Composition containing chlorinated polyvinyl chloride resin for preparing football shoe sole and preparation method

A chlorinated polyvinyl chloride and soccer shoe sole technology, which is applied in the field of mixtures containing chlorinated polyvinyl chloride resin, can solve the problems of insufficient rubber properties and processing difficulties, and achieve the goal of improving plasticization, durability and fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

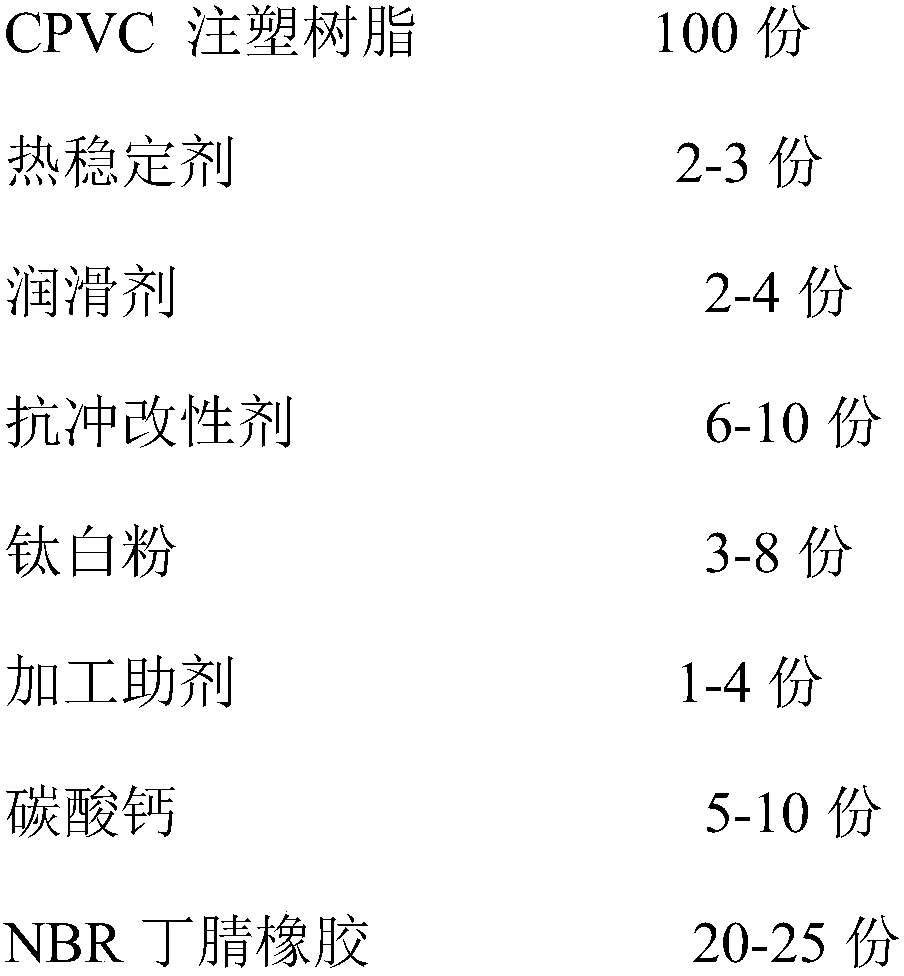

[0022] Recipe: (by weight)

[0023]

[0024] Described thermostabilizer is organotin stabilizer, can adopt the product of Rohm and Haas company trade mark to be TM-181FS;

[0025] The lubricant is OPE wax with a melting point of 95°C

[0026] The impact modifier is MBS, its chemical name is methyl methacrylate, butadiene, styrene terpolymer, and the product with the brand name 564 of Japan Zhongyuan Company can be used.

[0027] The titanium dioxide is anatase titanium dioxide;

[0028] The processing aid is ACR, and its main component is methyl methacrylate; the product of the brand name PA40 of Zhongyuan Company of Japan can be used.

[0029] The calcium carbonate is Shanghai Yuanjiang brand light calcium carbonate.

[0030] The NBR nitrile rubber is Lanzhou Petrochemical nitrile rubber N41

[0031] Preparation:

[0032] (1) Mix chlorinated polyvinyl chloride injection molding resin, heat stabilizer, lubricant, titanium dioxide, calcium carbonate, and processing aids...

