Deep well exhaust device and method in oil exploitation process

A technology of oil extraction and exhaust device, which is applied in the direction of wellbore/well valve device, production fluid, earthwork drilling and production, etc. It can solve the problem of associated gas release without a good solution, the influence of electric submersible pump performance, oil field Problems such as development loss, to achieve the effect of being suitable for promotion, low installation process requirements, and timely exhaust methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

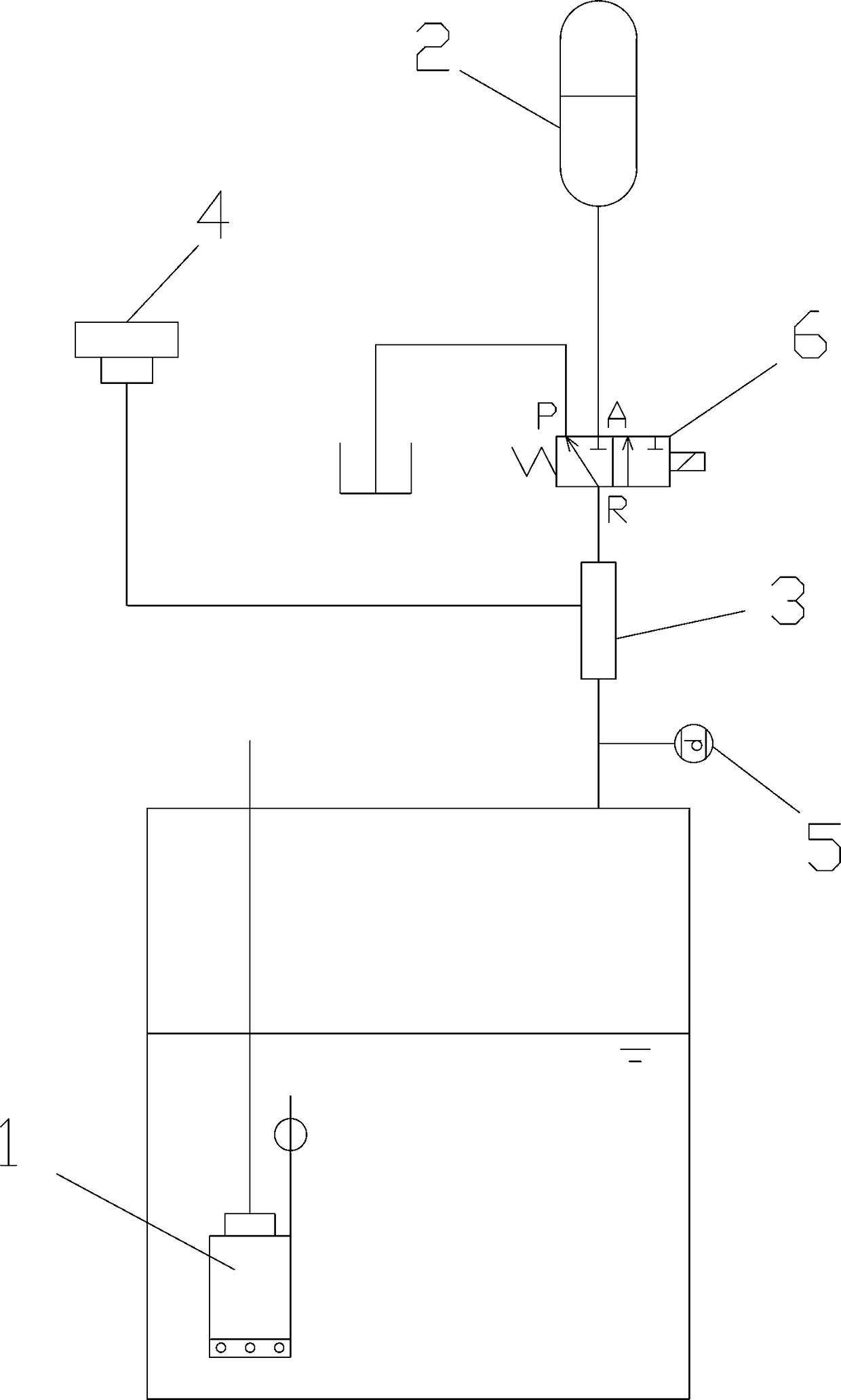

[0021] like figure 1 and 2 As shown, a deep well exhaust device in the process of oil exploitation includes an exhaust valve 3, an accumulator 2, a two-position three-way solenoid valve and a controller.

