Nailing gun

A nailing gun and gun nozzle technology, applied in the field of nailing guns, can solve the problems of inability to hit continuously, poor hit uniformity, short service life, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

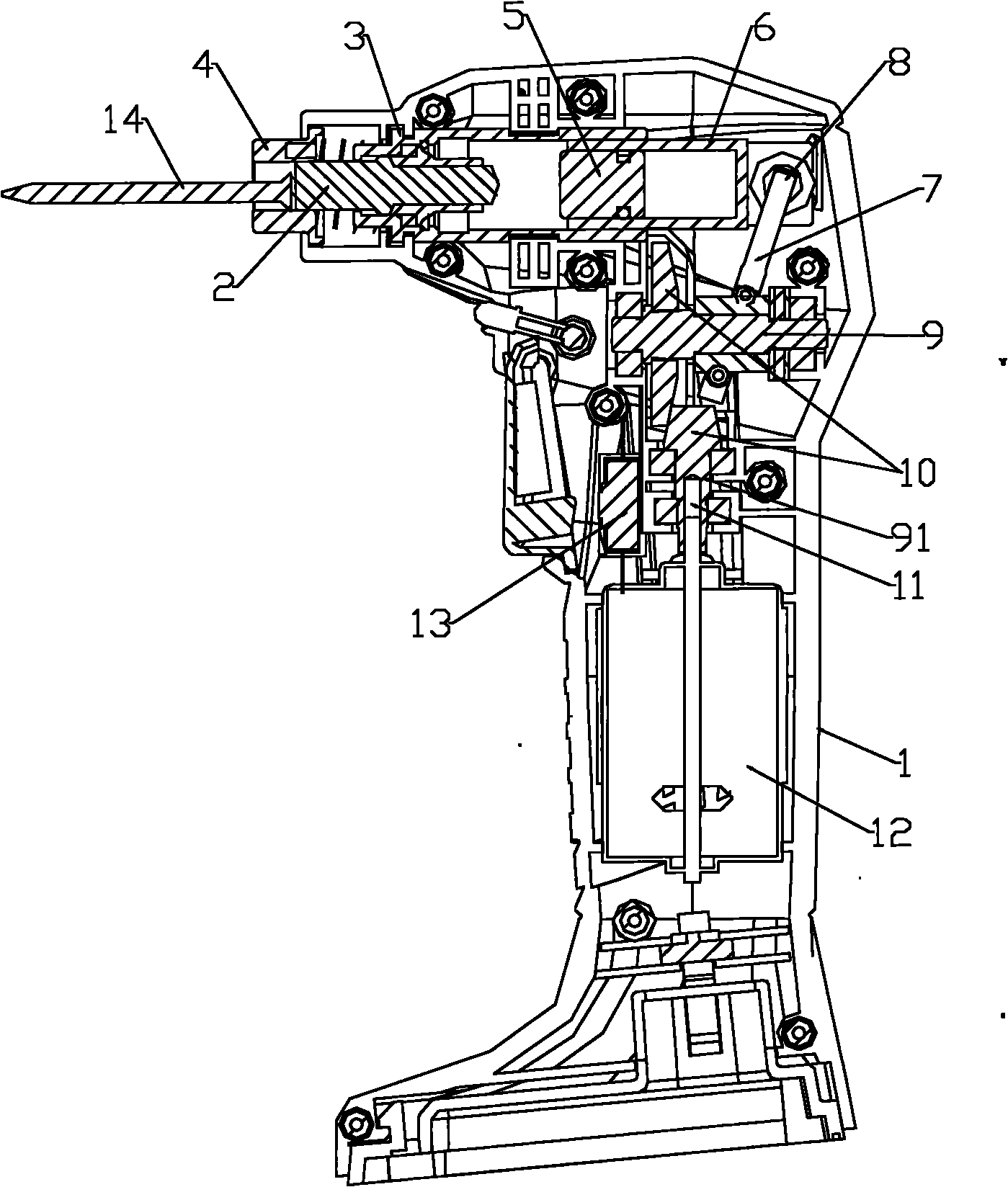

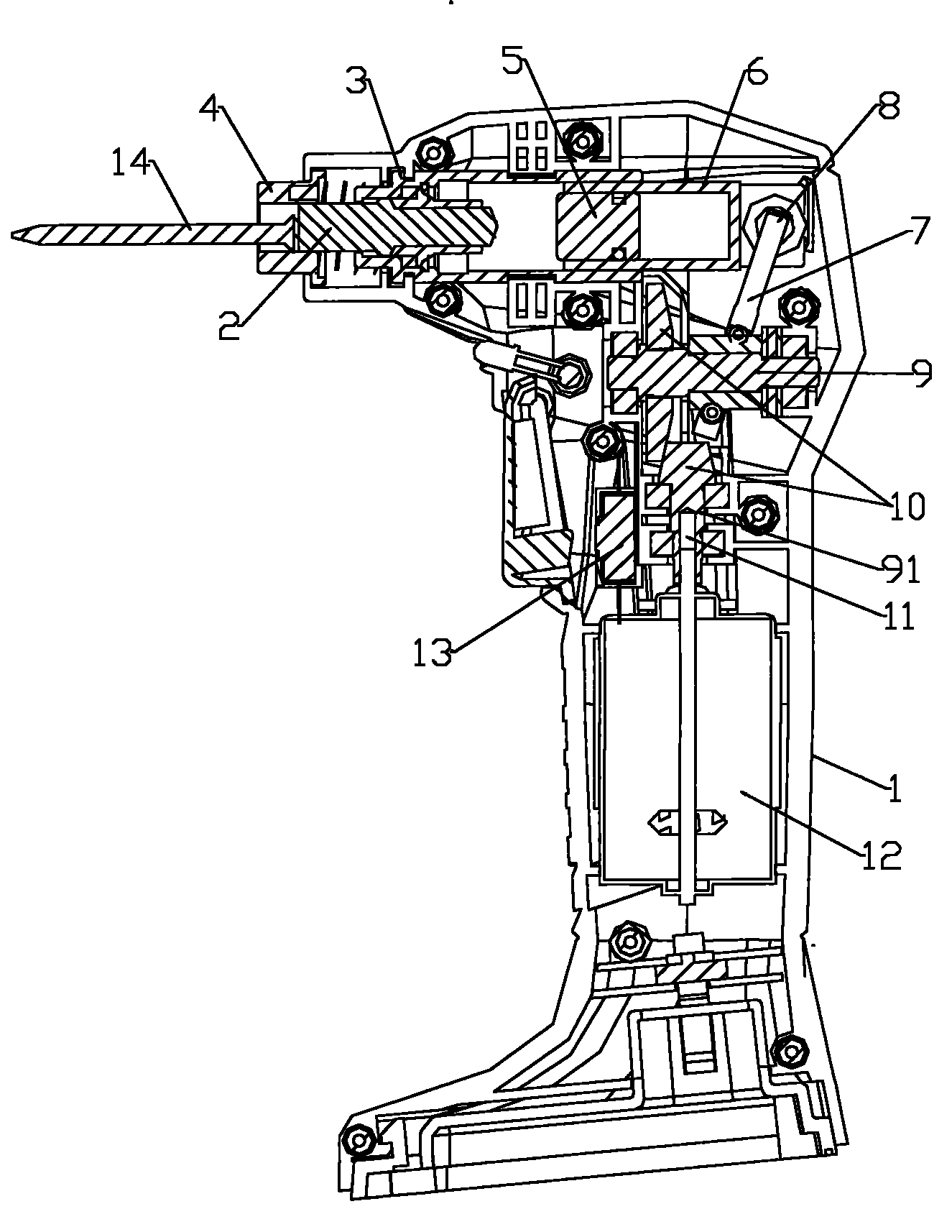

[0019] Below in conjunction with accompanying drawing, nailing gun of the present invention will be further described.

