Patents

Literature

30results about How to "Exhaust in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

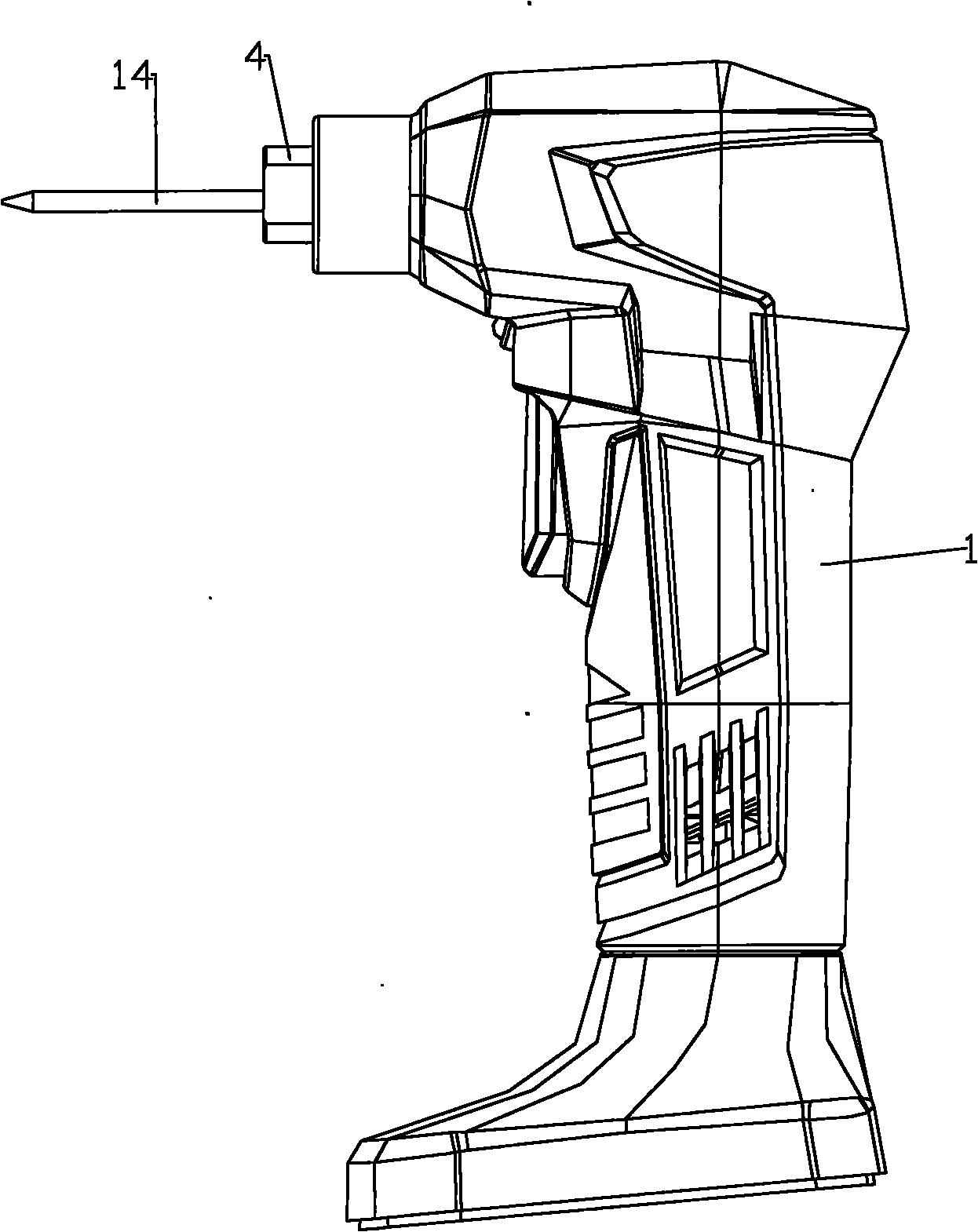

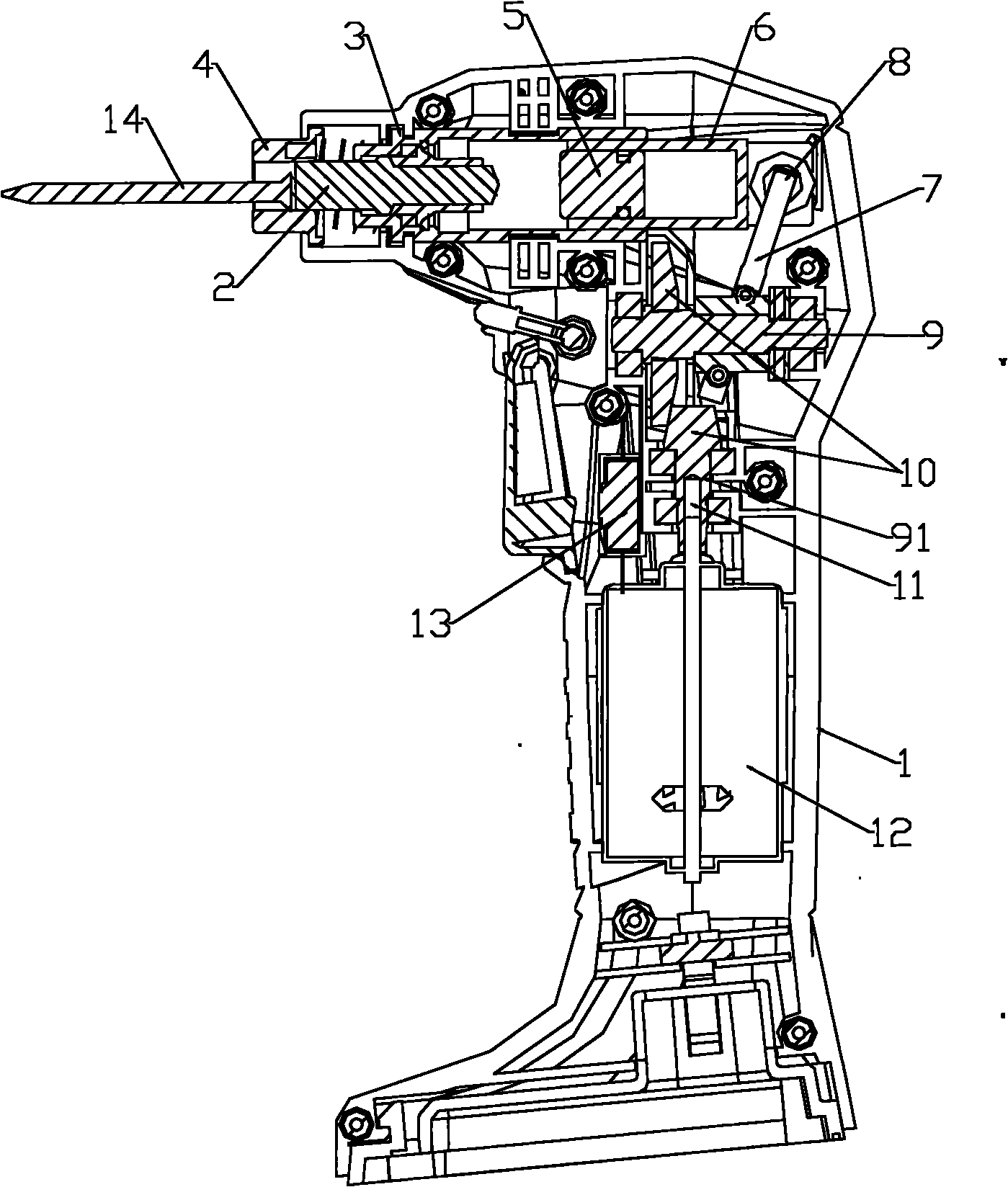

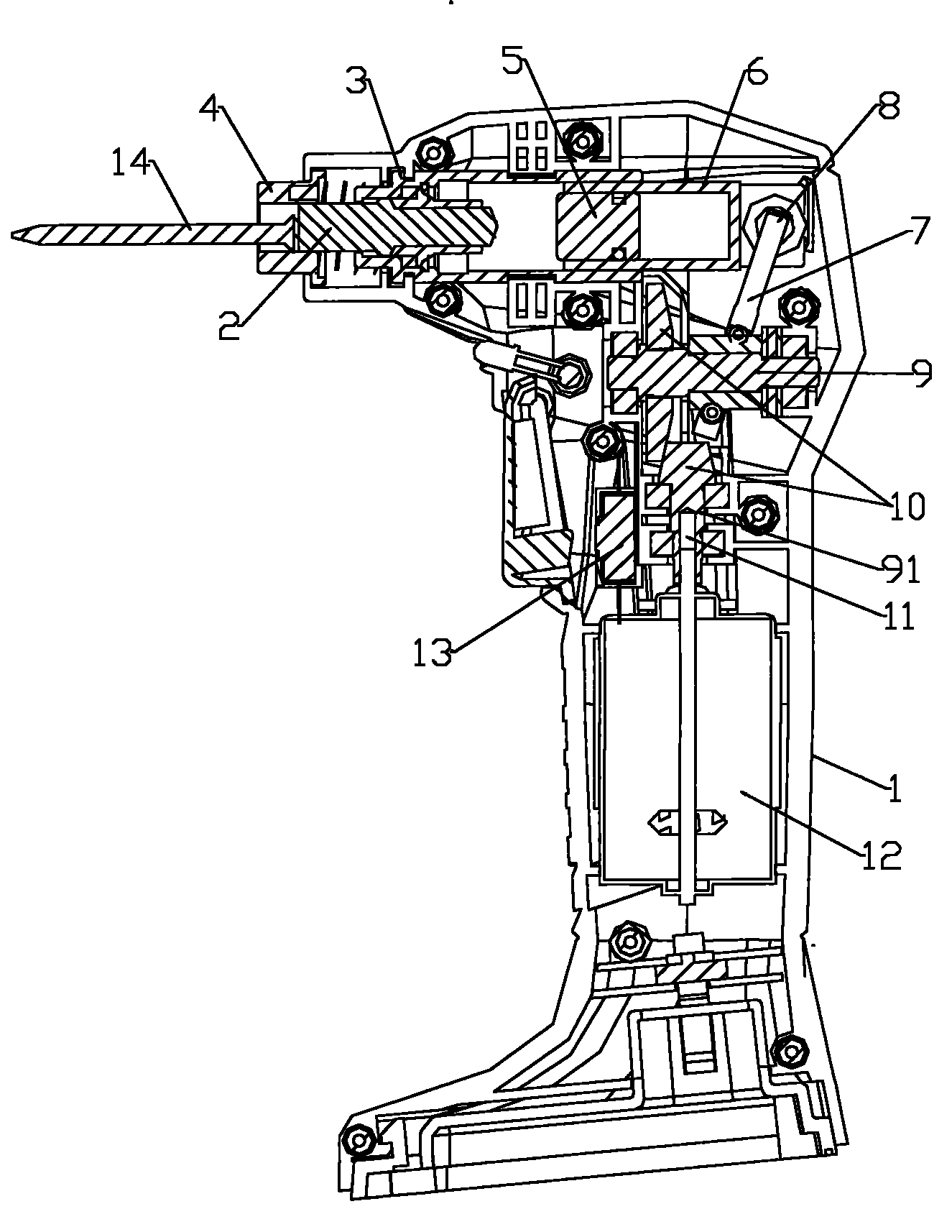

Nailing gun

The invention discloses a nailing gun which comprises a shell cavity and a motor, wherein the shell cavity is formed by carrying out involution on a left half shell and a right half shell; a rotary-linear motion conversion transmission mechanism is arranged in the shell cavity; the motor is connected with a piston through the rotary-linear motion conversion transmission mechanism; a nail striking pin for nailing is arranged in a gun mouth of the nailing gun and fixed in a cylinder body; the piston is mounted in the cylinder body; an axial cavity with an opening at one end of the axial cavity is arranged in the piston; an air hammer is mounted in the axial cavity of the piston; the gun mouth is also provided with a nail accommodating port formed by an indention structure; and the axis of the nail accommodating port is coaxial with that of the nail striking pin. By utilizing the structure provided by the invention, a continuous hammering function is realized in a compact space, and the energy utilization efficiency is improved; continuous efficient striking on a nail can be achieved, thereby effectively avoiding the trouble that the nail cannot be nailed by a single-shot nailing gun under certain working conditions; and moreover, as the nail is stricken by the air hammer, the striking force is great.

