Double-furnace-core-rod sintering device with stable temperature field and stable flow field

A sintering device and temperature field technology, applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of prolonged operation time, high cost, and large consumption of helium gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

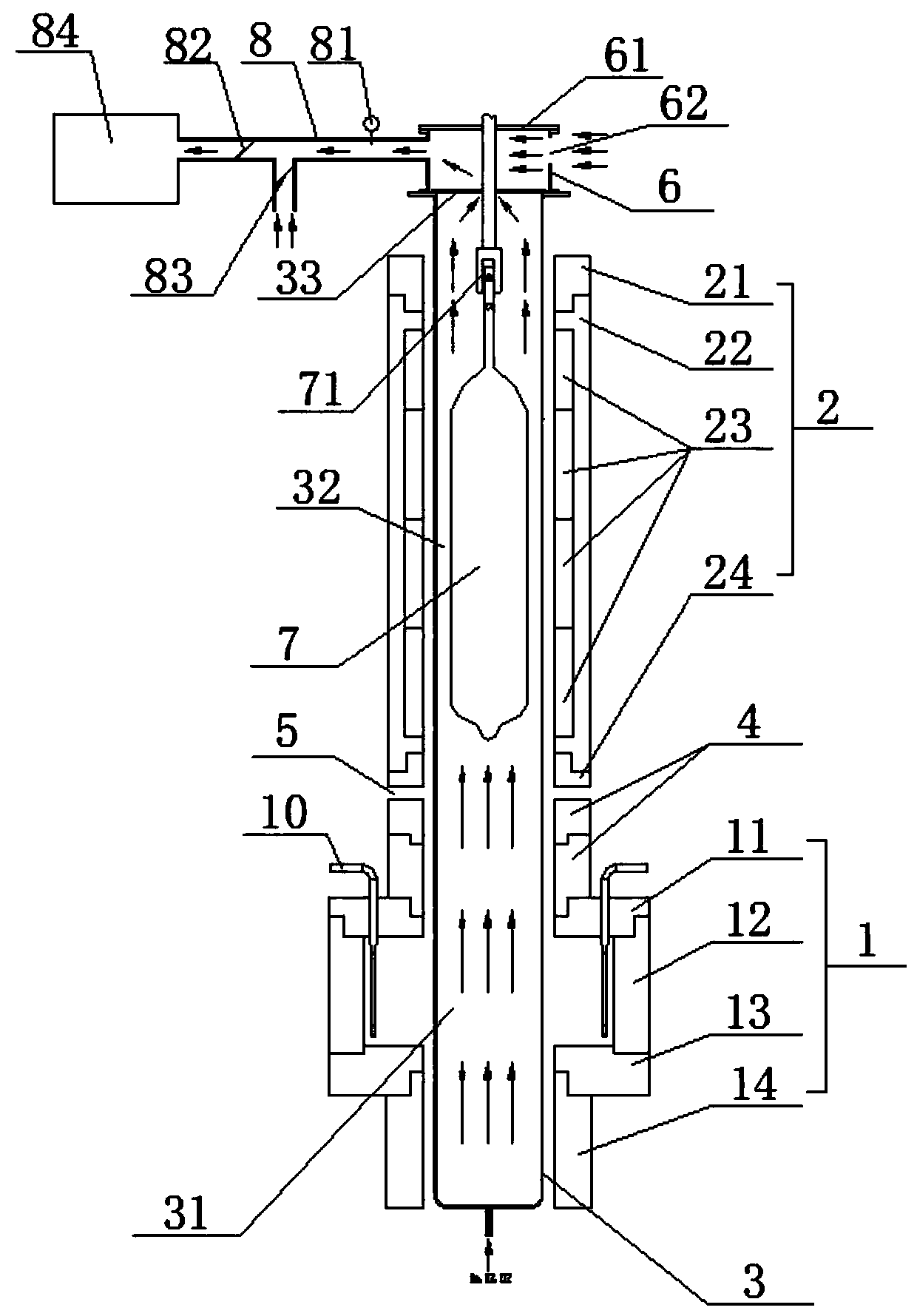

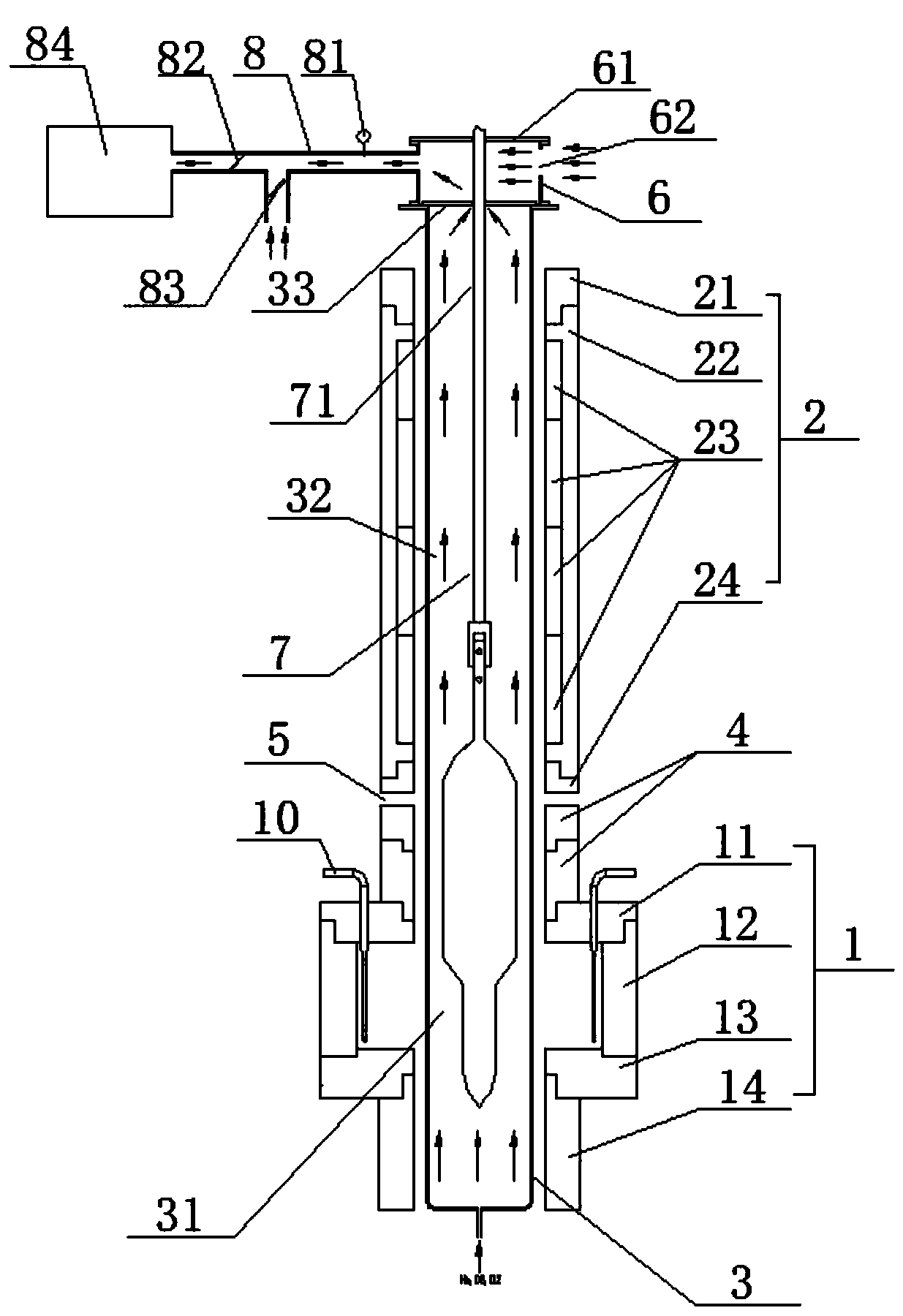

[0021] refer to figure 1 , figure 2 , the present invention is a double-furnace mandrel sintering device with stable temperature field and flow field. Tube 3, process gas helium, oxygen and chlorine enter from the bottom of muffle tube 3, between sintering furnace 1 and dehydration furnace 2 there is an inter-furnace insulation 4 and a temperature balance zone 5, the inside of muffle tube 3 corresponds to sintering furnace 1 The inner area of the dehydration furnace 2 is a sintering zone 31 and a dehydration zone 32 respectively, the top of the muffle tube 1 is provided with a muffle tube cover plate 33, and the air inlet and exhaust waste treatment device includes an exhaust hood with an exhaust hood cover plate 61 and an air inlet 62. Gas hood 6, exhaust pipe 8, exhaust gas treatment device 84, exhaust pipe 8 is provided with fresh air branch with fresh air valve 83, pressure gauge 81 and main air valve 82, exhaust hood cover plate 61 and muffle pipe cover A traction de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com