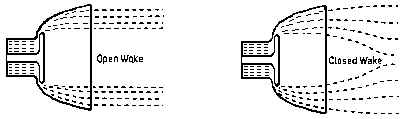

High Thrust Closed Expansion Cycle Rocket Engine Based on Improved Expansion Deflection Nozzle

A rocket engine and high-thrust technology, applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of difficult cooling of the center body and low efficiency of the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

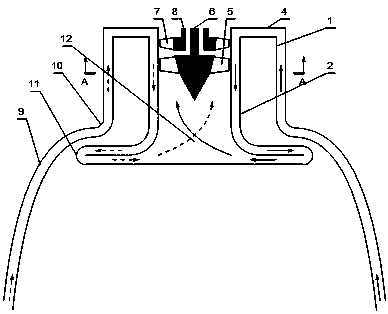

[0015] Figure 4 is along image 3 The cross-sectional view of the A-A line in the center reflects the positional relationship between the outer contour of the cross-section of the central fungus part and the surrounding injector and the side wall of the combustion chamber. implementation plan. Figure 4 Among them, 1 is the inner wall of the columnar combustion chamber, 2 is the cross-section of the fungus part of the central body with convex rounded square pillow shape, and 3 represents the installation position of the pintle injector numbered 1 on the top cover of the combustion chamber. image 3 It is a cross-sectional view showing the cooling passage and the position of the twin-shaft turbine embedded in the center body. The entire flow path of the cooling medium is: from bottom to top through the combustion chamber throat 10, upward through the combustion chamber side wall 1, from the edge of the combustion chamber top cover 4 radially inward through the combustion cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com