Owner:JIANGSU HEHUI POWER TOOLS CO LTD

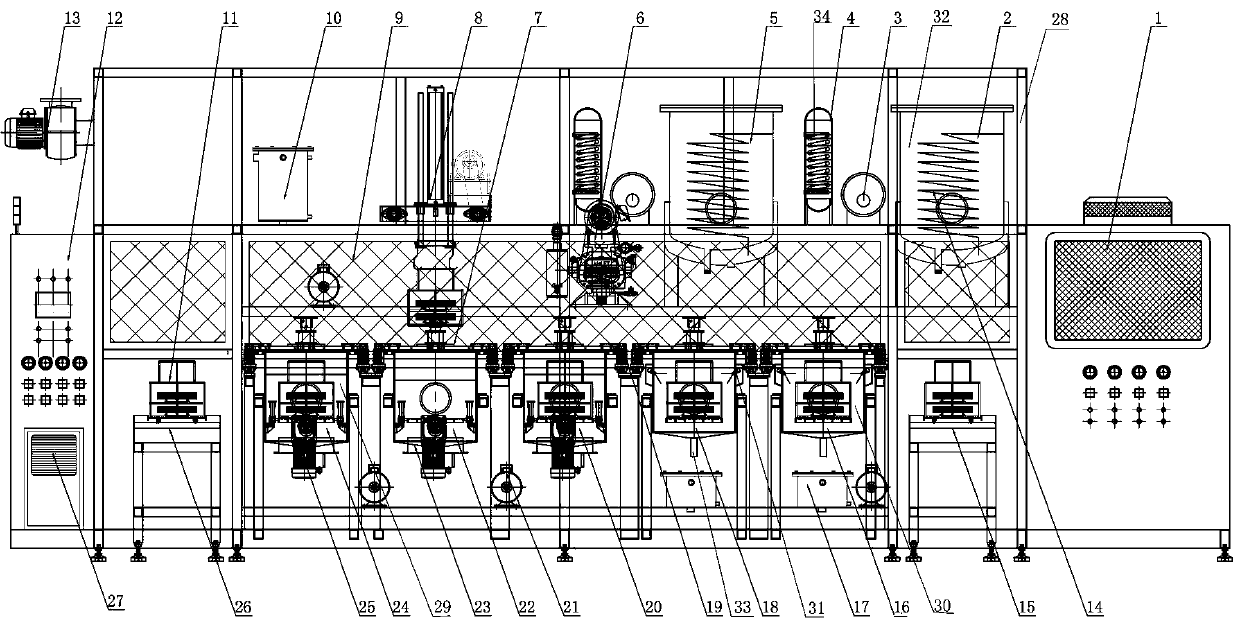

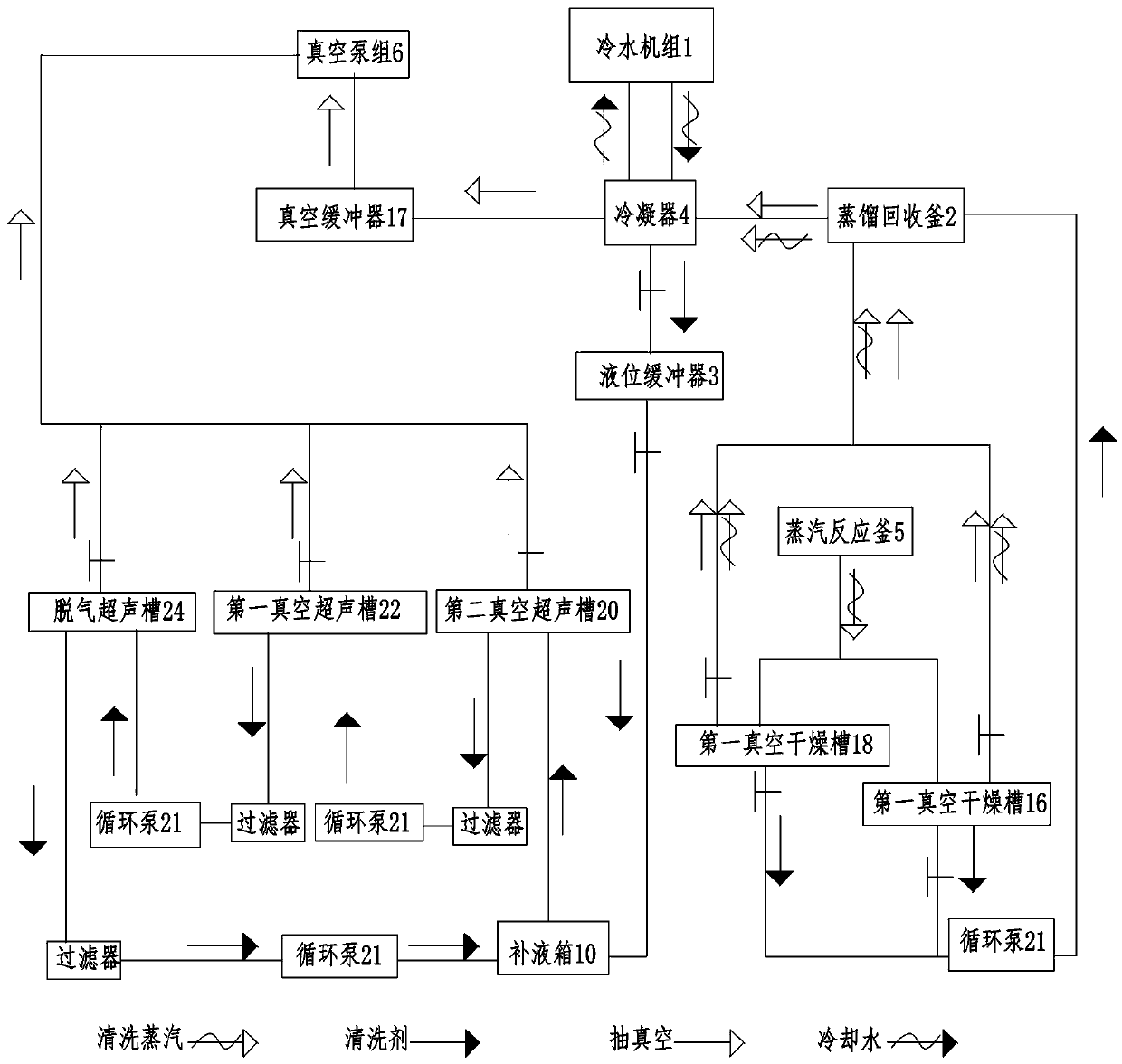

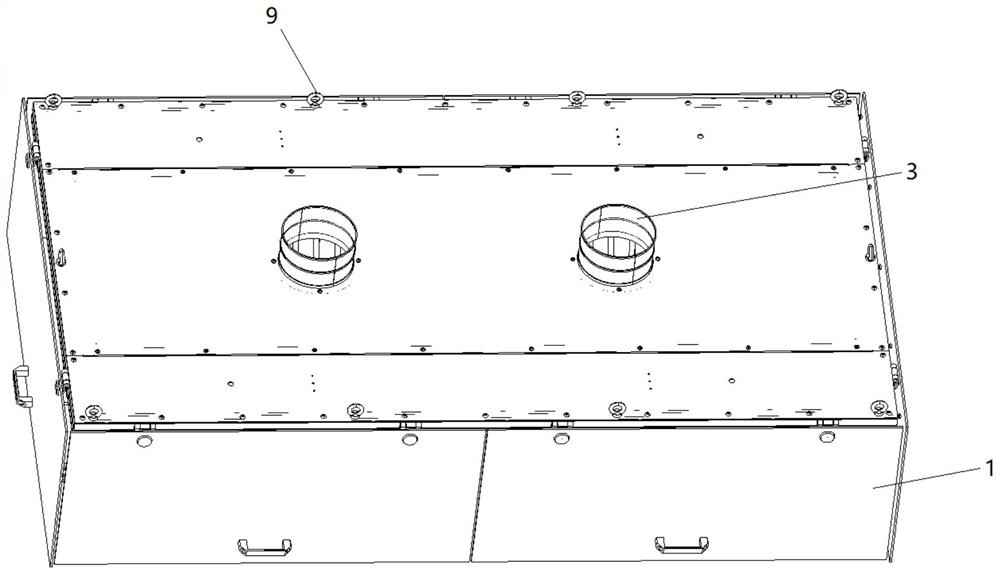

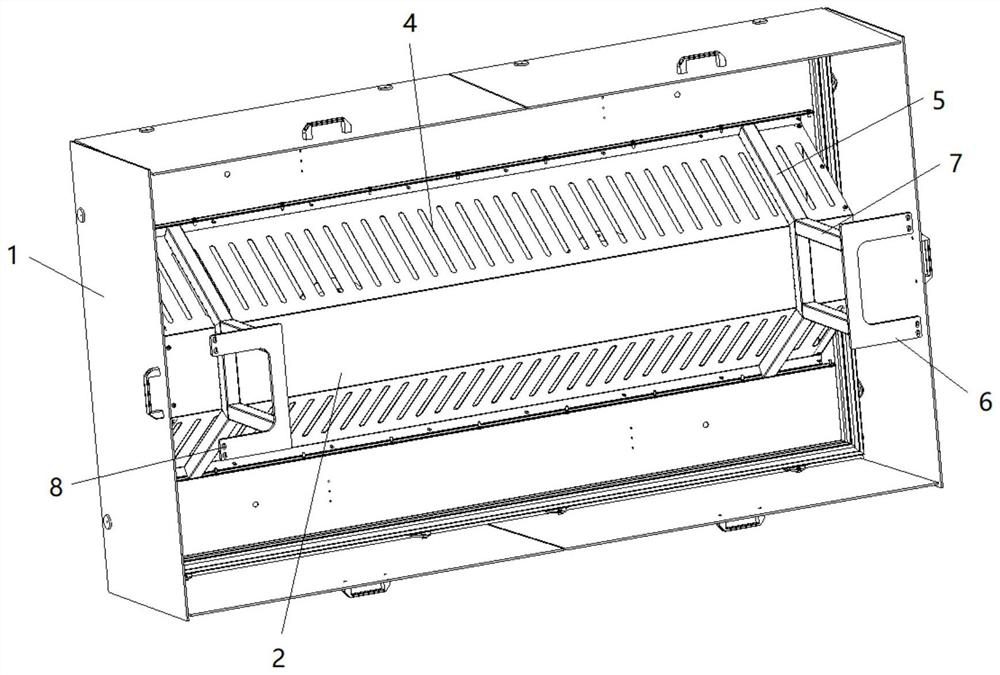

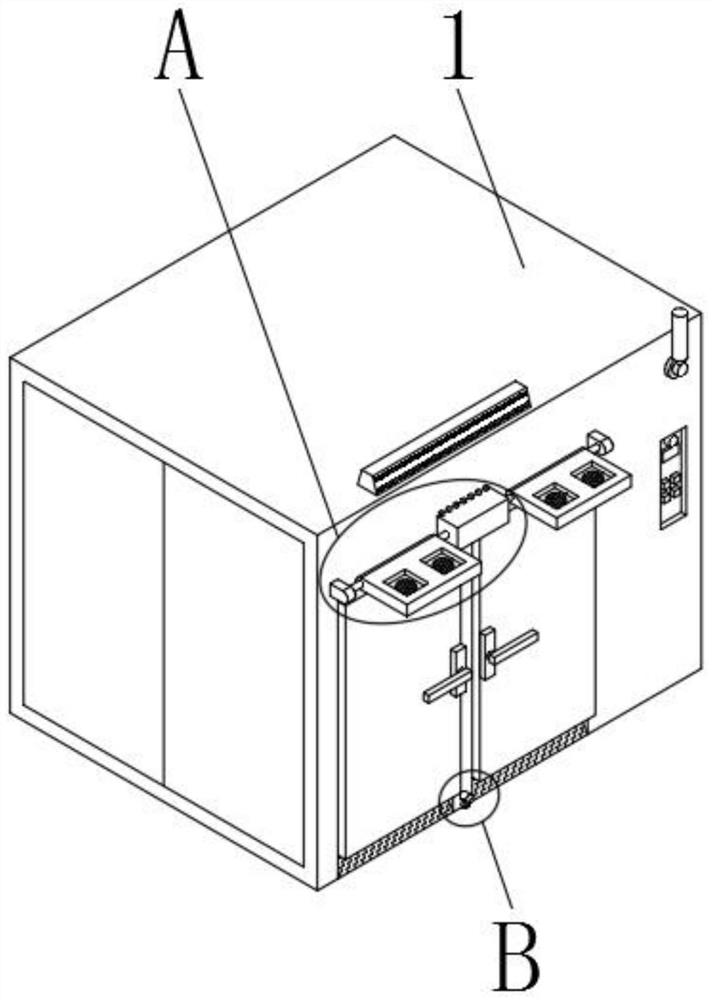

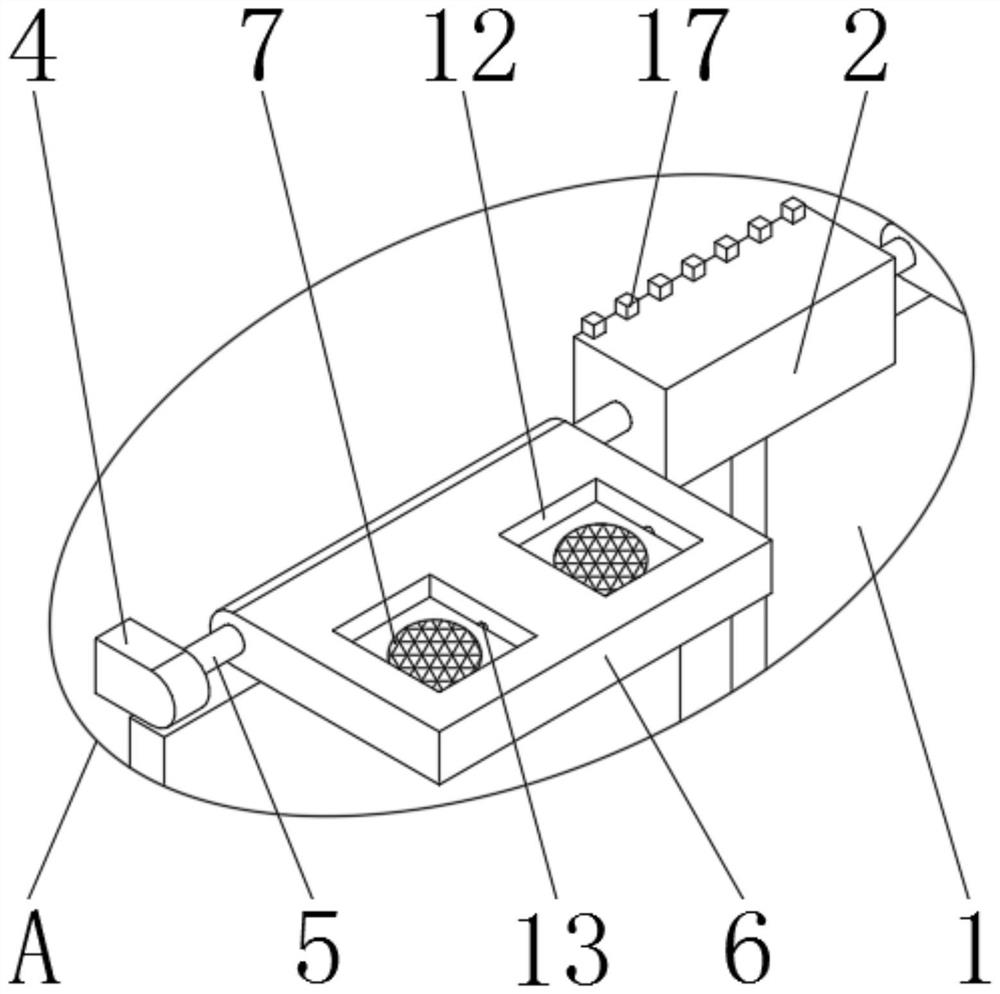

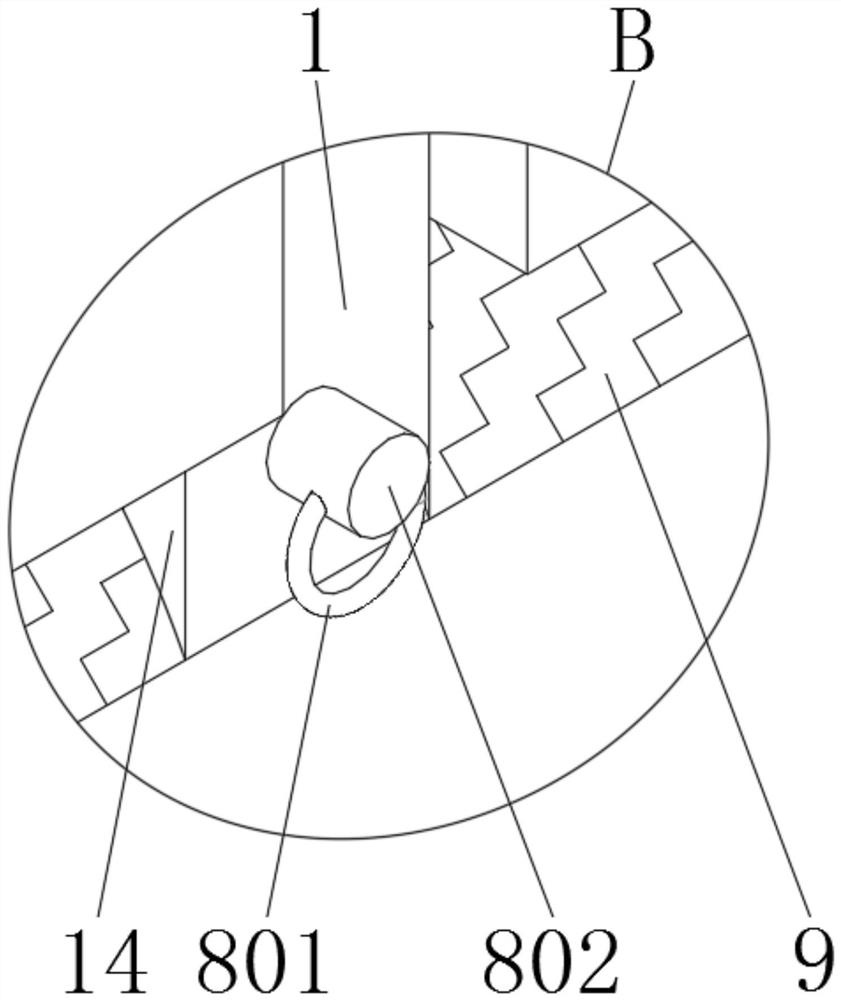

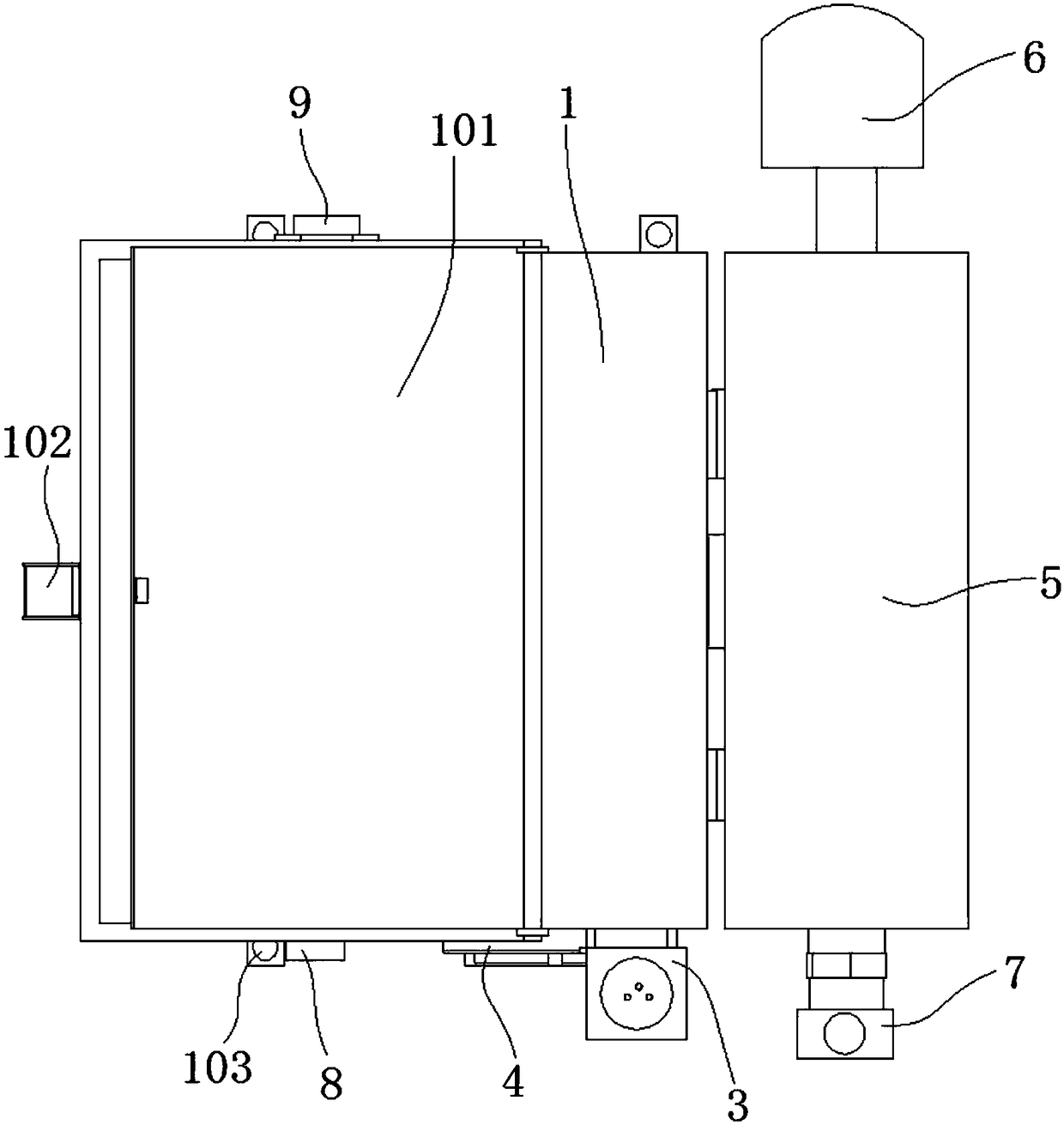

Multi-groove type vacuum hydrocarbon cleaning and drying machine for alloy stamping parts

PendingCN110894609ASolve turnover handling problemsReduce manual labor intensityCleaning using liquidsProcess engineeringVacuum pump

The invention discloses a multi-groove type vacuum hydrocarbon cleaning and drying machine for alloy stamping parts. An exhaust fan, an electric appliance control cabinet, a cabinet cooling air conditioner and a water chilling unit are installed outside a cabinet, observation windows are arranged in both the front and back sides, a feeding table and a discharging table are arranged at the two endsof the interior of the cabinet respectively, and an ultrasonic cleaning assembly and a vacuum drying assembly are sequentially installed between the feeding table and the discharging table. A carrying assembly is arranged over the feeding table, the ultrasonic cleaning assembly, the vacuum drying assembly and the discharging table; a liquid supplementing box, a vacuum pump set, a steam reaction kettle and a distillation recovery assembly are arranged over the carrying assembly; the ultrasonic cleaning assembly and the liquid supplementing box are circularly connected through a pipeline; the vacuum drying assembly, the distillation recovery assembly and the liquid supplementing box are in pipeline connection; and the vacuum pump set is connected with air exhaust ports of the ultrasonic cleaning assembly and the distillation recovery assembly. The cleaning and drying machine has the effects of being high in automation degree and little in pollution, and the problems that in the prior art, pollution is serious, the quality and efficiency are low, and labor intensity is large are solved.

Owner:ZHANGJIAGANG GANGWEI ULTRASONIC ELECTRONICS

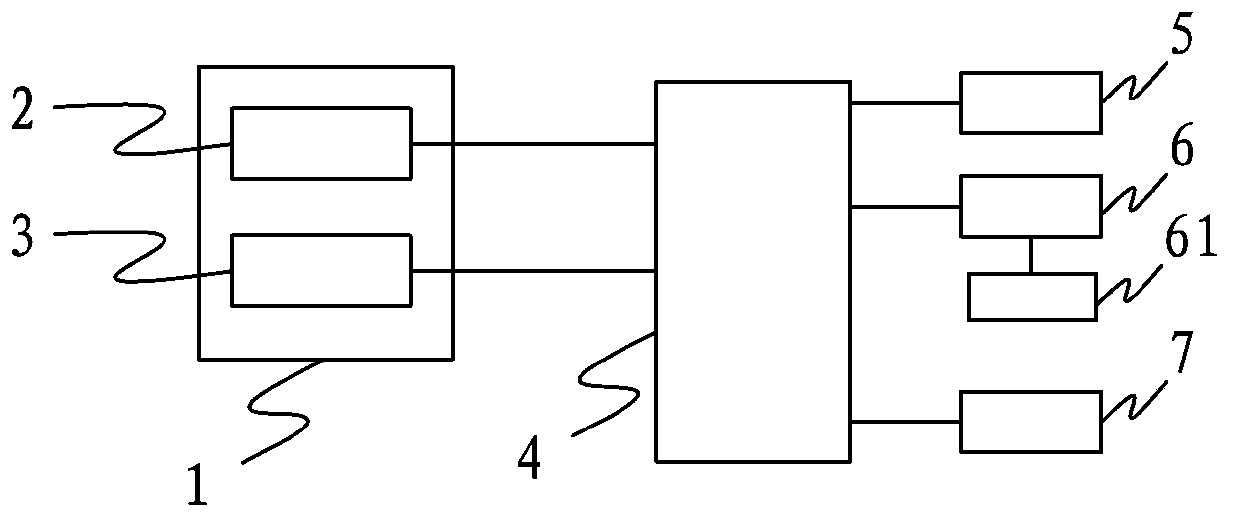

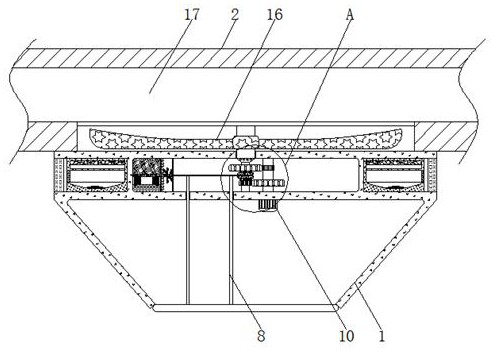

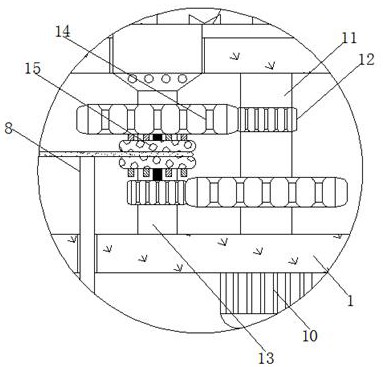

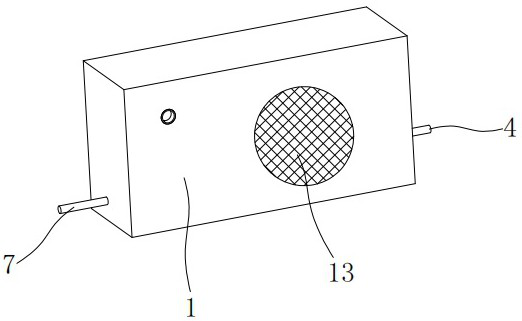

Smog-temperature alarm smoke ventilator and district alarm system

InactiveCN103473881AExhaust in timeDomestic stoves or rangesLighting and heating apparatusEngineeringEmergency situations

The invention mainly discloses a smog-temperature alarm smoke ventilator and a district alarm system. The smoke ventilator includes a smoke ventilator body, a carbon-monoxide sensor, a temperature sensor, a control unit and an alarm circuit. The carbon-monoxide sensor and the temperature sensor are arranged on the smoke ventilator body. Signals of the carbon-monoxide sensor and the temperature sensor are connected with the control unit. The control unit is connected with an alarm circuit and an air-exhaust motor. The district alarm system includes an upper computer installed within district property monitoring. Smog-temperature alarm smoke ventilators installed by users in the district are used as lower computers. The upper computer is in data communication with the lower computers and processes data and the upper computer sends out an alarm when abnormal data are acquired. The district alarm system intelligently monitors lampblack and temperature states in kitchens and sends out the alarm timely about occurrence of emergency situations. The system is capable of carrying out remote monitoring of the kitchens in the district and realizing double insurance, and finding a dangerous situation first time similarly when there is no one in a house and affirmative measures are taken.

