Long-distance sand transportation silt construction method and equipment

A long-distance, sand-transporting technology, applied in construction, mechanical equipment, liquid variable capacity machinery, etc., can solve problems such as reducing work efficiency, affecting construction progress, and deteriorating construction benefits, so as to improve measurement accuracy and improve work efficiency. The effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

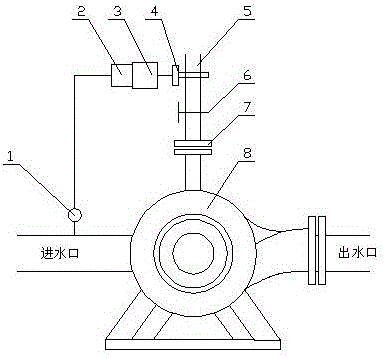

[0017] The method of long-distance sand transportation and silting construction includes the following procedures: setting out line positioning - sand pumping vessel in place - installation of sand transportation pipeline - installation of relay pump 8 - installation of sand measuring valve - installation of pressure gauge - installation of relay pump 8 Install the anti-cavitation device on the top - install the leveling valve - start the sand pump to pump sand - observe and analyze the sand concentration data - selectively open the anti-cavitation device, adjust the speed of the sand pump and the relay pump and Change the direction of silt construction. Lay the leveling valve at an appropriate position in the area, observe the elevation of the top surface of the silting in time according to the progress of the silting work and the on-site silting operation, and selectively open different slurry valves on the leveling valve to make the mud flow evenly to the silt The lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com