High-precision mold cleaning device

A cleaning device and high-precision technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of reduced production efficiency, unstable product forming quality, limited cleaning effect, etc., and achieve precise positioning cleaning effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

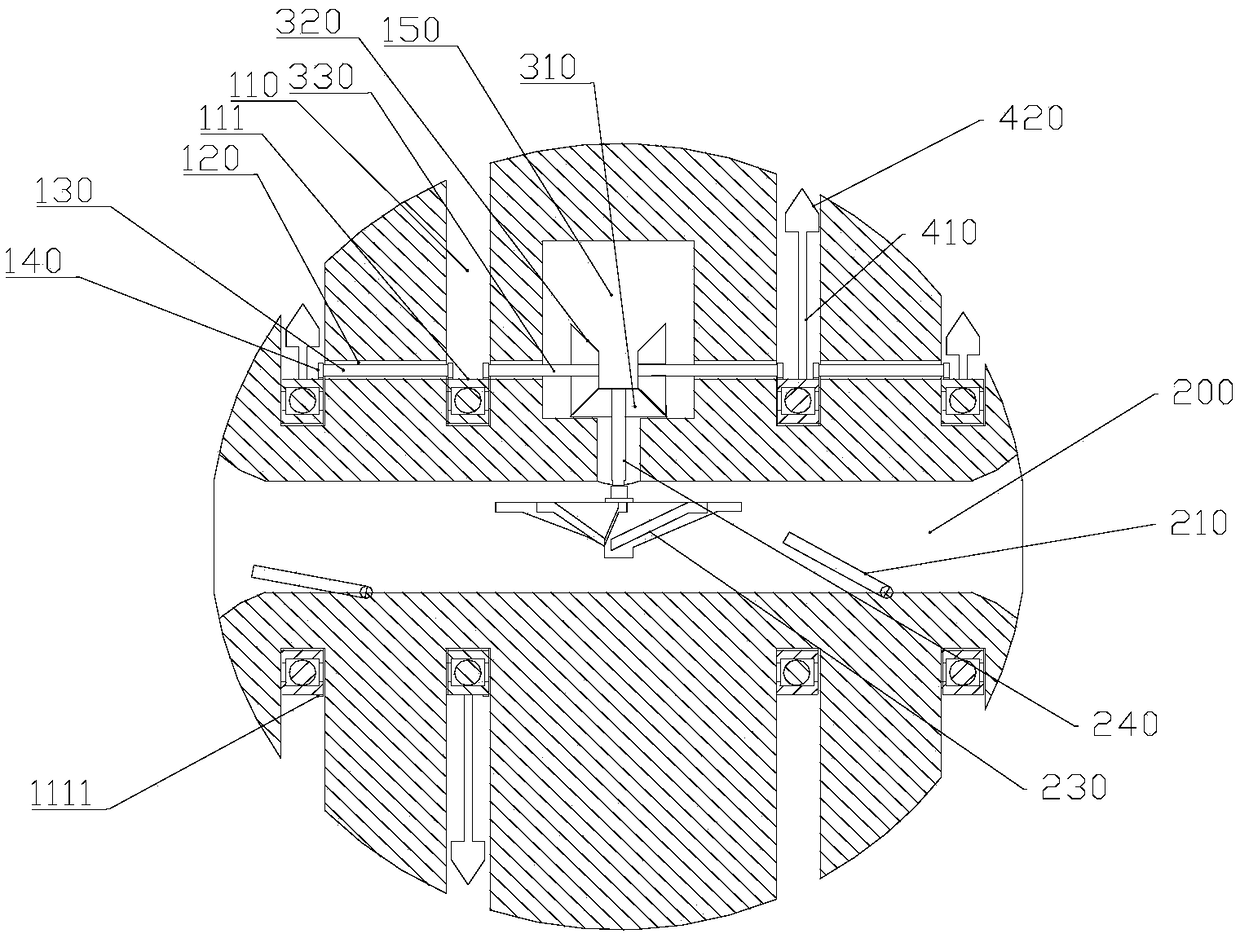

[0019] The reference signs in the accompanying drawings of the specification include: cleaning main body 100, middle through hole 200, baffle plate 210, annular groove 110, communication hole 120, deep groove ball bearing 111, annular tooth 1111, communication shaft 130, connecting tooth 140, installation Groove 150, water wheel 230, water wheel axle 240, the first bevel gear 310, the second bevel gear 320, the second gear shaft 330, cleaning part 400, elastic rope 410, cleaning cone 420.

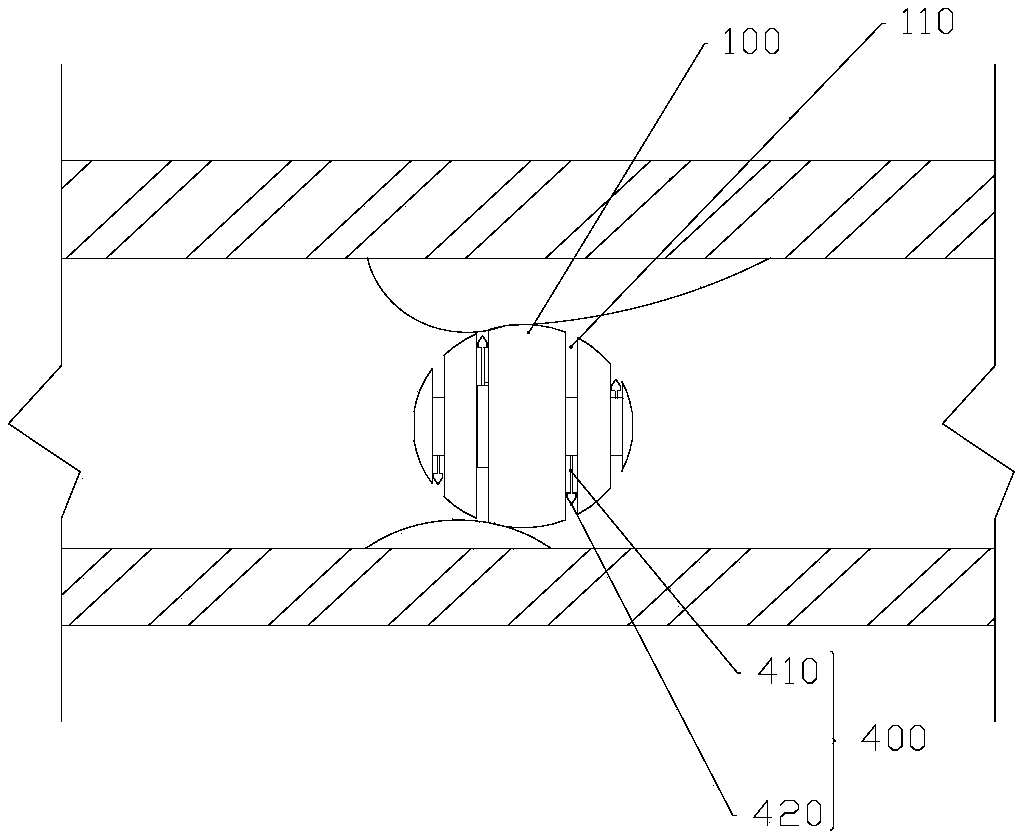

[0020] The embodiment is basically as attached figure 1 Shown: a high-precision mold cleaning device, including a cleaning body 100 whose maximum diameter is smaller than the diameter of the waterway, which is roughly 0.7-0.8 times the diameter of the waterway. When cleaning the mold waterway, put the cleaning body 100 into the waterway, and then inject high-pressure water into the waterway The maximum diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com