Owner:绍兴市弗兰特电器股份有限公司

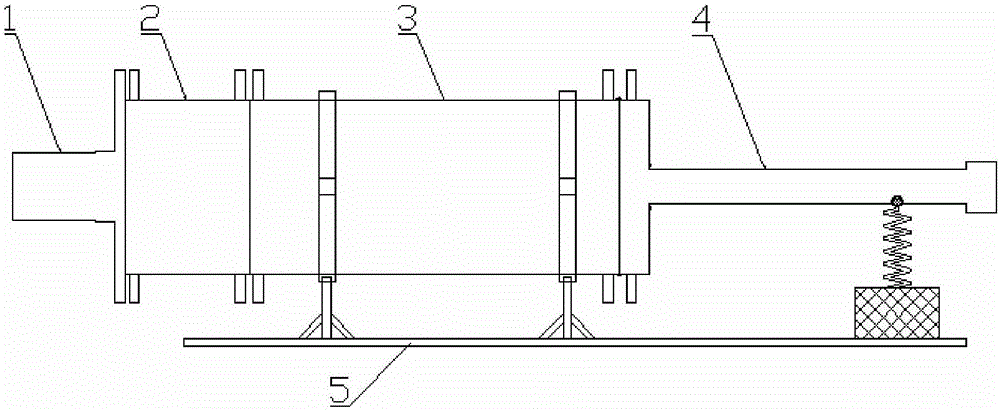

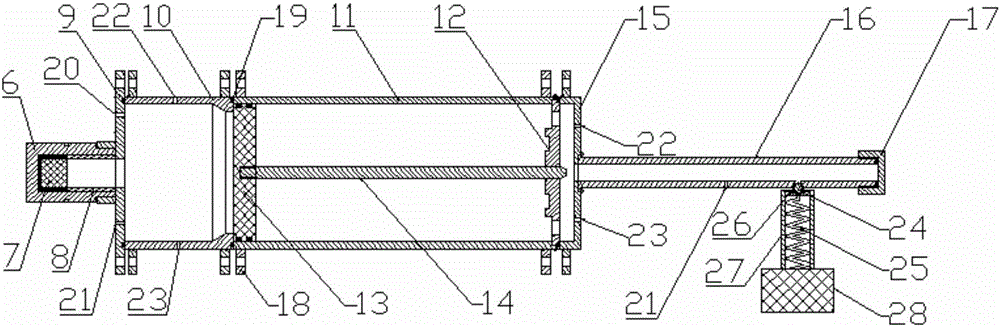

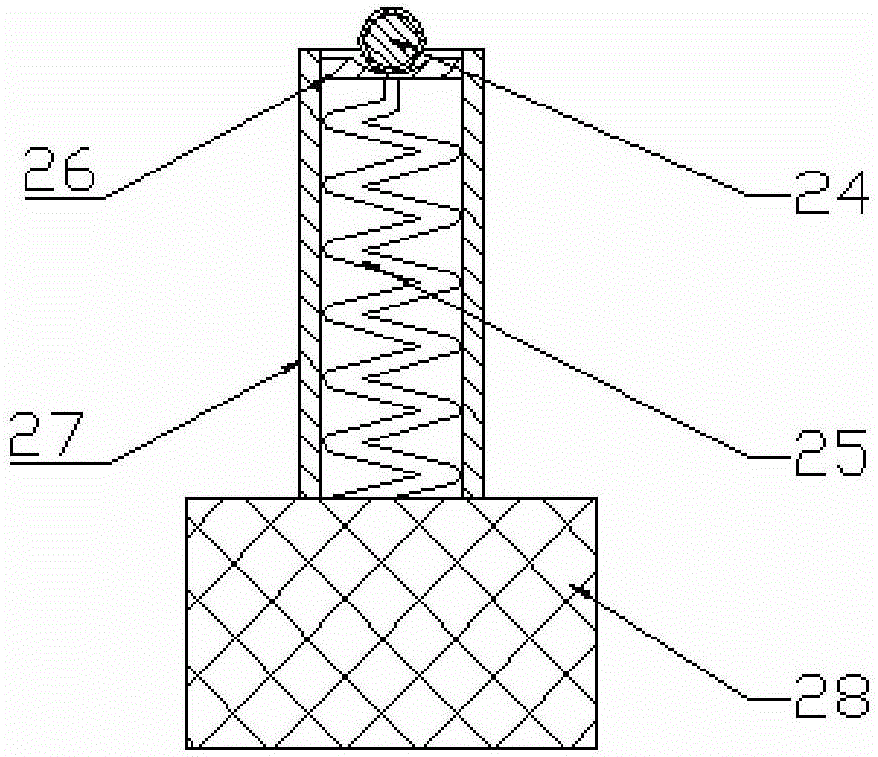

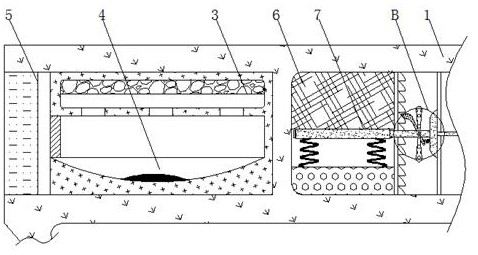

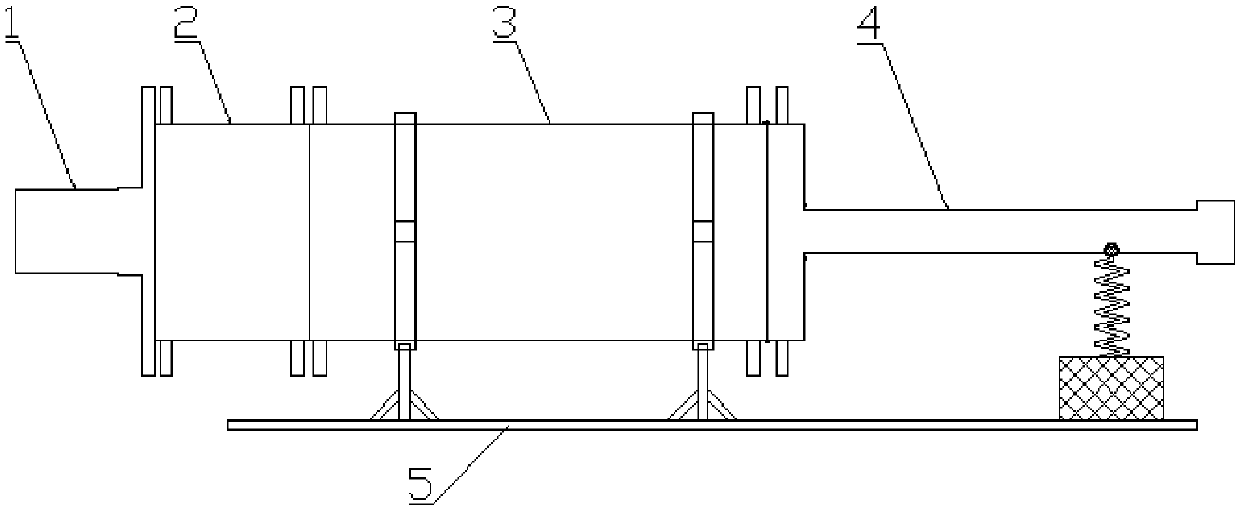

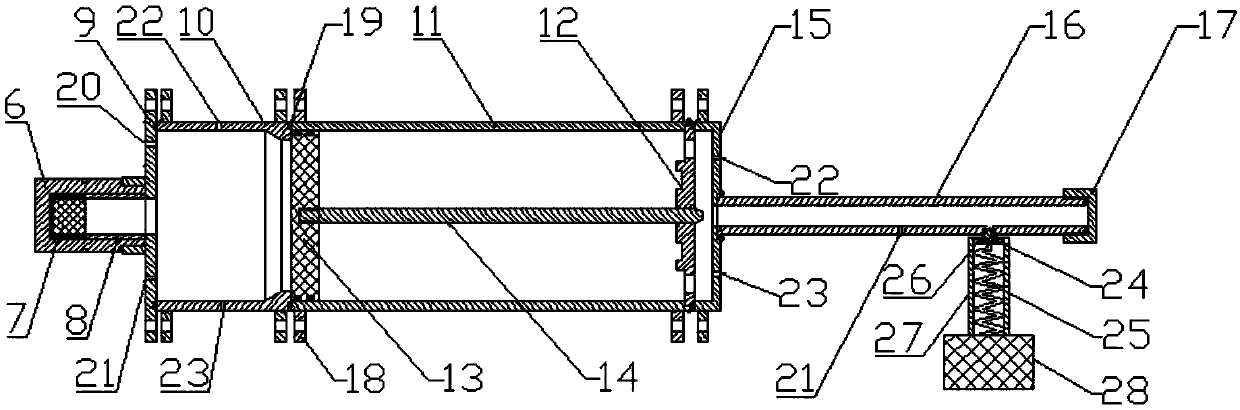

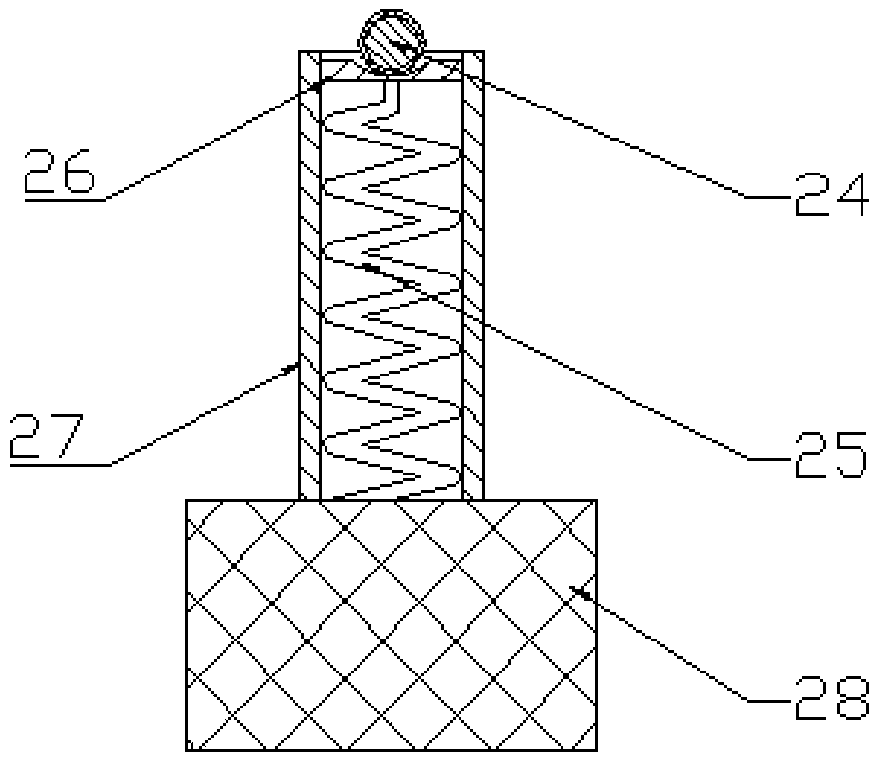

Condensed-phase combustion product collecting device controlling constant pressure through spring force

InactiveCN106289869ARealize pollution-free collectionSimple structureChemical analysis using combustionWithdrawing sample devicesCombustion chamberEngineering

The invention discloses a condensed-phase combustion product collecting device controlling constant pressure through spring force. A stable pressure environment in an engine combustion chamber is simulated through automatic pressure relief of spring force, and therefore pollution-free collection on all condensed-phase combustion products in the engine combustion chamber is achieved. The volume of the collecting device is regulated through movement of a piston to regulate pressure of the two sides of the piston; air is exhausted outwards through a steel ball and a spring mechanism which are arranged at an exhaust port of a tail cavity pipe, therefore, the pressure of the two sides of the piston achieves a balanced state, and a stable and balanced pressure environment which is kept under test-specified pressure is established. By arranging a fluororubber seal ring in a groove formed in the ring surface of the piston, sealing of space of the two sides of the piston is achieved, and it is guaranteed that the condensed-phase combustion products are not polluted; the steel ball is coated with a silicone rubber layer, so that the leakproofness of the steel ball and the spring mechanism is guaranteed. The length of a propellant support in the engine combustion chamber is regulated as needed, and therefore the condensed-phase combustion product can be conveniently collected under the conditions of different flow distances. The collecting device is simple in structure, small in size and easy to machine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

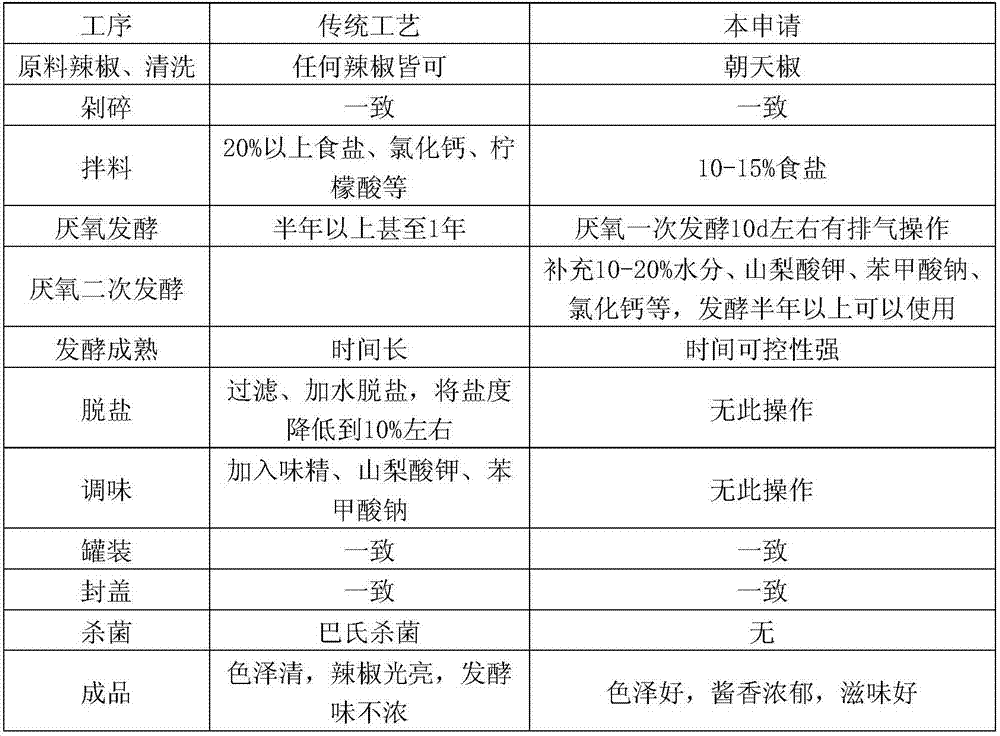

Compound fresh-keeping method for hot peppers through control in secondary fermentation low-salt mode

ActiveCN107198183AExhaust in timeReduce flatulenceFruit and vegetables preservationFood ingredient as flavour affecting agentFlavorSodium benzoate

The invention discloses a compound fresh-keeping method for hot peppers through control in a secondary fermentation low-salt mode. The method comprises the following steps: taking fresh pod peppers, sterilizing, washing, chopping, adding salt, weight of which accounts for 10-15% of hot peppers, sealing and fermenting under normal temperature, and performing gas-exhausting treatment; adding cold boiled water, rice wine, lysozyme, potassium sorbate and sodium benzoate, continuously sealing and fermenting at the room temperature, and directly filling. According to the compound fresh-keeping method disclosed by the invention, the pod peppers and low salt (10-15%) fermentation are adopted, fermentation is performed in stages (primary fermentation mainly refers to gas exhaustion and continuous fermentation after seasoning), and direct filling is performed without sterilizing, so that product salinity is reduced, loss of nutrient ingredients is reduced, waste emission is avoided in the whole production process, production process links are reduced, stability of product quality is guaranteed, and a processing process can be standardized. The obtained product is bright in color and luster, is strong in sauce smell, is salt and delicious in taste, and is good in fermenting flavor.

Owner:HUNAN TANTANXIANG FOODS TECH

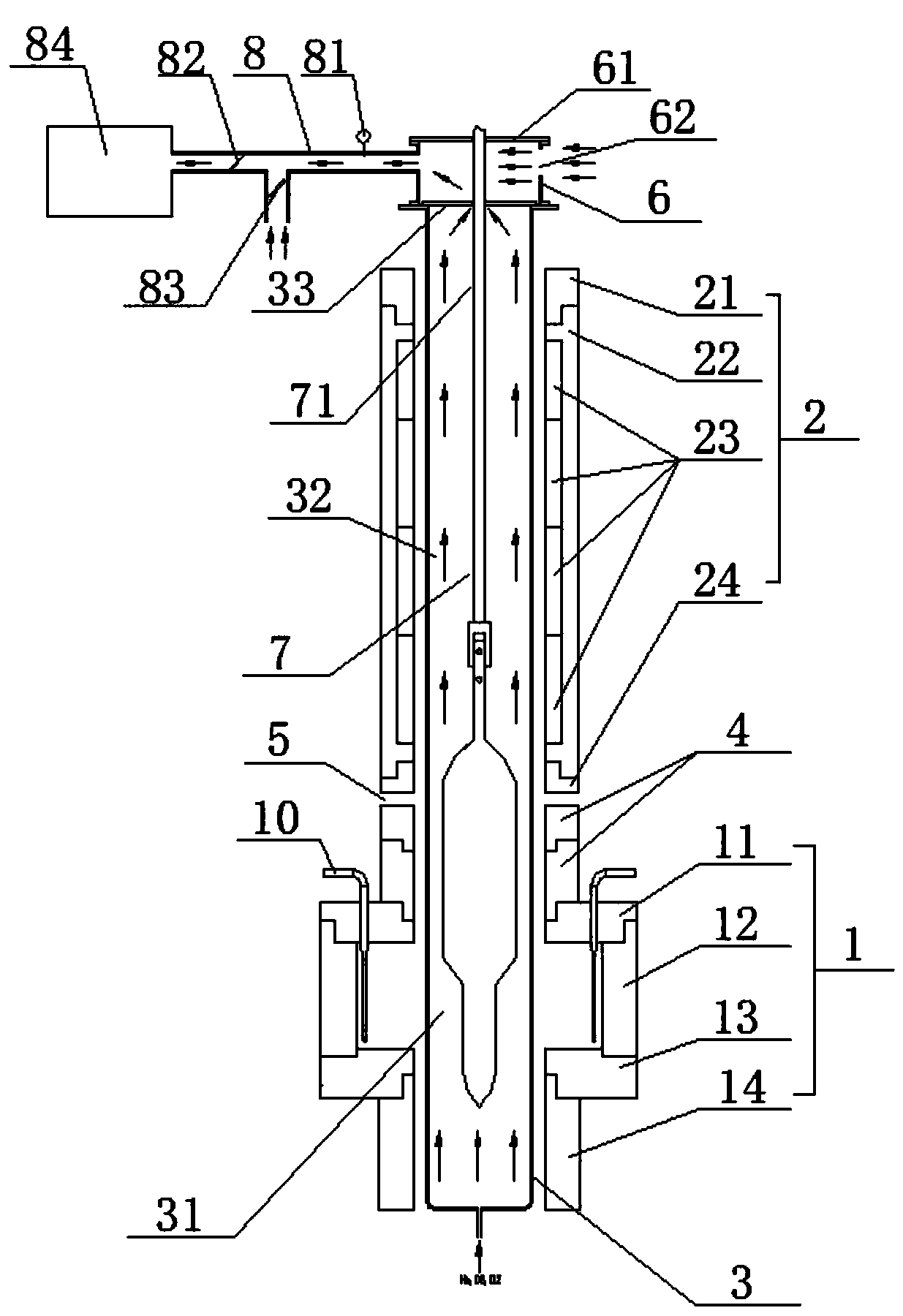

Double-furnace-core-rod sintering device with stable temperature field and stable flow field

PendingCN111377606ASmall temperature fluctuationsReduce the use effectGlass making apparatusHeat conservationFresh air

The invention discloses a double-furnace-core-rod sintering device with a stable temperature field and a stable flow field. The device comprises a sintering furnace, a dehydration furnace, an air inlet waste discharge treatment device and a muffle pipe arranged in the sintering furnace and the dehydration furnace in a penetrating mode. An inter-furnace heat preservation piece and a temperature balance area are arranged between the sintering furnace and the dehydration furnace. A sintering area and a dehydration area are arranged in the muffle pipe; a muffle tube cover plate is arranged at thetop of the muffle pipe; and the air inlet and waste discharge treatment device comprises an exhaust hood, an exhaust pipe and a waste gas treatment device. A fresh air branch with a fresh air valve, apressure gauge and a main air valve are arranged on the exhaust pipe, a traction device is arranged on the exhaust hood cover plate and the muffle tube cover plate in the penetrating mode, a loose product is installed at the lower end of the traction device and inserted into the muffle tube to be dehydrated and sintered, and the exhaust hood, the muffle tube, the exhaust pipe and the waste gas treatment device are communicated. The device has the advantages that the temperature in the furnace and the temperature and the pressure in the muffle tube are stable, the sintering dehydration operation time and the production cost are reduced, the overall working efficiency is improved, and a temperature field and a flow field are stable.

Owner:杭州永通智造科技有限公司

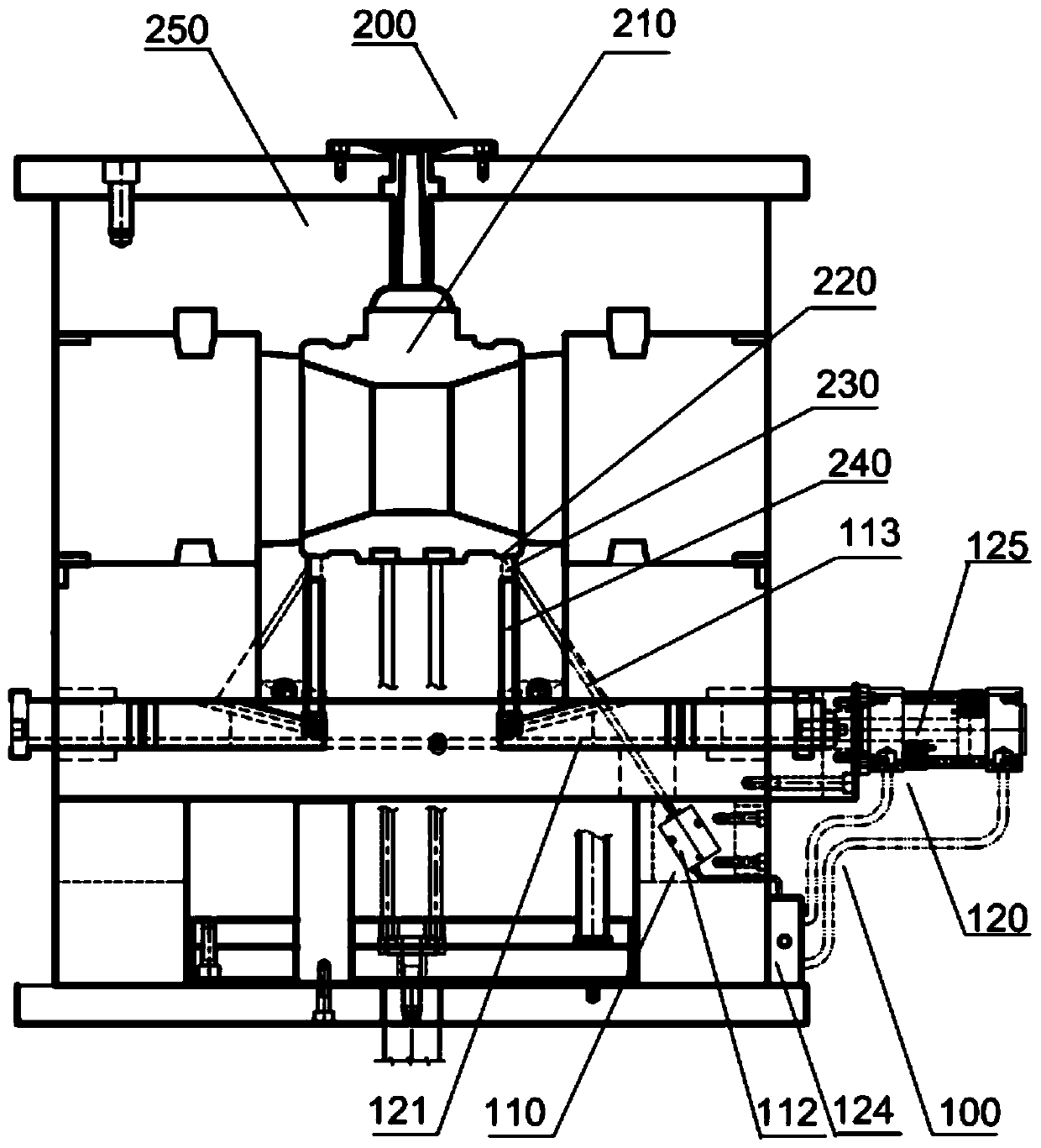

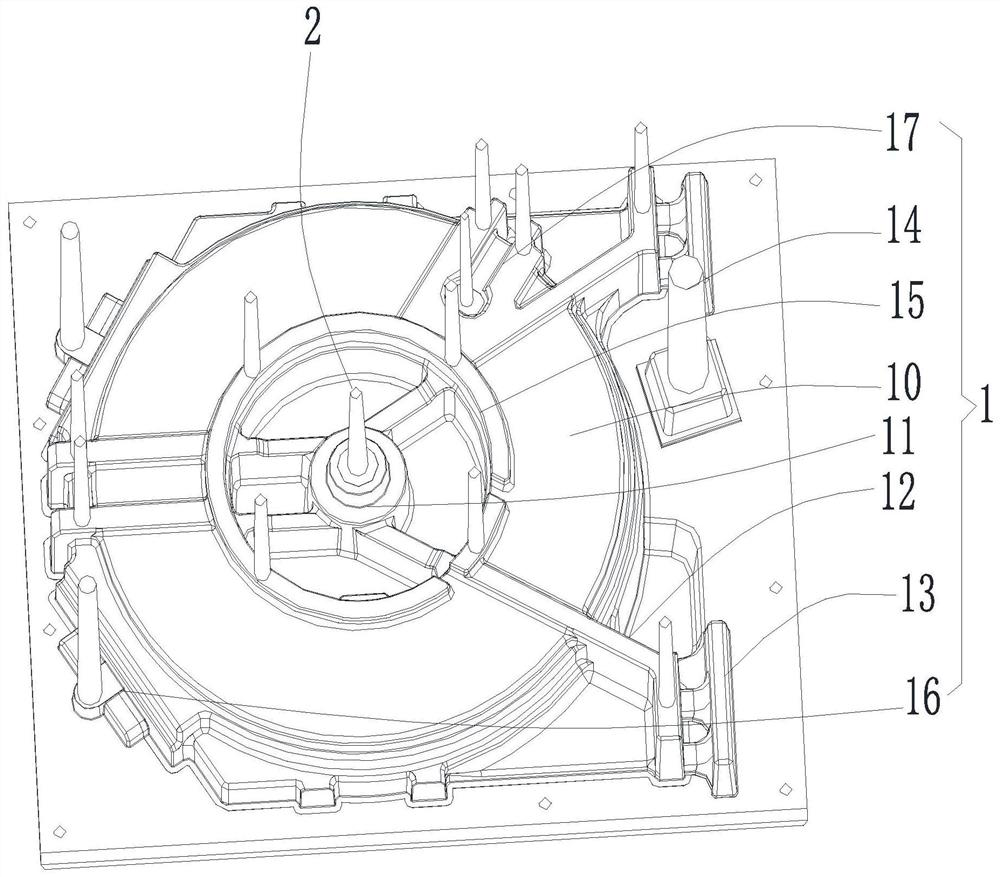

Exhaust device, exhaust control method and mold structure with exhaust device

The invention relates to the technical field of plastic molding, in particular to an exhaust device, an exhaust control method and a mold structure with the exhaust device. The exhaust device is applied to the mold structure, wherein a cavity capable of communicating with the external environment is arranged in the mold structure, and a temperature sensing point is arranged at the bottom of the cavity; the exhaust device comprises a controller, a temperature sensing mechanism connected to the input end of the controller and a mechanical sliding block mechanism connected to the output end of the controller, and the temperature sensing mechanism is in signal connection with the temperature sensing point; and a guide hole communicating with the cavity is arranged in the mold structure, and asealing insert needle capable of rising by the action of the mechanical sliding block mechanism to seal the cavity is arranged in the guide hole. According to the exhaust device, the exhaust control method and the mold structure with the exhaust device, the open type cavity is adopted to inject plastic products firstly, so that the air exhaust is quickly carried out in time, and the defective phenomena of gas entrapment, charring, insufficient welding, bursting in performance test and the like of the plastic products are effectively avoided; and when high-temperature fluid plastic flows to thetemperature sensing point, the mechanical sliding block mechanism is triggered to drive the sealing insert needle to rise to seal the cavity, so that it is ensured that the injection molding processof the plastic products is smoothly completed.

