Water ring type injector heating device and capsule preparation system and use method thereof

A heating device and a technology for preparing capsules are applied in the field of heating injection molding models, which can solve the problems of different molding sizes and shapes, long heat energy transfer time, and difficulty in uniform heating, and achieve the effects of improving quality, reducing work intensity and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

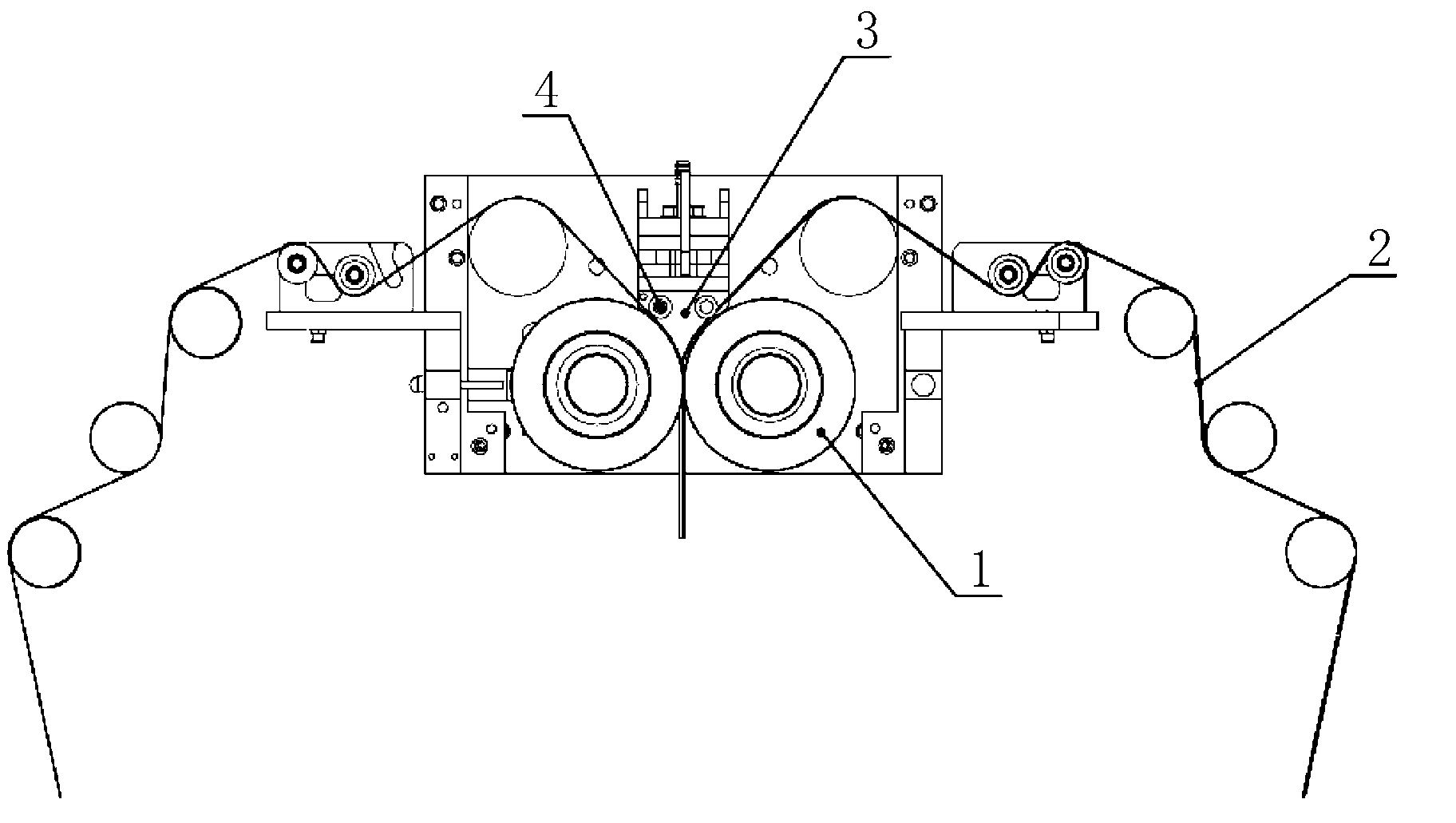

[0046] The water ring syringe heating device includes the heat preservation water pipe 5, and the heating pipe forms a closed vacuum inner chamber inside the syringe through the hot water ring vacuum pump 8, so that hot water can circulate and conduct heat between the inside of the syringe and the hot water ring vacuum pump 8.

