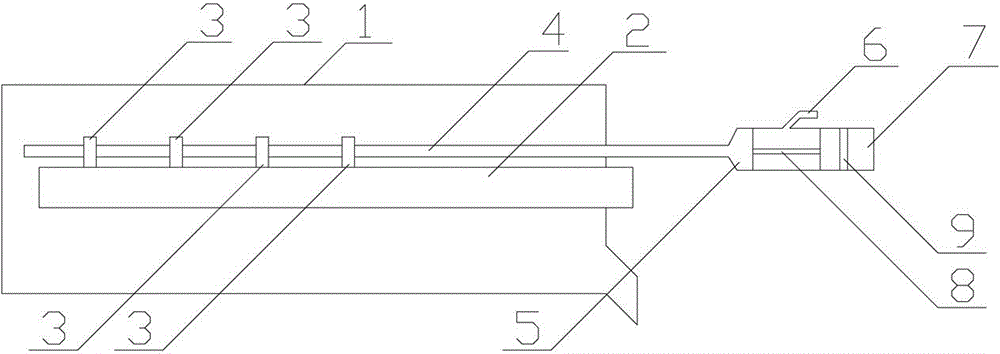

Freezing pipe capable of exhausting air

A freezing pipe and exhaust pipe technology, applied in the field of exhaustable freezing pipes, can solve the problems of inability to freeze, waste salt water, discharge salt water, etc., and achieve the effect of ensuring construction safety and construction quality, shortening the construction period of the project, and reducing the workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In conjunction with the embodiment in the accompanying drawings, it is as follows: a certain subway construction communication channel freezing method construction site, due to the discovery of the upper part of the frozen pipe in the frozen area, especially the highest part of the upper frozen pipe whose elevation angle is a positive value, there is often gas during the construction of the first communication channel. Accumulation, which seriously hinders the circulation of brine, abnormal temperature detection data, and the development of the upper frozen wall is obviously slow. The valve set at the highest point needs to be manually operated, and can only discharge the gas in the distribution and liquid collection rings. It has no effect on the gas at the highest point of the upper freezing pipe with a positive elevation angle. After exhausting, the temperature monitoring data of the upper freezing wall has no effect. Significant improvement caused the upper permafros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com