Owner:HESHAN LESSO IND DEV

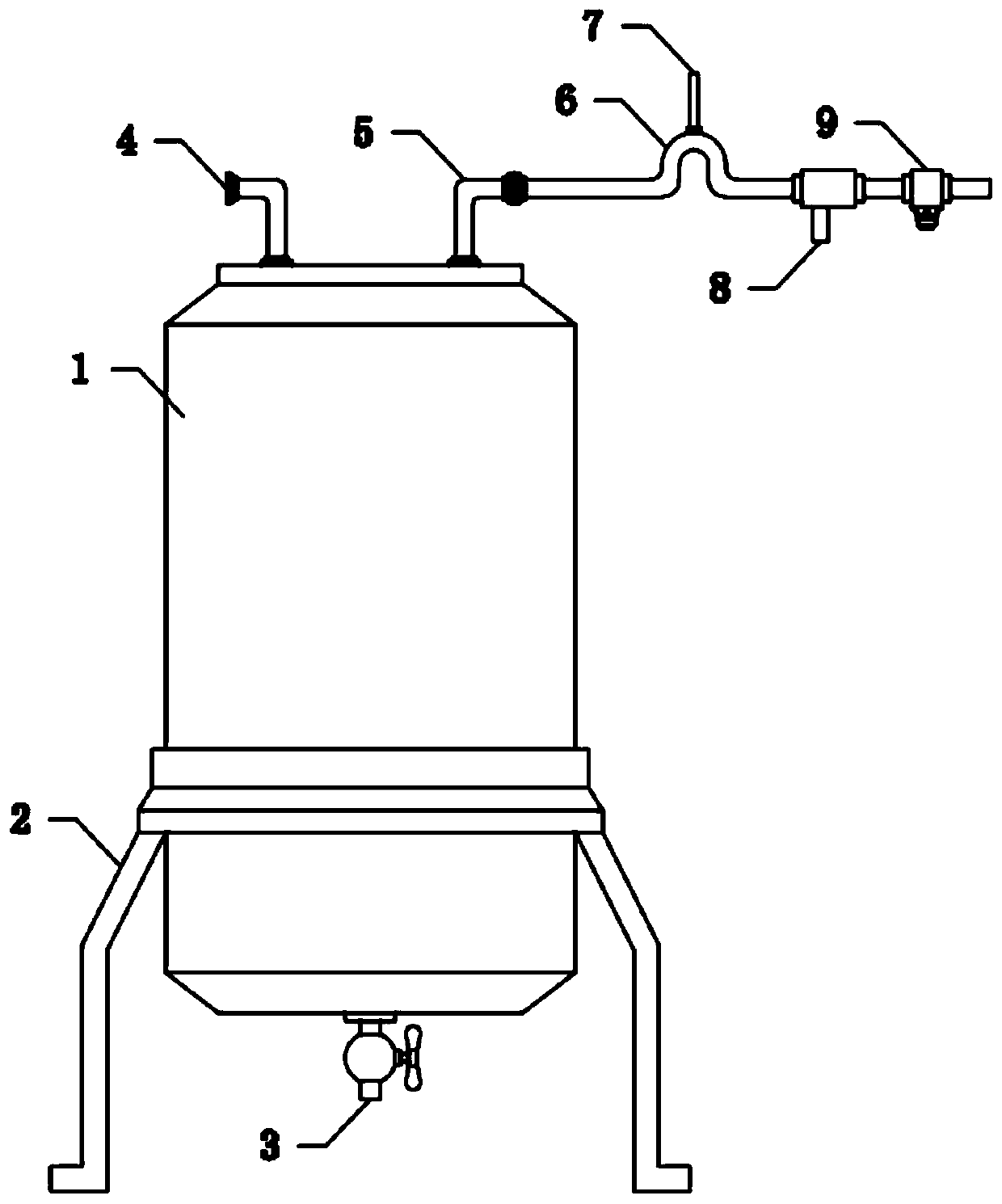

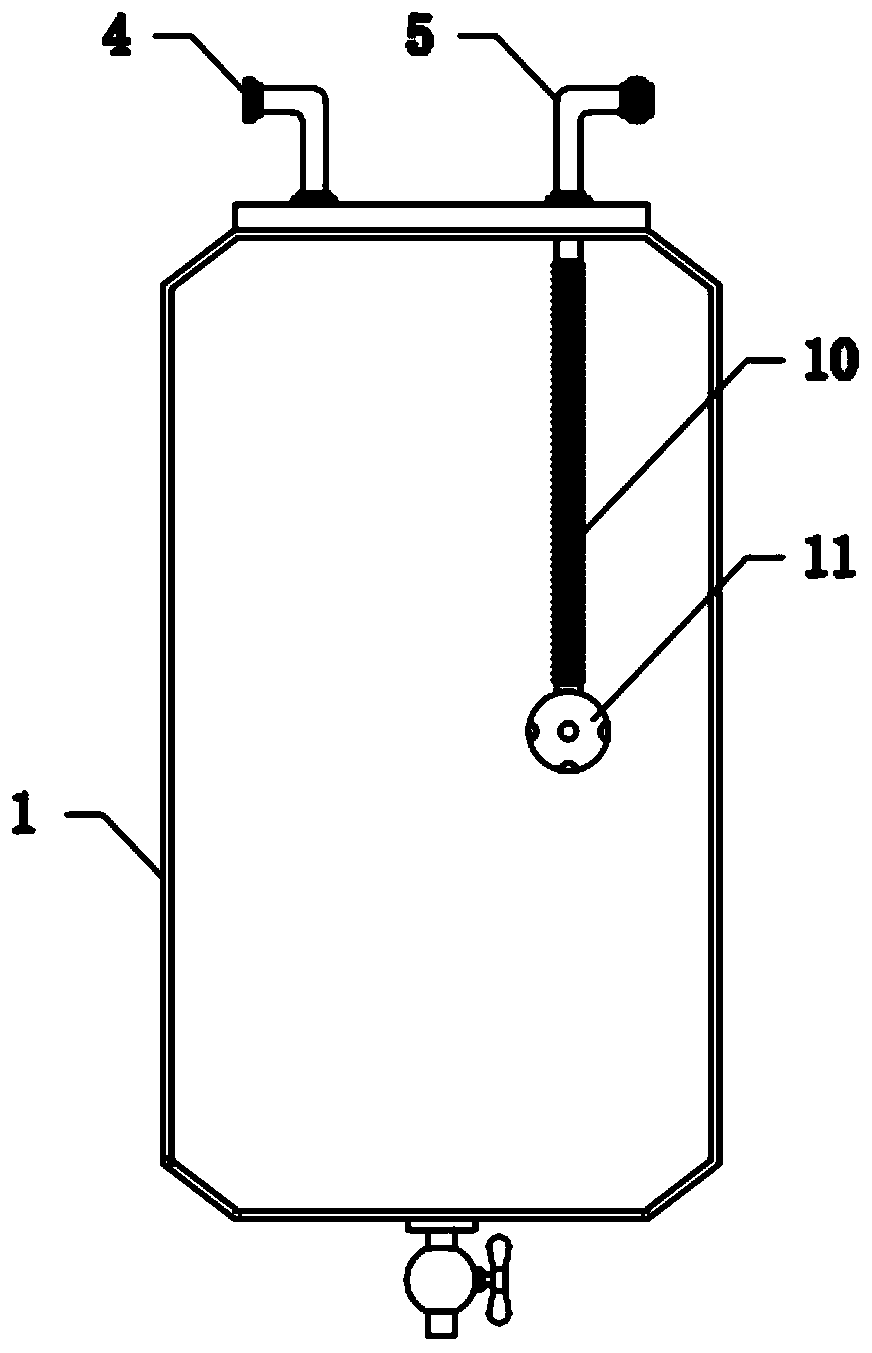

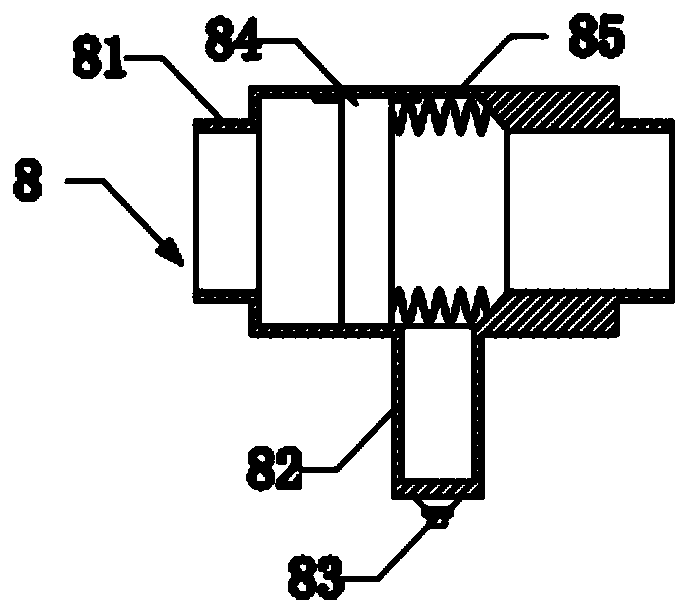

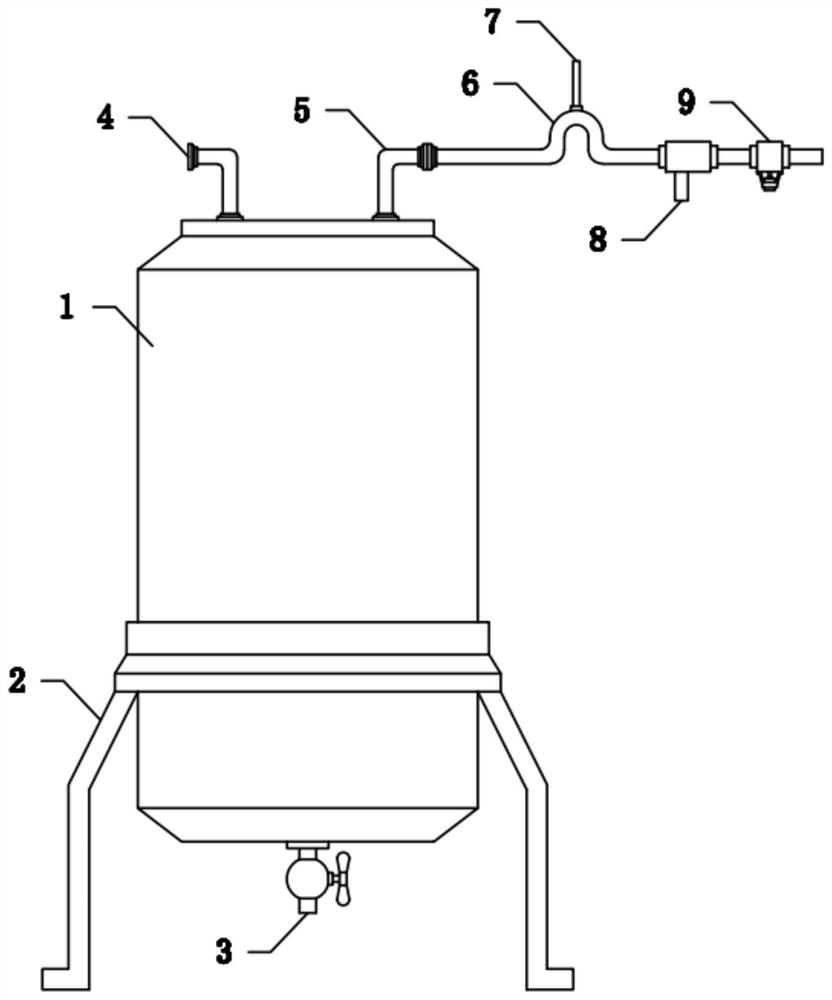

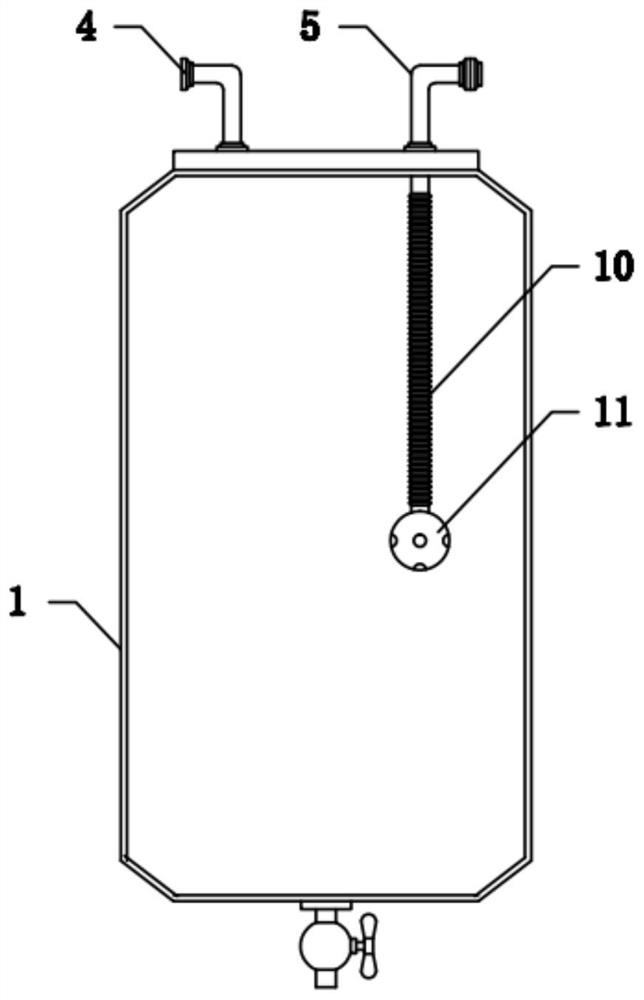

Ship fuel oil supply system with filtering function

ActiveCN110735744AReduce entryExhaust in timeMachines/enginesLiquid fuel feedersMarine engineeringPlastic materials

The invention belongs to the technical field of ship fuel oil supply, and particularly relates to a ship fuel oil supply system with a filtering function. The ship fuel oil supply system comprises anoil storage tank, a slag discharging opening, a filling pipe and an output pipe, wherein the slag discharging opening is connected to the center of the lower surface of the oil storage tank; through the cooperation function of a suction pipe and a suction head, the suction head is made of plastic materials, the suction head can float on fuel oil, accordingly, the fuel oil can be sucked from the upper side, and impurities are reduced; through the arrangement of suction sieve holes in the suction head, the impurities can be filtered from the suction source, and the impurities are reduced from entering the suction pipe; through the arrangement of a filtering device, the impurities in the output process can be filtered, and gas in the output pipe can be exhausted through the cooperation function of an inverted U-shaped pipe and a gas outlet; and opening and closing of the gas outlet can be controlled through a control valve, accordingly, gas exhausting can be conducted in time, and the normal fuel oil output function cannot be influenced.

Owner:上海蓝魂环保科技有限公司

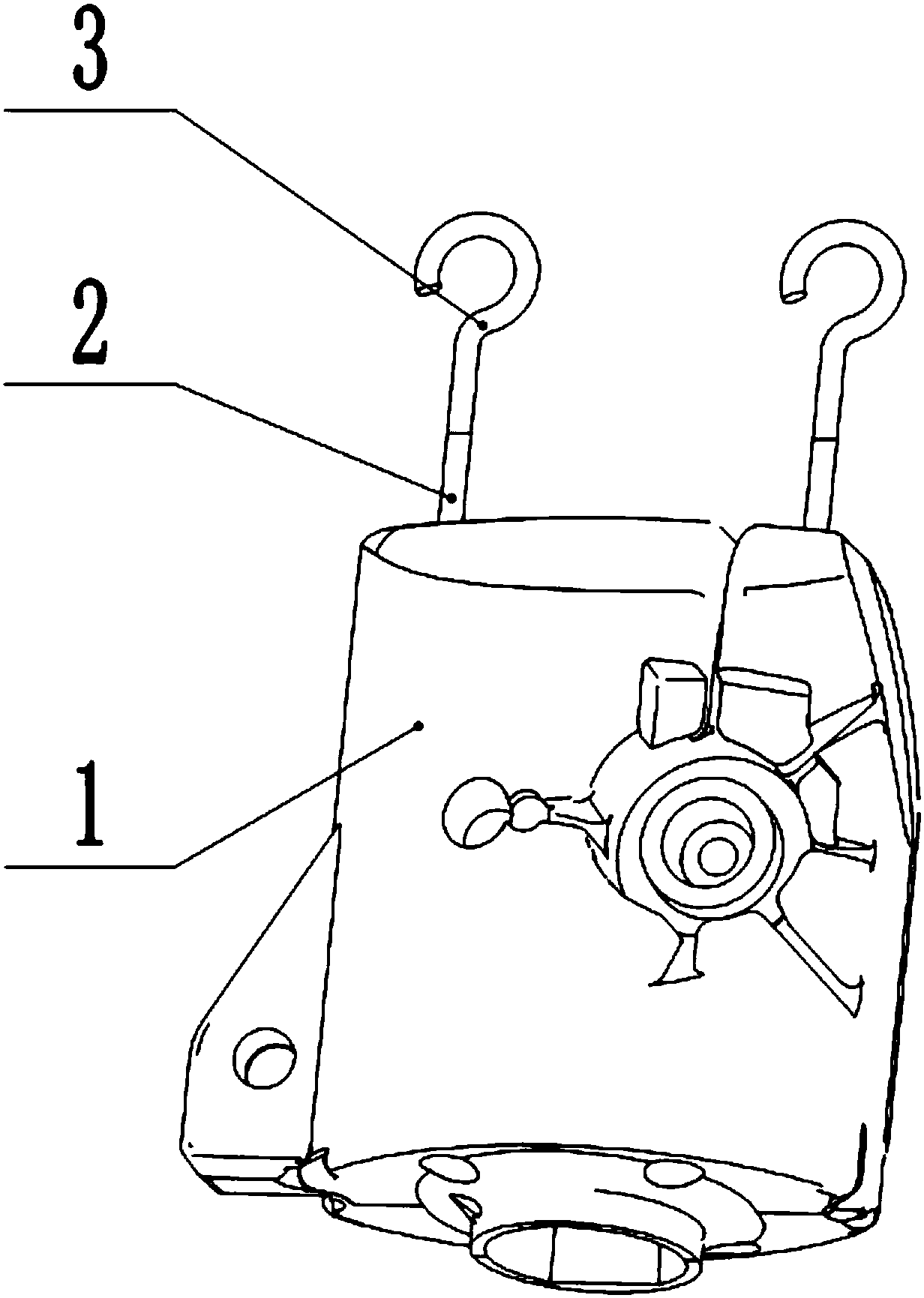

Hoisting tool capable of facilitating mounting and preventing damage of sand core

InactiveCN108057850ANo external damageExhaust in timeFoundry mouldsFoundry coresEngineeringInverted t

The invention discloses a hoisting tool capable of facilitating mounting and preventing damage of a sand core. The hoisting tool comprises the sand core, and two arbors are arranged in the sand core;the top ends of the arbors vertically stretch out of the top of the sand core; the two arbors are symmetrical about the vertical axis of the sand core; threaded holes are formed in the top ends of thearbors; hooks are mounted in the threaded holes; the arbors are of an inverted-T-shaped structure; horizontal rod parts of the inverted-T-shaped structures of the arbors are positioned in the sand core; and vertical rod parts of the inverted-T-shaped structure of the arbors upwards stretch out of the top of the sand core. According to the hoisting tool, hoisting is achieved by mounting the arborsof the simple structure in the sand core, the sand core does not need to be externally clamped during the mounting process, and the external part of the sand core is not damaged; and besides, the arbors and the hooks can be disassembled, so that the size can be decreased, and the integral hoisting tool is prevented from being affected when the hooks are damaged.

Owner:TIANJIN HANGYU METAL PROCESSING

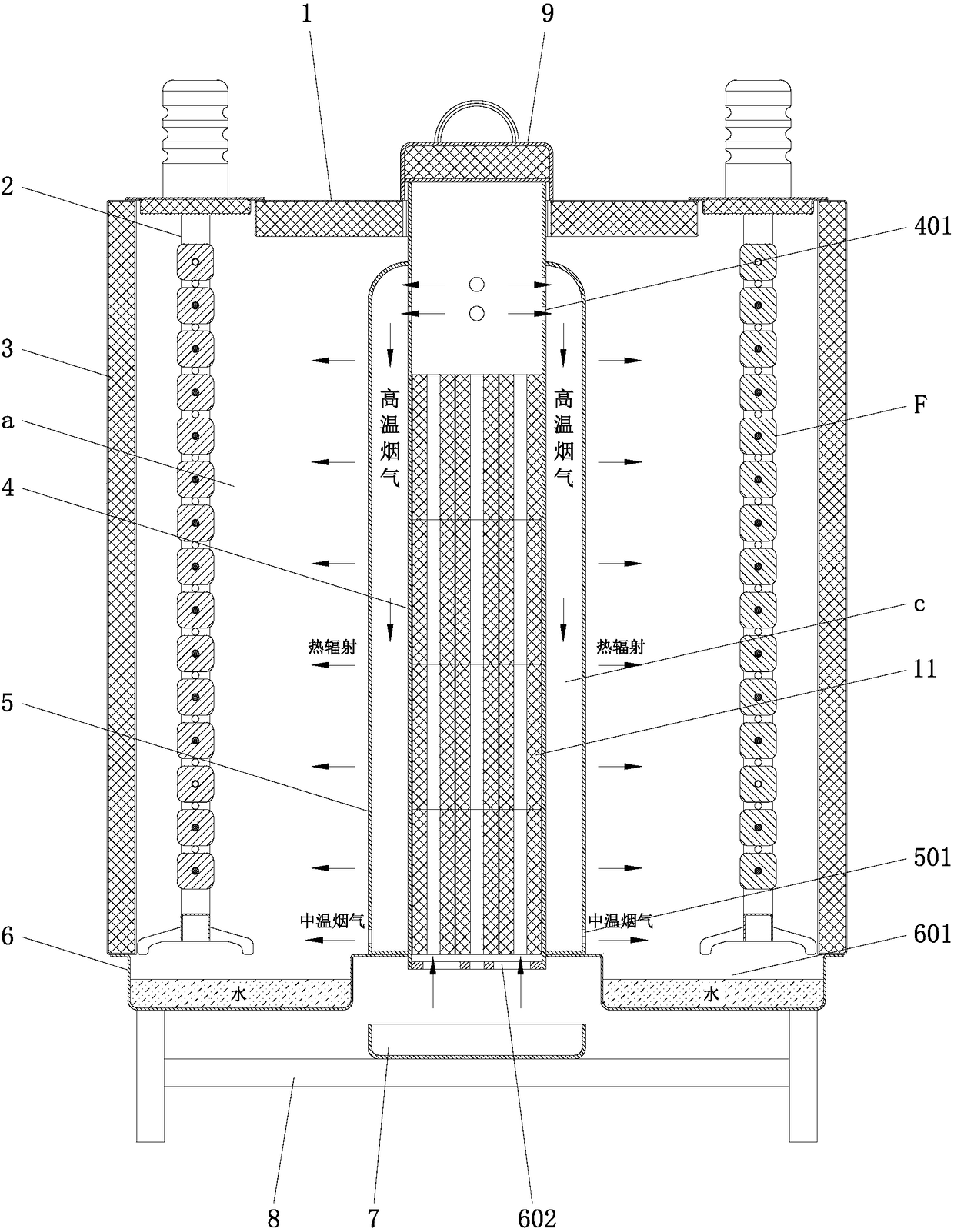

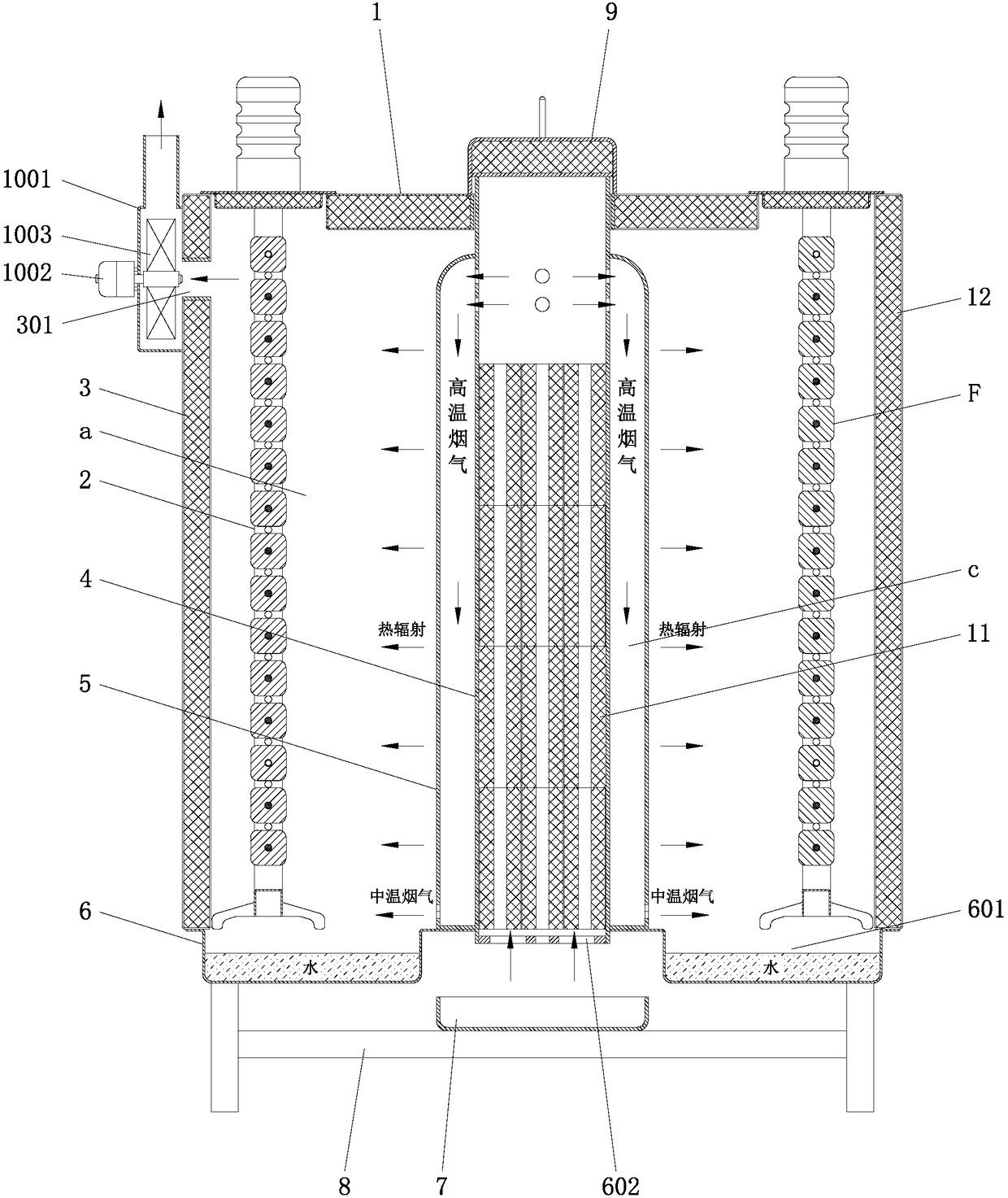

Forced-exhaust-type radiant carbon stove

InactiveCN108402111AReduce pollutionReduce contentOven air-treatment devicesCombustion chamberEngineering

The invention relates to a forced-exhaust-type radiant carbon stove. The forced-exhaust-type radiant carbon stove comprises a stove body, wherein a heating chamber is arranged in the stove body; a sleeve-type radiation mechanism is arranged in the heating chamber, and is composed of a combustion tube and a radiation tube; the radiation tube sleeves the outer side of the combustion tube, and a high-temperature smoke passage is formed between the combustion tube and the radiation tube; the inner chamber of the combustion tube is a combustion chamber, and a bottom of the combustion chamber communicates with the outside; high-temperature smoke outlets are formed in the combustion tube, and the combustion chamber communicates with the high-temperature smoke passage via the high-temperature smoke outlets; medium-temperature smoke outlets are formed in the radiation tube, and the high-temperature smoke passage communicates with the heating chamber via the medium-temperature smoke outlets; anda smoke exhaustion mechanism is arranged on the stove body. During operation, smoke produced by charcoal combustion in the combustion chamber enters the high-temperature smoke passage via the high-temperature smoke outlets, and then, enters the heating chamber via the medium-temperature smoke outlets; and then, forced exhaustion of the smoke in the heating chamber is realized by the smoke exhaustion mechanism. The forced-exhaust-type radiant carbon stove is capable of realizing completely enclosed radiant barbecue, and is convenient and practical in operation; moreover, the forced-exhaust-type radiant carbon stove is enhanced in heating performance, low in pollution, high in heat utilization rate, good in heating effect, and high in heating efficiency.