Embodiment 2

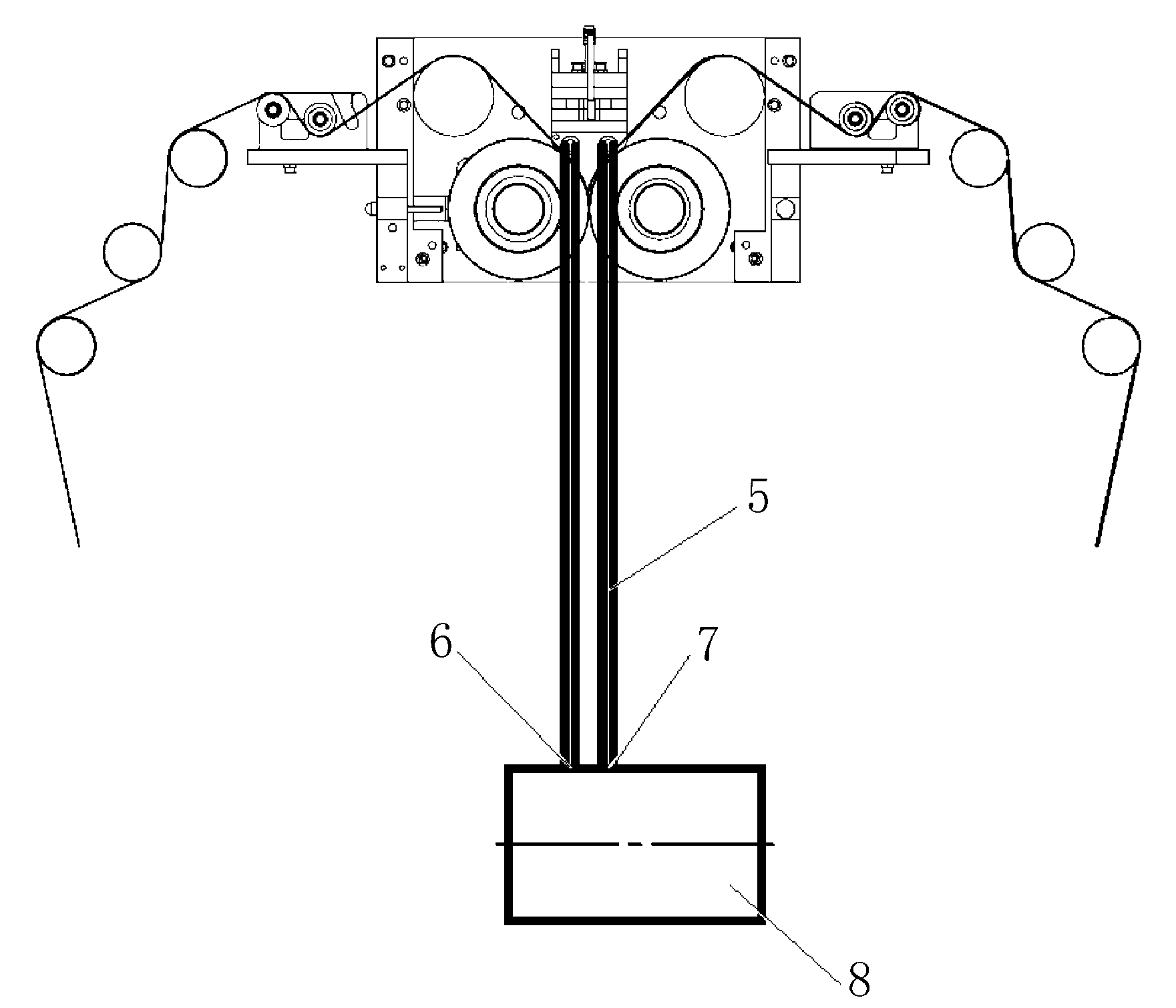

[0048] Such as figure 2 As shown, the water ring syringe heating device is the same as that in Example 1, except that the heat preservation water pipe 5 is set on the syringe through the water inlet 6 and the water outlet 7 and through the hot water ring vacuum pump 8 .

Embodiment 3

[0050] The water ring injector heating device is the same as that in Embodiment 2, except that the heat preservation water pipe 5 is set as a single guide through the water inlet 6 and the water outlet 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com