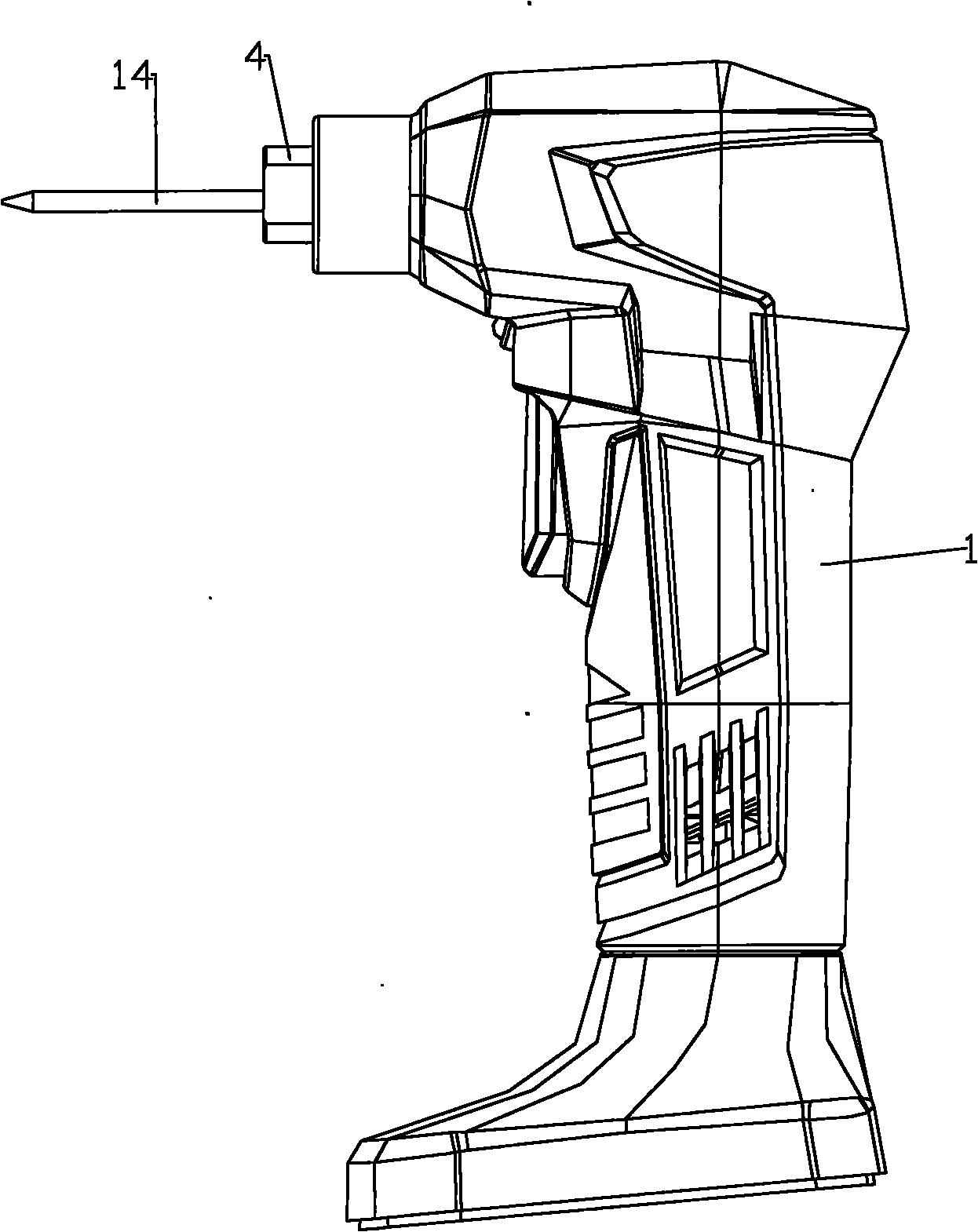

[0020] Such as Figure 1-2 As shown, the nailing gun of the present invention includes a casing cavity and a motor 12. The casing cavity is formed by combining the left and right halves of the casing 1, and the main body of the casing cavity forms a vertical handle. , the upper end of the main part of the casing cavity protrudes forward to form a transverse gun mouth, and a cylinder block 3 is installed on the upper end of the main part of the casing cavity, and the cylinder block 3 is provided with an air inlet and two A vent hole, the casing cavity is provided with a rotation-linear motion conversion transmission mechanism, the motor 12 is connected with the piston 6 through the rotation-linear motion conversion transmission mechanism, and the nailing pin 2 of the top nail 14 is provided in the gun mouth, The nailing pin 2 is arranged horizontally, and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com