Owner:胡丽君

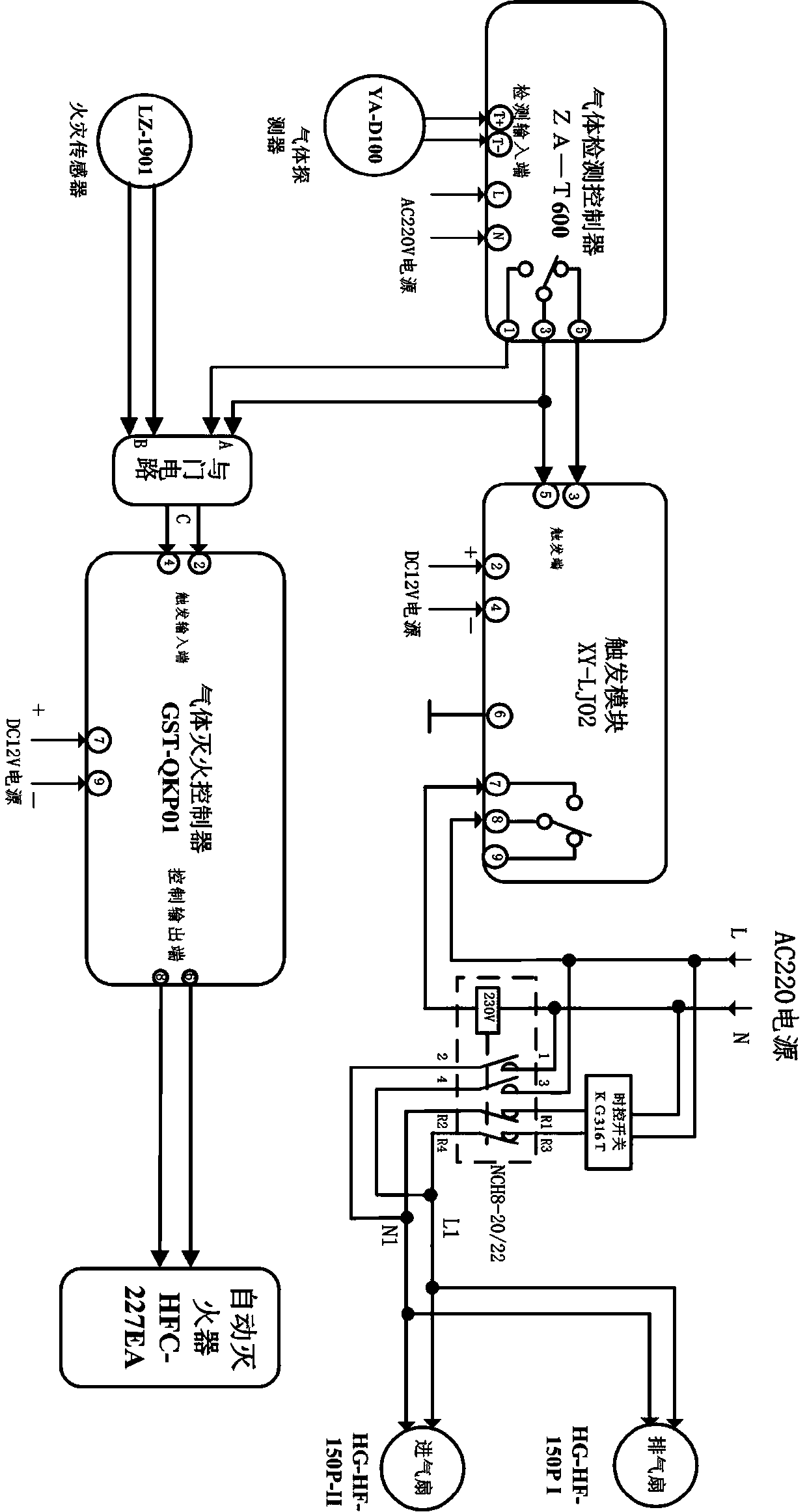

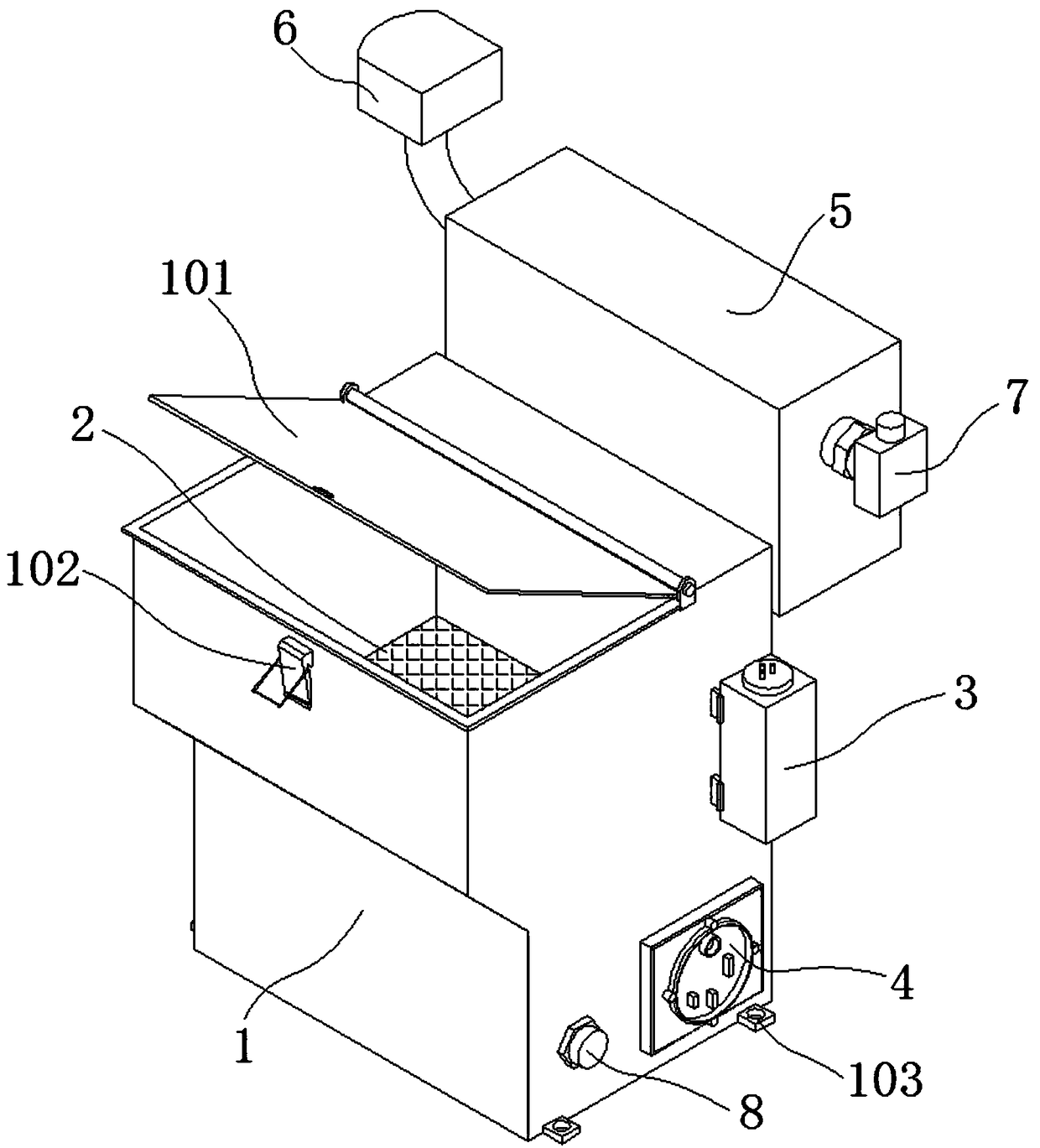

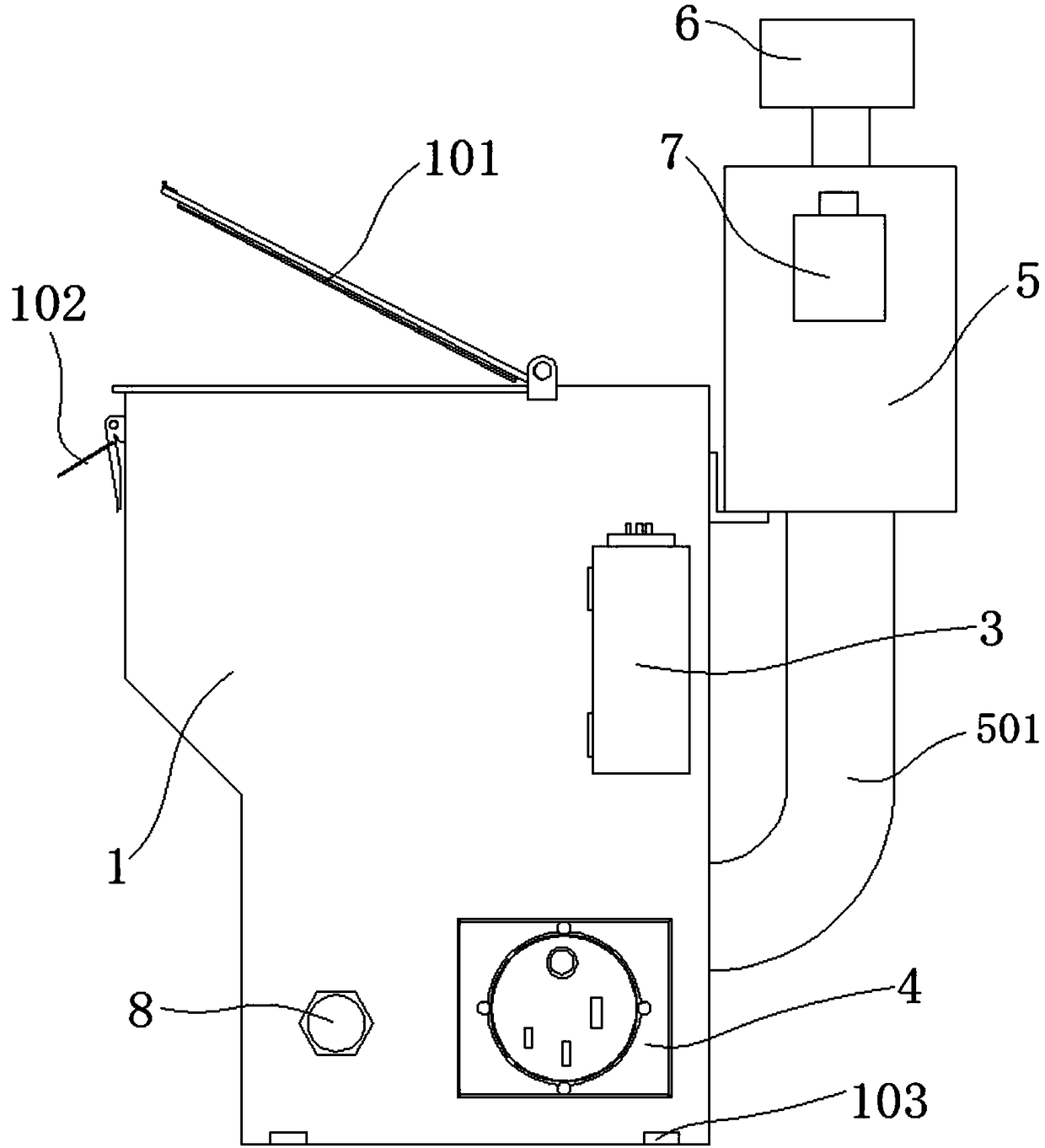

Unattended substation accumulator room fire-proof and explosion-proof device

PendingCN110090375AExhaust in timeExhaust in time and automaticallyFire rescueGas detectorGaseous detectors

The invention discloses an unattended substation accumulator room fire-proof and explosion-proof device which comprises a gas detector, a gas detection controller, a trigger module, an alternating current contactor, a time switch, a fire disaster sensor, an and gate circuit, a fire extinguishing controller and an alternating current (AC) power supply. According to the device, a substation accumulator room can realize periodical exhaust with fixed time and fixed location and can realize automatic exhaust in time when encountering an explosive gas mixture, and automatic fire extinguishment can be timely realized when a fire breaks out in the accumulator room.

