Pneumatic rotary drilling percussion drill for super-hard rock

A percussion drilling rig, superhard technology, applied in the direction of earthwork drilling, drilling equipment, drilling equipment and methods, etc., can solve the problems of poor practicality, high energy consumption, poor aerodynamic impact effect of drilling rigs, etc., and achieve easy movement and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

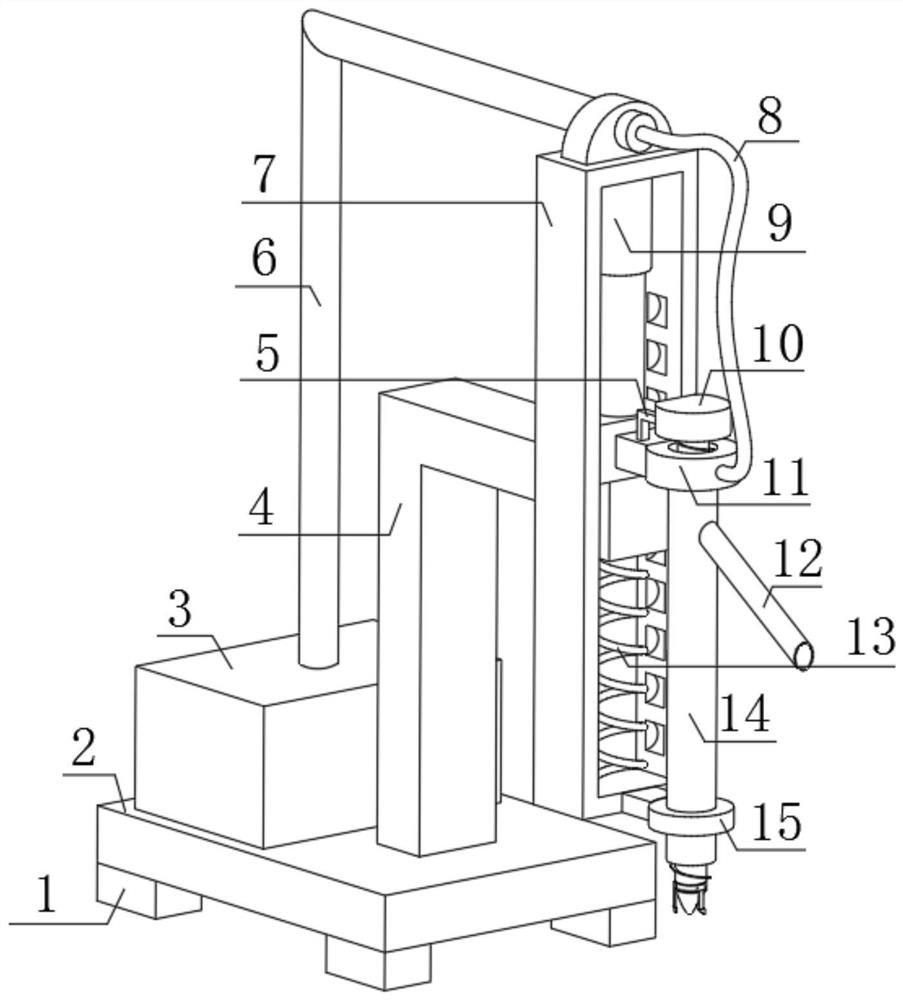

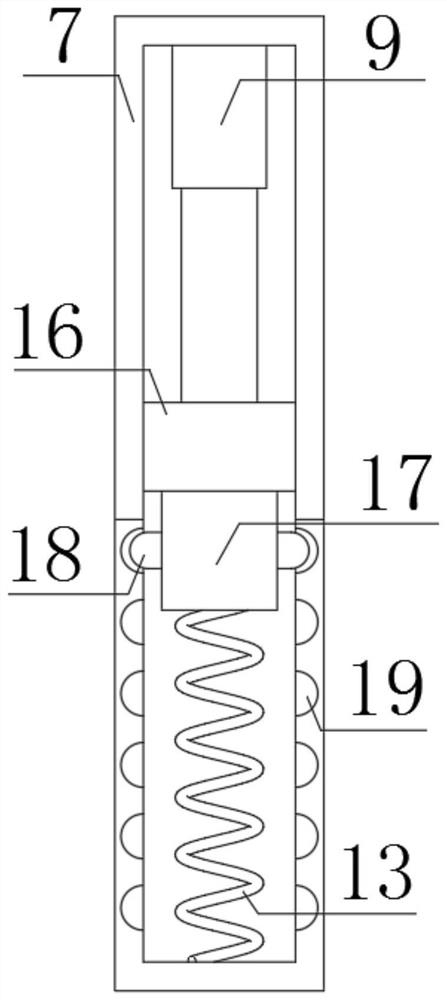

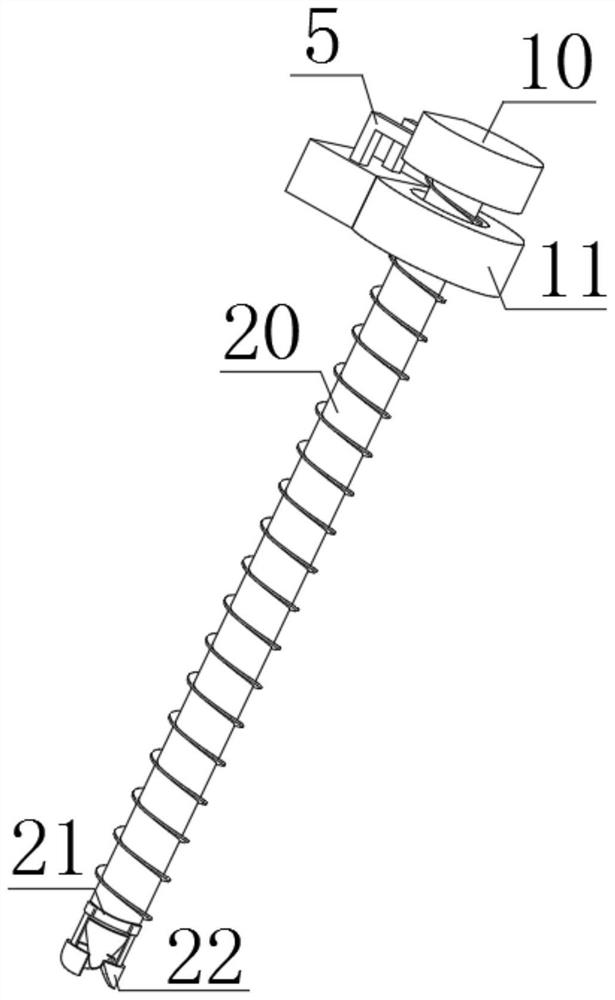

[0024] refer to Figure 1-3 , a pneumatic rotary drilling percussion drilling rig for superhard rock, comprising a base plate 2, a support rod 4 is fixedly connected to one side of the top outer wall of the base plate 2, a main body frame 7 is fixedly connected to one side outer wall of the support rod 4, and one part of the main body frame 7 An adjustment groove is provided on the side outer wall, and the top inner wall of the adjustment groove is fixedly connected with a cylinder 9, and one end of the piston rod of the cylinder 9 is fixedly connected with a slider 16, and the slider 16 is slidably connected on the inner wall of the adjustment groove, and the two sides of the adjustment groove Fitting grooves 19 distributed equidistantly are arranged on the side inner walls, pads 17 are provided on the outer wall of the bottom of the slider 16, and adapter blocks 18 are arranged on the outer walls of both sides of the pads 17. The outer wall of the opposite side is fixedly co...

Embodiment 2

[0032] refer to Figure 4 , a pneumatic rotary drilling percussion drilling machine for superhard rock. Compared with Embodiment 1, this embodiment further includes a universal wheel 23, and the universal wheel 23 is fixedly connected to the bottom outer wall of the support pad 1.

[0033]Working principle: when in use, the set universal wheels 23 are located at the bottom of each support pad 1, which is more conducive to movement when excavating at different positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com