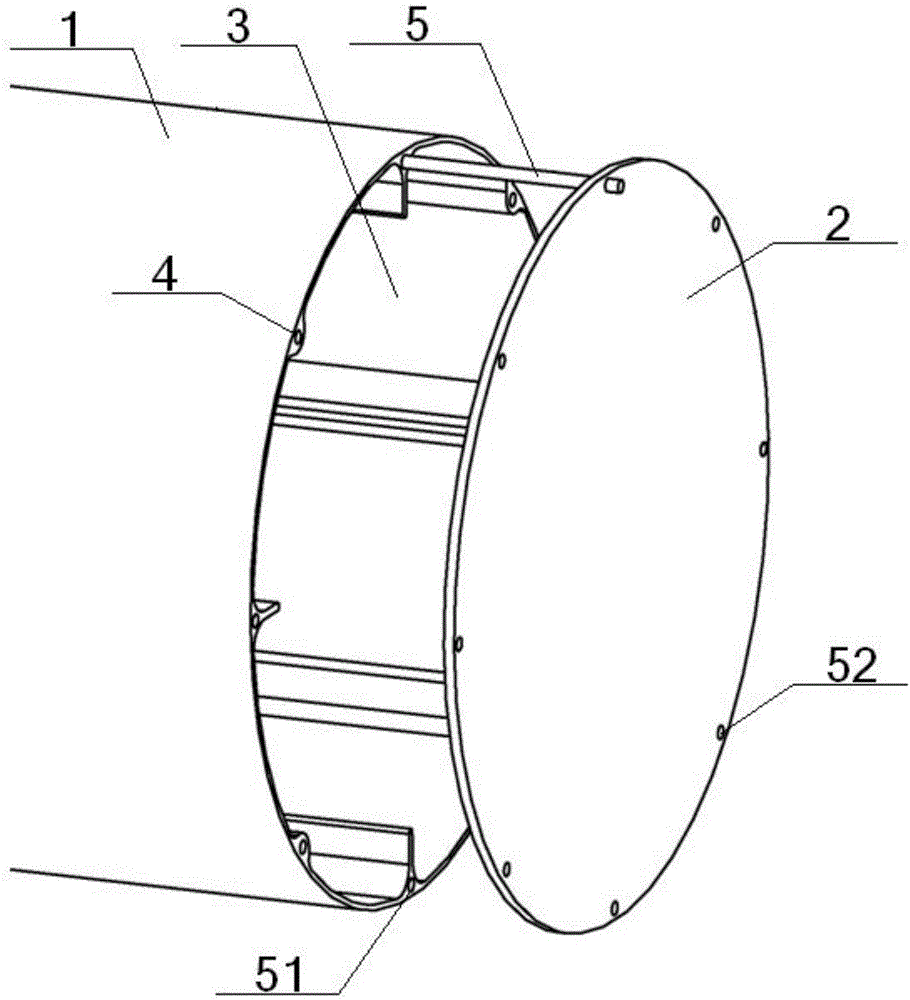

[0034] see figure 1 , figure 2 , an aluminum alloy air storage tank for vehicles, comprising a cylinder body 1, an end cover 2, a reinforcing rib 4 and a connecting rod 5, the two ends of the cylinder body 1 are opening structures 3, and the inner wall of the cylinder body 1 along the central axis The direction is provided with a plurality of reinforcing ribs 4, the bottom of the reinforcing ribs 4 is connected with the inner wall of the cylinder 1, and the top of the reinforcing ribs 4 extends into the cylinder 1, and the distance between the top of the reinforcing ribs 4 and the inner wall of the cylinder 1 is greater than The distance between the bottom of the reinforcing rib 4 and the inner wall of the cylinder body 1, a rib screw hole 51 is provided near the bottom of the reinforcing rib 4, and the rib screw hole 51 and the cover screw hole 52 provided on the end cover 2 are one by one. Correspondingly, the rib screw hole cavity 51 is connected with its corresponding co...

Embodiment 2

[0036] Basic content is the same as embodiment 1, the difference is:

[0037] A plurality of reinforcing ribs 4 are evenly arranged along the same circumference, and the shape of the cross section of the reinforcing ribs 4 is a boss, I-shape or T-shape.

Embodiment 3

[0039] Basic content is the same as embodiment 1, the difference is:

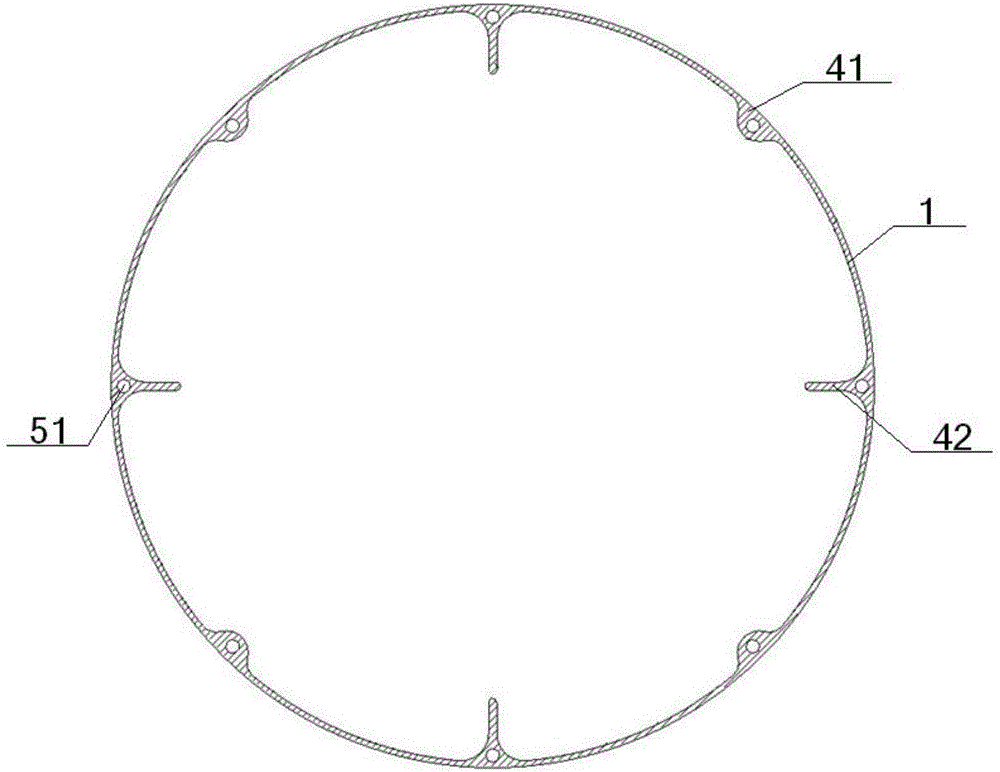

[0040] The quantity of rib 4 is eight, including four boss ribs 41 and four I-type ribs 42, the shape of the cross-section of the boss rib 41 is a boss, and the shape of the cross-section of the I-type rib 42 is It is I type, four boss ribs 41 are evenly arranged along the same circumference, four I-type ribs 42 are evenly arranged along the same circumference, and an I-type rib 42 is arranged between adjacent boss ribs 41. A boss rib 41 is arranged between adjacent I-shaped ribs 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com