Owner:STATE GRID HUBEI ELECTRIC POWER CO XIAOGAN POWER SUPPLY CO

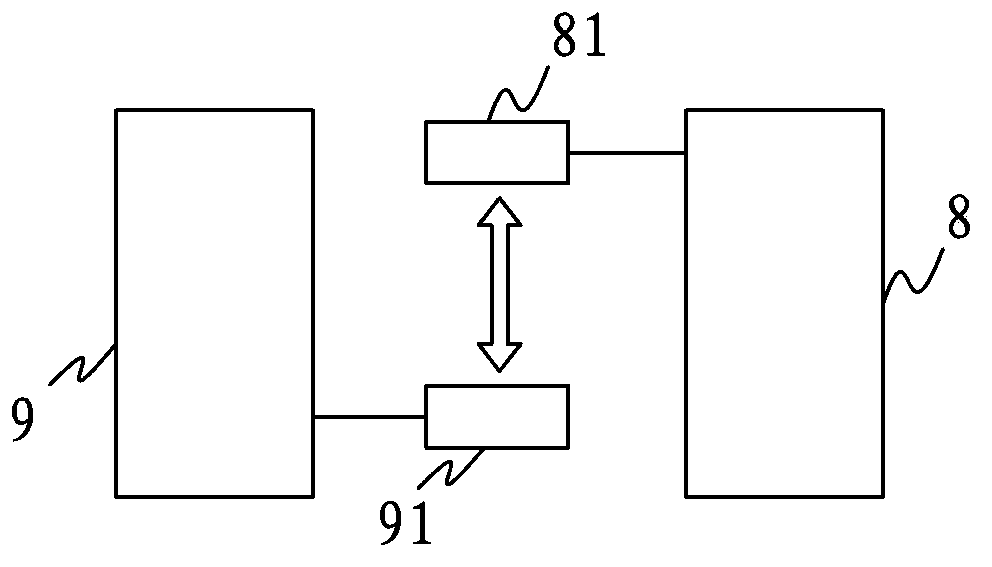

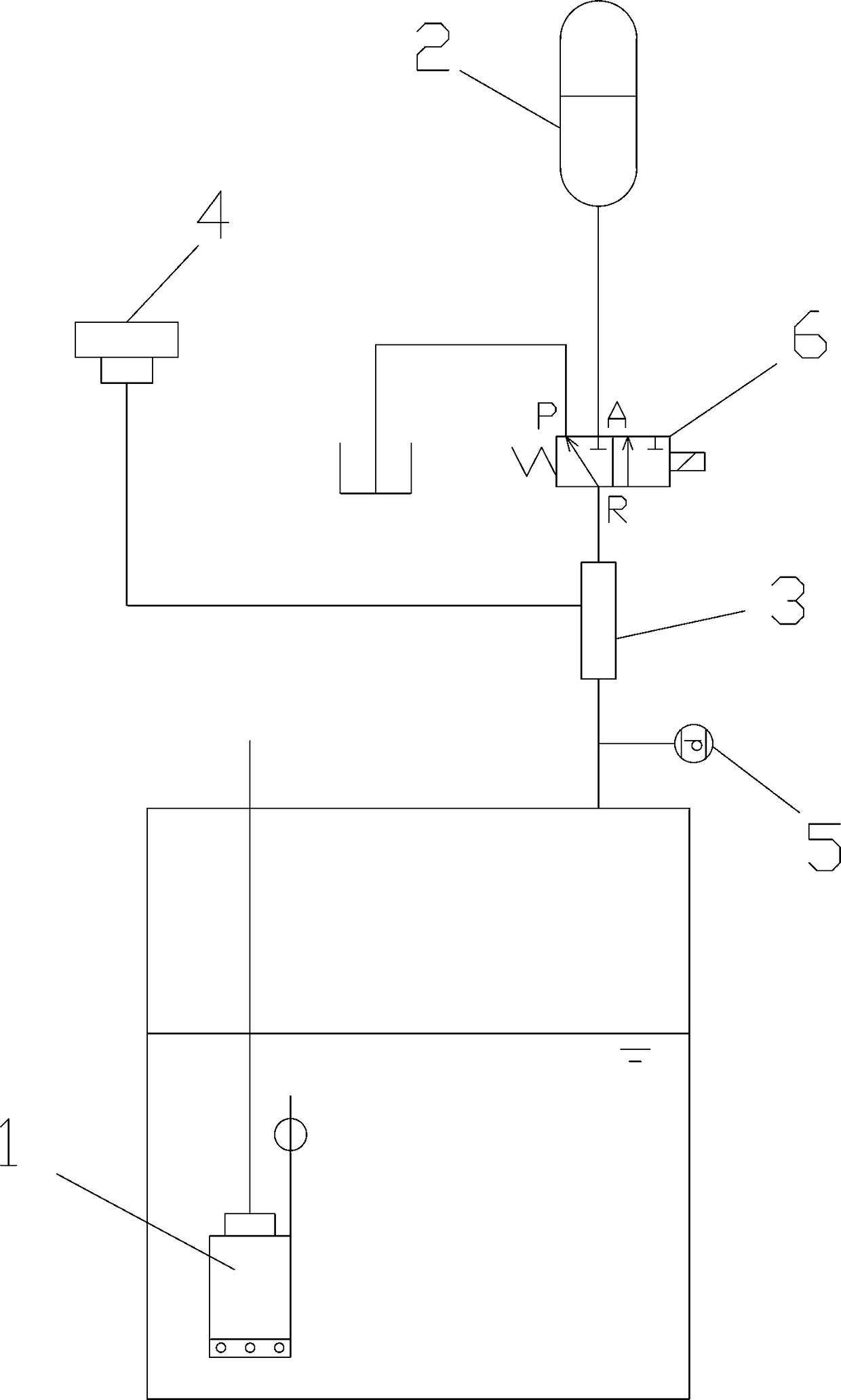

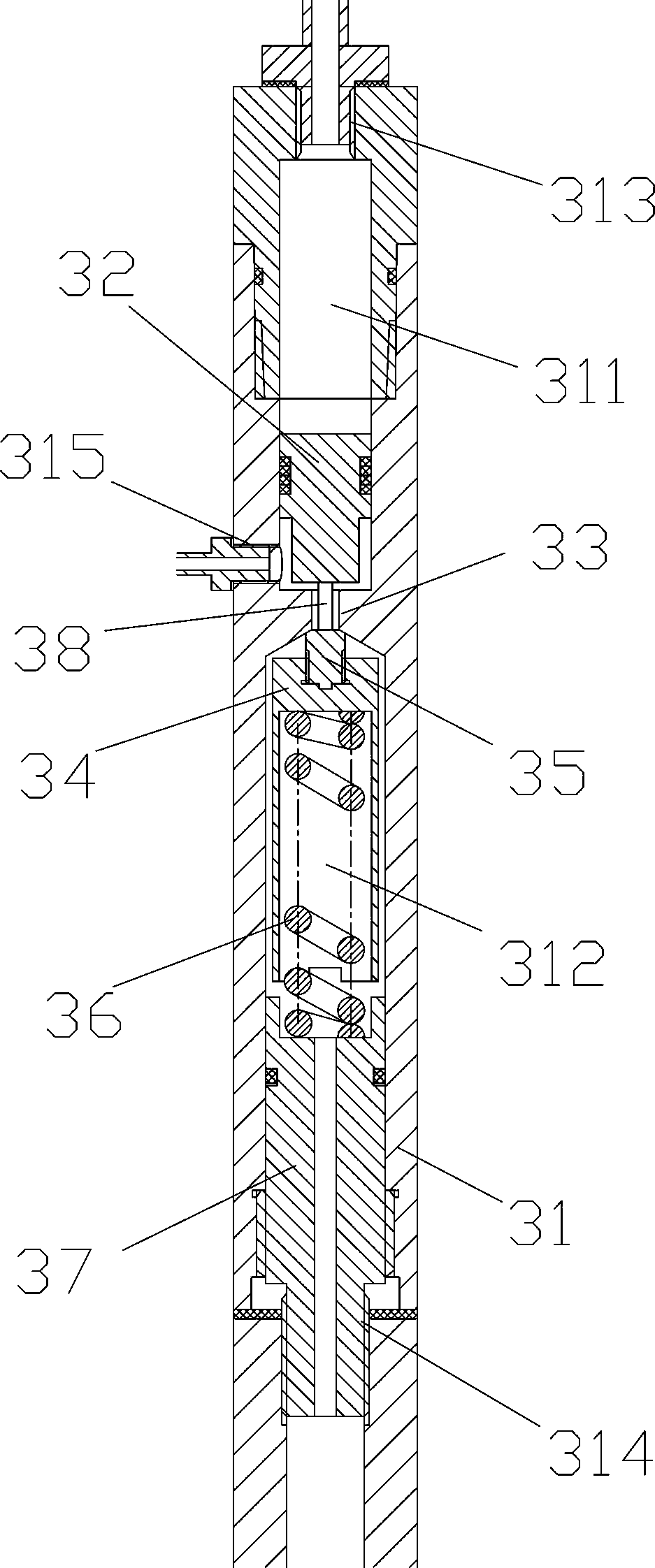

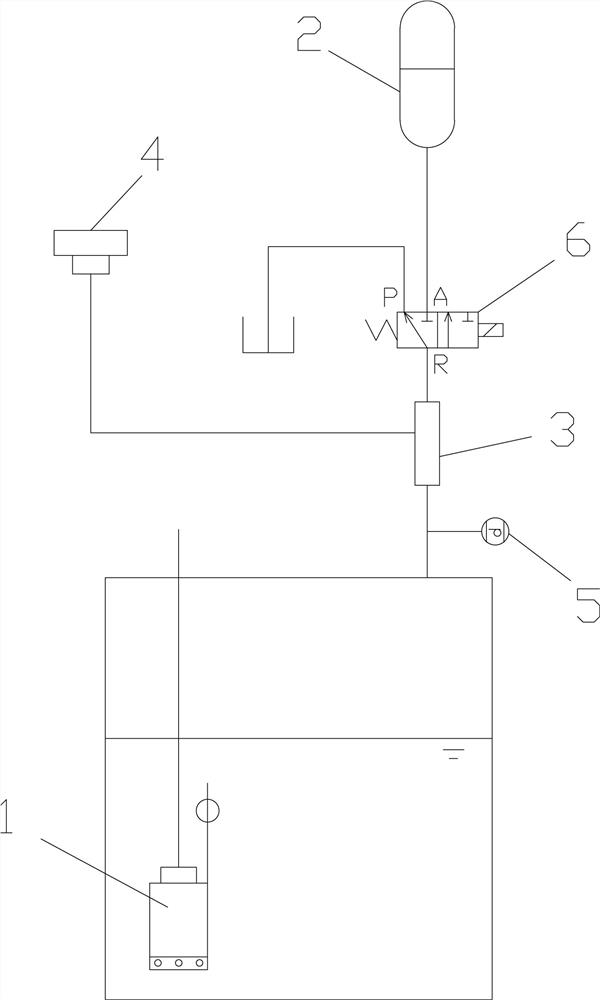

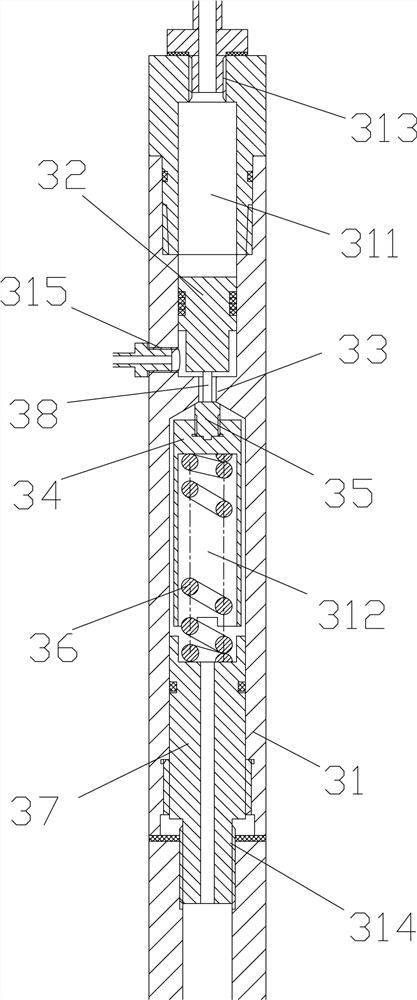

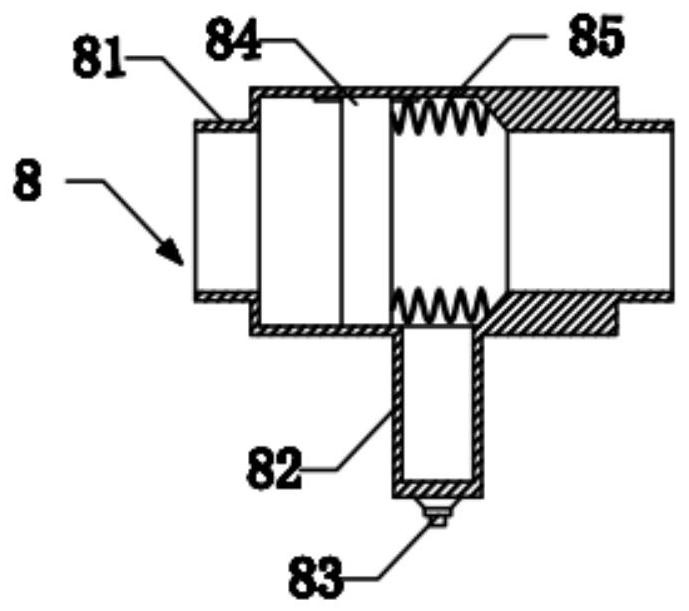

Deep well exhaust device and method in oil exploitation process

ActiveCN108915639ASimple structureLow installation process requirementsSurveyFluid removalExhaust valvePulp and paper industry

Disclosed is a deep well exhaust device in the oil exploitation process. The device comprises an exhaust valve, an energy accumulator, a two-position three-way electromagnetic valve and a controller.The energy accumulator is communicated with a port A of the two-position three-way electromagnetic valve through a pipeline, a port P of the two-position three-way electromagnetic valve is communicated with an oil cabinet through a pipeline, a port R of the two-position three-way electromagnetic valve is communicated with a liquid inlet of the exhaust valve through a pipeline, an exhaust port of the exhaust valve is communicated with a fire resisting cap through an exhaust pipe, an air inlet of the exhaust valve is communicated with a deep well through an air inlet pipe, the controller controls the two-position three-way electromagnetic valve, the device further comprises a pressure sensor connected to the air inlet pipe, and the pressure sensor transmits a monitored signal to the controller. The device is used for solving the problem that an adverse influence is caused by associated gas on working reliability of an exploitation device in the oil production process, and the invention provides a deep well exhaust device and method for the oil exploitation process.

Owner:CHINA THREE GORGES UNIV

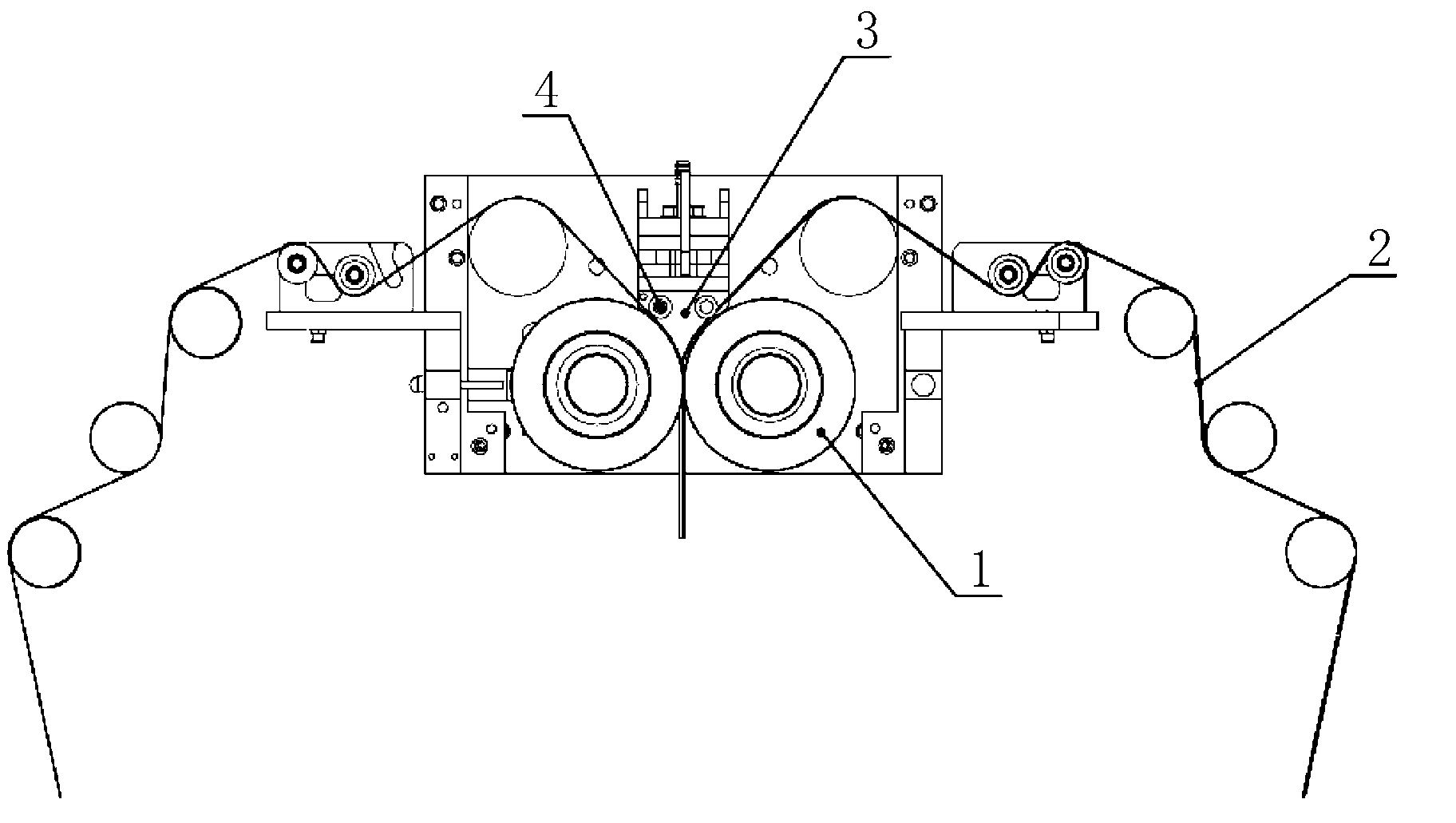

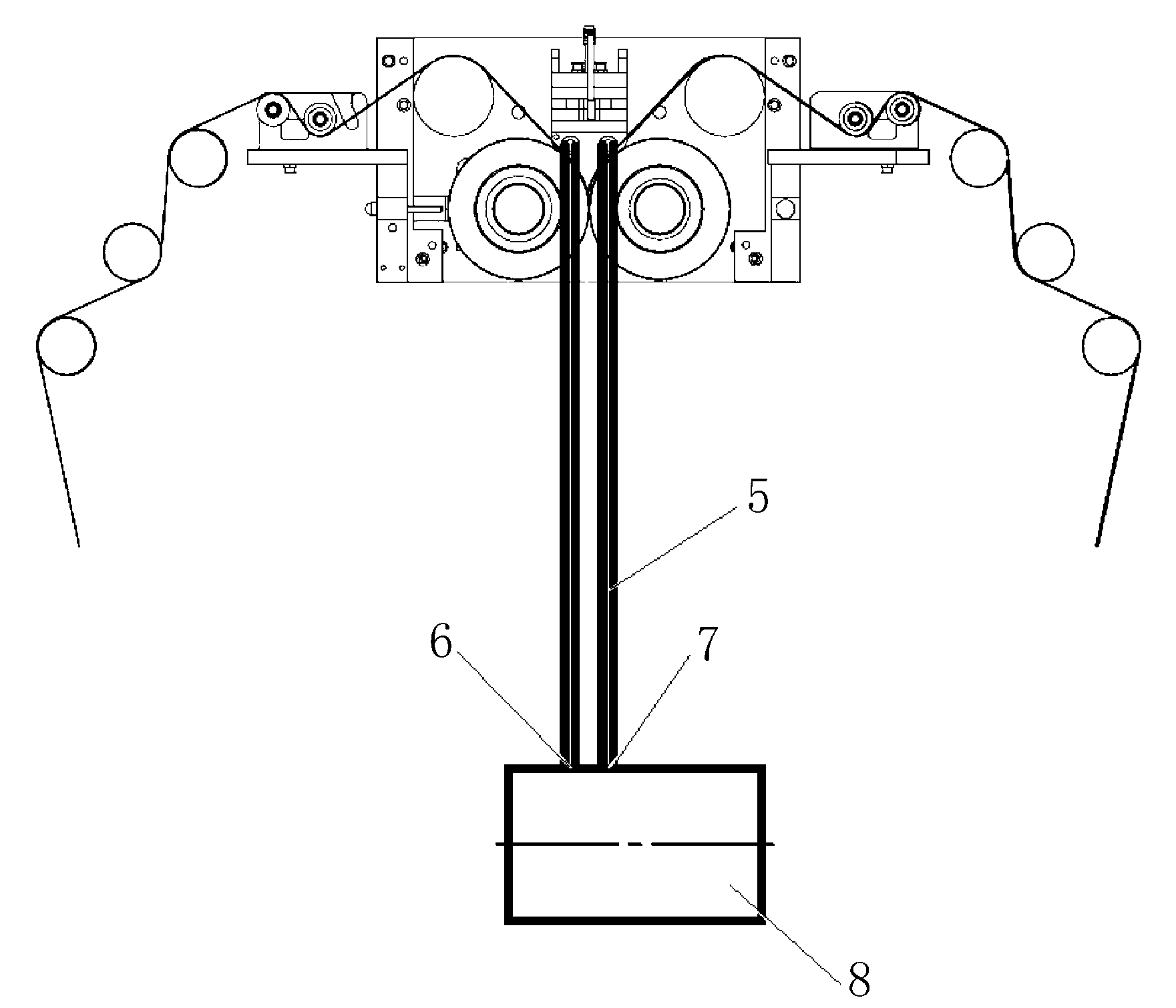

Protective device and roller coating machine with same

PendingCN114405778AKeep healthyImprove the protective effectLiquid surface applicatorsCoatingsStructural engineeringIndustrial engineering

The invention relates to the technical field of plate processing, in particular to a protection device and a roller coating machine with the same. A protection device comprises a cover body, a cover body, a cover body, a cover body and a cover body, the cover body is provided with an opening, the opening is suitable for being assembled with a machine body to form a sealing structure, and at least one suction opening is formed in the top wall, opposite to the opening, of the cover body; the suction structure is arranged on the inner side of the top wall of the cover body, is opposite to the machine body and is provided with a plurality of open holes, and the open holes are communicated with the suction opening through an inner cavity of the suction structure. The invention provides the protection device with a good protection effect and the roller coating machine with the protection device.

Owner:TIANJIN DAYIN BUILDING MATERIAL CO LTD

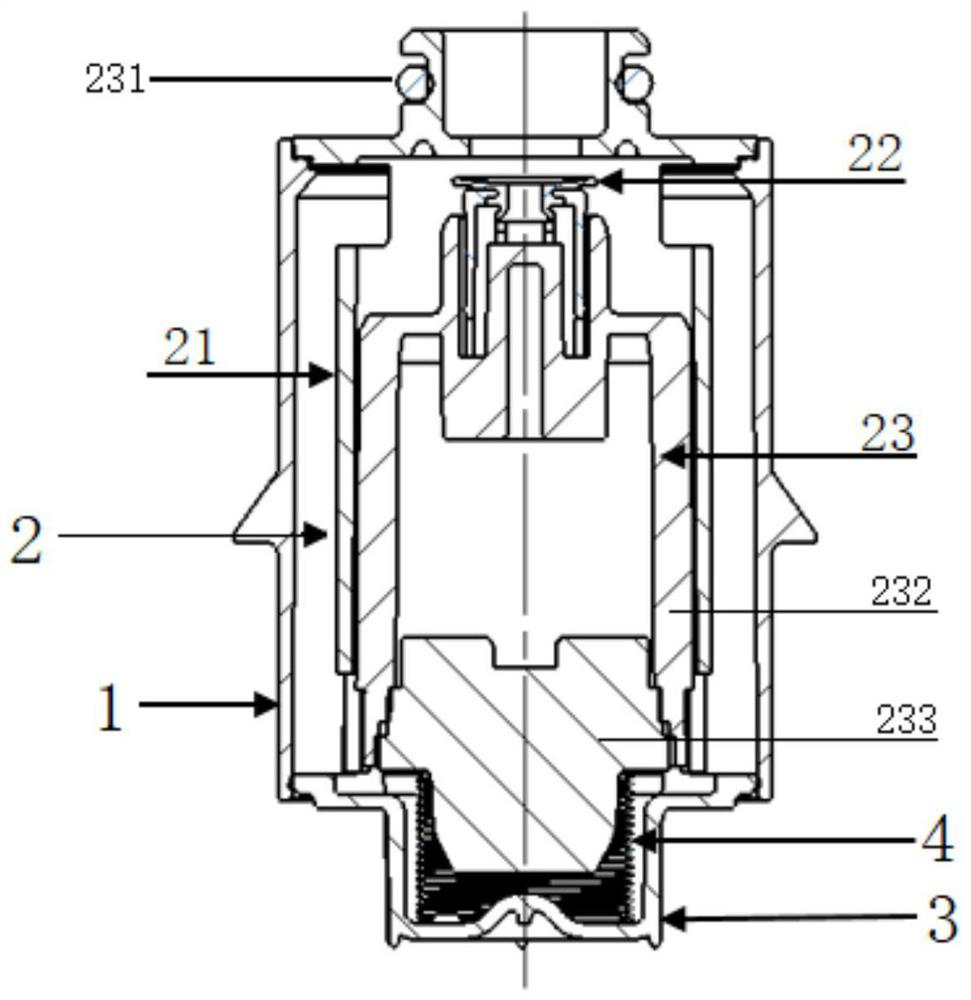

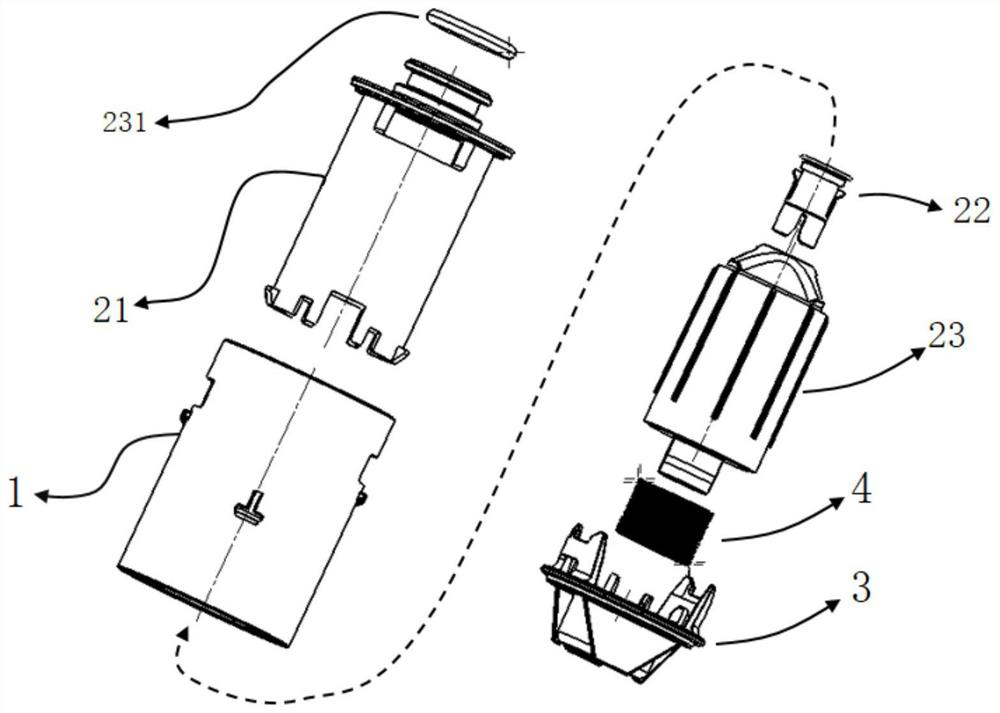

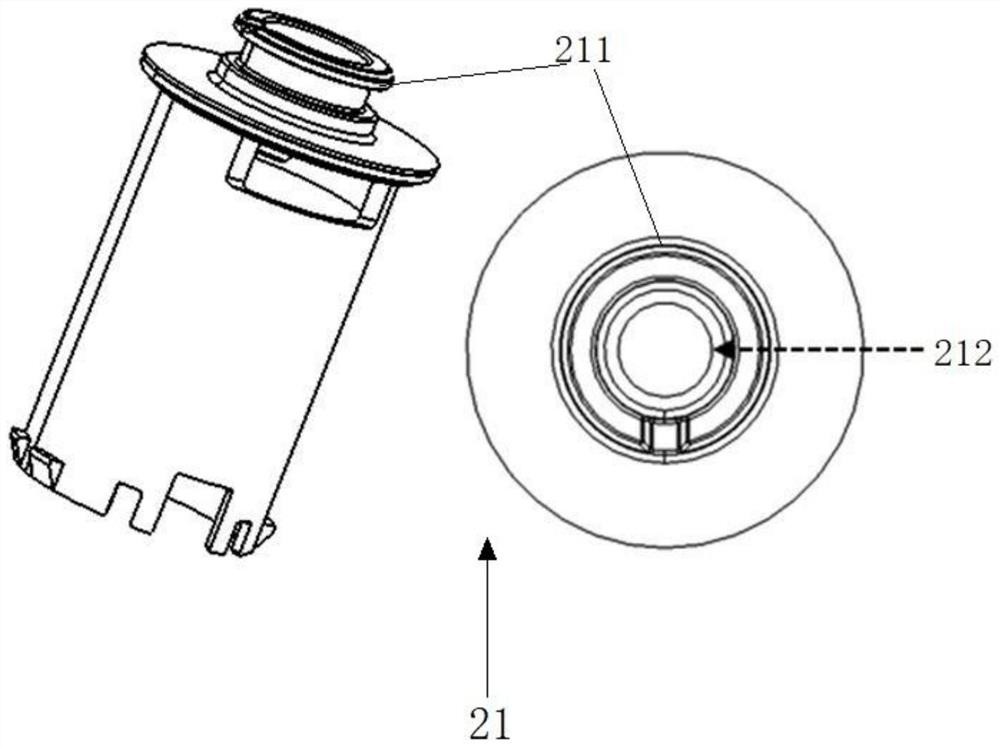

Double-wall high-performance refueling limiting valve and working method thereof

PendingCN112628409AQuick turn on buckRelieve stressOperating means/releasing devices for valvesVenting valvesMarine engineeringFuel tank

The invention relates to a double-wall high-performance refueling limiting valve and a working method thereof. The double-wall high-performance refueling limiting valve comprises a shell, a floater assembly and a bottom cover, wherein the shell is arranged outside the floater assembly in a sleeving mode; the bottom cover is installed at the bottom of the shell and makes contact with the bottom of the floater assembly through a spring; the floater assembly comprises a floater shell, a sealing door and a floater; the sealing door is assembled at the upper part of the floater and is arranged in the floater shell together with the floater; the spring is arranged between the bottom of the floater and the bottom cover; the floater can move up and down in the floater shell; and a secondary opening vent hole is formed in the center of the upper end surface of the floater shell. According to the double-wall high-performance refueling limiting valve and the working method thereof provided by the invention, through a two-stage opening mode of the valve, rapid opening and pressure reduction under the high-pressure condition are achieved, and the safety of an oil tank and a vehicle system is improved; a double-wall structure is adopted, so that the dynamic leakage of liquid is zero under a dynamic condition; and different closing heights are achieved through modular design, so that diversified requirements are met.

