Rapid transformation method and device for in-situ dry dedusting of blast furnace wet dedusting

A technology of wet dedusting and dry dedusting, which is applied to blast furnaces, dust collectors, blast furnace details, etc., can solve problems such as smoothness, rationality, safety impact, tight time, and short blast furnace overhaul period of the gas pipeline system, and achieve The effect of eliminating safety and quality risks, abundant time and saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

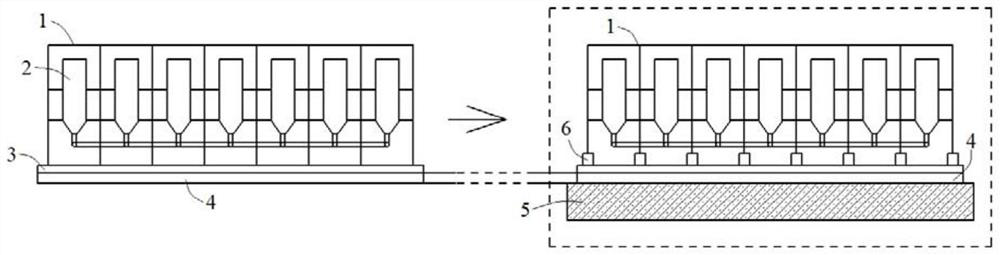

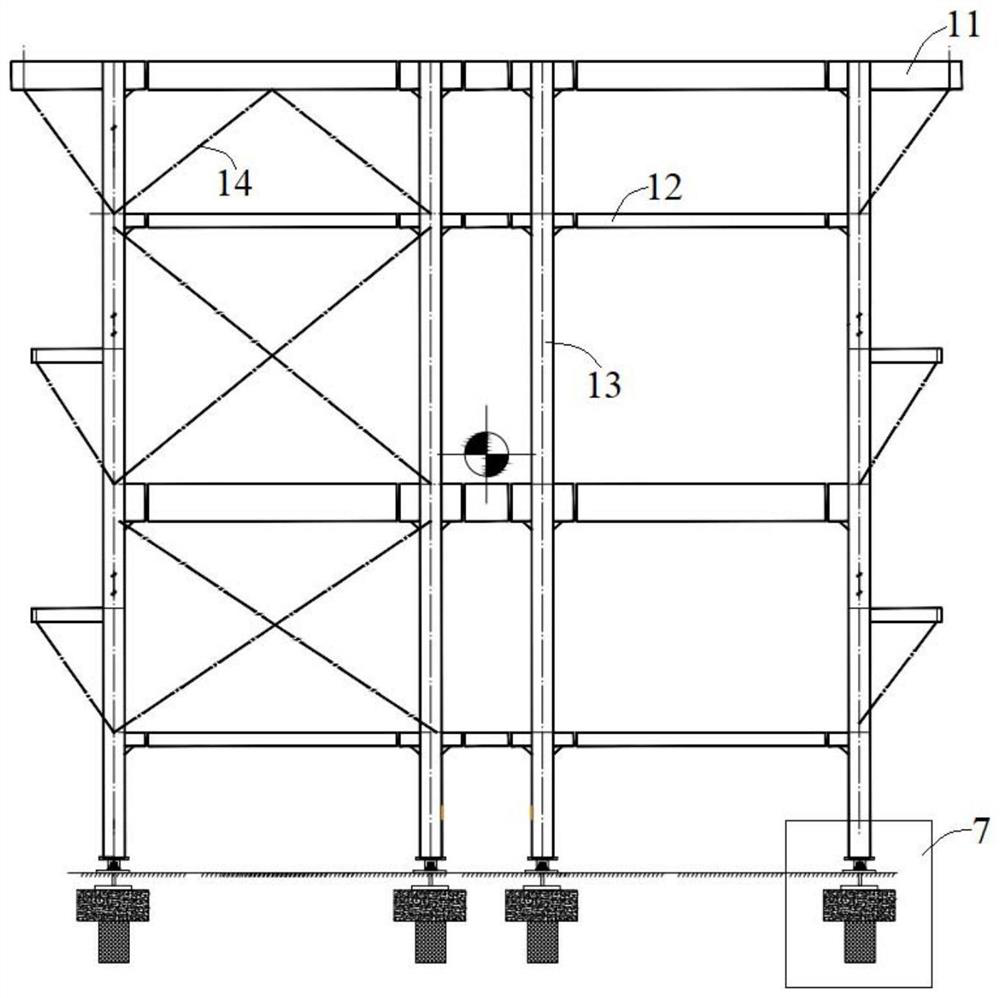

[0040] combine figure 1 , a kind of device of the present invention that is used for blast furnace wet dedusting in situ to perform dry dedusting rapid transformation, comprising a new dedusting frame 1, a frame foundation 5 built on the original wet dedusting site and a frame for moving the dedusting frame 1 Push structure 7; said push structure 7 is arranged on the lower part of the bottom frame 3 at the bottom of the dust removal frame 1 to support the bottom frame 3; the upper part of the frame foundation 5 is equipped with a column foundation 6; the dust removal frame 1 is temporarily fixed beside the frame foundation 5 , The dust removal frame 1 is connected with the frame foundation 5 by a track 4 .

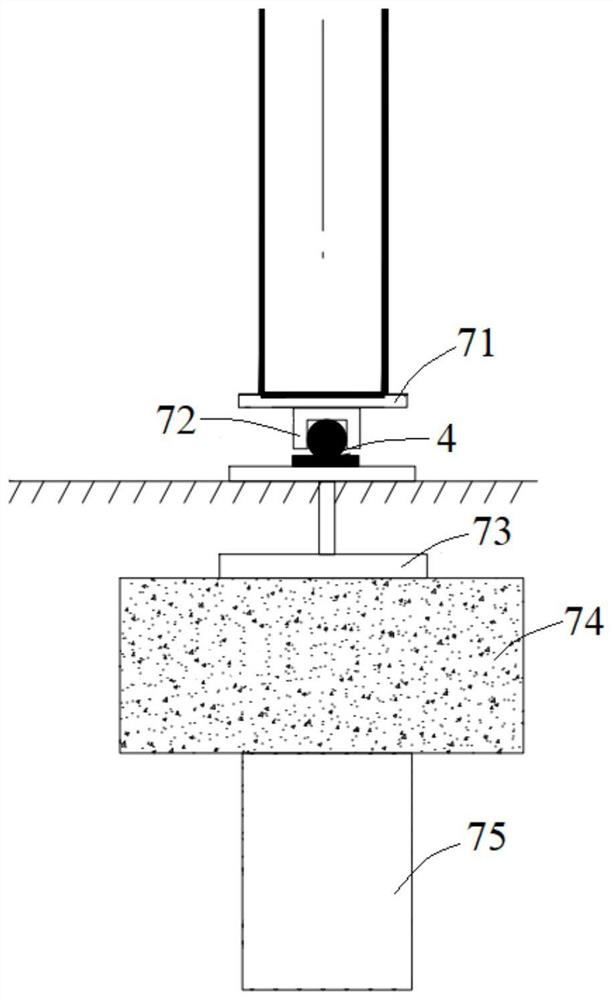

[0041] combine image 3 , in this embodiment, the pushing structure 7 includes a bottom plate 71, a card slot 72, a section steel 73, a platform 74 and a pile foundation 75; the bottom plate 71 is arranged at the bottom of the dust removal frame 1 and carries the column 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com