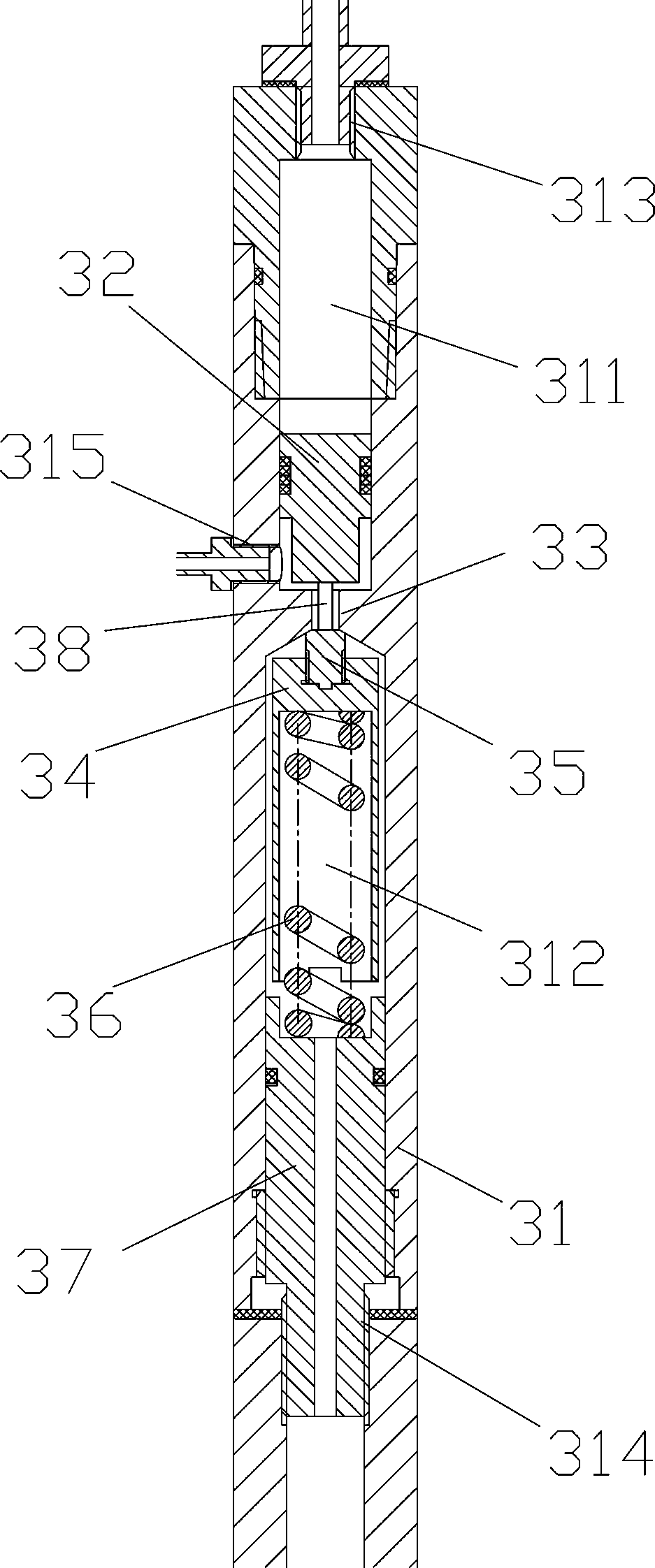

[0022] Exhaust valve 3 comprises valve body 31, is provided with cavity in valve body 31, is provided with liquid inlet 313 at the upper end of cavity, and is provided with air inlet 314 at the lower end of cavity, is provided with a circle inwardly extending protrusion in cavity. Rib 33, the flange 33 separates the cavity into an upper cavity 311 and a lower cavity 312, a piston 32 is installed in the upper cavity 311, and an exhaust port 315 is opened on the valve body 31 at the lower end of the upper cavity 311; A base 37 is connected, a guide sleeve 34 is provided between the base 37 and the flange 33, there is a gap between the guide sleeve 34 and the inner wall of the lower cavity 312, a spring 36 is arranged inside the guide sleeve 34, and the upper end of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com