Owner:STANT AUTOMOTIVE SYST SUZHOU

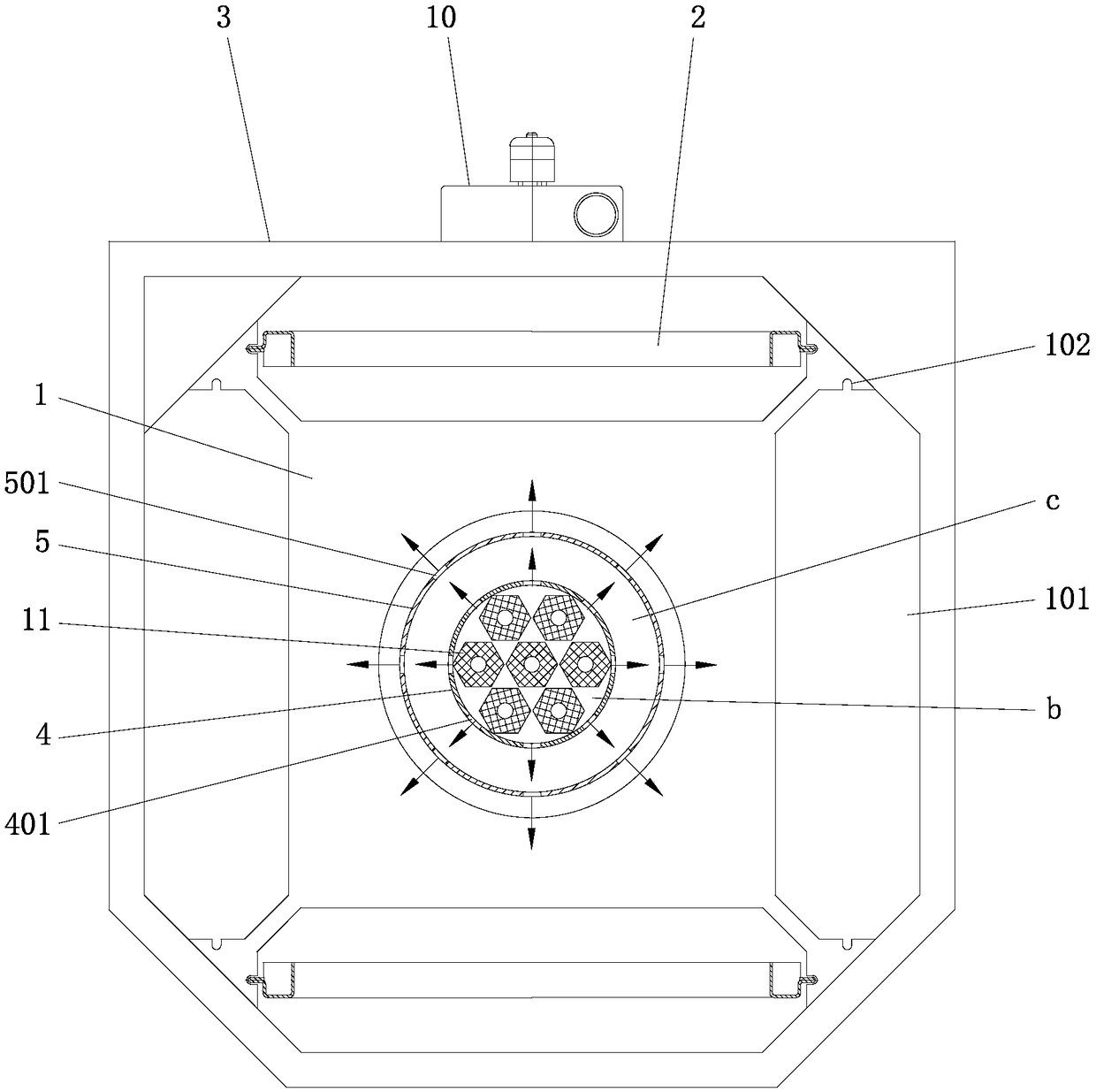

Smoke alarm devices for fire fighting

ActiveCN111968337BExhaust in timeSensitive alarm functionFire alarm smoke/gas actuationFire protectionFirefighting

The invention relates to the technical field of firefighting, and discloses a smoke alarm device for firefighting, which includes a housing and a wall. The inside of the housing is fixedly connected with a photosensitive component, the inside of the housing is fixedly connected with lamp beads, and the inside of the housing is fixedly connected with The filter membrane is fixedly connected with an electromagnet inside the shell, and is connected with a touch plate inside the shell. The outside of the touch plate is fixedly connected with a fixed assembly, and the outside of the fixed assembly is connected with a clamp rod. Under the interaction between all the structures of the device, the device can exhaust the indoor environment when it is used under normal conditions, which not only ensures the smooth flow of air in the indoor environment, but also makes the smoke emission point far away. The smoke can be gathered to the outside of the device, and the smoke alarm function can be played in time, so that the smoke alarm function of the device is more sensitive.

Owner:广东爱得威建设(集团)股份有限公司

Resin sand ductile iron riserless casting mold

ActiveCN109940128BGuarantee unimpededImprove compactnessFoundry mouldsFoundry coresPolymer scienceDuctile iron

The invention provides a resin sand ductile iron feederless casting mould which comprises a section mould integrally molded to form a casting cavity, and multiple air outlet needles arranged on the section mould. The multiple air outlet needles are arranged along the direction perpendicular to a horizontal plane on which the section mould is located. Compared with the prior art, according to the resin sand ductile iron feederless casting mould provided by the invention, the production efficiency is improved, the product quality is improved, and the acceptability is high.

Owner:湖南诚今电梯部件制造有限公司

A deep well exhaust device and method in the process of oil extraction

ActiveCN108915639BSimple structureLow installation process requirementsSurveyFluid removalExhaust valveThermodynamics

Disclosed is a deep well exhaust device in the oil exploitation process. The device comprises an exhaust valve, an energy accumulator, a two-position three-way electromagnetic valve and a controller.The energy accumulator is communicated with a port A of the two-position three-way electromagnetic valve through a pipeline, a port P of the two-position three-way electromagnetic valve is communicated with an oil cabinet through a pipeline, a port R of the two-position three-way electromagnetic valve is communicated with a liquid inlet of the exhaust valve through a pipeline, an exhaust port of the exhaust valve is communicated with a fire resisting cap through an exhaust pipe, an air inlet of the exhaust valve is communicated with a deep well through an air inlet pipe, the controller controls the two-position three-way electromagnetic valve, the device further comprises a pressure sensor connected to the air inlet pipe, and the pressure sensor transmits a monitored signal to the controller. The device is used for solving the problem that an adverse influence is caused by associated gas on working reliability of an exploitation device in the oil production process, and the invention provides a deep well exhaust device and method for the oil exploitation process.

Owner:CHINA THREE GORGES UNIV

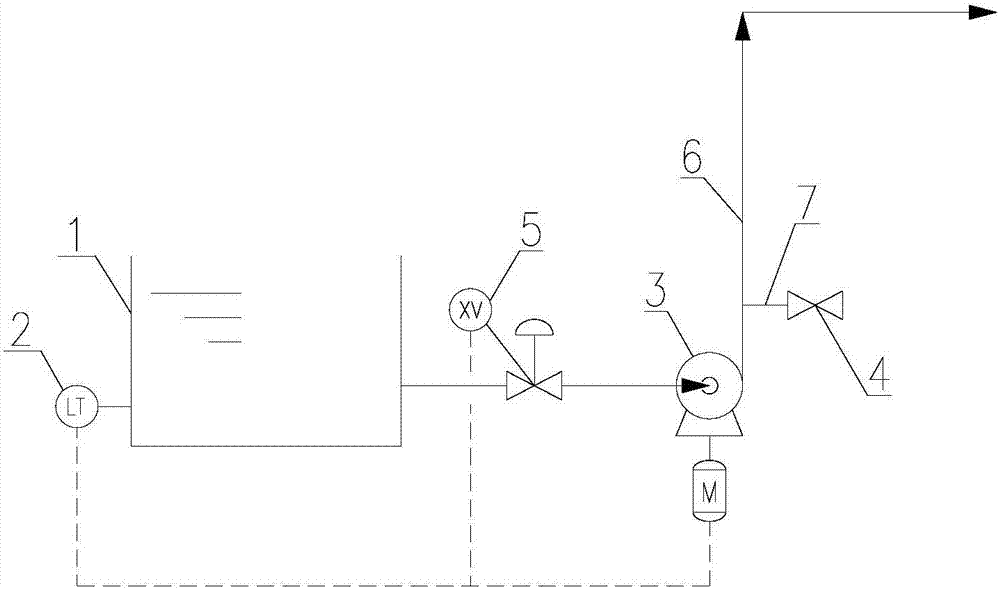

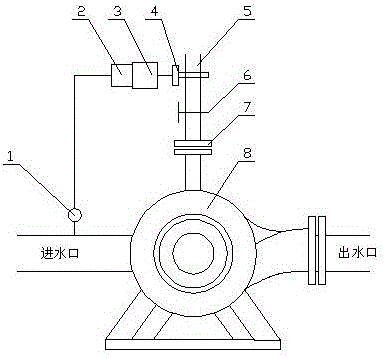

High-pressure clean water pump exhaust system

InactiveCN107542652ALow maintenanceExhaust in timePositive displacement pump componentsPump controlElectricityExhaust valve

The invention relates to fluid conveying machinery, in particular to a high-pressure clean water pump exhaust system. The high-pressure clean water pump exhaust system includes a high-pressure pump, which is connected to the pool through a pneumatic switch valve; the high-pressure pump is driven by a motor, and a branch pipe is connected to the outlet pipeline, and the branch pipe is connected to a DN15 exhaust valve; There is a level transmitter. Among them, the pneumatic switch valve, the motor and the liquid level transmitter are respectively electrically connected with the PLC. The invention solves the problem of emptying of the high-pressure pump in the prior art, has the characteristics of energy saving and environmental protection, low maintenance cost, and timely exhaust, and ensures the normal operation of the equipment by timely discharging the gas in the pipeline.

Owner:SHANDONG HUALIAN MINING

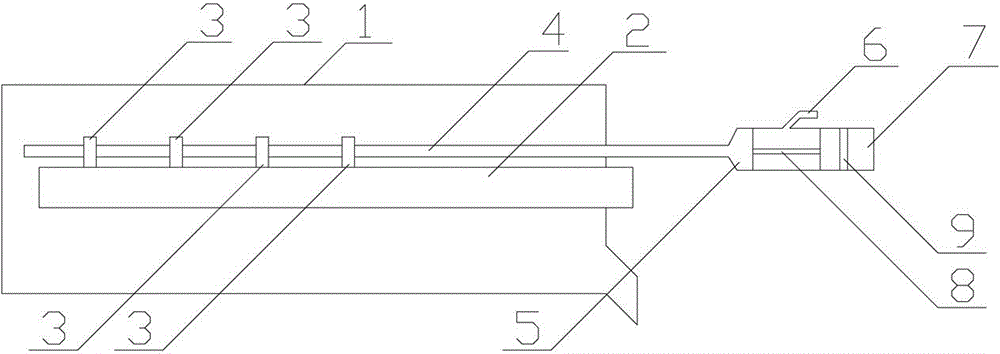

Long-distance sand transportation silt construction method and equipment

InactiveCN105672392AAvoid cloggingImprove flatnessSoil-shifting machines/dredgersPositive-displacement liquid enginesCavitationWater channel

The invention belongs to the technical field of water channel construction, and in particular, discloses a long-distance sand transportation silt construction method and equipment. The method comprises the process of: paying-off positioning-positioning of a sand pumping ship-installation of a sand transportation pipe-installation of a feeder pump-installation of a sand measurement valve-installation of a pressure gauge-installation of a cavitation prevention device on the feeder pump-installation of a leveling valve-starting of the sand pumping ship to pump sand-observation of sand content data and analysis-selective opening of the cavitation prevention device, adjustment of rotating speeds of the sand pumping pump and the feeder pump and change of a silt construction direction. The method is convenient to operate, high in efficiency and low in cost.

Owner:HENAN ZHONGYUAN HYDRAULIC & HYDROELECTRIC ENG GRP CO LTD D

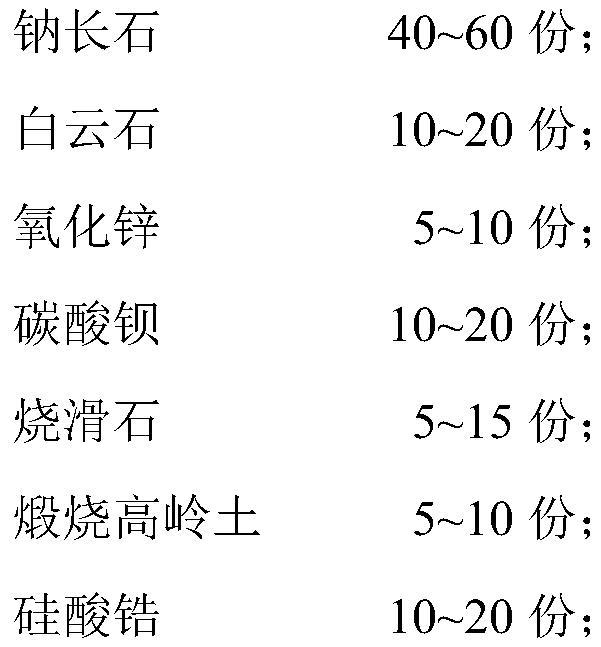

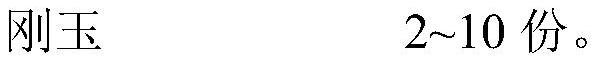

Imitation marble soft light brick surface glaze, imitation marble soft light brick and preparation method thereof

The invention discloses a marble imitation soft light tile surface glaze, which comprises the following components in parts by weight of raw materials: 40-60 parts of albite, 10-20 parts of dolomite, 5-10 parts of zinc oxide, and 10 parts of barium carbonate ~20 parts, calcined talc 5~15 parts, calcined kaolin 5~10 parts, zirconium silicate 10~20 parts, corundum 2~10 parts. The invention optimizes and adjusts the surface glaze components and proportions, and the glaze has a uniform color development effect and stable glaze gloss, thereby endowing the surface of imitation marble tiles with a more delicate soft light effect, making the imitation marble texture decoration and soft light After the effect is combined, it still maintains an excellent simulation degree, and at the same time, the glazed surface has excellent antifouling and wear resistance after firing. The invention also discloses a marble imitation soft light brick applied with the surface glaze and a preparation method thereof.

Owner:广东金牌陶瓷有限公司

Process line for bread production

PendingCN113712057ASolve the problem of easily scalding workers and affecting the work efficiency of workersExhaust in timeOven air-treatment devicesVibration suppression adjustmentsElectric machineryEngineering

The invention discloses a process line for bread production. The process line comprises a baking device body, a motor shell, a bidirectional motor, fixing bases, connecting rods, connecting plates, exhaust fans and a slope component, wherein the motor shell is fixedly connected to the front face of the baking device body, the bidirectional motor is arranged in the motor shell, the fixing bases are fixedly connected to the front face of the baking device body and located on the two sides of the motor shell, the connecting rods are fixedly connected to the two sides of the bidirectional motor, the surfaces of the connecting rods are sleeved with the connecting plates, and the exhaust fans are arranged in the connecting plates. Through cooperative use of the baking device body, the motor shell, the bidirectional motor, the fixing bases, the connecting rods, the connecting plates, the exhaust fans and the slope component, the problems that a large amount of hot air will be emitted from an existing baking device after baking, workers will face a large amount of hot steam when unloading and loading a baking cart, the workers are prone to being scalded, and the working efficiency of the workers is affected are solved.

Owner:安徽老约翰食品有限公司

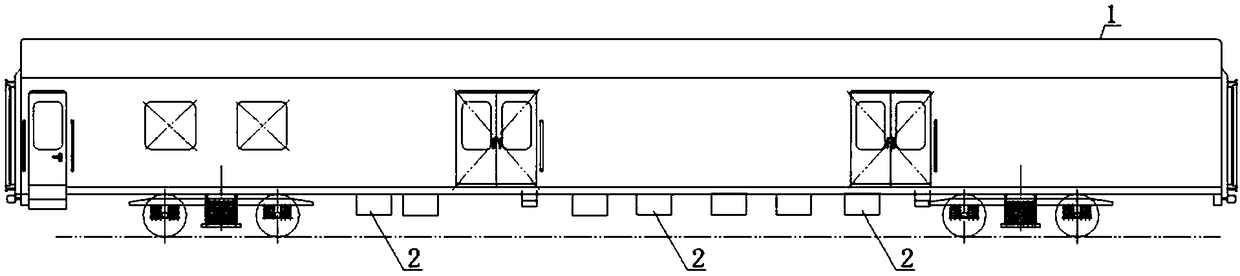

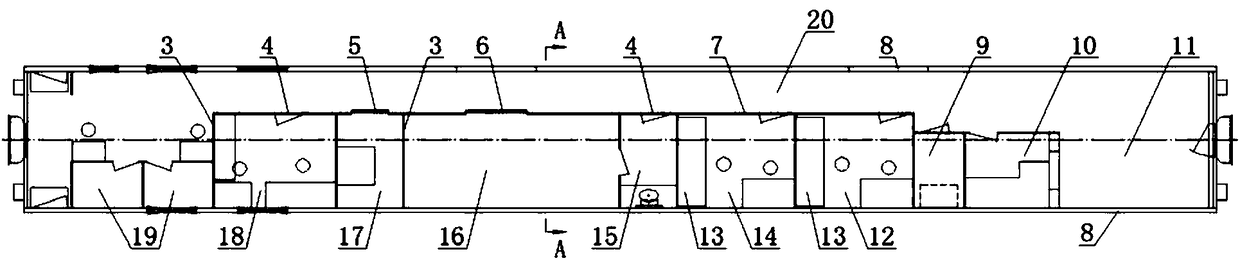

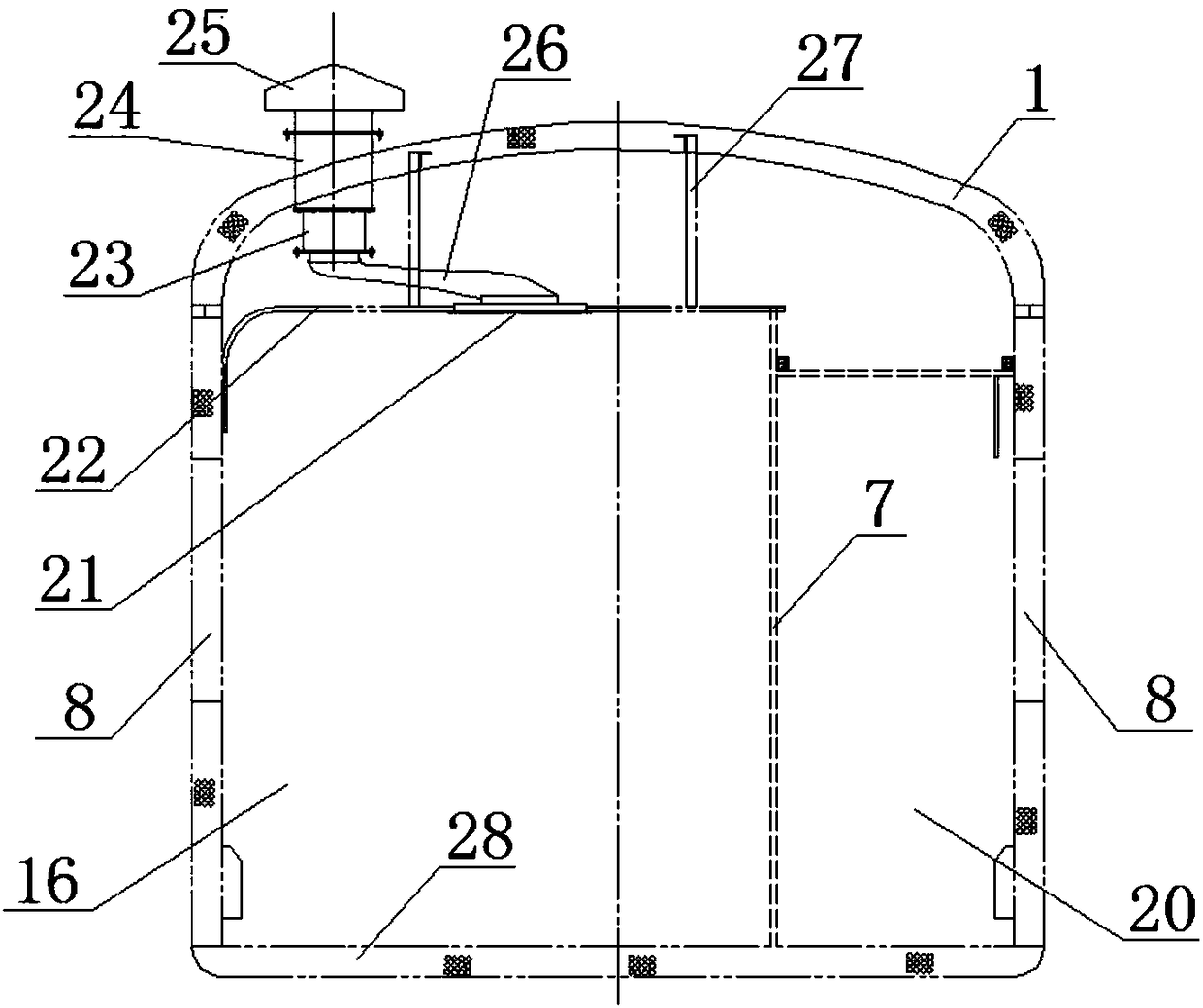

Health medical treatment train with operating room

PendingCN108545091AExhaust in timeTimely ventilationRailway heating/coolingCarriagesEngineeringMedical treatment

The invention provides a health medical treatment train with an operating room. The train comprises a train compartment jointly composed of side wall boards (8), a train top frame (1) and a floor (28). The operating room (16) is arranged in the compartment. A top board (22) is arranged in the operating room (16). A ventilation opening (21) is formed in the top board (22). An exhaust emission air chimney comprising an exhaust emission draught fan (23) and a ventilation cap (25) is arranged at the top of the operating room (16). A fixed connecting structure is formed between the exhaust emissiondraught fan (23) and the train top frame (1). The ventilation cap (25) is exposed out of the train top frame (1) and communicates with an outlet of the exhaust emission draught fan (23). An inlet ofthe exhaust emission draught fan (23) communicates with the ventilation opening (21). Air convection between the operating room and the external environment can be enhanced through the train, the environment cleanliness of the operating room is improved, the safety for performing an operation on the train can be improved, and the train can conveniently move to a remote area with people distributedin a scattered way to perform the simple operation.

Owner:CSR CHENGDU

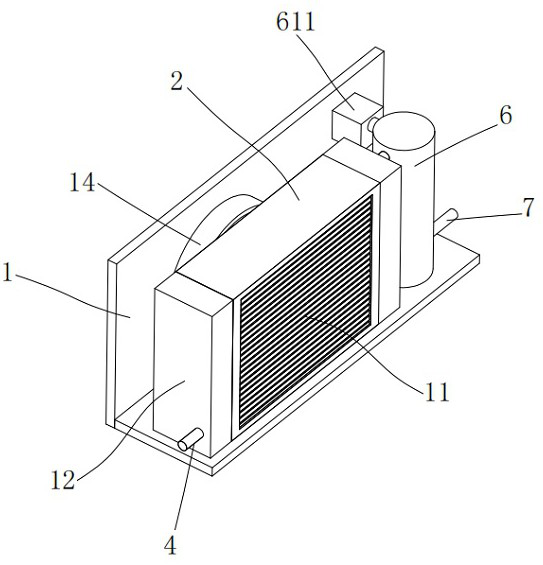

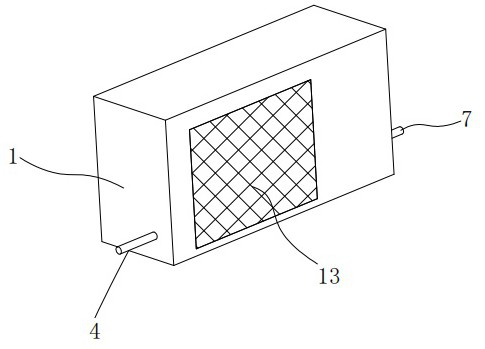

A condenser with automatic gas-liquid separation for central air-conditioning

The invention discloses a condenser with automatic gas-liquid separation for a central air conditioner, comprising a first installation box, a second installation box is installed inside the first installation box, and a condensation pipe is arranged in the second installation box The inlet of the condensation pipe is connected with a liquid inlet pipe, the end of the condensation pipe away from the liquid inlet pipe is connected with a communication pipe, and the end of the communication pipe away from the condensation pipe is connected with a gas-liquid separation mechanism, the gas-liquid separation mechanism A liquid outlet pipe is communicated with the lower side of one end away from the communication pipe, the liquid inlet pipe and the liquid outlet pipe both penetrate the first installation box and extend to the outside, and the middle of the rear side wall of the first installation box is welded with a mounting frame A servo motor is fixed on the mounting frame by bolts, and a fan blade is fixed at the end of the output shaft of the servo motor. The fan blade is inside the first installation box, and the second installation box is located in the positive direction of the fan blade. front side. Realize automatic gas-liquid separation, the gas can be automatically discharged, the work efficiency is high, and the use is convenient.

