Exhaust device, exhaust control method and mold structure with exhaust device

An exhaust device and mold technology, applied in the coating and other directions, can solve the problems of low gas reserves, bursting, air trapping in plastic products, etc., and achieve the effect of avoiding trapped air and timely and rapid exhausting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

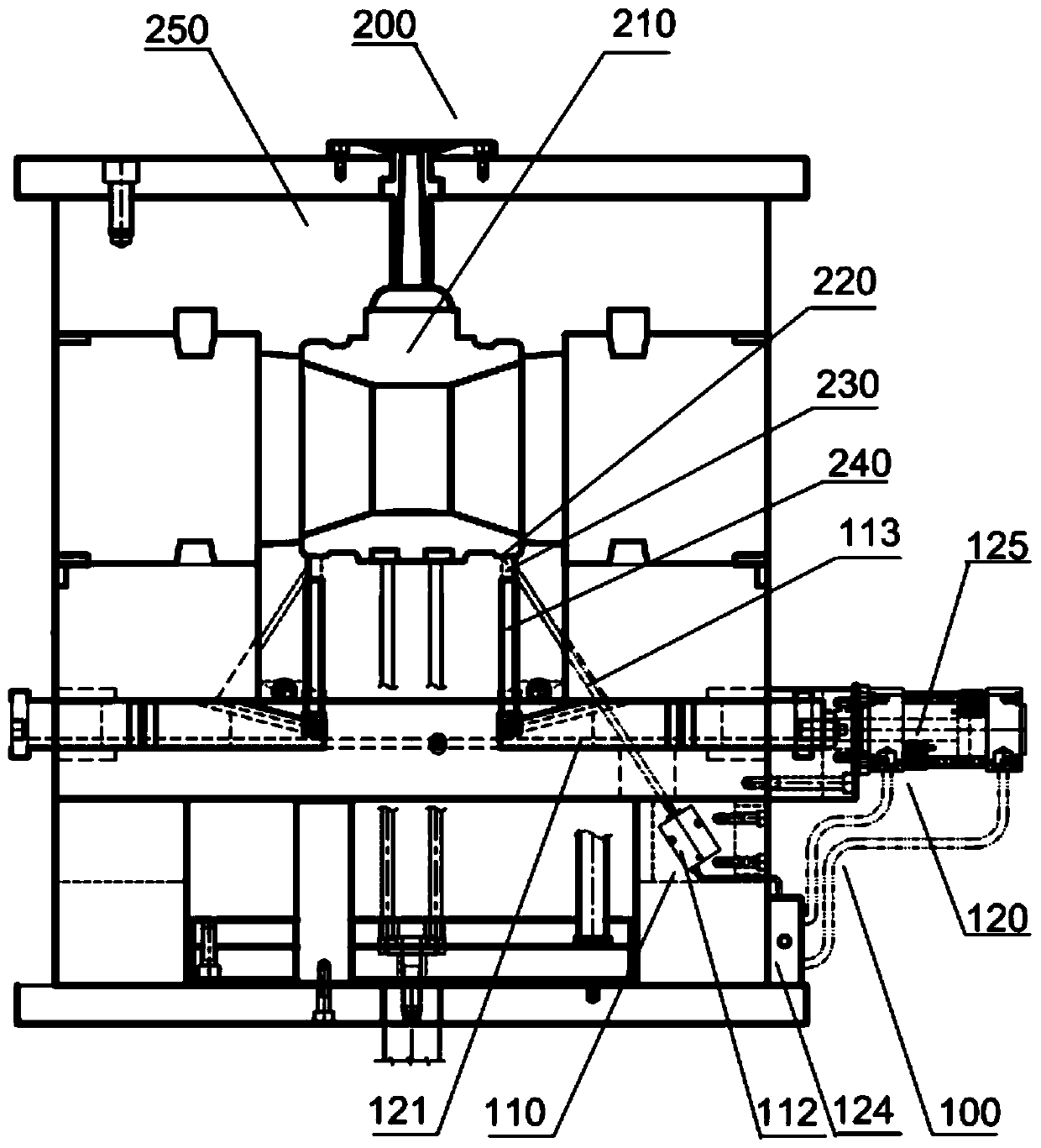

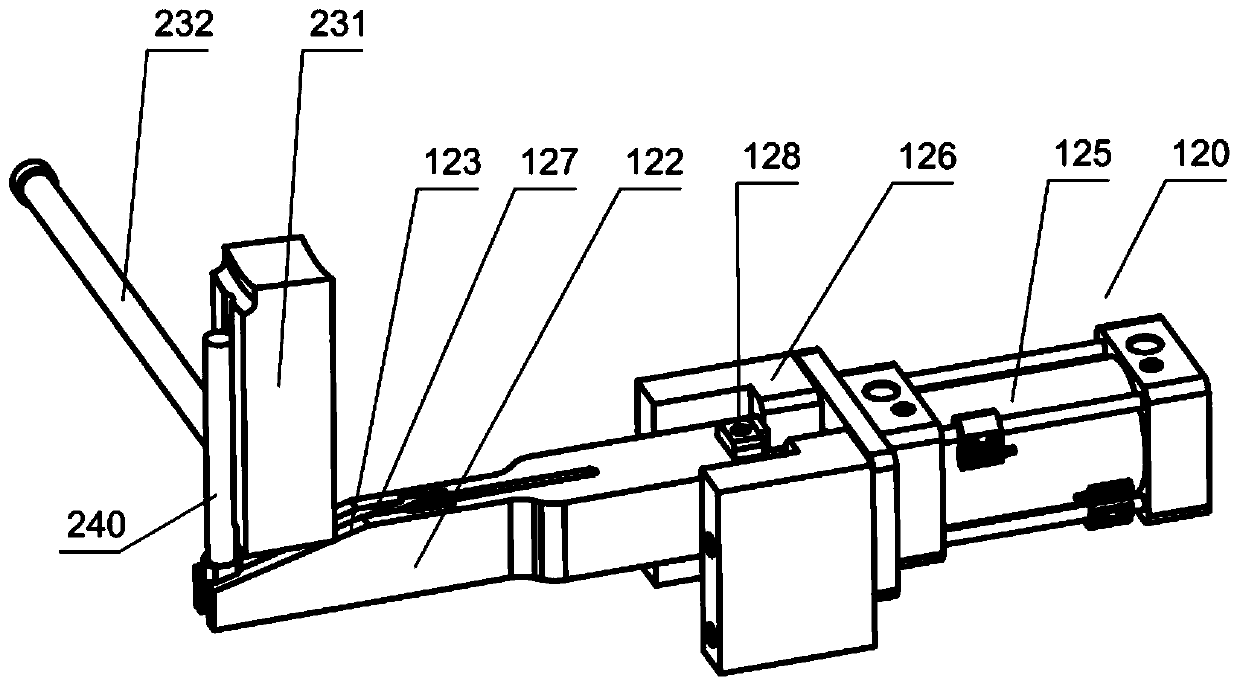

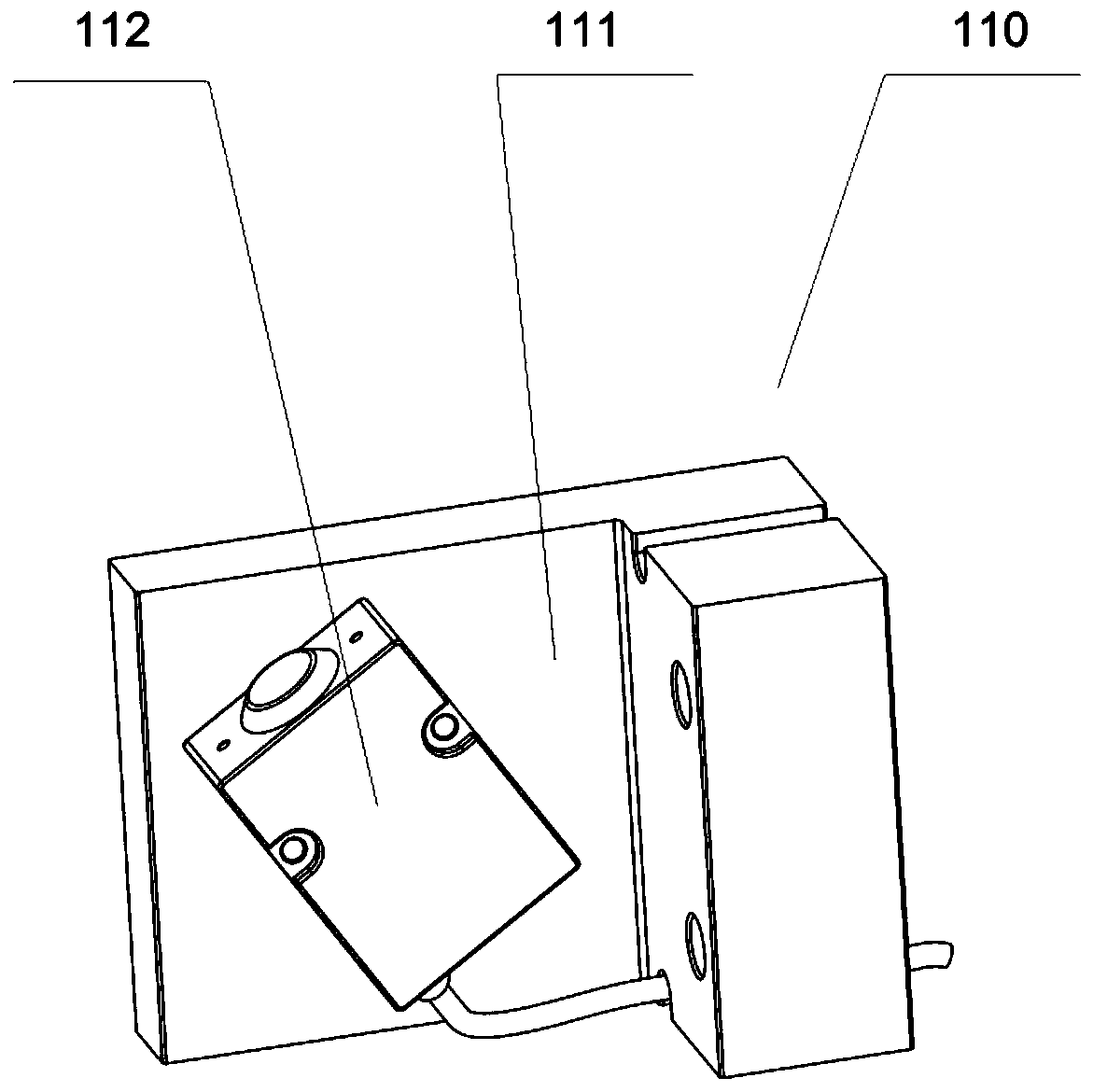

[0032] Such as Figure 1 to Figure 3 Shown is an embodiment of the exhaust device 100 of the present invention, the exhaust device 100 of this embodiment is applied to a mold structure 200; the mold structure 200 is provided with a cavity 210 that can communicate with the external environment, and the bottom of the cavity 210 A temperature-sensing point 220 is provided; the exhaust device 100 includes a controller, a temperature-sensing mechanism 110 connected to the input end of the controller, and a mechanical slider mechanism 120 connected to the output end of the controller, and the temperature-sensing mechanism 110 is