Ship fuel oil supply system with filtering function

A technology for filtering and supplying systems, applied in charging systems, liquid fuel feeders, engine components, etc., can solve problems such as blockage of fuel supply lines, inability to start, poor stability, etc., to reduce the entry of impurities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

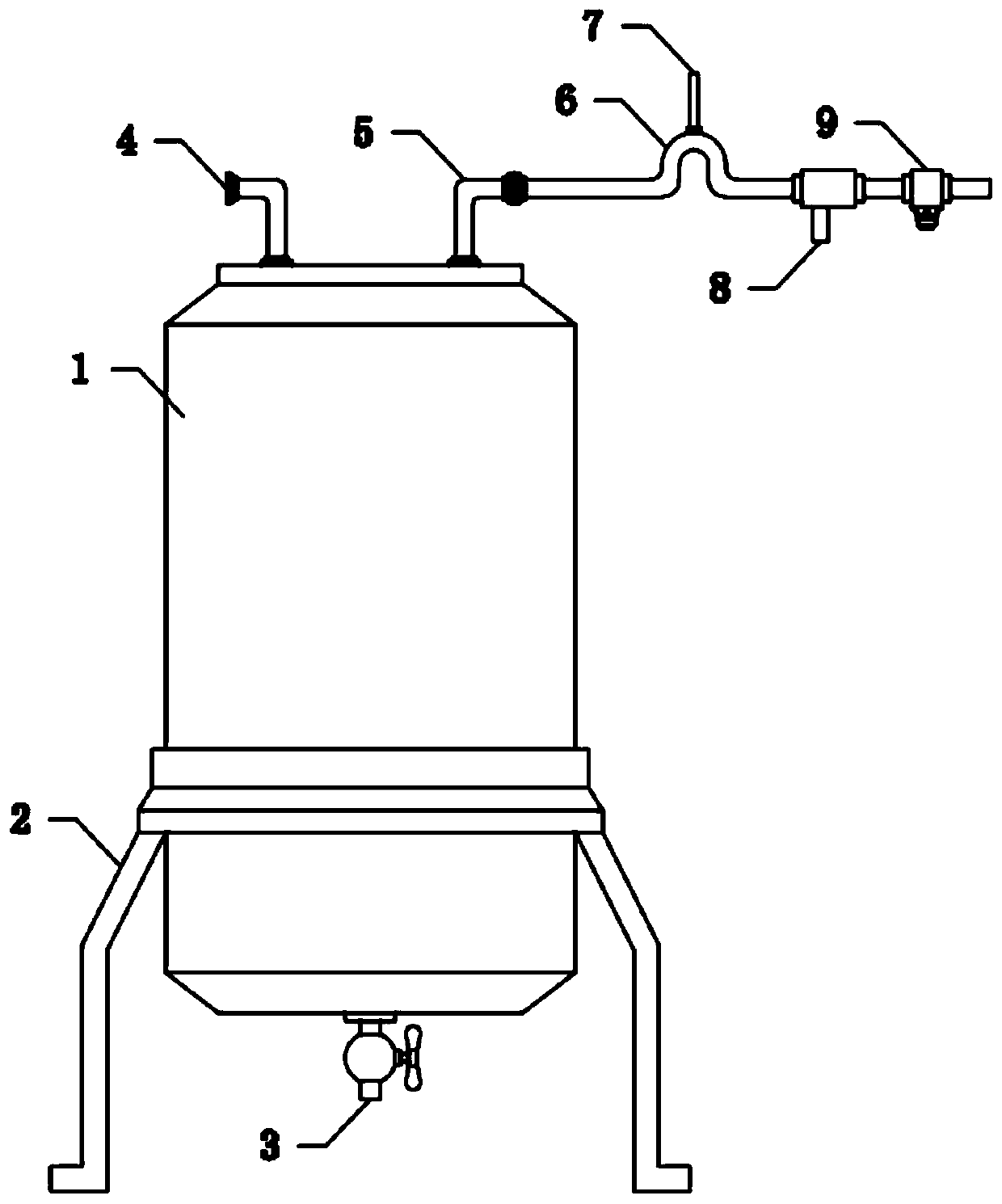

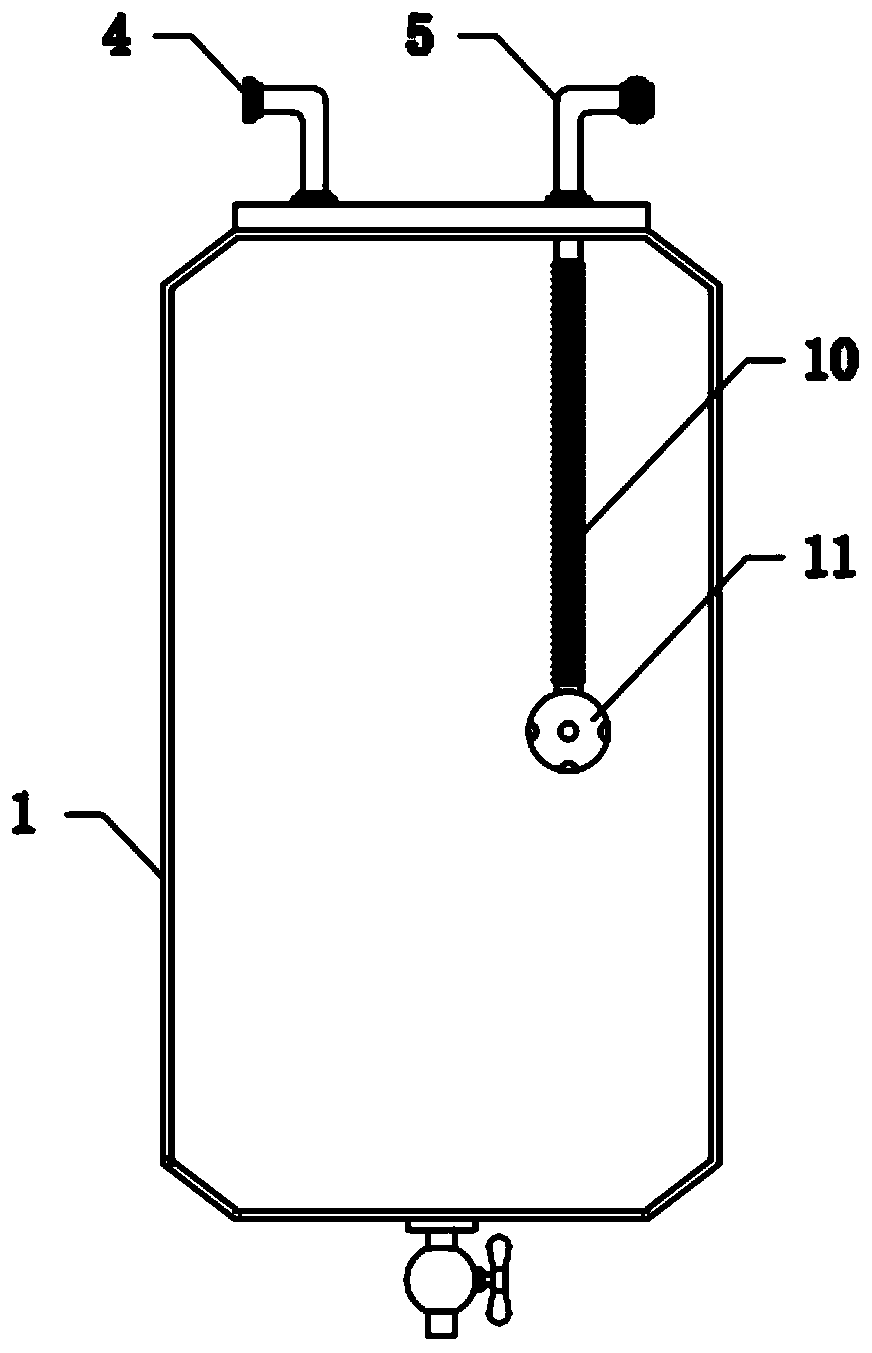

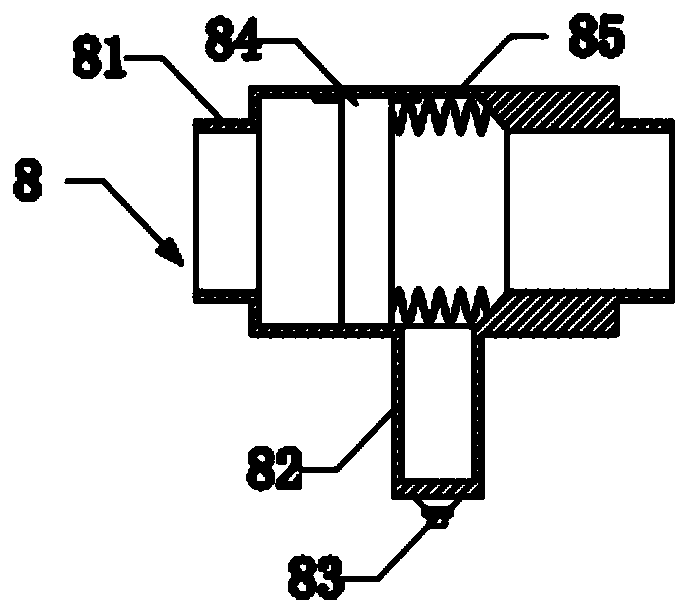

[0027] see Figure 1-3 , the present invention provides a technical solution: a ship fuel oil supply system with filtering function, comprising an oil storage tank 1, a slag discharge port 3, a filling pipe 4 and an output pipe 5, the slag discharge port 3 is connected to the oil storage tank At the center of the lower surface of 1, the filling pipe 4 and the output pipe 5 are respectively connected to the left and right sides of the upper surface of the oil storage tank 1, and the slag outlet 3, the filling pipe 4 and the output pipe 5 are all connected to the inner The cavity is connected, the bottom end of the output pipe 5 is connected with a suction pipe 10, the bottom end of the suction pipe 10 is provided with a suction head 11, the suction pipe 10 is a corrugated flexible suction pipe, and the outer wall of the suction head 11 Suction meshes are evenly opened on the top, and the suction meshes communicate with the suction pipe 10. The suction head 11 is a suction head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com