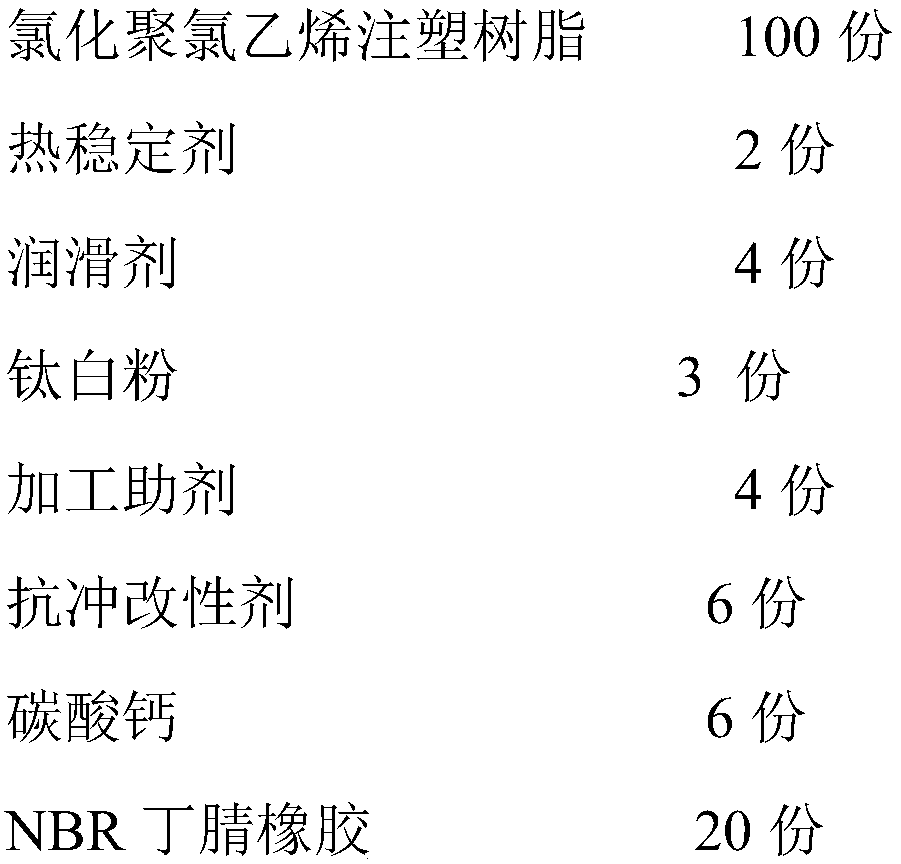

Embodiment 2

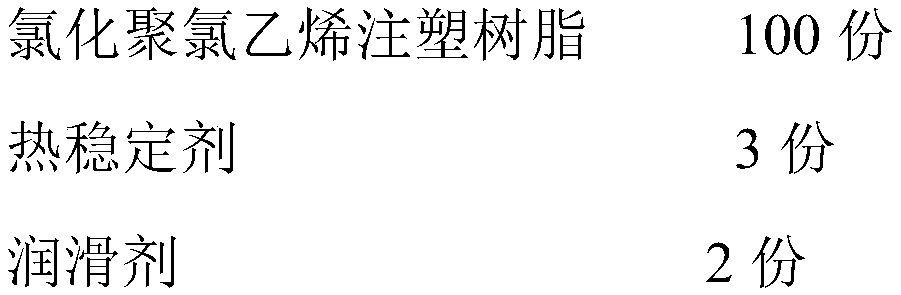

[0037] Recipe: (by weight)

[0038]

[0039]

[0040] Described thermostabilizer is organotin stabilizer, can adopt the product of Rohm and Haas company trade mark to be TM-181FS;

[0041] The lubricant is OPE wax with a melting point of 105°C

[0042] The impact modifier is MBS, its chemical name is methyl methacrylate, butadiene, styrene terpolymer, and the product with the brand name 521 of Zhongyuan Company of Japan can be used.

[0043] The titanium dioxide is rutile titanium dioxide;

[0044] The processing aid is ACR, the main component of which is methyl methacrylate; the product of Japan Zhongyuan Company with the brand name PA60 can be used.

[0045] Described calcium carbonate is Shanghai Botong brand heavy calcium carbonate.

[0046] The NBR nitrile rubber is Lanzhou Petrochemical nitrile rubber N41

[0047] Preparation:

[0048] (1) Mix chlorinated polyvinyl chloride injection molding resin, heat stabilizer, lubricant, titanium dioxide, calcium carbonat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com