signal-connected to the temperature-sensing point 220; The mold structure 200 is provided with a guide hole 230 communicated with the cavity 210 , and the guide hole 230 is provided with a sealing insert 240 that can be raised by the mechanical slider mechanism 120 to close the cavity 210 .

[0033]During the implementation of this embodiment, the high-tempe...

Embodiment 2

[0037] This embodiment is an embodiment of the exhaust gas control method of the exhaust device 100 in the first embodiment, including the following steps:

[0038] When the high-temperature fluid plastic flows to the temperature sensing point 220 in the cavity 210, the infrared temperature sensor 112 transmits the received signal to the controller, and the controller controls the solenoid valve 124 to open, connecting the air source and the cylinder 125;

[0039] The air cylinder 125 pushes the slider 122 to move under the air pressure, and the end of the sealing insert 240 slides in the T-shaped groove 127 and moves upward along the slope 123 to close the cavity 210 .

[0040] Through the above steps, the gas in the cavity 210 can be effectively and quickly removed, and the cavity 210 can be closed in time to ensure the smooth molding of the plastic product.

Embodiment 3

[0042] Such as Figure 4 to Figure 5 Shown is an embodiment in which the exhaust structure of Embodiment 1 is applied to a mold structure 200. The mold structure 200 includes a mold frame 250, a cavity 210, a glue injection system 260 communicating with the cavity 210, a core pulling system 270, and a thimble system 280 As well as the previous exhaust device 100 , the temperature sensing mechanism 110 , the mechanical slider mechanism 120 , the glue injection system 260 , the core pulling system 270 , and the thimble system 280 are all installed on the mold frame 250 .

[0043] During the implementation of this embodiment, the high-temperature molten high-temperature fluid plastic is injected into the cavity 210 through the injection system 260. When the high-temperature fluid plastic touches the temperature-sensing mechanism 110, the mechanical slider mechanism 120 is controlled to drive the sealing insert 240 Rising and closing the cavity 210, the high-temperature fluid plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com