Owner:深圳日海新能源科技有限公司

A device for collecting condensed phase combustion products using spring force to control constant pressure

InactiveCN106289869BRealize pollution-free collectionSimple structureChemical analysis using combustionWithdrawing sample devicesCombustion chamberPiston ring

The invention discloses a condensed-phase combustion product collecting device controlling constant pressure through spring force. A stable pressure environment in an engine combustion chamber is simulated through automatic pressure relief of spring force, and therefore pollution-free collection on all condensed-phase combustion products in the engine combustion chamber is achieved. The volume of the collecting device is regulated through movement of a piston to regulate pressure of the two sides of the piston; air is exhausted outwards through a steel ball and a spring mechanism which are arranged at an exhaust port of a tail cavity pipe, therefore, the pressure of the two sides of the piston achieves a balanced state, and a stable and balanced pressure environment which is kept under test-specified pressure is established. By arranging a fluororubber seal ring in a groove formed in the ring surface of the piston, sealing of space of the two sides of the piston is achieved, and it is guaranteed that the condensed-phase combustion products are not polluted; the steel ball is coated with a silicone rubber layer, so that the leakproofness of the steel ball and the spring mechanism is guaranteed. The length of a propellant support in the engine combustion chamber is regulated as needed, and therefore the condensed-phase combustion product can be conveniently collected under the conditions of different flow distances. The collecting device is simple in structure, small in size and easy to machine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Freezing pipe capable of exhausting air

InactiveCN103088810BDoes not require constant careEnsure safety and qualityShaft sinkingSoil preservationExhaust valveEngineering

The invention relates to a freezing pipe capable of exhausting air and an achieving method of the freezing pipe capable of exhausting the air. The freezing pipe comprises a pipe body, a liquid supply pipe, a locating ring, an air exhaust pipe and a valve and is characterized by further comprising an automatic exhaust valve. The liquid supply pipe and the air exhaust pipe are arranged in the pipe body. The locating ring is fixed in the pipe body. The air exhaust pipe penetrates through the locating ring and is connected with the valve. The automatic exhaust valve is arranged at the rear end of the valve and connected with the valve. The achieving method of the freezing pipe capable of exhausting the air comprises judging whether the air gathers on the upper portion of the freezing pipe or not and conducting air exhausting operation. The freezing pipe capable of exhausting the air and the achieving method have the advantages that the air gathering on the upper portion of the freezing pipe can be exhausted, development of an upper portion freezing wall is guaranteed, project period is shortened, construction safety and quality are guaranteed, the air can be exhausted automatically and in time, work load is reduced, observation of workers is not required, structure is simple, installation is convenient and the freezing pipe and the achieving method are widely applicable to various freezing projects.

Owner:徐州地铁集团有限公司

A ship fuel oil supply system with filtering function

ActiveCN110735744BReduce entryExhaust in timeMachines/enginesLiquid fuel feedersMarine engineeringPlastic materials

Owner:上海蓝魂环保科技有限公司

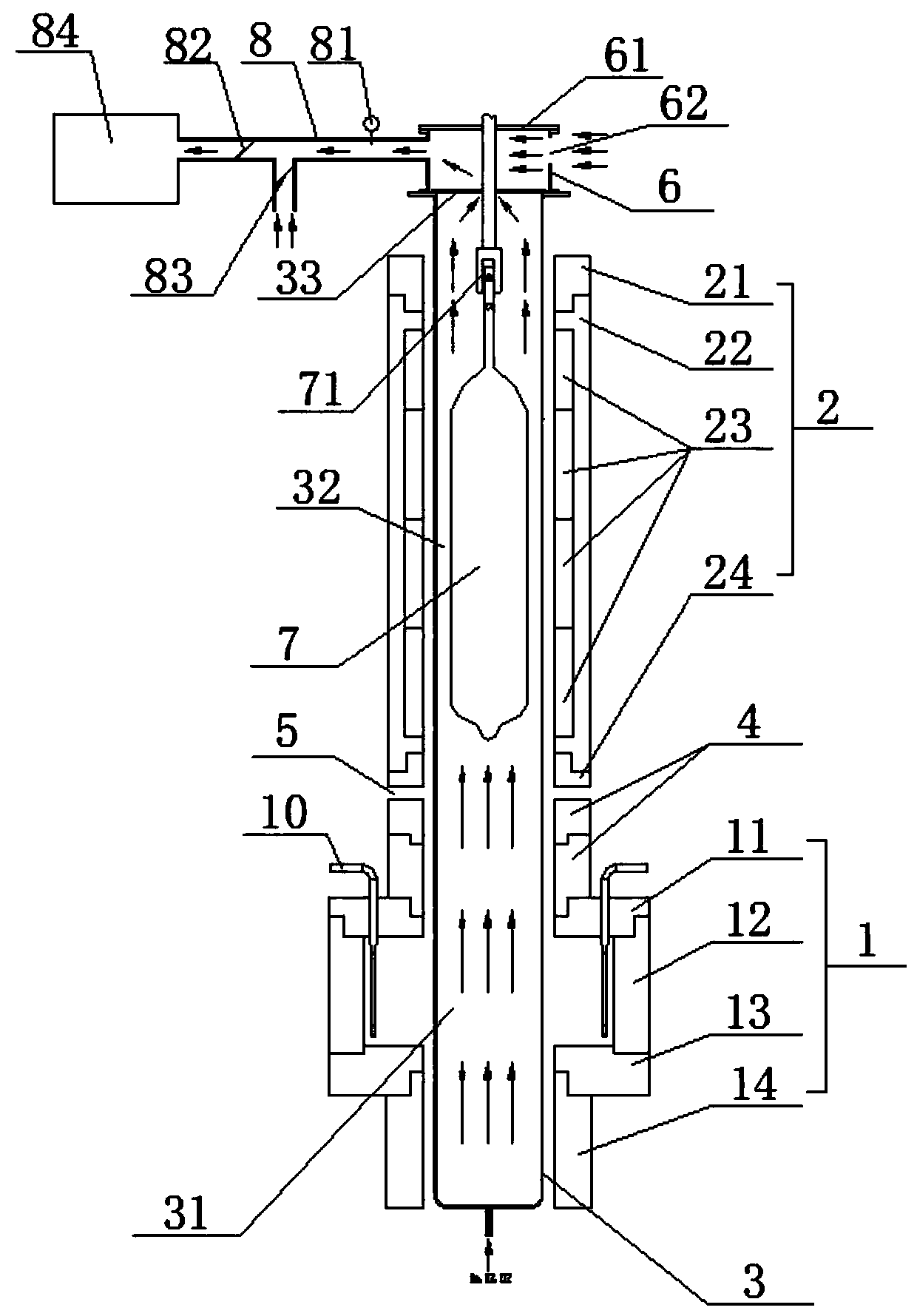

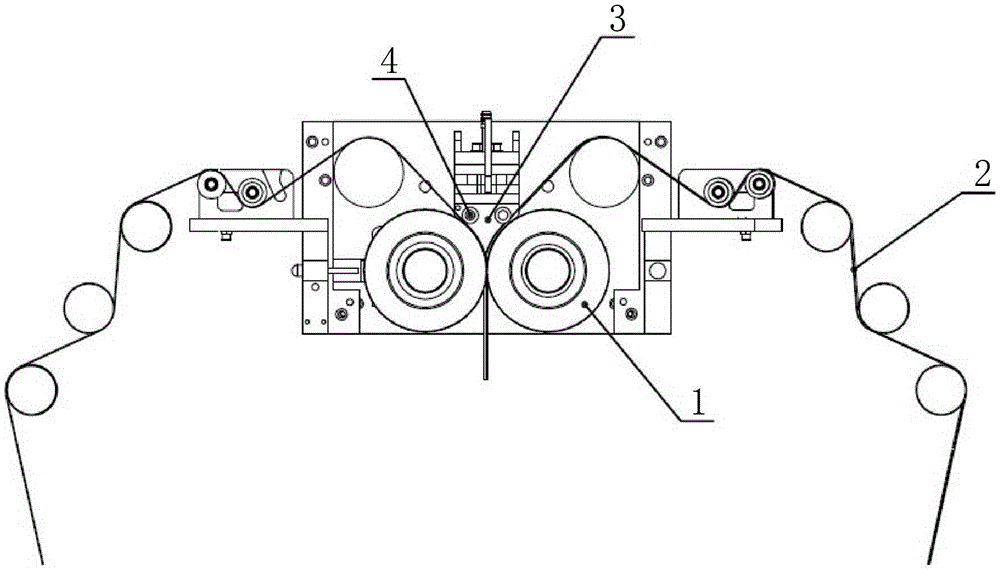

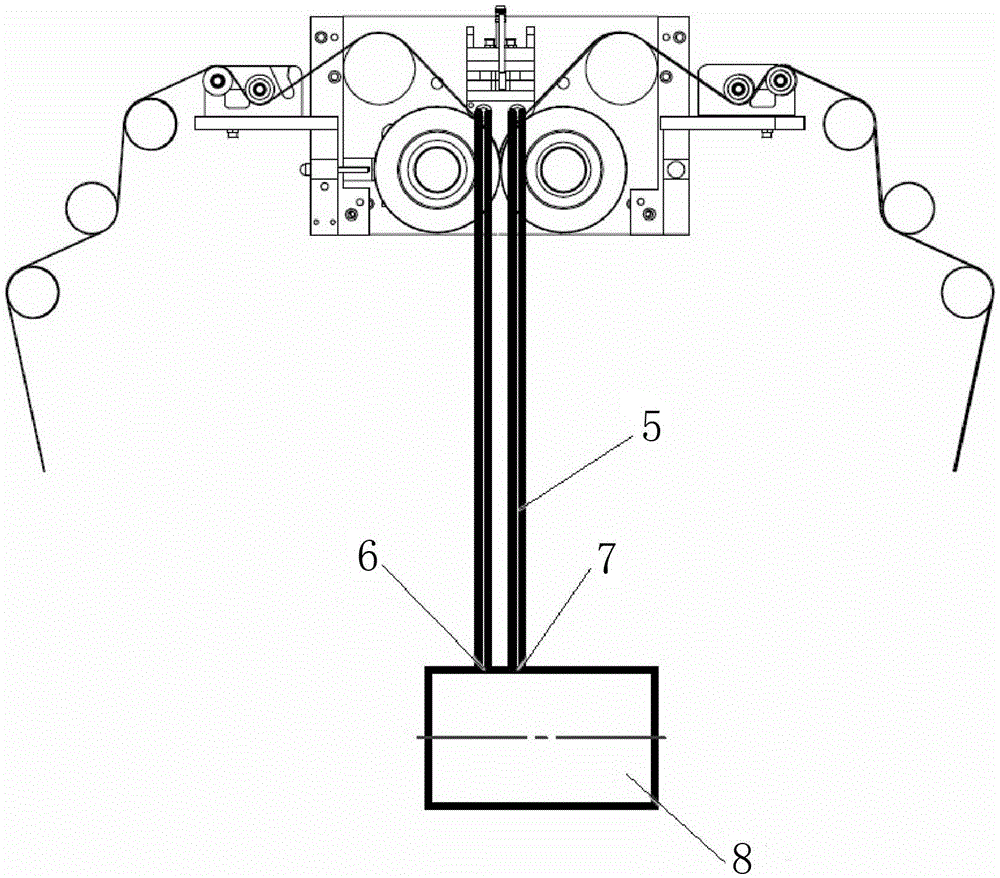

Water ring type injector heating device and capsule preparation system and use method thereof

ActiveCN103231498AOvercome the defects of different molding sizes and shapesSolve the problem of high energy consumptionThermal insulationBonding process

The invention relates to a water ring type injector heating device and a capsule preparation system and a use method thereof. The water ring type injector heating device comprises a thermal insulation pipe, wherein a heating pipe forms a closed vacuum internal chamber inside an injector through a hot water ring vacuum pump to ensure that hot water can circulate between the inside of the injector and the hot water ring vacuum pump for heat conduction, the thermal insulation pipe passes through a water inlet and a water outlet and is arranged on the injector through the hot water ring vacuum pump; and the thermal insulation pipe passes through the water inlet and the water outlet in a one-way guiding direction. By adopting the capsule preparation system adopting the water ring injector heating device and the use method of the capsule preparation system, the hot water can be directly added, thus the problems of large energy consumption, long heat energy transfer time, long heating time, high cost and difficulty in uniform heating are solved, the problems of cracks and leakage in a rubber bonding process when a soft capsule device is used for finally carrying out pelleting and forming are avoided, the defect that sizes and shapes of formed capsules are different is overcome, the qualified rate of finished capsules of the soft capsule device is increased, and the output, quality and economic benefit of enterprises are increased.

Owner:ZHEJIANG JIANGNAN PHARMA MACHINERY

Atomization device for fumigation and control system of atomization device

PendingCN108227797AEasy to cleanImprove atomization effectSimultaneous control of multiple variablesControl systemEngineering

The invention discloses an atomization device for fumigation and a control system of the atomization device, and relates to the technical field of atomization devices. The device comprises an atomization case body, wherein the atomization case body comprises an upper atomization case and a lower atomization case which are matched and corresponding in position, an atomization tank is fixed on one side of the atomization case body, and a liquid level sensor is fixedly arranged on the atomization case body; a heater and an isolation screen are arranged in the atomization case body, and electromagnetic valves are arranged in a water outlet pipe and a water inlet pipe; the atomization tank is communicated with the atomization case body through a condensing pipe. According to the atomization device, the isolation screen is arranged in the atomization case body, the electromagnetic valves are arranged in the water outlet pipe and the water inlet pipe, drugs are placed on the isolation screen,so that drug residues are convenient to clean, the atomization device is simple and practical, the atomization effect is good, and exhaust of the atomization tank is controlled by the first electromagnetic valve and the second electromagnetic valve; water outlet and water inlet of the atomization case body are controlled by driving the electromagnetic valves to act, energy is saved, automatic water inlet and outlet are achieved, and the intelligence degree is high.

Owner:安徽鑫诺医疗设备有限公司

Water ring syringe heating device, capsule preparation system and usage method thereof

ActiveCN103231498BOvercome the defects of different molding sizes and shapesAvoid damageThermal insulationBonding process

The invention relates to a water ring type injector heating device and a capsule preparation system and a use method thereof. The water ring type injector heating device comprises a thermal insulation pipe, wherein a heating pipe forms a closed vacuum internal chamber inside an injector through a hot water ring vacuum pump to ensure that hot water can circulate between the inside of the injector and the hot water ring vacuum pump for heat conduction, the thermal insulation pipe passes through a water inlet and a water outlet and is arranged on the injector through the hot water ring vacuum pump; and the thermal insulation pipe passes through the water inlet and the water outlet in a one-way guiding direction. By adopting the capsule preparation system adopting the water ring injector heating device and the use method of the capsule preparation system, the hot water can be directly added, thus the problems of large energy consumption, long heat energy transfer time, long heating time, high cost and difficulty in uniform heating are solved, the problems of cracks and leakage in a rubber bonding process when a soft capsule device is used for finally carrying out pelleting and forming are avoided, the defect that sizes and shapes of formed capsules are different is overcome, the qualified rate of finished capsules of the soft capsule device is increased, and the output, quality and economic benefit of enterprises are increased.

Owner:ZHEJIANG JIANGNAN PHARMA MACHINERY

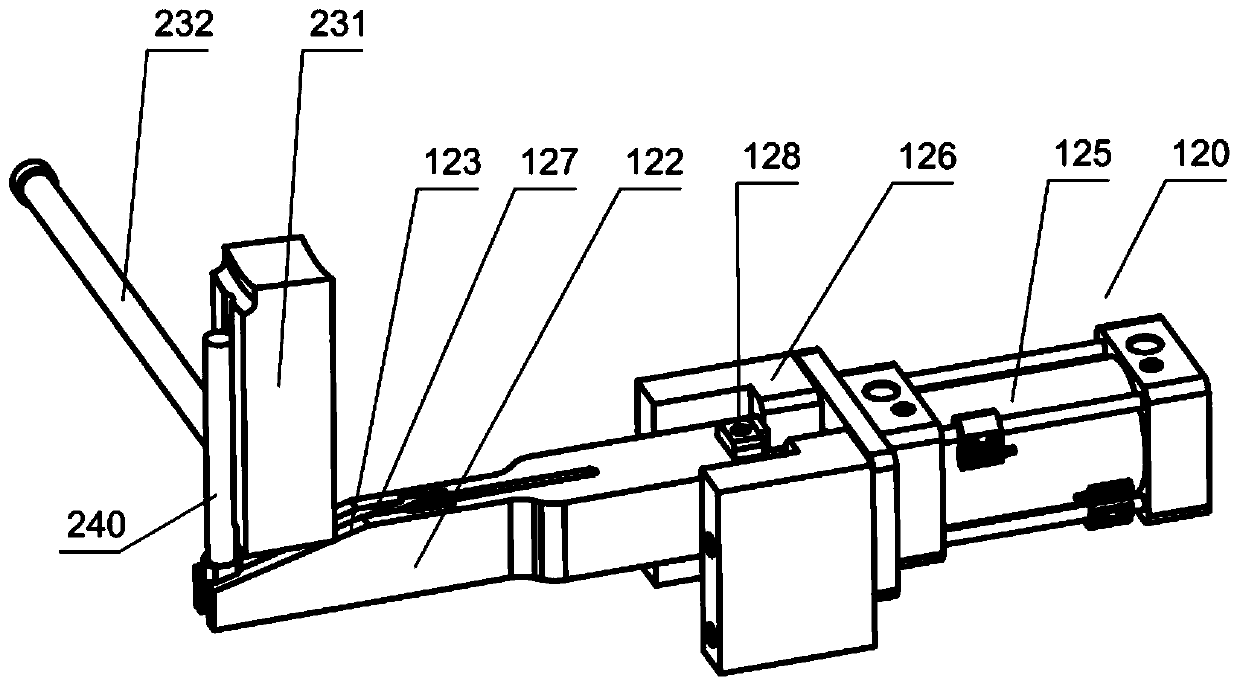

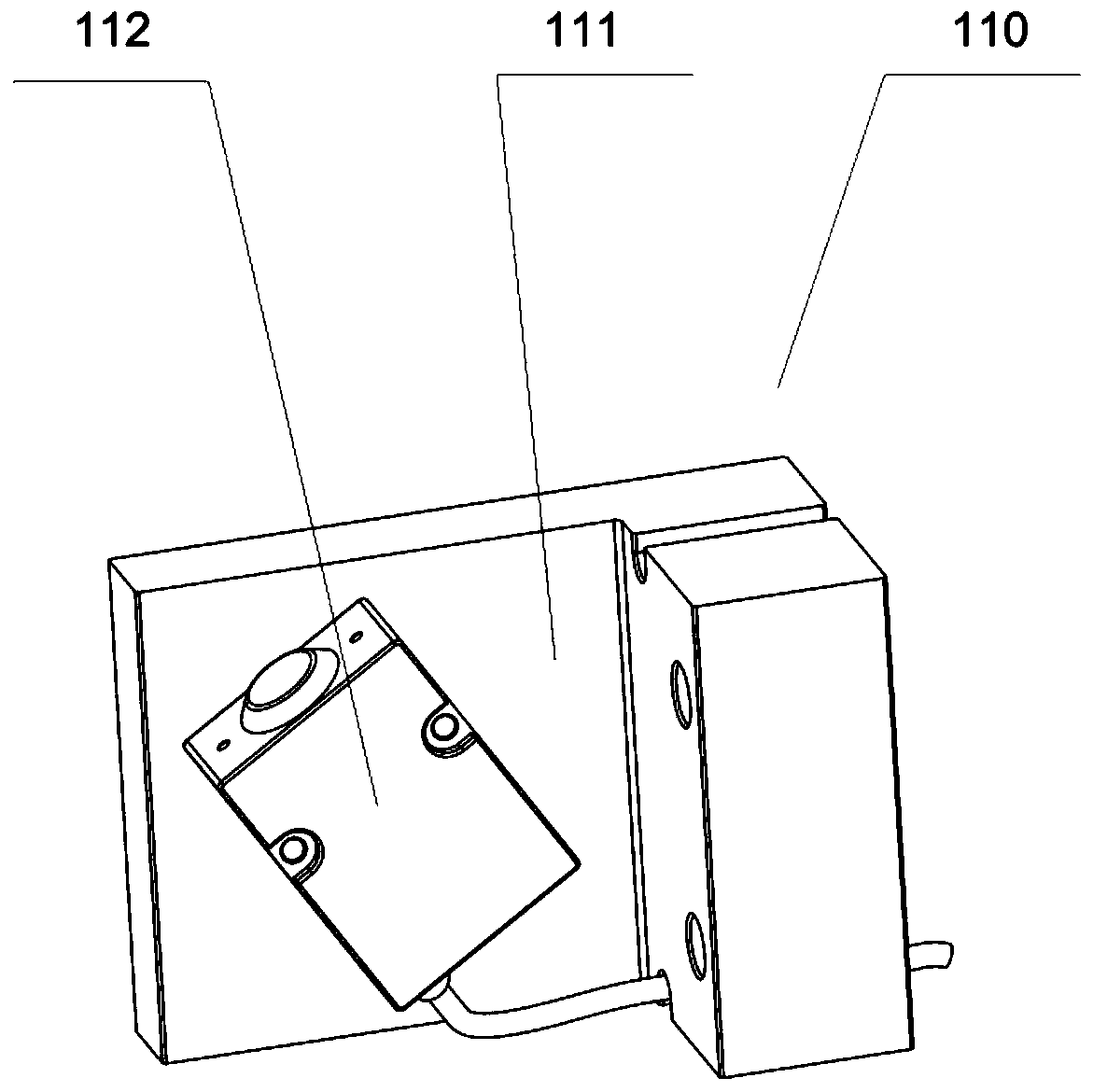

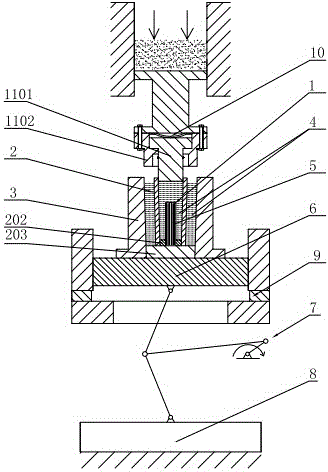

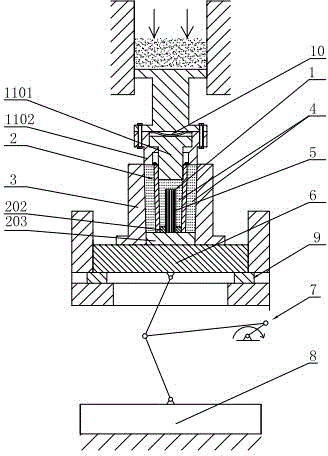

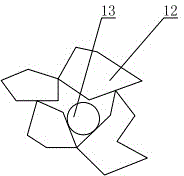

Technology and die-casting device for aluminium silicon carbide accurate die-casting forming

ActiveCN103143695BImprove densification performanceHigh hardnessPositive pressureReciprocating motion

The invention relates to a technology and a die-casting device for aluminium silicon carbide accurate die-casting forming. The die-casting device comprises a forming die, an inner die sleeve, and an outer die sleeve, wherein the forming die is mounted in a cavity of the inner die sleeve; the inner die sleeve provided with the forming die is mounted in a cavity of the outer die sleeve; the bottom surface of the outer die sleeve is connected with a workbench; and the other side of the workbench is connected with a workbench base by an articulated mechanism. With the adoption of the technology and the die-casting device, air mass formed between silicon carbide can be discharged by a die bottom plate and sent into aluminium liquid of an outer die cavity; silicon carbide particles in an inner die cavity are bonded with each other due to positive pressure and negative pressure action during continuous reciprocating motion; air is exhausted timely; the compactness of aluminium liquid permeation is improved greatly; and finished silicon carbide has better hardness and elastic modulus.

Owner:江苏时代华宜电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com